HV, HB, le HRC kaofela ke litekanyo tsa boima bo sebelisoang litekong tsa thepa. A re li aroleng:

1) HV Hardness (Vickers Hardness): HV hardness ke tekanyo ea ho hanyetsa ha thepa ho indentation. E khethoa ka ho sebelisa mojaro o tsejoang holim'a lisebelisoa ho sebelisa indenter ea daemane le ho lekanya boholo ba indentation e hlahisoang. HV hardness e hlahisoa ka likarolo tsa Vickers hardness (HV) 'me hangata e sebelisoa bakeng sa lisebelisoa tse tšesaane, lirafshoa le likaroloana tse nyane.

2) HB Hardness (Brinell Hardness): HB hardness ke tekanyo e 'ngoe ea ho hanyetsa ha thepa ho indentation. E kenyelletsa ho sebelisa mojaro o tsejoang ho thepa ho sebelisa indenter ea bolo ea tšepe e thata le ho lekanya bophara ba sephetho se hlahisoang. HB hardness e hlahiswa ka diyuniti tsa Brinell hardness (HB) mme hangata e sebediswa bakeng sa disebediswa tse kgolo le tse ngata, ho kenyeletswa dimetale le alloys.

3) HRC Hardness (Rockwell Hardness): Ho thatafala ha HRC ke tekanyo ea khanyetso ea thepa ho indenting kapa ho kena. E sebelisa litekanyo tse fapaneng (A, B, C, joalo-joalo) ho latela mokhoa o ikhethileng oa tlhahlobo le mofuta oa indenter e sebelisitsoeng (khoune ea daemane kapa bolo ea tšepe e thata). Sekala sa HRC se atisa ho sebelisoa ho lekanya ho thatafala ha thepa ea tšepe. Boleng ba boima bo emeloa e le nomoro sekala sa HRC, joalo ka HRC 50.

Tafole ea papiso e thata ea HV-HB-HRC e sebelisoang hangata:

| Tafole e tloaelehileng ea papiso ea ferrous metal hardness (matla a ka bang a fetoha) | ||||

