CNC e fetoha eng?

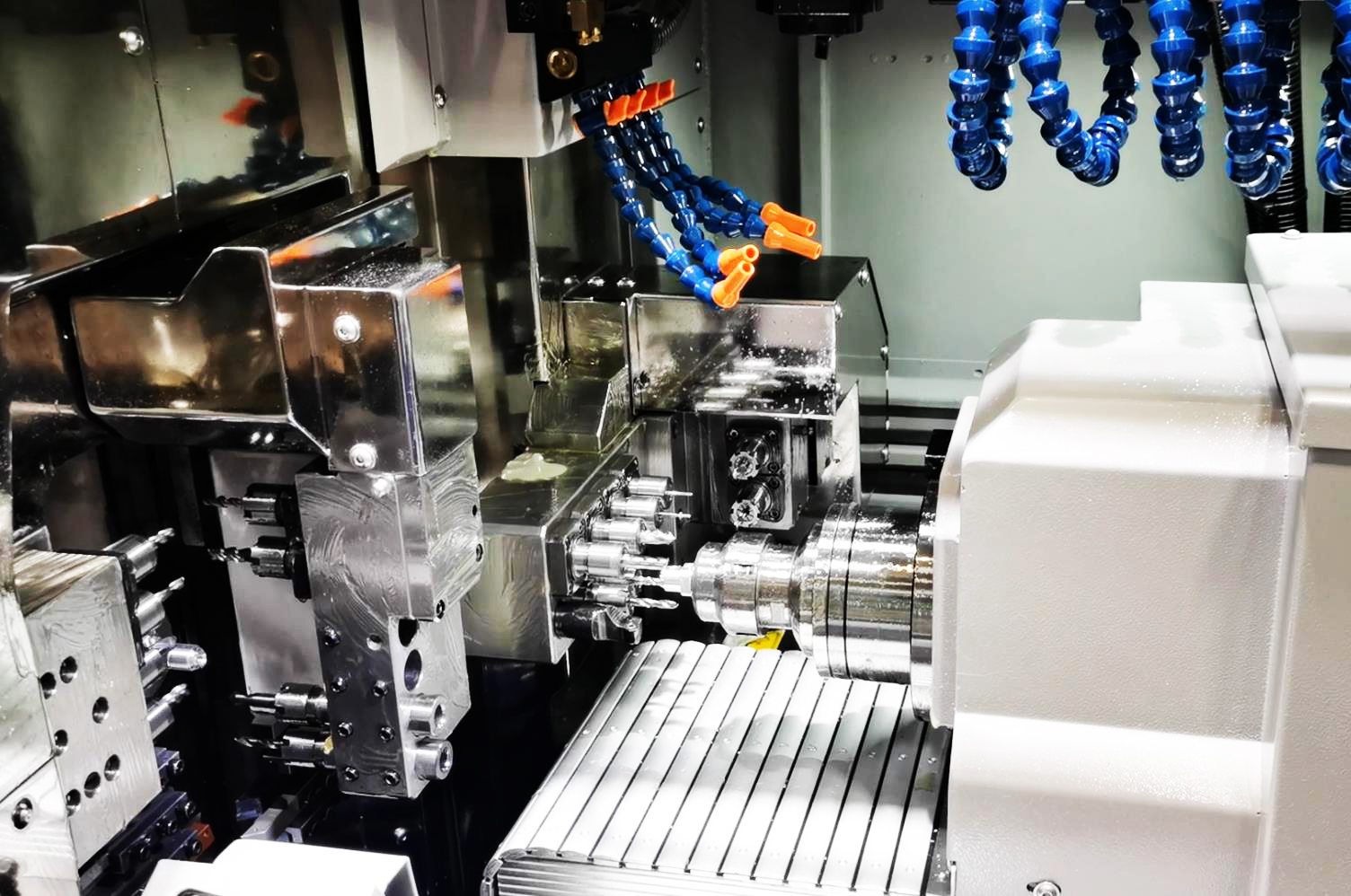

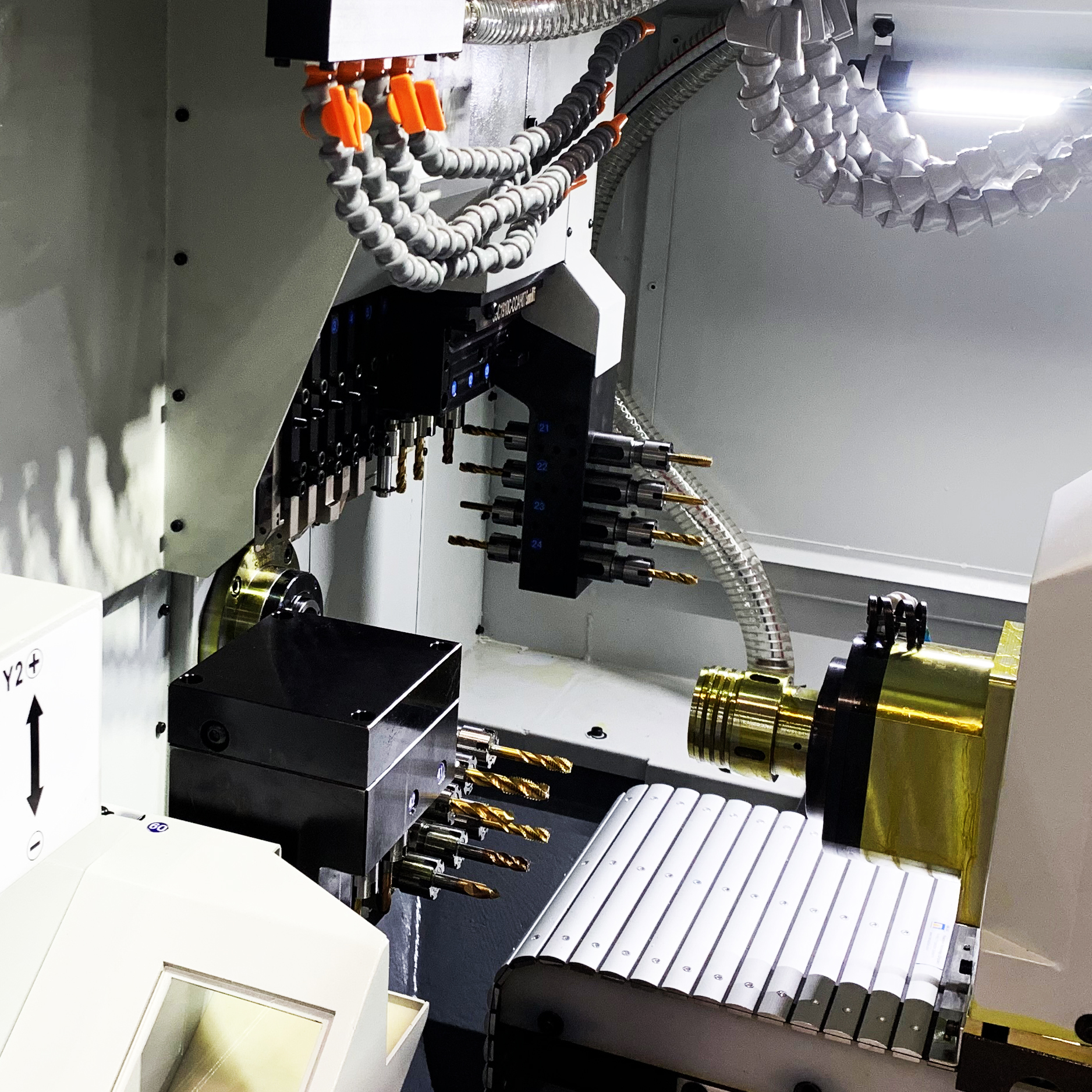

CNC lathe ke sesebelisoa sa mochini o ikemetseng o sebetsang hantle haholo, o sebetsang hantle haholo. E na le li-turret tsa li-multi-station kapa turret ea matla, sesebelisoa sa mochine se na le mefuta e mengata ea theknoloji ea ho sebetsa, e ka sebetsana le li-cylinders tse nang le mela, li-cylinders tse diagonal, li-arcs le li-workpieces tse fapa-fapaneng tse rarahaneng tse kang likhoele le li-grooves, tse nang le linear interpolation le circular interpolation.

