Ts'ebeletso ea mochini oa CNC

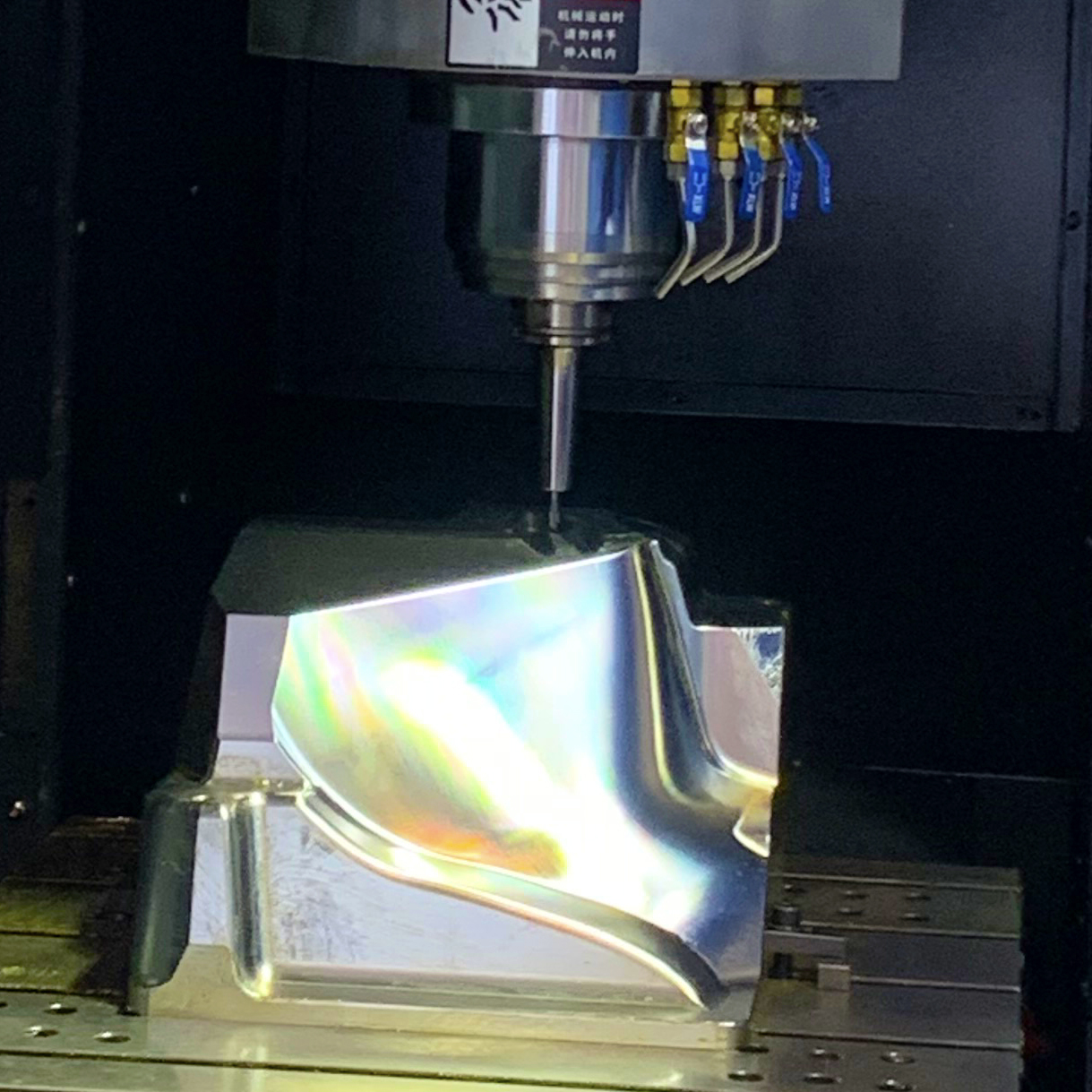

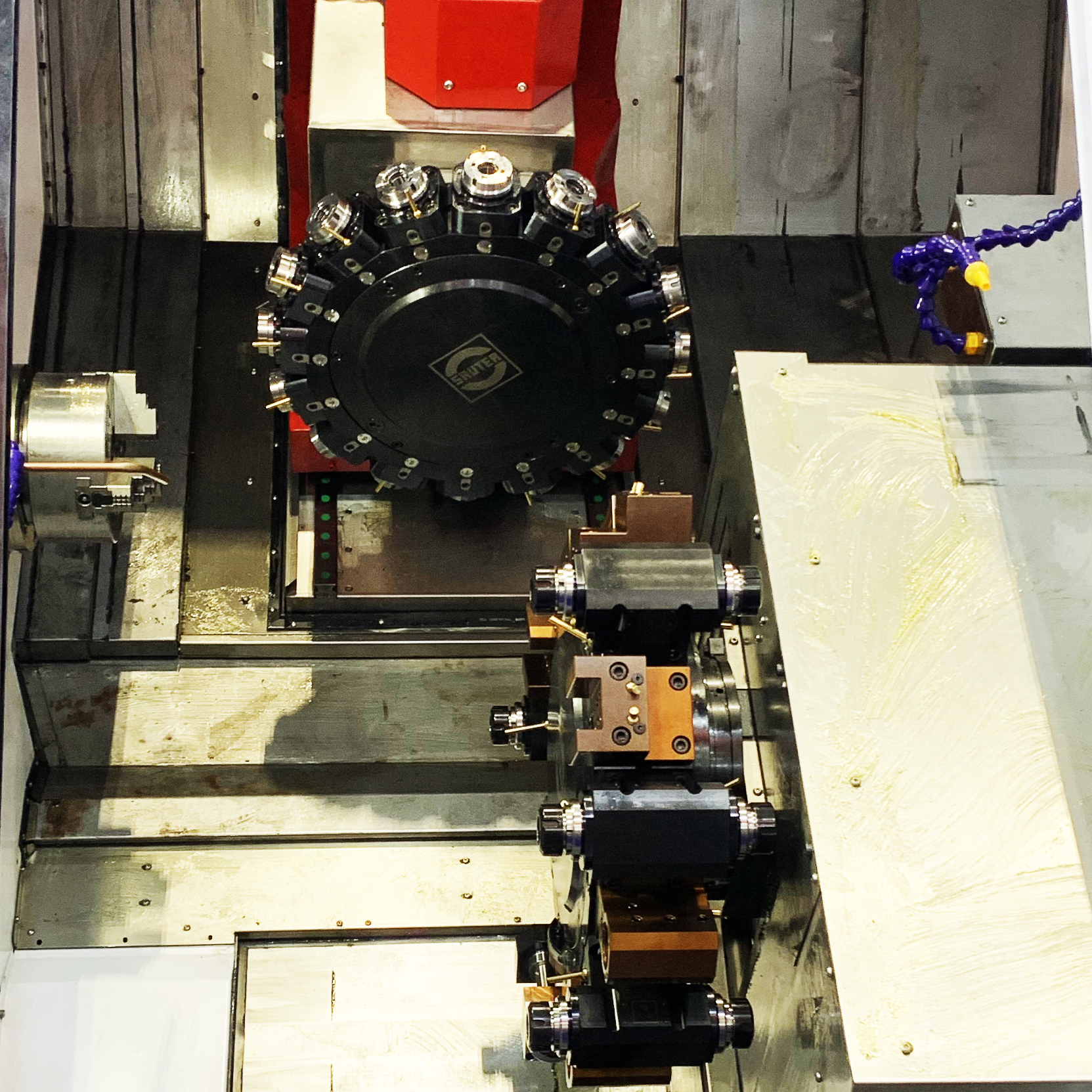

Anebon e na le lisebelisoa tse tsoetseng pele ho u fa mefuta e mengata ea lits'ebeletso tsa machining tsa CNC, ho kenyelletsa le ho sila, ho reteleha, EDM, ho khaola terata, ho sila ka holim'a metsi le tse ling. Re sebelisa litsi tsa machining tsa 3, 4 le 5-axis CNC tse tsoang kantle ho naha ho u fa ho nepahala ho hoholo, ho tenyetseha ho makatsang, le tlhahiso e ntle bakeng sa projeke efe kapa efe ea machining. Ha re na mechine e fapaneng feela, empa hape re na le sehlopha sa litsebi, tse ikemiselitseng ho u fa litšebeletso tse ntle ka ho fetisisa tsa maemo a holimo Chaena. Mechine ea rona e nang le litsebo e ka sebelisa lisebelisoa tse fapaneng tsa polasetiki le tšepe ho hlahisa likarolo tse bilikang le ho sila.