| Karolelano ea boima | Matla a tšepe N/mm2 | |||

| Rockwell | Vickers | Brinell | ||

| HRC | HRA | HV | HB | |

| 17 | - | 211 | 211 | 710 |

| 17.5 | - | 214 | 214 | 715 |

| 18 | - | 216 | 216 | 725 |

| 18.5 | - | 218 | 218 | 730 |

| 19 | - | 221 | 220 | 735 |

| 19.5 | - | 223 | 222 | 745 |

| 20 | - | 226 | 225 | 750 |

| 20.5 | - | 229 | 227 | 760 |

| 21 | - | 231 | 229 | 765 |

| 21.5 | - | 234 | 232 | 775 |

| 22 | - | 237 | 234 | 785 |

| 22.5 | - | 240 | 237 | 790 |

| 23 | - | 243 | 240 | 800 |

| 23.5 | - | 246 | 242 | 810 |

| 24 | - | 249 | 245 | 820 |

| 24.5 | - | 252 | 248 | 830 |

| 25 | - | 255 | 251 | 835 |

| 25.5 | - | 258 | 254 | 850 |

| 26 | - | 261 | 257 | 860 |

| 26.5 | - | 264 | 260 | 870 |

| 27 | - | 268 | 263 | 880 |

| 27.5 | - | 271 | 266 | 890 |

| 28 | - | 274 | 269 | 900 |

| 28.5 | - | 278 | 273 | 910 |

| 29 | - | 281 | 276 | 920 |

| 29.5 | - | 285 | 280 | 935 |

| 30 | - | 289 | 283 | 950 |

| 30.5 | - | 292 | 287 | 960 |

| 31 | - | 296 | 291 | 970 |

| 31.5 | - | 300 | 294 | 980 |

| 32 | - | 304 | 298 | 995 |

| 32.5 | - | 308 | 302 | 1010 |

| 33 | - | 312 | 306 | 1020 |

| 33.5 | - | 316 | 310 | 1035 |

| 34 | - | 320 | 314 | 1050 |

| 34.5 | - | 324 | 318 | 1065 |

| 35 | - | 329 | 323 | 1080 |

| 35.5 | - | 333 | 327 | 1095 |

| 36 | - | 338 | 332 | 1110 |

| 36.5 | - | 342 | 336 | 1125 |

| 37 | - | 347 | 341 | 1140 |

| 37.5 | - | 352 | 345 | 1160 |

| 38 | - | 357 | 350 | 1175 |

| 38.5 | - | 362 | 355 | 1190 |

| 39 | 70 | 367 | 360 | 1210 |

| 39.5 | 70.3 | 372 | 365 | 1225 |

| 40 | 70.8 | 382 | 375 | 1260 |

| 40.5 | 70.5 | 377 | 370 | 1245 |

| 41 | 71.1 | 388 | 380 | 1280 |

| 41.5 | 71.3 | 393 | 385 | 1300 |

| 42 | 71.6 | 399 | 391 | 1320 |

| 42.5 | 71.8 | 405 | 396 | 1340 |

| 43 | 72.1 | 411 | 401 | 1360 |

| 43.5 | 72.4 | 417 | 407 | 1385 |

| 44 | 72.6 | 423 | 413 | 1405 |

| 44.5 | 72.9 | 429 | 418 | 1430 |

| 45 | 73.2 | 436 | 424 | 1450 |

| 45.5 | 73.4 | 443 | 430 | 1475 |

| 46 | 73.7 | 449 | 436 | 1500 |

| 46.5 | 73.9 | 456 | 442 | 1525 |

| 47 | 74.2 | 463 | 449 | 1550 |

| 47.5 | 74.5 | 470 | 455 | 1575 |

| 48 | 74.7 | 478 | 461 | 1605 |

| 48.5 | 75 | 485 | 468 | 1630 |

| 49 | 75.3 | 493 | 474 | 1660 |

| 49.5 | 75.5 | 501 | 481 | 1690 |

| 50 | 75.8 | 509 | 488 | 1720 |

| 50.5 | 76.1 | 517 | 494 | 1750 |

| 51 | 76.3 | 525 | 501 | 1780 |

| 51.5 | 76.6 | 534 | - | 1815 |

| 52 | 76.9 | 543 | - | 1850 |

| 52.5 | 77.1 | 551 | - | 1885 |

| 53 | 77.4 | 561 | - | 1920 |

| 53.5 | 77.7 | 570 | - | 1955 |

| 54 | 77.9 | 579 | - | 1995 |

| 54.5 | 78.2 | 589 | - | 2035 |

| 55 | 78.5 | 599 | - | 2075 |

| 55.5 | 78.7 | 609 | - | 2115 |

| 56 | 79 | 620 | - | 2160 |

| 56.5 | 79.3 | 631 | - | 2205 |

| 57 | 79.5 | 642 | - | 2250 |

| 57.5 | 79.8 | 653 | - | 2295 |

| 58 | 80.1 | 664 | - | 2345 |

| 58.5 | 80.3 | 676 | - | 2395 |

| 59 | 80.6 | 688 | - | 2450 |

| 59.5 | 80.9 | 700 | - | 2500 |

| 60 | 81.2 | 713 | - | 2555 |

| 60.5 | 81.4 | 726 | - | - |

| 61 | 81.7 | 739 | - | - |

| 61.5 | 82 | 752 | - | - |

| 62 | 82.2 | 766 | - | - |

| 62.5 | 82.5 | 780 | - | - |

| 63 | 82.8 | 795 | - | - |

| 63.5 | 83.1 | 810 | - | - |

| 64 | 83.3 | 825 | - | - |

| 64.5 | 83.6 | 840 | - | - |

| 65 | 83.9 | 856 | - | - |

| 65.5 | 84.1 | 872 | - | - |

| 66 | 84.4 | 889 | - | - |

| 66.5 | 84.7 | 906 | - | - |

| 67 | 85 | 923 | - | - |

| 67.5 | 85.2 | 941 | - | - |

| 68 | 85.5 | 959 | - | - |

| 68.5 | 85.8 | 978 | - | - |

| 69 | 86.1 | 997 | - | - |

| 69.5 | 86.3 | 1017 | - | - |

| 70 | 86.6 | 1037 | - | - |

HRC/HB Malebela a Hakang a Phetoho

Ho thatafala ho feta 20HRC, 1HRC≈10HB,

Ho thatafala ho tlase ho 20HRC, 1HRC≈11.5HB.

