Kune injini, shaft zvikamu zvakaita se crankshafts, camshafts, uye silinda liners anoshandisa chucks mune yega yega kugadzirisa. Panguva yekugadzirisa, iyo chucks pakati, sunga uye kutyaira iyo workpiece. Zvinoenderana nekugona kwe chuck kubata iyo workpiece uye kuchengetedza yepakati, yakakamurwa kuita yakasimba chuck uye inoyangarara chuck. Ichi chinyorwa chinonyanya kukurukura idzi mbiri dzechucks 'sarudzo dzemisimboti uye yemazuva ese ekugadzirisa.5aixs CNC machining zvikamu

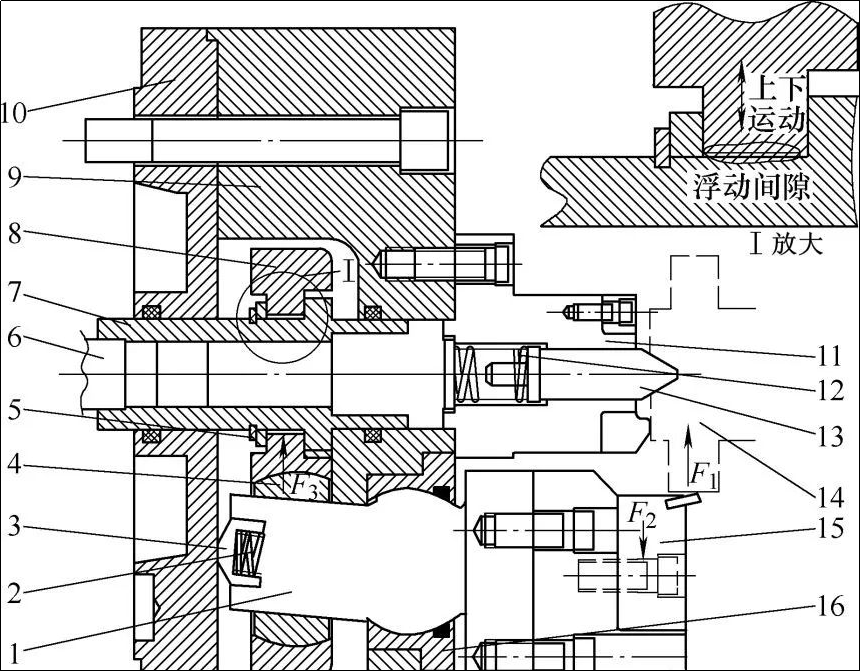

Rigid chucks uye chucks anoyangarara akasiyana zvakanyanya muchimiro uye nzira dzekugadzirisa. Tichitora akatevedzana chucks yerudzi rweJapan semuenzaniso, Mufananidzo 1 unoratidza maitiro eiyo chuck inoyangarara: iyo workpiece iri pasi pechiito cheiyo yekumisikidza bhuroko uye kumusoro. Axial uye radial chinzvimbo uye clamping inoitwa. Zvadaro, chuck cylinder inotyaira chuck centre tie rod, gap adjustment plate, jaw arm support plate, spherical joint, uye ruoko rweshaya nepakati petambo tsvimbo, pakupedzisira waona chuck shaya kusungirira workpiece.

Kana paine kutsauka kwakakosha kweiyo coaxially pakati pepakati peshayi nhatu dzechuck uye pakati peiyo workpiece, shaya yechuck inobata workpiece yekutanga inoiswa pasi pesimba F2, iro rinopfuudzwa kushaya. ndiro yerutsigiro yeruoko kuburikidza neruwoko rweshaya uye pajoini redenderedzwa. F3 inoshanda pane claw ruoko inotsigira ndiro. Kune chuck inoyangarara, pane mukaha pakati pepakati pemudonzvo wechuck neclaw arm support plate. Pasi pechiito chesimba F3, ndiro yerutsigiro yeruoko inoshandisa gap rinoyangarara (gap kugadzirisa ndiro, Iyo yepakati inodhonza tsvimbo yechuck, uye ndiro yekutsigira yeruoko rweshaya pamwe chete inoumba nzira inoyangarara yechuck), famba uchienda kune simba kusvika shaya nhatu dzasunga workpiece zvachose.