Re le tiisetsa hore ho sa tsotellehe boholo ba mosebetsi, litsebi tsa rona li o nka joalokaha eka ke oa bona. Hape re ka fana ka lits'ebeletso tsa mochini oa CNC tse ka u thusang ho fumana setšoantšo se hlakileng sa sehlahisoa sa ho qetela.

Ke hobane'ng ha u re khetha?

Anebon e bile moetapele oa ho etsa lihlahisoa tse ncha. Specialty Integrated Services e ntlafalitse boitsebelo le lits'ebetso tsa eona. Khampani e hlahisa hoo e ka bang likarolo tsohle tsa tšepe tsa maemo a holimo lefatšeng. Baenjiniere ba rona ba tla sebetsa le uena ho netefatsa boleng bo phahameng ba moralo bakeng sa tlhahiso le kopano. Ts'ebeletso e ntle ea bareki le khotsofalo ke matšoao a k'hamphani ea rona ebile ke motheo oa katleho ea khoebo ea rona.

Ka nako - Rea utloisisa hore likarolo tse ling tsa mosebetsi oa rona li na le nako e potlakileng ea ho qetela, 'me re na le litsebo le mekhoa ea ho netefatsa hore re fana ka nako ka nako ntle le ho senya boleng ba mosebetsi oo re o etsang.

Ba nang le boiphihlelo - esale re fana ka lits'ebeletso tsa ho milling tsa CNC ka lilemo tse fetang 10. Re bokelletse metjhini e mengata e tsoetseng pele ea ho sila bakeng sa lits'ebetso tse fapaneng mme re na le sehlopha se nang le boiphihlelo sa baenjiniere le basebetsi ho fana ka lihlahisoa tsa boleng bo holimo ho bareki bohle ba rona.

Bokhoni - Ka mefuta-futa ea mechini ea rona, re khona ho netefatsa ho nepahala ha lintho tsohle ka boholo bohle.

CNC machining ke eng?

CNC machining ke ts'ebetso ea tlhahiso e fokolang e fokotsang thepa e tala ka lisebelisoa tse fapaneng tsa ho itšeha ka nepo. Software e tsoetseng pele e sebelisoa ho laola sesebelisoa ho latela litlhaloso tsa moralo oa 3D. Sehlopha sa rona sa baenjiniere le mechini se hlophisa lisebelisoa ho ntlafatsa nako ea ho itšeha, pheletso ea bokaholimo le mamello ea ho qetela ho fihlela litlhoko tsa hau. Re sebelisa machining a CNC ho se etse likarolo le li-prototypes feela, empa hape le ho etsa lisebelisoa tsa hlobo.

Moralo Melao-motheo:

(1) Tlhaloso ea ts'ebetso e hlophisitsoeng e tla netefatsa boleng ba ts'ebetso ea likarolo tsa mochine (kapa boleng ba kopano ea mochine) le ho finyella litlhoko tsa tekheniki tse boletsoeng litšoantšong tsa moralo.

(2) Ts'ebetso e lokela ho ba le tlhahiso e phahameng mme sehlahisoa se lokela ho behoa 'marakeng kapele kamoo ho ka khonehang.

(3) Leka ho fokotsa litšenyehelo tsa tlhahiso

(4) Ela hloko ho fokotsa matla a basebetsi le ho netefatsa polokeho ea tlhahiso.

Tlhahiso e Tlase ea Molumo

Ho etsa lihlahisoa ka bongata bo tlase ke tharollo e nepahetseng bakeng sa ho laola thepa ea hau le ho leka 'maraka pele o hlahisa bongata bo boholo. ho khetha Low-Volume Manufacturing ke khetho ea hau e ntle ka ho fetisisa.

Anebon e tla khetha theknoloji e sebetsang ka ho fetesisa ho latela thepa, kalafo ea bokaholimo le bongata, empa hape e fana ka liphutheloana le ts'ebeletso e 'ngoe ea ho emisa.

CNC Machining ea rona, prototype e potlakileng le tlhahiso e tlase ea Volume e loketseng indasteri e mengata joalo ka Likoloi, Lithuthuthu, Mechini, Lifofane, terene ea likulo, Libaesekele, Metsi, Elektronike, Thepa ea Saense, Theater ea Laser, Liroboto, Litsamaiso tsa Taolo ea Oli le Khase, Lisebelisoa tsa bongaka. , lisebelisoa tse amohelang mats'oao, Lisebelisoa tsa Optical, Khamera & Foto, Thepa ea lipapali Botle le Lebone, Thepa.