Maikutlo: Bakeng sa ts'ebetso ea ho itšeha, ha e le hantle e ka fetoloa ka mokhoa o ts'oanang 1HRC≈10HB (bothata ba lisebelisoa tsa mosebetsi bo na le mefuta e fapaneng ea ho fetoha)

Ho thatafala ha thepa ea tšepe

Ho thatafala ho bolela bokhoni ba thepa ho hanela deformation ea lehae, haholo-holo deformation ea polasetiki, indentation kapa scratching. Ke index ea ho lekanya bonolo le boima ba thepa.

Ho latela mekhoa e fapaneng ea liteko, boima bo arotsoe ka mefuta e meraro.

①Bothata ba mokwatla. Haholo-holo e sebelisoa ho bapisa bonolo le boima ba liminerale tse fapaneng. Mokhoa ke ho khetha molamu o nang le ntlha e 'ngoe ka thata' me qetellong e 'ngoe e le bonolo, ho fetisa boitsebiso bo lokelang ho lekoa hammoho le molamu, le ho fumana hore na ho thata hakae ho lekoa ho ea ka boemo ba mongoapo. Ha re bua ka boleng, lintho tse thata li etsa mengoallo e melelele 'me lintho tse bonolo li etsa mengoallo e mekgutshwane.

②Ho thatafala ha indentation. Haholo-holo e sebelisoang bakeng sa lisebelisoa tsa tšepe, mokhoa ona ke ho sebelisa mojaro o itseng ho hatella inndenter e boletsoeng ka har'a lintho tse lokelang ho lekoa, le ho bapisa bonolo le boima ba thepa e lokelang ho lekoa ka boholo ba deformation ea polasetiki ea sebakeng seo holim'a metsi. thepa. Ka lebaka la phapang ea bolelele ba nako, mojaro le nako ea mojaro, ho na le mefuta e mengata ea boima ba ho indentation, haholo-holo ho kenyelletsa le Brinell hardness, Rockwell hardness, Vickers hardness le microhardness.

③Rebound hardness. Haholo-holo e sebelisetsoang lisebelisoa tsa tšepe, mokhoa ona ke ho etsa hamore e khethehileng e nyenyane e oela ka bolokolohi ho tloha bophahamong bo itseng ho ama sampuli ea thepa e lokelang ho lekoa, 'me e sebelise boholo ba matla a matla a bolokiloeng ('me a lokolloe) ka sampuli nakong ea impact (ka ho kgutla ha hamore e nyane) ho lekanya bophahamo ba ho tlola) ho fumana boima ba ntho e itseng.

Bongata bo atileng haholo ba Brinell, Rockwell hardness le Vickers hardness ea lisebelisoa tsa tšepe ke tsa boima ba ho indentation. Boleng ba boima bo bontša bokhoni ba holim'a lintho tse bonahalang ho hanyetsa deformation ea polasetiki e bakoang ke ntho e 'ngoe e hatelloa; C) ho lekanya boima, 'me boleng ba boima bo emela boholo ba ts'ebetso ea rekere ea deformation ea tšepe.

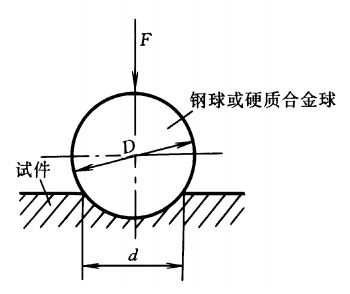

Brinell Hardness

Sebelisa bolo ea tšepe e tingoeng kapa bolo e thata ea alloy e nang le bophara ba D e le indenter, e hatelle ka holim'a karolo ea teko ka matla a lekanang a teko F, 'me ka mor'a nako e behiloeng, tlosa matla a teko ho fumana indentation le. bophara ba d. Arola matla a teko ka karolo e ka holimo ea ho indentation, 'me boleng bo hlahang ke boleng ba Brinell hardness,' me letšoao le emeloa ke HBS kapa HBW.

Phapang pakeng tsa HBS le HBW ke phapang pakeng tsa indenter. HBS e bolela hore indenter ke bolo ea tšepe e thata, e sebelisetsoang ho metha lisebelisoa tse nang le boleng ba Brinell hardness ka tlase ho 450, joalo ka tšepe e bonolo, tšepe e bohlooho le litšepe tse se nang ferrous. HBW e bolela hore indenter ke carbide e samenteng, e sebelisetsoang ho lekanya thepa ka boleng ba boima ba Brinell bo ka tlase ho 650.