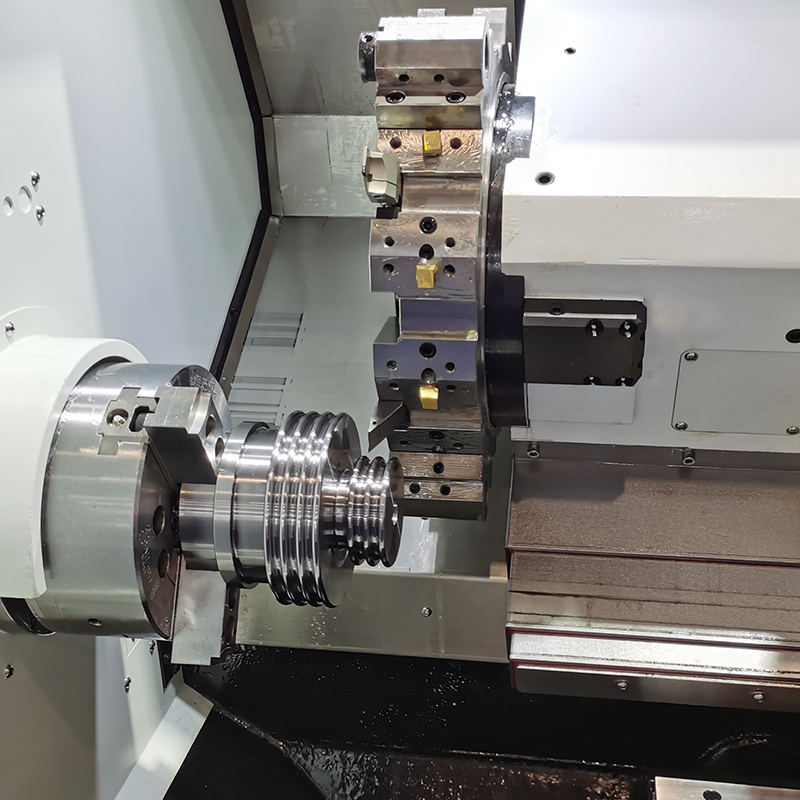

Ha CNC e phethola, mekoallo ea thepa e ts'oaroa ka har'a chuck ebe e potoloha, 'me sesebelisoa se feptjoa ka li-angles tse fapaneng,' me libopeho tse ngata tsa lisebelisoa li ka sebelisoa ho theha sebopeho se lakatsehang. Ha setsi se na le mesebetsi ea ho reteleha le ho sila, o ka emisa ho potoloha ho lumella ho sila ha libopeho tse ling. Theknoloji ena e lumella mefuta e sa tšoaneng ea libopeho, boholo le mefuta ea thepa.

Lisebelisoa tsa CNC lathe le setsi sa ho phethoha li behiloe holim'a turret. Re sebelisa sesebelisoa sa CNC se nang le sesebelisoa sa "nako ea sebele" (mohlala, Tšebeletso ea Bopula-maliboho), e emisang ho potoloha le ho eketsa mesebetsi e meng e kang ho cheka, li-grooves le libaka tsa ho sila.

Tšebeletso ea ho fetola CNC

Haeba o hloka ho fetoha ha CNC, re ba bang ba bahlahisi ba nang le bokhoni le ba theko e phahameng ka ho fetesisa. Ka li-lathes tse 14 tse tsoetseng pele, sehlopha sa rona se ka hlahisa thepa ka nepo le ka nako. Mefuta e mengata ea bokhoni ba tlhahiso e lumella Anebon ho fana ka likarolo tse ikhethang tsa sampole. Thepa ea rona ea tlhahiso ea bongata e netefatsa ho fetoha ha rona le ho itšepa. 'Me re tla fihlela litlhoko tsa indasteri e' ngoe le e 'ngoe eo re e sebeletsang ka litekanyetso tse thata ka ho lekaneng. Re tsepamisitse maikutlo ho boleng le tšebeletso ea bareki.

Likarolo tse fetolang tsa CNC tseo re li etsang

Re hlahisitse likarolo tse ngata tse fetohang tsa CNC ka lilemo tse 10 mme sehlopha sa rona sa boenjiniere se 'nile sa fa bareki ba rona litharollo tse molemo ho rarolla mathata a bona ha ho etsoa likarolo tsa ho fetola CNC. Re etsa bonnete ba hore ho sebetsa ka mokhoa o tsitsitseng oa boleng bo phahameng, esita le tabeng ea likarolo tse rarahaneng, ho sebelisa li-module tsa mochine o rarahaneng le ho sebelisa mochine o nang le tsebo ea CNC ho sebelisa mochine. Hobane Anebon e lula e pota-potile ho nepahala ho phahameng!

LIKHETHO TSA MOSEBETSI KA HO FETOLA CNC

Ka lisebelisoa tsa rona tsa morao-rao le tse phahameng tsa ts'ebetso tse kenyelletsang

Litsi tsa phetolo tsa CNC le4-axis mechine e fetolang.

Re fana ka mefuta e fapaneng ea likhetho tsa tlhahiso.

Hore na likarolo tse bonolo kapa tse rarahaneng tse fetotsoeng, likarolo tse telele kapa tse khutšoane tse fetotsoeng hantle,

re hlomeletsoe hantle bakeng sa maemo ohle a mathata.

- Prototype machining / zero letoto la tlhahiso

- Tlhahiso ea lihlopha tse nyenyane

- Tlhahiso ea boholo ba batch e mahareng

Lintho tse bonahalang

Lisebelisoa tse latelang tse thata li sebelisoa hangata: aluminium, tšepe e sa hloekang, koporo, nylon, tšepe, acetal, polycarbonate, acrylic, koporo, PTFE, titanium, ABS, PVC, bronze joalo-joalo.

Litšobotsi

1. CNC lathe moralo CAD, moralo moralo modularization

2. Lebelo le phahameng, ho nepahala ho phahameng le ho tšepahala ho phahameng

3. Le hoja thepa ea ho qala hangata e le chitja, e ka ba libopeho tse ling, tse kang sekoere kapa hexagon.E 'ngoe le e' ngoe e hlobolisa le boholo e ka hloka "clip" e itseng (subtype ea collet - ho etsa molala ho potoloha ntho).

4. Bolelele ba bar bo ka fapana ho itšetlehile ka lijo tsa bar.

5. Lisebelisoa tsa li-lathe tsa CNC kapa li-turning centers li kenngoa ho turret e laoloang ke k'homphieutha.

6. Qoba libopeho tse thata tse kang tse telele haholo tse tšesaane

7. Ha karo-karolelano ea botebo ho bophara e phahame, ho phunya ho ba thata.

Konopo ea li-tripod tsa khamera

Likarolo tsa Aluminium Anodized

Likarolo tse Fetohileng tsa Precision