Likarolo tsa Plastiki tse Fetolang CNC

Khampani ea rona e tla latela filosofi ea khoebo ea "Boleng ba Pele, bo tsitsitseng le bo botle, bo shebaneng le batho, boqapi ba theknoloji". Boiteko ba ho tsoela pele ho hatela pele, boqapi indastering, le ho leka ka hohle ho ba khoebo ea maemo a pele. Re ikitlaelletsa ho aha mohlala oa tsamaiso ea mahlale, ho ithuta tsebo e ruileng ea profeshenale, ho nts'etsapele lisebelisoa tse tsoetseng pele tsa tlhahiso le thekenoloji ea tlhahiso, ho theha boleng ba 'nete, theko e ntle, litšebeletso tse ntle, phano e potlakileng, le ho u etsetsa boleng bo bocha.

Phello ea thepa ea polasetiki ka mokhoa oa ho itšeha. Litšobotsi tsa li-chips tsa polasetiki li nyane ho feta tsa tšepe. Matla a mocheso a polasetiki a nyenyane, mocheso oa mocheso o futsanehile (motlakase oa mocheso ke likete tse tharo feela kapa ka tlaase ho tšepe), 'me coefficient ea ho atolosa mocheso o moholo (1.5 ~ e kholoanyane ho feta tšepe) makhetlo a 20). Ka hona, mocheso o hlahisoang ke khohlano nakong ea ho itšeha o fetisetsoa haholo ho sehahi.

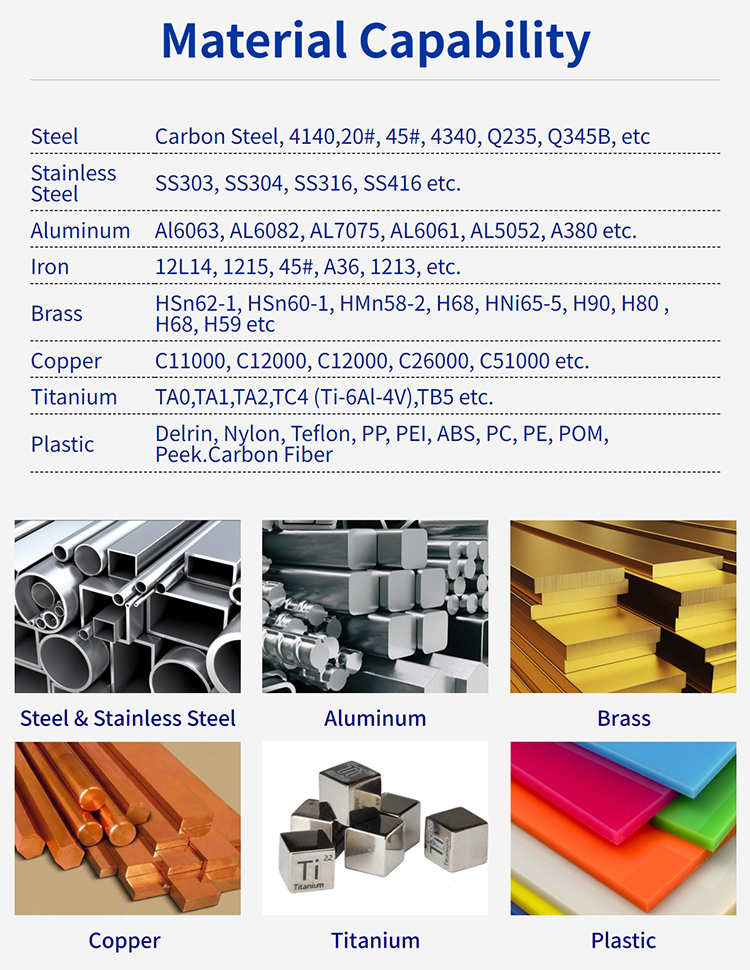

Khetho ea lisebelisoa:

Ka kakaretso, ho thibetsoe ho otlolla shaft e tšesaane ka ho toba.

Ho phaella moo, lehlakoreng le ka ntle la ho fetola ka ntle la sesebelisoa sa ho fetola ka ntle se ka ba seholo ho feta 90 °.

Ka lisebelisoa tsa carbide, boleng ba mochini bo bobe haholo ebile ha bo khonehe ho e etsa.

Ha ho etsoa lenaneo, lehlakoreng le leholo la morao, ho kgothaletswa ho nahana ka carbide e entsoeng ka samente, mocheso o phahama ka potlako, 'me lehare le bohale haholo.