Tshebeletso ya Die Casting

Die casting esale e le ntho e ikhethang ea Anebon ka lilemo tse fetang 10. Litšebeletso tsa rona tsa ho lahlela aluminium li ntse li thusa baenjiniere, baqapi ba lihlahisoa le litsebi tsa meralo ea meralo ho etsa hore meralo ea bona e phele ka meralo ea boemo bo holimo le boleng bo tšepahalang. Ka lebaka la phihlelo ea rona indastering, hammoho le lisebelisoa tsa rona tsa morao-rao, litsebi tsa rona tsa ho etsa lihlahisoa le lienjiniere tsa boleng, le basebetsi ba tlhahiso, u tiiselitsoe ho etsoa ha likarolo le lihlahisoa tsa hau ka tekanyo ea moruo le Anebon.Re bahlahisi ba netefalitsoeng ba ISO 9001:2015 ba sebetsanang ka ho khetheha le litšebeletso tsa lefu bakeng sa liindasteri le lik'hamphani tse etelletseng pele lefatšeng. Lisebelisoa tsa rona li akaretsa hoo e batlang e le litlhoko tsohle tsa boenjiniere ba ho lahla, boqapi le nts'etsopele eo k'hamphani ea hau e ka e hlokang.

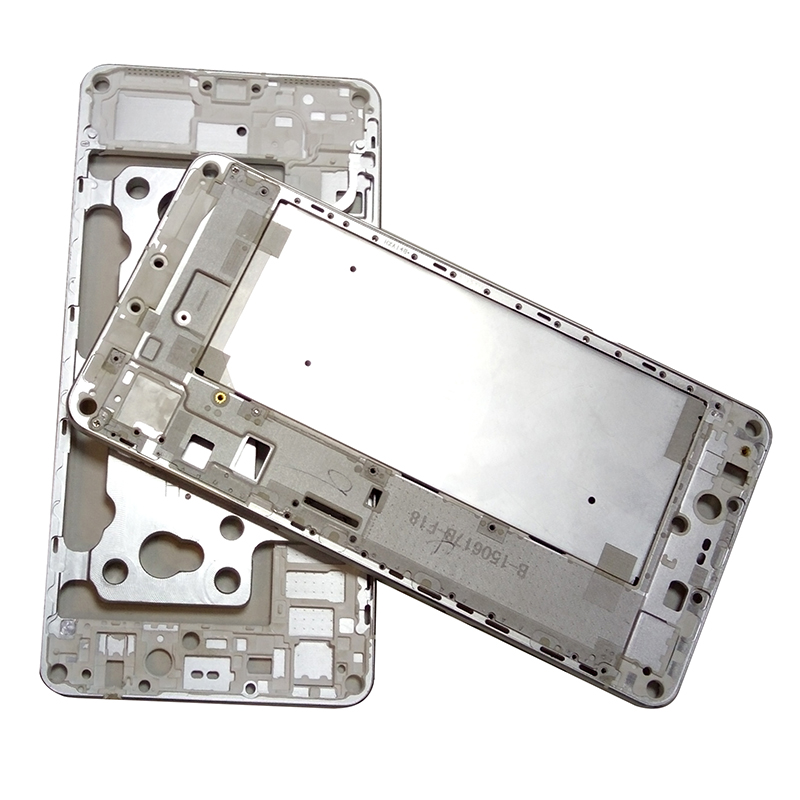

Lisebelisoa tsa ho lahla le hlobo li theko e boima, ka hona, mokhoa oa "die casting" o sebelisoa feela ho hlahisa lihlahisoa tse ngata. Ho batla ho le bonolo ho etsa likarolo tsa die-cast, tseo ka kakaretso li hlokang mehato e mene feela e kholo, 'me theko e le 'ngoe e eketseha e le tlase. Die casting e loketse ka ho khetheha bakeng sa ho etsa palo e kholo ea li-castings tse nyenyane le tse mahareng, kahoo ho lahla ke mokhoa o sebelisoang ka ho fetisisa oa mekhoa e sa tšoaneng ea ho lahla. Ha ho bapisoa le mekhoa e meng ea ho lahla, bokaholimo ba "die-cast" bo bataletse ebile bo na le maemo a holimo.

Die Casting ke eng?

Die casting ke ts'ebetso ea ho lahla ea tšepe e khetholloang ka tšebeliso ea sekoti sa hlobo ho kenya khatello e phahameng ho tšepe e qhibilihisitsoeng. Hangata hlobo e entsoe ka li-alloys tse matla tse phahameng, tse ling tsa tsona li tšoana le ho bopa ente. Boholo ba li-die castings ha li na tšepe, joalo ka zinki, koporo, aluminium, magnesium, lead, tin, le li-alloys tsa lead-tin le lisebelisoa tse ling. Ho ipapisitsoe le mofuta oa ho lahlela lefu, mochini o batang oa mochini oa ho lahla kapa mochini o chesang oa kamore e chesang oa hlokahala.