Mufananidzo 1 Inoyangarara chuck chimiro

1. Chikwambo ruoko

2. Rectangular chitubu

3. Spherical top cover

4. Spherical joint

5. Clearance kugadzirisa ndiro

6. Cylinder dhonza tsvimbo

7. Chuck centre dhonza tsvimbo

8. Claw ruoko rutsigiro ndiro

9. Muviri waChuck 10. Chivharo chekupedzisira cheChuck

10. Positioning rutsigiro block

12. Workpiece inofanira kugadziriswa

13. Chuck Jaws 16. Bhora rutsigiro

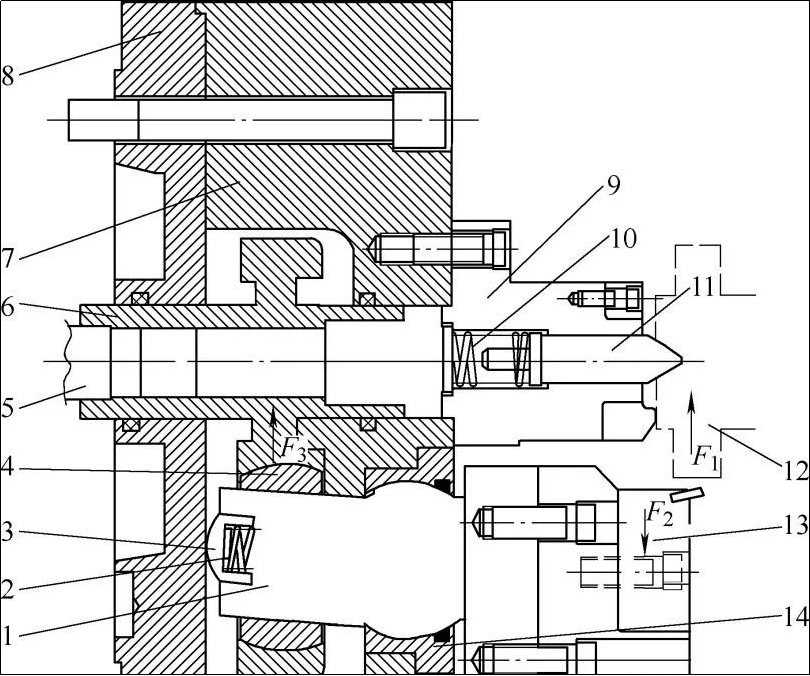

Mufananidzo 2 unoratidza maitiro ekuita kweiyo yakasimba chuck

Pasi pechiito chenzvimbo yekumisikidza chivharo uye nechepamusoro, chidimbu chebasa chinomiswa uye chakasungirirwa axially uye radially, uye ipapo chuck silinda yemafuta inotyaira yepakati dhonza tsvimbo, spherical joint uye shaya yechuck kuburikidza netsvimbo yekudhonza. Ruoko runofambisa, uye pakupedzisira, chuck shaya dzinosunga workpiece. Sezvo nzvimbo yepakati inokweva tsvimbo yechuck yakanyatsobatanidzwa neyakatenderedzwa uye ruoko rweshaya, mushure meiyo chuck shaya (matatu shaya) akasungwa, nzvimbo yekunamatira ichaumbwa. Iyo clamping centre inoumbwa nepamusoro haipindire, uye workpiece ichava nechajeka clamping deformation mushure mekunge chuck yasungwa. Iyo chuck isati yashandiswa, zvinodikanwa kugadzirisa kupindirana pakati pepakati pechuck nepakati pepakati kuti ive nechokwadi chekuti chuck haizoratidzike chaiyo mushure mekurovera. Clamped condition.

