1. Zviitiko zvemuviri zvetitanium machining

Simba rekucheka retitanium alloy processing yakakwira zvishoma pane iyo yesimbi ine kuoma kwakafanana. Zvakadaro, chiitiko chemuviri chekugadzirisa titanium alloy chakanyanya kuomarara kupfuura icho chekugadzira simbi, izvo zvinoita kuti titanium alloy kugadzirisa kutarisana nematambudziko makuru.

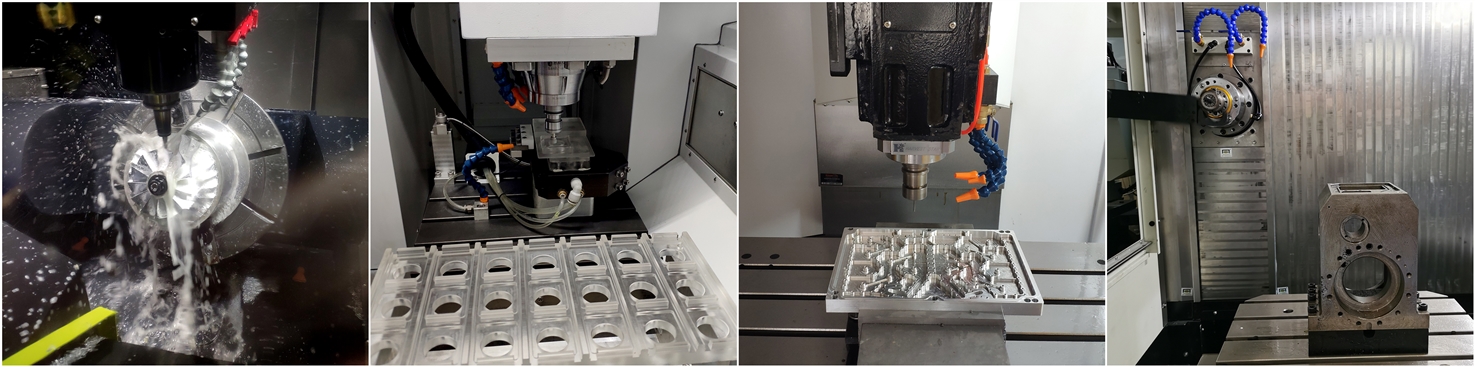

Iyo yekupisa conductivity yeakawanda titanium alloys yakadzikira, chete 1/7 yesimbi uye 1/16 yealuminium. Nokudaro, kupisa kunogadzirwa pakucheka titanium alloys hakuzokurumidza kuendeswa kune workpiece kana kutorwa nemachipisi. Zvakadaro, inoungana munzvimbo yekucheka, uye tembiricha inogadzirwa inogona kunge yakakwira kusvika 1,000 ° C kana kupfuura, izvo zvinozoita kuti mudziyo wekucheka wemudziyo upfeke, chip, uye kuputika nekukurumidza. Kuumbwa kwemupendero wakavakirwa uye kukurumidza kutaridzika kwemupendero wakasakara kunogadzira kupisa kwakawanda munzvimbo yekucheka, zvichiwedzera kupfupisa hupenyu hwechishandiso.titanium machining

Kupisa kwepamusoro kunogadzirwa panguva yekucheka kunoparadzawo kutendeseka kwepamusoro kwetitanium alloy zvikamu, zvichiita kuti kuderera kwejometri yakarurama yezvikamu uye kushanda kuoma kunoderedza zvakanyanya simba ravo rekuneta.

Iyo elasticity yetitanium alloys inogona kubatsira kune chikamu chekuita, asi panguva yekucheka, iyo elastic deformation yeworkpiece ndicho chikonzero chakakosha chekudengenyeka. Kudzvanya kwekucheka kunoita kuti "elastic" workpiece iende kure nechishandiso uye kubounce, saka kupokana pakati pechishandiso uye workpiece kwakakura pane kucheka chiito. Iyo friction process inoburitsawo kupisa, zvichiwedzera dambudziko rekushata kwekupisa kwetitanium alloys.