Melemo ea machining ea CNC

CNC machining e loketse mefuta e fapaneng ea litlhoko tsa nts'etsopele ea sehlahisoa. Mona ke e meng ea melemo ea ho etsa machining ka nepo:

• Ho sebetsa ka mechine ea li-alloys tsa titanium, li-superalloys, li-non-metal, joalo-joalo, moralo oa hlobo le tlhahiso.

• Moralo le tlhahiso ea thepa e sa tloaelehang

• Mokhoa oa machining: ho cheka, ho sila likhoele, broaching, taping, spline, reaming, cutting, Profile, finish, turning, threading, internal form, dimples, knurling, countersunk, boring, reverse drilling, hobbing

• Ka potlako tlosa lisebelisoa tse ngata tsa tšepe

• E loketse mefuta e mengata e fapaneng ea li-substrates

• Chelete e tlaase ea lichelete tsa hlobo le litšenyehelo tsa ho lokisa

• E nepahetse haholo ebile e ka phetoa

• Moqapi le tlhahiso ea hlobo

• Mamello: ± 0.002mm

• Moruo

R&D

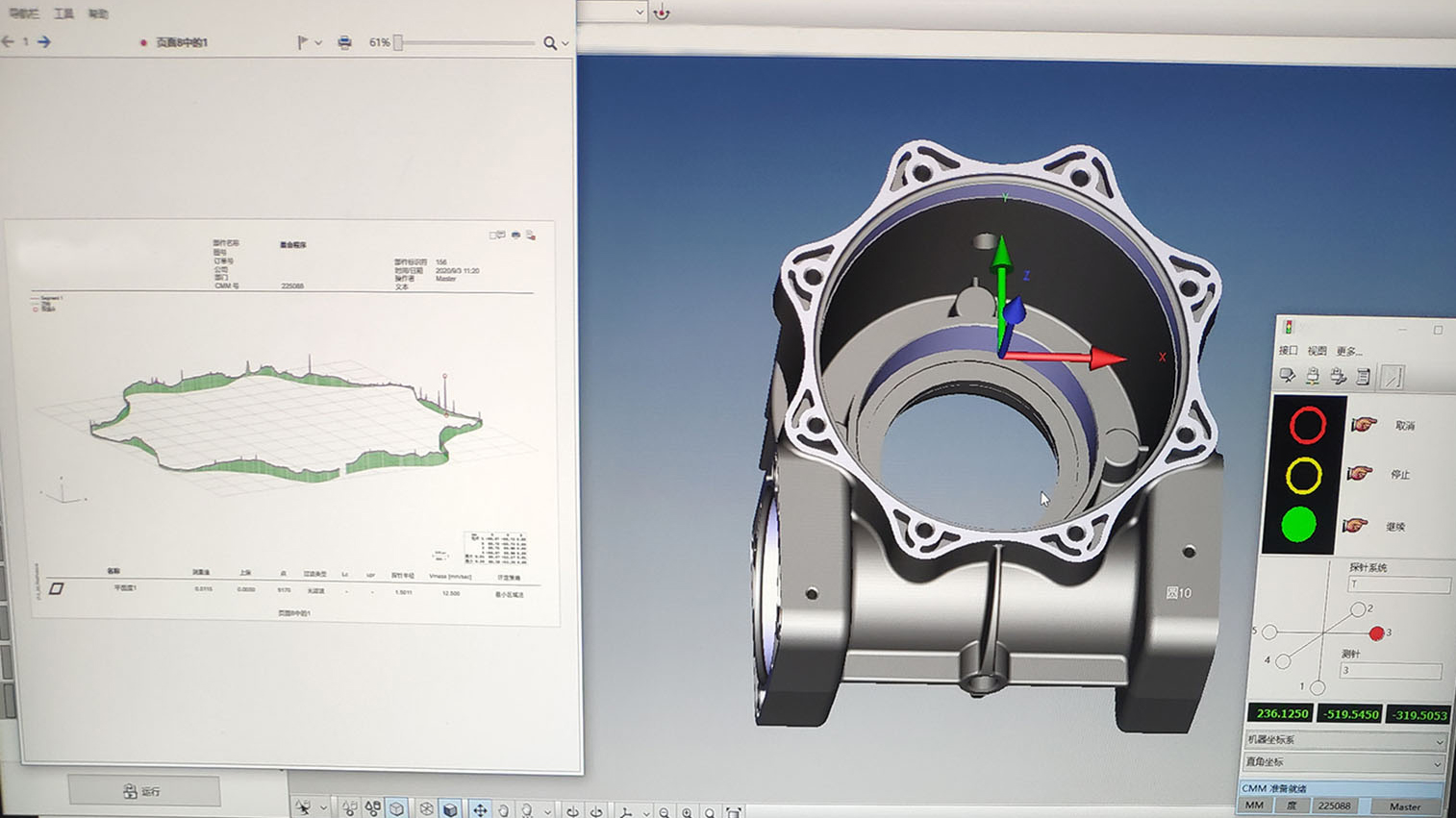

Re na le boiphihlelo bo fetang lilemo tse leshome ho moralo oa 3D. Sehlopha sa rona se sebetsa le bareki ho hlahisa meralo / likarolo tse fihlelang litlhoko tsa bona, ha re ntse re nahana ka litšenyehelo, boima le mekhoa ea tlhahiso.Ka mor'a hore moralo o phethoe, re theha mokhoa oohle oa boenjiniere le tlhahiso ea sesebelisoa. 'Me re ka qala teko e latelang feela ka mor'a hore lefapha la boleng le amohele sesebelisoa.

Re tsepamisa maikutlo lits'ebetsong tsena tsa mantlha ts'ebetsong ea R&D:

Moqapi oa likarolo

Sesebelisoa DFM

Moqapi oa lisebelisoa / hlobo

Mold Flow - Ketsiso

Ho taka

CAM

Mofuta oa sesebelisoa sa ho sebetsa

Ho na le mefuta e mengata ea lisebelisoa tsa ts'ebetso tse ka sebelisoang li le mong kapa li kopantsoe le lisebelisoa tse ling mehatong e fapaneng ea ts'ebetso ea tlhahiso ho fihlela karolo e lakatsehang ea geometry. Likarolo tse kholo tsa lisebelisoa tsa ho sebetsa:

• Lisebelisoa tsa Boring: Lisebelisoa tsena li atisa ho sebelisoa e le lisebelisoa tsa ho qetela ho atolosa masoba a neng a sehiloe ka har'a thepa.

• Lisebelisoa tsa ho seha: Lisebelisoa tse kang lisakha le likere ke lisebelisoa tse emelang lisebelisoa tsa ho seha. Hangata li sebelisoa ho seha thepa e nang le boholo bo reriloeng esale pele, joalo ka letlapa la tšepe, hore e be sebopeho se lakatsehang.

• Sesebediswa sa ho phunya: Sehlopha sena se kenyelletsa swivel e nang le mahlakore a mabeli e etsang lesoba le chitja le bapileng le axis ea ho potoloha.

• Lisebelisoa tsa ho sila: Lisebelisoa tsena li sebelisa lebili le potolohang bakeng sa mochini o motle kapa ho seha hanyenyane holim'a mosebetsi.

• Lisebelisoa tsa ho sila: Lisebelisoa tsa ho roala li sebelisa sebaka sa ho itšeha se potolohang se nang le lisebelisoa tse ngata ho etsa lesoba le se nang selikalikoe kapa ho khaola moqapi o ikhethang ho tloha thepa.

• Lisebelisuoa tse phetholang: Lisebelisoa tsena li pota-pota sesebedisoa se holim'a shaft ha sesebelisoa sa ho seha se e bōpa.

Lintho tse bonahalang

| Tšepe | Carbon Steel, 4140,20 #, 45 #, 4340, Q235, Q345B, joalo-joalo |

| Ts'epe e sa beng le mabali | SS303, SS304, SS316, SS416 joalo-joalo. |

| Aluminium | Al6063, AL6082, AL7075, AL6061, AL5052, A380 joalo-joalo. |

| Tšepe | 12L14, 1215, 45#, A36, 1213, joalo-joalo. |

| Koporo | HSn62-1, HSn60-1, HMn58-2, H68, HNi65-5, H90, H80 , H68, H59 joalo-joalo. |

| Koporo | C11000, C12000, C12000, C26000, C51000 joalo-joalo. |

| Plastiki | Delrin, Nylon, Teflon, PP, PEI, ABS, PC, PE, POM, Peek.Carbon Fiber |