Mufananidzo 2 Rigid chuck chimiro

1. Chikwambo ruoko

2. 10. Rectangular chitubu

3. Spherical top cover

4. Spherical joint

5. Cylinder tie tsvimbo

6. Chuck centre tie tsvimbo

7. Muviri waChuck

8. Chivharo chemashure cheChuck

9. Positioning rutsigiro block

10. Pamusoro

11. Workpiece inofanira kugadziriswa

12. Chuck's shaya

13. Spherical rutsigiro

Kubva pakuongorora kwemaitiro echuck muMufananidzo 1 uye Mufananidzo 2, chuck inoyangarara uye yakasimba chuck ine misiyano inotevera.

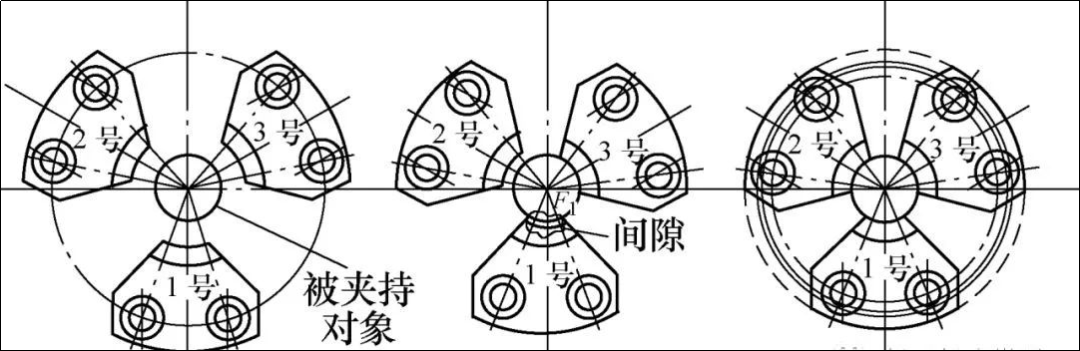

Inoyangarara chuck: Sezvinoratidzwa muFigure 3, mukuita kusungirira iyo workpiece, nekuda kwehurefu hwakasiyana hweworkpiece isina chinhu kana iyo yakakura kutenderera kushivirira kweiyo blank, iyo No. 3 shaya ichasangana neye workpiece pamusoro uye iyo Nha. 1 uye Nha. 2 shaya dzichaonekwa. Kana iyo workpiece isati yabatwa, panguva ino, iyo inoyangarara nzira yechuck inoyangarara inoshanda, ichishandisa pamusoro peiyo workpiece sechitsigiro chekuyangarara No. 3 rushaya. Chero bedzi iyo inoyangarara yakawanda yakakwana, iyo Nhamba 1 uye Nha. Iyo workpiece ine zvishoma mhedzisiro pakati peiyo workpiece.