Bakeng sa thibelo e tšoanang ea teko, ha maemo a mang a liteko a tšoana hantle, liphello tsa liteko tse peli li fapane, 'me boleng ba HBW hangata bo feta boleng ba HBS,' me ha ho na molao oa palo o lokelang ho lateloa.

Ka mor'a 2003, naha ea heso e amohetse litekanyetso tsa machaba ka mokhoa o ts'oanang, li-indenters tsa tšepe tse hlakotsoeng, le lihlooho tsohle tse sebelisitsoeng tsa bolo ea carbide. Ka hona, HBS e felisitsoe, 'me HBW e sebelisetsoa ho emela letšoao la boima ba Brinell. Maemong a mangata, boima ba Brinell bo hlahisoa feela ka HB, ho bua ka HBW. Leha ho le joalo, HBS e ntse e bonoa nako le nako lipampiring tsa lingoliloeng.

Mokhoa oa ho lekanya boima ba Brinell o loketse tšepe e entsoeng ka tšepe, li-alloys tse se nang ferrous, litšepe tse fapaneng tse tingoeng le tse tingoeng, 'me ha lia lokela ho etsa liteko kapalikarolo tse fetolang cnctse thata haholo, tse nyane haholo, tse tshesane haholo, kapa tse sa dumelleng ho kena ka bongata bokahodimong.

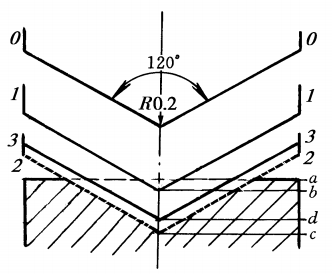

Rockwell Hardness

Sebelisa khoune ea daemane e nang le angle ea khoune ea 120 ° kapa Ø1.588mm le Ø3.176mm libolo tsa tšepe tse tingoeng joalo ka indenter le mojaro ho sebelisana le eona. Mojaro oa pele ke 10kgf mme kakaretso ea mojaro ke 60, 100 kapa 150kgf (ke hore, mojaro oa pele hammoho le mojaro o moholo). Boima bo bontšoa ke phapang pakeng tsa botebo ba ho indentation ha mojaro o moholo o tlosoa le botebo ba indentation ha mojaro o moholo o bolokoa le botebo ba indentation tlas'a mojaro oa pele ka mor'a hore mojaro o feletseng o sebelisoe.

Teko ea boima ba Rockwell e sebelisa matla a mararo a liteko le li-indenters tse tharo. Ho na le metsoako e 9 ea tsona, e tsamaellanang le sekala sa 9 sa Rockwell hardness. Tšebeliso ea babusi bana ba 9 e akaretsa hoo e batlang e le lisebelisoa tsohle tsa tšepe tse sebelisoang hangata. Ho na le HRA tse tharo tse sebelisoang ka tloaelo, HRB le HRC, tseo HRC e leng tsona tse sebelisoang haholo.

Tafole e sebelisoang hangata ea tlhahlobo ea boima ba Rockwell:

| Ho thatafala | | | Ho thatafala | |

| | | | | Carbide, carbide, |

| | | | | Anealed, normalized steel, aluminium alloy |

| | | | | tšepe e thata, e tingoeng le e halefileng, e tebileng |

Lenane la tšebeliso ea sekala sa HRC ke 20 ~ 70HRC. Ha boleng ba boima bo ka tlase ho 20HRC, hobane conicalkarolo ea aluminium cnc machiningea indenter e hatelloa haholo, kutlo e fokotseha, 'me sekala sa HRB se lokela ho sebelisoa sebakeng sa eona; ha boima ba sampuli bo le boholo ho feta 67HRC, khatello ea ntlha ea indenter e kholo haholo, 'me daemane e senyeha habonolo. Bophelo ba indenter bo tla khutsufatsoa haholo, kahoo sekala sa HRA se lokela ho sebelisoa ka kakaretso.

Teko ea ho thatafala ha Rockwell e bonolo, e potlakile ebile e nyane, 'me e ka leka bokaholimo ba lihlahisoa tse felileng le lisebelisoa tse thata le tse tšesaane. Ka lebaka la ho indentation e nyane, bakeng sa lisebelisoa tse nang le sebopeho se sa lekaneng le boima, boleng ba boima bo fetoha haholo, 'me ho nepahala ha hoa lekana le boima ba Brinell. Ho thatafala ha Rockwell ho sebelisoa ho tseba ho thatafala ha tšepe, litšepe tse se nang ferrous, li-alloys tse thata, joalo-joalo.

