Likarolo tsa tšepe tsa CNC tse potlakileng tsa Prototyping

Chelete e rekisoang ka nepo e etselitsoeng likarolo tsa tšepe tsa CNC tsa machining tsa CNC

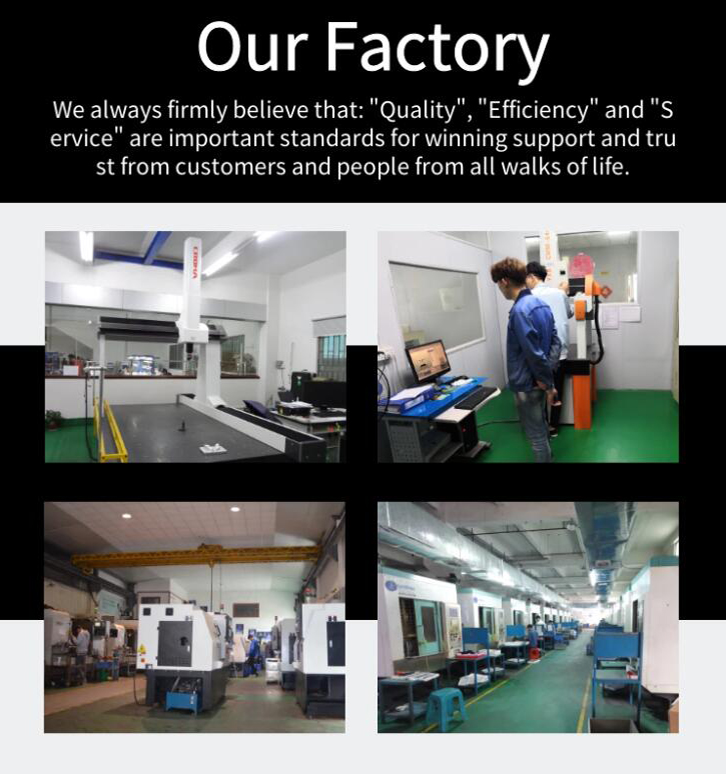

Re ikemiseditse ho taelo e tiileng ya boleng bo phahameng ka ho fetisisa le tshehetso e nahanelang ya ho reka thepa. Basebeletsi ba rona ba nang le boiphihlelo le bareki ba ka buisana ka tlhoko ea hau ka nako efe kapa efe, 'me ba tla fihlela tlhoko ea moreki ka botlalo bakeng sa thekiso e chesang ea feme ea CNC Rapid Prototyping Metal Parts.

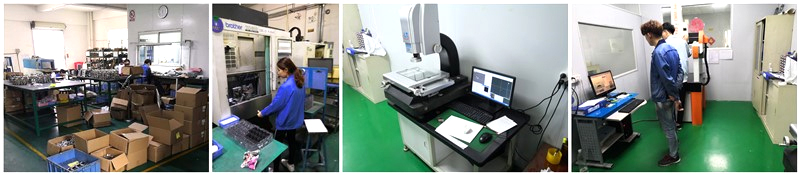

Feme ea rona ke ea Likarolo tsa ho sila tsa CNC, likarolo tsa machining tsa CNC tse nepahetseng, likarolo tsa tšepe tsa CNC tse ikhethileng. Re tsotella sehokelo se seng le se seng sa ts'ebeletso ea rona, ho tloha khethong ea feme, nts'etsopele ea sehlahisoa le moralo, lipuisano tsa litheko, tlhahlobo, ho isa 'marakeng oa thekiso ea kamora thekiso. Re kentse tšebetsong tsamaiso e thata le e felletseng ea taolo ea boleng ho netefatsa hore sehlahisoa se seng le se seng se ka fihlela litlhoko tsa boleng ba bareki. Ho feta moo, lihlahisoa tsohle tsa rona li hlahlojoa ka thata pele li romelloa. Katleho ea hau, tlotla ea rona: sepheo sa rona ke ho thusa bareki ba rona ho fihlela sepheo sa bona. Re leka ho fihlela boemo bona ba win-win.

| Standard | GB/ISO2768-M, GB/T6892-2006 | |

| Setifikeiti | ISO9001,ISO14001 | |

| Mokhoa oa tlhahiso | Drawing-Opening hlobo-Raw material -Molding-Deep processing-Surface treatment-Inspection- Packaging | |