Mufananidzo 3 Kurovera maitiro ekuyangarara chuck shaya

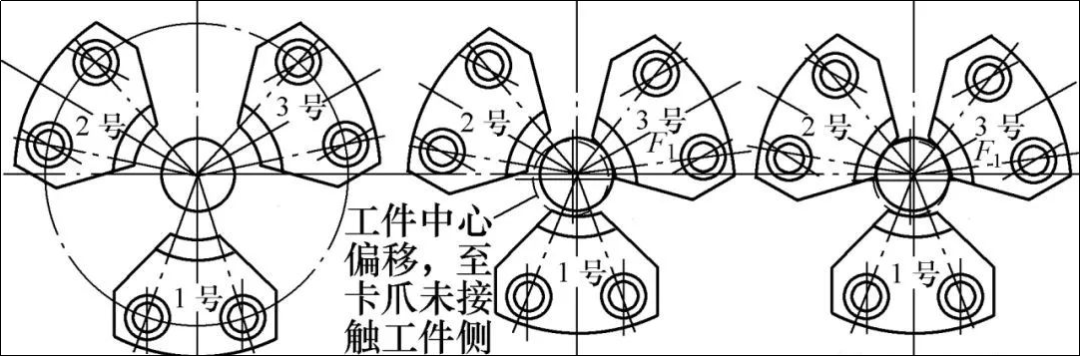

Rigid chuck: Sezvinoratidzwa muFigure 4, panguva yekuvhara, kana concentricity pakati pechuck uye workpiece isina kugadziriswa zvakanaka, shaya 3 ichabata workpiece, uye No. 1 uye No. sangana neworkpiece. , ipapo chuck clamping simba F1 ichaita pane workpiece. Kana simba racho rakakura zvakakwana, workpiece ichagadziriswa kubva panzvimbo yakatemerwa, ichimanikidza workpiece kuti iende pakati pechuck; apo iyo clamping simba ye chuck idiki, zvimwe zviitiko zvichaitika. Kana shaya dzisingakwanise kubata zvizere workpiece, vibration inoitika panguva yekugadzira.cnc milling connector

Mufananidzo 4 Kubata maitiro eakaomarara chuck shaya

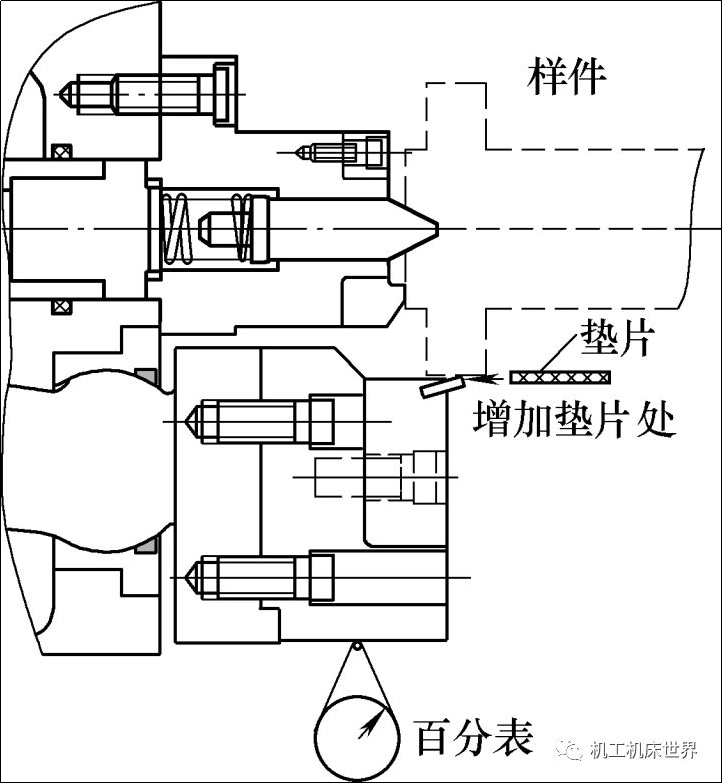

Kugadzirisa zvinodiwa chuck isati yashandiswa: Iyo yakasimba chuck inoumba iyo clamping nzvimbo yechuck pachayo mushure mekusunga. Paunenge uchishandisa iyo yakaomesesa chuck, zvinodikanwa kugadzirisa iyo clamping yepakati yechuck kuti ienderane neiyo clamping uye yekumisikidza nzvimbo yeworkpiece, sezvakaratidzwa mumufananidzo 5.cnc machining aluminium chikamu

Mufananidzo 5 Kugadziriswa kweiyo yakasimba chuck centre

Zvinoenderana nekuongororwa kwemaitiro epamusoro, zvinokurudzirwa kutevedzera zvinotevera misimboti mukugadzirisa nekuchengetedza chuck: Iyo yekuzora uye girisi yezvikamu zvinofamba mukati mechuck zvinogara zvichitsiviwa. Kufamba pakati pezvikamu zvinofamba mukati me chuck ndiko kutsvedza kunotsvedza. Izvo zvinodikanwa kuwedzera uye kugara uchitsiva iyo yakatsanangurwa giredhi yekuzora mafuta / girizi zvinoenderana nezvinodiwa zvekuchengetedza zvechuck. Paunenge uchiwedzera girizi, zvinodikanwa kusvina girizi yese yakashandiswa munguva yakapfuura, wobva wavhara chiteshi chekuburitsa oiri mushure mekusunga chuck kudzivirira mukati memukati wechuck kuti urege kudzoserwa kumashure.