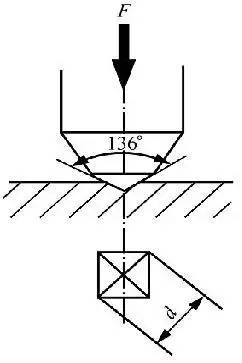

Vickers Hardness Vickers Hardness

Molao-motheo oa ho lekanya boima ba Vickers o tšoana le oa Brinell hardness. Sebelisa indenter ea piramite e sekoere ea taemane e nang le angle e kenyellelitsoeng ea 136 ° ho hatella holim'a thepa ka matla a boletsoeng a teko F, 'me u tlose matla a teko ka mor'a ho boloka nako e behiloeng. Ho thatafala ho bontšoa ke khatello e tloaelehileng karolong e ka holimo ea yuniti ea lisekoere tsa phiramide. Boleng, letšoao la letšoao ke HV.

Lethathamo la tekanyo ea boima ba Vickers le leholo, 'me le khona ho lekanya thepa ka thatafala ho tloha ho 10 ho isa ho 1000HV. Indentation e nyane, 'me hangata e sebelisoa ho lekanya lisebelisoa tse tšesaane le likarolo tse thata tse kang carburizing le nitriding.

Leeb Hardness Leeb Hardness

Sebelisa 'mele oa tšusumetso o nang le boima bo itseng ba hlooho ea bolo ea tungsten carbide ho ama bokaholimo ba karolo ea teko tlas'a ketso ea matla a itseng, ebe o khutlela morao. Ka lebaka la boima bo fapaneng ba lisebelisoa, lebelo la rebound ka mor'a tšusumetso le lona le fapane. Magnete e sa feleng e kentsoe sesebelisoa sa tšusumetso. Ha 'mele oa tšusumetso o ea holimo le tlase, khoele ea eona ea peripheral e tla hlahisa lets'oao la motlakase le lekanang le lebelo, ebe e le fetola boleng ba boima ba Leeb ka potoloho ea elektroniki. Letšoao le tšoailoe e le HL.

Leeb hardness tester ha e hloke sesebelisoa sa ho sebetsa, 'me sensor ea eona e thata e nyenyane joaloka pene, e ka sebelisoang ka ho toba ka letsoho,' me e ka fumanoa habonolo hore na ke mosebetsi o moholo, o boima kapa oa mosebetsi o nang le litekanyo tse rarahaneng tsa geometri.

Molemo o mong oa boima ba Leeb ke hore o na le tšenyo e fokolang haholo holim'a sehlahisoa, 'me ka linako tse ling e ka sebelisoa e le teko e sa senyeheng; e ikhetha ka liteko tsa boima ka mahlakoreng 'ohle, libaka tse moqotetsane le tse khethehilenglikarolo tsa aluminium.

Anebon e khomarela molao-motheo oa "Botšepehi, ho sebetsa ka thata, ho sebetsa ka thata, ho qapa" ho fumana litharollo tse ncha kamehla. Anebon e nka litebello, katleho e le katleho ea eona ea botho. E re Anebon e hahe letsoho la bokamoso le atlehileng bakeng sa likarolo tse entsoeng ka koporo le likarolo tsa Complex titanium cnc / lisebelisoa tsa setempe. Hona joale Anebon e na le phepelo e felletseng ea thepa hammoho le theko ea ho rekisa ke molemong oa rona. Rea u amohela ho botsa ka lihlahisoa tsa Anebon.

Lihlahisoa tse Tloaelehileng tsa China CNC Machinging Part le Precision Part, ha e le hantle haeba efe kapa efe ea lintho tsena e ka u khahla, ka kopo, re tsebise. Anebon e tla thabela ho u fa khotheishene ha u fumana lintlha tse qaqileng tsa motho. Anebon e na le lienjineri tsa rona tsa R&D tsa setsebi ho fihlela litlhokahalo life kapa life. Anebon e labalabela ho fumana lipotso tsa hau haufinyane 'me o tšepa ho ba le monyetla oa ho sebetsa le uena nakong e tlang. Rea u amohela ho sheba mokhatlo oa Anebon.

Nako ea poso: May-18-2023