Kalafo ea Bokaholimo

| Kalafo ea Bokaholimo ba Mechini | Ho qhomisa lehlabathe, Ho Thunya ho Thunya, Ho sila, Ho Rolling, Ho bentša, Ho Hlōla, Ho Fafatsa, Ho Penta, Ho Penta Oli jj. |

| Kalafo ea Bokaholimo ba Lik'hemik'hale | Bluing le Blackening, Phosphating, Pickling, Electroless Plating ea Metals le li-alloys tse sa tšoaneng joalo-joalo. |

| Electrochemical Surface Treatment | Anodic oxidation, Electrochemical Polishing, Electroplating joalo-joalo. |

| Kalafo ea Sejoale-joale ea Sebaka | CVD, PVD, Ion implantation, Ion Plating, Laser Surface Treatment ect. |

| Ho phatloha ha lehlabathe | Ho phatloha ha lehlabathe le omileng, ho phatloha ha lehlabathe le metsi, ho phatloha ha lehlabathe la Atomized joalo-joalo. |

| Ho fafatsa | Ho fafatsa ka Electrostatic, Ho Hasa Botumo, Ho Fafatsa ka Phofo, Ho Fafatsa ka polasetiki, Ho Fafatsa ka Plasma. |

| Electroplating | Ho roala ha koporo, ho roala ka Chromium, ho roala zinki, ho roala ka nikelo |

Sehlahisoa

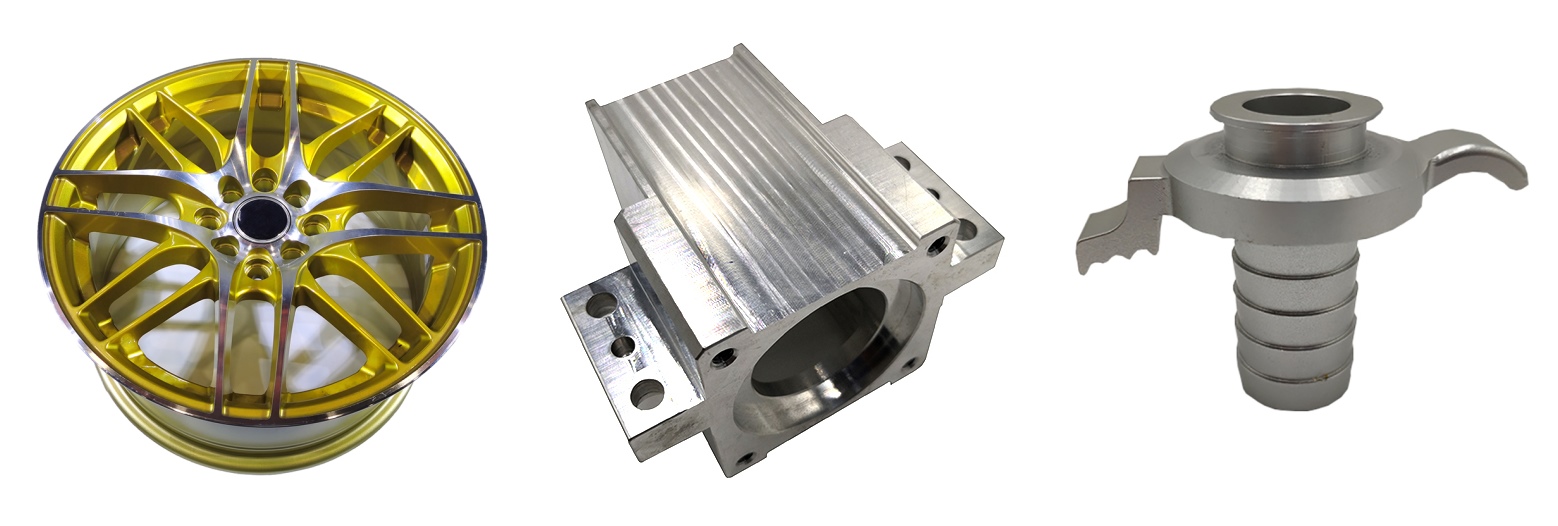

CNC Precision Wheels

CNC Aluminium Milling

CNC Machining Prototyping

5 Axies CNC Machining

Lisebelisoa tse tloaelehileng tsa CNC Machining

Mochini oa ho fetola oa CNC