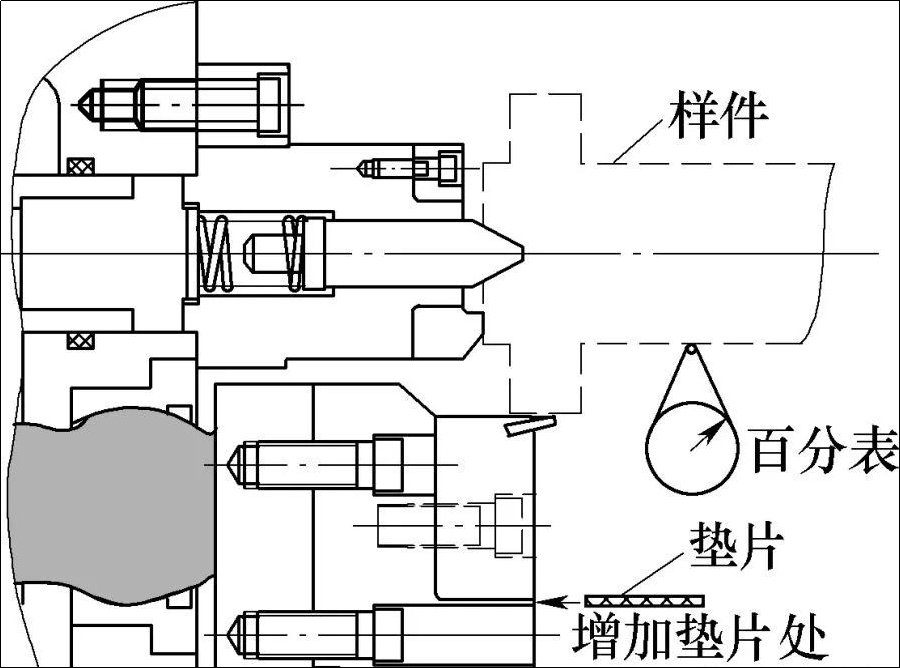

Kugara uchiongorora uye kugadzirisa kweiyo clamping yepakati yeiyo yakasimba chuck uye yepakati peiyo workpiece: Iyo yakaoma chuck inoda nguva nenguva kuyera kana iyo yepakati chuck uye yepakati peiyo workpiece spindle inowirirana. Edza kubuda kwe disc. Kana ichipfuura chiyero chinodiwa, wedzera spacers zvakakodzera pane imwe kana maviri shaya inoenderana nenzvimbo yakakwirira, uye dzokorora matanho ari pamusoro kusvika izvo zvinodiwa zvasangana.

Kuongororwa nguva nenguva kwehuwandu hunoyangarara hwechuck inoyangarara (ona Mufananidzo 6). Mukugadzirisa kwezuva nezuva chuck, zvinodikanwa kugara uchiyera huwandu hunoyangarara uye inoyangarara chaiyo yeiyo inoyangarara chuck, uye nekupa gwara rekuchengetedza kwemukati kwechuck mune inotevera nhanho. Iyo yekuyera nzira yekuyangarara nemazvo: mushure mekunge chuck yasunga sampuli, isa chuck kuyerwa. Tenderedza rukudzo kuenda kunzvimbo yekuyeresa yakaringana, yera chinongedzo chedhiyari (chinodiwa kubatanidza chigadziko chemagineti kune shaft inofamba), womaka nzvimbo yekuyera senzvimbo ye zero. Wobva wadzora iyo servo axis kuti ufambise dial chiratidzo, vhura chuck, isa gasket ine ukobvu hweAmm pakati peshaya kuti kuyerwa uye sampuli, sunga sampuli pane chuck, fambisa dial chiratidzo kune zero point chinzvimbo, uye simbisa kana iyo data yakatsikirirwa neiyo dial chiratidzo ndeye Amm. Kana zvirizvo, zvinoreva kuti iko kuyerera kwacho kwakanaka. Kana iyo data ichisiyana zvakanyanya, zvinoreva kuti pane dambudziko neinoyangarara nzira yechuck. Kuyera kwedzimwe shaya kwakafanana nepamusoro.