Dambudziko iri rakatonyanya kuoma kana uchigadzira mativi akatetepa-ane madziro kana mhete, anoremara nyore nyore. Hazvisi nyore kugadzira zvitete-walled titanium alloy zvikamu kune zvinotarisirwa dimensional kurongeka. Kana chishandiso chikasundidzira iyo workpiece kure, iyo yakatetepa madziro deformation inodarika elastic renji; plastiki deformation inoitika, uye kusimba kwezvinhu uye kuoma kwenzvimbo yekucheka kunowedzera zvakanyanya. Machining pane yakambotemerwa kucheka kumhanya inova yakanyanya kukwirira, zvichikonzera kupfeka kwakapinza kwemidziyo.

"Kupisa" ndiyo "mhosva" inoita kuti zviome kugadzira titanium alloys!

2. Tekinoroji kuziva-sei kwetitanium CNC machining

Kubva pakunzwisisa magadzirirwo etitanium alloys uye nekuwedzera ruzivo, yekutanga maitiro ekuziva magadzirirwo etitanium alloys ndeaya anotevera:

(1) Inopinza ine yakanaka geometry inoshandiswa kuderedza simba rekucheka reworkpiece, kupisa kupisa, uye deformation.

(2) Chengetedza chikafu chinogara chiripo kuti udzivise kuoma kweworkpiece. Chishandiso chinofanira kugara chiri mukudya panguva yekucheka, uye iyo radial yekucheka huwandu hunofanira kunge iri 30% yeradius panguva yekugaya.

(3) High-pressure uye yakakura-inoyerera yekucheka mvura inoshandiswa kuve nechokwadi chekudzikama kwekupisa kweiyo machining process uye kudzivirira workpiece kuderera kwepamusoro uye kukuvara kwechishandiso nekuda kwekupisa kwakanyanya.

(4) Chengeta mupendero wakapinza; maturusi asina kujeka anokonzera kupisa-kukwira uye kupera, nekukurumidza zvichitungamira mukukundikana kwechishandiso.

(5) Machining mune yakapfava mamiriro etitanium alloy zvakanyanya sezvinobvira nekuti zvinhu zvinova zvakanyanya kunetsa kumushini mushure mekuoma, uye kupisa kwekupisa kunowedzera simba rechinhu uye kupfeka kwekuisa.

(6) Shandisa mhino yakakura kana chamfer kuti ucheke zvakanyanya sezvinobvira mumucheto wekucheka. Izvi zvinoderedza simba rekucheka uye kupisa panzvimbo yega yega uye kudzivirira kuparara kwenzvimbo. Pakugaya titanium alloys, pakati pematanho ekucheka, kumhanya kwekucheka kune yakanyanya kukosha pahupenyu hwechishandiso vc, inoteverwa neradial engagement (milling deep) ae.

3. Tanga neblade kugadzirisa dambudziko rekugadzirisa titanium

Kupfeka kweiyo groove yekuisa panguva yekugadzira titanium alloys ndeyekupfeka kwenzvimbo kumashure uye kumberi munzira yekudzika kwekuchekwa, iyo inowanzo kukonzerwa neyakaomeswa yakasiiwa neyakapfuura kugadzirisa. Iko kemikari kuita uye kupararira kwechishandiso uye chishandiso chekushanda pane tembiricha yekugadzira inopfuura 800 ° C zvakare zvikonzero zvekuumbwa kwekupfeka kwegroove. Nokuti panguva yekugadzira, titanium molecules ye workpiece inounganidza pamberi pechidzitiro uye "yakasungirirwa" kune blade kumucheto pasi pekumanikidzwa kukuru uye kupisa kwepamusoro, kuumba muganhu wakavakwa. Kana iyo yakavakirwa-mupendero ichibvisa pamucheto wekucheka, inobvisa iyo carbide coating yekuisa, saka titanium machining inoda yakasarudzika yekuisa zvinhu uye geometries.cCustomprecision machining

4. Chigadziro chekushandisa chinokodzera titanium machining

Kutarisa kwetitanium alloy processing ndiko kupisa, uye yakawanda-yepamusoro-inopisa yekucheka mvura inofanira kupfapfaidzwa pamucheto wekucheka nekukasira uye nemazvo kubvisa kupisa nekukurumidza. Kune akasiyana masisitimu ezvigayo anocheka akananga machining titanium.

Anebon Metal Products Limited inogona kupa CNC Machining, Die Casting, Sheet Metal Fabrication service, ndapota inzwa wakasununguka kutibata nesu.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Nguva yekutumira: Jan-18-2022