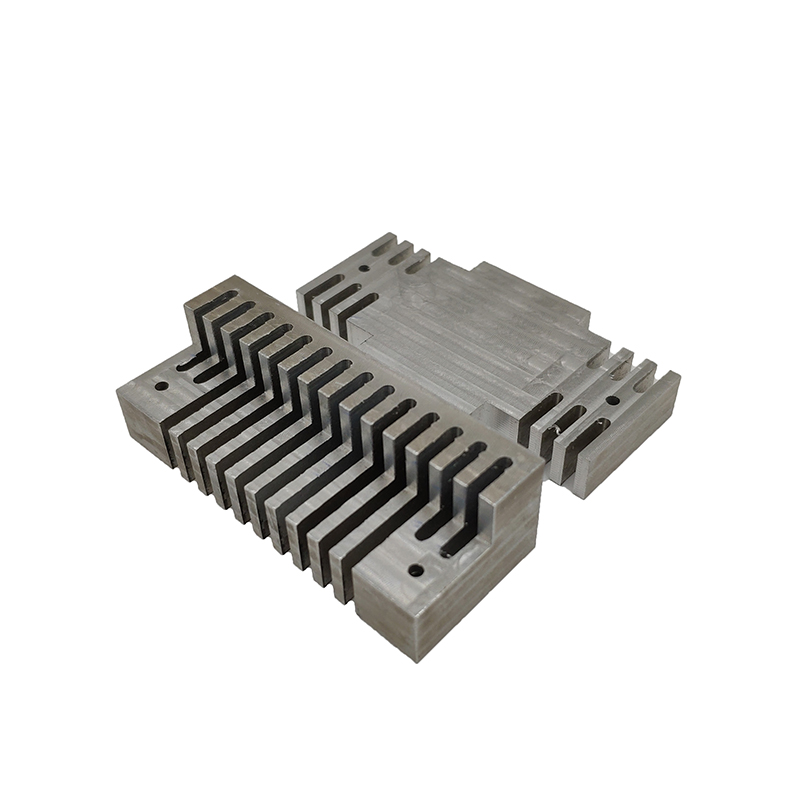

| Theknoloji ea ho sebetsa | Katoloso (//) CNC machining joalo ka ho cheka, ho sila, ho reteleha, ho kobeha, ho seha, ho tjheseletsa, ho phunya, jj. | |

| Thepa e tebileng ea Ts'ebetso | Punch ea CNC | Ho phunya/ho hatakela-Bophahamo bo phahameng ba Leqephe la Metal Fabrication |

| CNC Ho Kobeha | Koba-Phahameng ka nepo ho kobeha seamless | |

| CNC Milling | Mlling e nepahetseng e phahameng, taolo ea lipalo e betla le ho sila, ho betla le ho sila ka CNC | |

| CNC Machining Center | Ho sila, ho phunya, ho reteleha, ho thaepa, ho tlanya, ho bora, ho shebana, ho thiba, ho kopanya | |

| Welding | GMAW WeldingMIG Welding | |

| Ho itšeha ka laser | Ho itšeha ho holimo | |

| Phekolo ea bokaholimo | Seipone anodizing | Ka ho buffing le mokhoa oa anodizing ho theha seipone joalo ka pheletso |

| Tloaelehileng anodizing | Anodizing layer = 10um, 'mala o ka etsoa | |

| Li-anodizing tse thata | Aanodizing layer≥40um, mmala o ka etsoa ka mokhoa o ikhethileng | |

| Ho taka/ ho borashe | Ka borashe le ts'ebetso ea lik'hemik'hale ho theha ho benya ka mohala | |

| Oli / Baking Pente | 'Mala o ka etsoa ka mokhoa o ikhethileng | |

| Ho roala ka phofo | Theha lera le teteaneng sireletsa bokaholimo, ho hanyetsa kutu e ntle | |

| Ho benya | Qetella aluminium ka boeona, tšepe e khanyang | |

| Electrophoresis | E ipapisitse le ts'ebetso ea anodized, filimi e pepeneneng e eketsehileng e hlakisa bokaholimo mme e shebahale eka e benya, e hanyetsa kutu e ntle. | |

| Ho qhomisa lehlabathe | Ho etsa hore bokaholimo bo be thata le bohloeki, bo ntlafatsa ho hanyetsa mokhathala le matla a ho khomarela lintho tsa khale. | |

Molemo oa Khamphani ea Rōna:

| 1. Re fektheri e fanang ka litšebeletso tsa CNC le likarolo tsa tšepe tsa machining |

| 2. Ho sebetsana le likarolo tsa mamello e thata haholo le geometry e rarahaneng haholo |

| 3. Low MOQ (10pcs e bile e amoheleha maemong a mang a khethehileng) |

| 4. E fana ka prototyping mahala le kapele (hangata beke e le 1) |

| 5. Ho tlisoa ka nako |

| 6. Boleng bo holimo bo tiisitsoeng ke basebetsi ba nang le tsebo, tsamaiso ea tsamaiso le boemo ba lisebelisoa. |

| 7. Letoto la litšebeletso tsa bobeli tse fumanehang, joalo ka ho lahlela; ho qapa; tjheseletsa; phekolo ea mocheso joalo-joalo. |

| 8. Ho fana ka litšebeletso tsa boeletsi mabapi le machining ea likarolo |

| 9. Customized boholo le spec / OEM fumaneha |

| Likarolo tsa Mechini ea Cnc | Aluminium Cnc Machining Service | Litšebeletso tsa Metal Cnc |

| Likarolo tsa Mochini oa Aluminium | Axis Machining | Ts'ebeletso ea China Cnc |

| Likarolo tsa Aluminium Cnc | Mochini | Likarolo tsa Aluminium tse entsoeng ka tloaelo |