Mufananidzo 6 Kuongororwa kwehuwandu hunoyangarara hwechuck inoyangarara

Kugara kuchitsiviwa kwezvikamu zvakaita sezvisimbiso, gaskets, uye zvitubu mukati mechuck: zvitubu zvine rectangular, chuck body, chuck yekumashure yekupedzisira chivharo, zvitubu zvine rectangular, uye zvisimbiso uye zvitubu mune zvakatenderedza zvitsigiso zvinofanirwa kuitwa zvinoenderana nekuwanda kwekushandiswa uye pamusoro. test results. Tsiva nguva dzose. Zvikasadaro, kuneta kuchaikuvadza, zvichikonzera huwandu hunoyangarara uye yakaoma chuck runout.

Kuburikidza nekuongorora kuri pamusoro apa kweiyo criticaly mapoinzi eiyo chuck chimiro kugadzirisa uye kugadzirisa, teerera kune anotevera misimboti mukusarudzwa kwechucks: kana iyo chuck clamping chikamu chechikamu chakagadziriswa chiri chinhu chisina chinhu, iyo inoyangarara chuck inosarudzwa, uye iyo yakasimba chuck. inoshandiswa mukugadzira. Iyo chuck clamping pamusoro pechikamu chakagadzirwa inzvimbo mushure mekuomarara, semi-kupedza / kupedza. Mushure mekutevera iyo iri pamusoro pekutanga mitemo, kuita sarudzo dzakanyatsoenderana neakasiyana mamiriro ekushanda anodiwa.

Kusarudzwa kwechuck yakaoma:

①Mamichina ekugadzirisa anoda huwandu hukuru hwekucheka uye simba guru rekucheka. Mushure mekusungirirwa neworkpiece kuti igadziriswe uye inotsigirwa nepakati furemu, muscular workpiece rigidity, uye hombe workpiece rotational kutyaira inodiwa.

②Kana pasina imwe-nguva yekumisa michina, senge kumusoro, dhizaini yechuck centering inodiwa.

Sarudzo yechuck inoyangarara:

①Zvakakwirira zvinodikanwa zvekuisa pakati peiyo workpiece spindle. Mushure mekunge chuck yakasungirirwa, kuyerera kwayo hakuzokanganise iyo yekutanga pakati peiyo workpiece spindle.

②Chiyero chekucheka hachina kukura, uye zvinongodiwa chete kutyaira workpiece spindle kutenderera uye kuwedzera kuomarara kweiyo workpiece.

Izvo zviri pamusoro zvinotsanangura kusiyana kwemaitiro uye kugadzirisa uye kusarudzwa kwezvinodiwa zvekuyangarara uye kuomarara chucks, ayo anobatsira pakushandisa nekugadzirisa. Iwe unoda kunzwisisa kwakadzama uye kushandiswa kunoshanduka; iwe unofanirwa kugara uchipfupisa ruzivo mukushandiswa kwesaiti uye kugadzirisa.

Anebon Metal Products Limited inogona kupa CNC Machining, Die Casting, Sheet Metal Fabrication service, ndapota inzwa wakasununguka kutibata nesu.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Nguva yekutumira: Mar-31-2022