Litšobotsi

Die casting ke mokhoa oa ho lahla moo mokelikeli o qhibilihisitsoeng oa alloy o tšeloang ka kamoreng ea khatello, sekoti sa hlobo ea tšepe se tlatsitsoe ka lebelo le phahameng, 'me mokelikeli oa alloy o tiisoa tlas'a khatello ea ho etsa casting. Likarolo tse ka sehloohong tsa ho lahlela lefu tse e khethollang ho mekhoa e meng ea ho lahla ke khatello e phahameng le lebelo le phahameng.

1. Tšepe e qhibilihisitsoeng e tlatsa sekoti tlas'a khatello 'me e phatsima ka khatello e phahameng. Khatello e tloaelehileng ke 15-100 MPa.

2 . Mokelikeli oa tšepe o tlatsa sekoti ka lebelo le phahameng, hangata ho 10-50 m / s, 'me tse ling li ka feta 80 m / s, (lebelo la mohala ho kena ka har'a sekoti - lebelo la ho bokella), kahoo nako ea ho tlatsa tšepe e entsoeng ka tšepe e qhibilihisoa haholo. e khutšoanyane, 'me sekoti se ka tlatsoa ka metsotsoana e ka bang 0.01-0.2 (ho itšetlehile ka boholo ba ho lahla).

Die-casting ke mokhoa o nepahetseng oa ho lahla. Likarolo tsa li-die-casting tse entsoeng ke die-casting, li na le mamello e nyane haholo le ho nepahala ha holimo. Maemong a mangata, likarolo tsa li-die-casting li ka kopanngoa ntle le ho reteleha. Likarolo li ka boela tsa lahleloa ka ho toba.

Melemo ea litšebeletso tsa "die casting" ke efe?

Ts'ebetso ea rona ea phetoho ea phetoho ea lefu e fana ka melemo e mengata ea bohlokoa, ho kenyelletsa:

l Customization: E thusa ho fihlela meralo le liforomo tse rarahaneng tse etsang hore ho be bonolo ho etsa li-castings ka mekhoa e itseng ea tlhahiso.

ll Theko e tlase

lll Ho sebetsa hantle haholo

llll E sebetsa ka bongata ebile e hana ho bola

Joalo ka moetsi oa li-die-casting, Anebon Die Casting e fana ka kopano e felletseng, e felletseng le tlhahlobo ea likarolo le lihlahisoa tsohle tsa die-cast. Ho sa tsotellehe hore na u thahasella likarolo tse khethehileng tse kang aluminium die casting kapa vacuum die casting, kapa u batla feela ho ba mohlala oa karolo e ncha, u ka fumana phihlelo ea tšebeletso e feletseng fekthering ea rona.

Mlintho tse bonahalang

Litšepe tseo re li sebelisitseng ho etsa die casting haholo-holo li kenyelletsa zinki, koporo, aluminium, magnesium, lead, tin, le li-alloys tsa lead-tin, joalo-joalo. Litšobotsi tsa litšepe tse fapa-fapaneng nakong ea ho lahla lefu ke tse latelang:

•Zinki: Tšepe ea die-cast e bonolo ka ho fetisisa, e nang le chelete e ngata ha e etsa likaroloana tse nyenyane, tse bonolo ho li roala, matla a phahameng a khatello, polasetiki e phahameng, le bophelo bo bolelele ba ho lahla.

•Aluminium: Boleng bo phahameng, tlhahiso e rarahaneng le li-castings tse nang le marako a tšesaane tse nang le botsitso bo phahameng ba mahlakoreng, ho hanyetsa kutu e phahameng, thepa e ntle ea mochine, mocheso o phahameng oa mocheso le motlakase oa motlakase, le matla a phahameng ka mocheso o phahameng.

•Magnesium: Ho bonolo ho mochine, tekanyo e phahameng ea matla ho boima ba 'mele, e bobebe ka ho fetisisa ea litšepe tse sebelisoang hangata.

•Koporo: Boima bo phahameng le ho hanyetsa ho matla ha kutu. Tšepe e sebelisoang ka ho fetisisa ea die-cast e na le lisebelisoa tse ntle ka ho fetisisa tsa mechine, li-anti-wear le matla a haufi le tšepe.

•Loto le thini: Boima bo phahameng le ho nepahala ho phahameng bakeng sa likarolo tse khethehileng tsa tšireletso ea kutu. Ka mabaka a bophelo bo botle ba sechaba, motsoako ona o ke ke oa sebelisoa e le setsi sa ho lokisa le ho boloka lijo. Li-alloys tsa lead-tin-bismuth (ka linako tse ling le tsona li na le koporo e nyenyane) li ka sebelisoa ho etsa litlhaku tse phethoang ka letsoho le ho hatisa setempe se chesang khatisong ea letterpress.

Aluminium Casting

Ho Lahlela Lisebelisoa tsa Mohala oa Mohala

Aluminium Die Cast