Iwe unofunga kuti hukama huripo pakati pekumhanya kwekucheka, kubata kwechishandiso, uye kumhanya kwekudya muCNC machining?

Kuti uite kwakaringana, zvakakosha kuti unzwisise hukama pakati pekumhanya kwekudya, kucheka kumhanya uye kushandisa chishandiso muCNC machining.

Kucheka Speed:

Iyo yekucheka kumhanya ndiyo chiyero chekutenderera kana kufamba kuburikidza nezvinhu. Kumhanya kunowanzoyerwa netsoka dzepamusoro pamaminitsi (SFM) kana mamita/miniti (m/min). Kucheka kumhanya kunotemerwa nezvinhu zvichagadzirwa muchina, chishandiso chekucheka, uye chinodiwa pamusoro pekupedzisira.

Tool Engagement

Iko kubatanidzwa kwechishandiso ndiko kudzika kweiyo chimbo chekucheka chinopinda paworkpiece panguva yekugadzira. Kubatanidzwa kwechishandiso kunokanganiswa nezvinhu zvakaita sekucheka chishandiso geometry uye mafeed uye kumhanya pamwe neinodiwa yemhando yepamusoro uye chiyero chekubvisa zvinhu. Nekusarudza iyo yakakodzera saizi yechishandiso, kudzika kwekucheka uye radial kuita, unogona kugadzirisa chishandiso kuita.

Feed Speed

Kumhanyisa kwekudya kunonzi zvakare chiyero chekudya kana chikafu pazino. Ndiwo chiyero icho chekucheka chishandiso chinofambira mberi pane revolution kuburikidza nezvinhu zveworkpiece. Sipidhi inopimwa nemamilimita kana mainji paminiti. Chiyero chekudya chinokanganisa zvakananga hupenyu hwechishandiso, mhando yepasi, uye kuita kwese kwemuchina.

Kazhinji, kumhanya kwepamusoro kwekucheka kunoguma nekukura kukuru kwekubvisa zvinhu. Zvisinei, dzinobudisawo kupisa kwakawanda. Kugona kwemudziyo wekucheka kubata kumhanya kwepamusoro, uye kugona kweanotonhodza mukubvisa kupisa zvinhu zvakakosha.

Iko kubatanidzwa kwezvishandiso kunofanirwa kugadziridzwa zvinoenderana nemidziyo yebasa rekushanda, iyo geometry yezvishandiso zvekucheka, uye inodiwa kupera. Kubata kwechishandiso kwakaringana kunozoita kuti chip chibviswe zvakanaka uye kuderedza kutsauswa kwechishandiso. Ichavandudzawo kushanda kwekucheka.

Iyo yekumhanyisa yekudyisa inofanirwa kusarudzwa kuti iwane chiyero chaunoda chekubvisa zvinhu uye kupedza, pasina kuremedza chishandiso. Chiyero chekudya chepamusoro chinogona kukonzera kupfeka kwezvishandiso zvakanyanya. Nekudaro, iyo yakaderera yekudyisa kumhanya inokonzeresa kushomeka kwepamusoro kupera uye kusashanda machining.

Mugadziri anofanira kunyora mirairo muchirongwa cheCNC kuti aone huwandu hwekucheka kwega rega rega. Kucheka kumhanya, kumashure-kucheka huwandu, kukurumidza kwekudya uye zvichingodaro zvese chikamu chekucheka kushandiswa. Nhamba dzakasiyana dzekucheka dzinodiwa kune dzakasiyana nzira dzekugadzirisa.

1. Kusarudzwa kwenheyo yekucheka huwandu

Kana roughing, chinotarisisa chikuru chinowanzo kuvandudza kugadzirwa, asi hupfumi uye mitengo yekugadzira inofanirwa kutariswa; kana semi-kupedza uye kupedzisa, kucheka kunyatsoita, hupfumi, uye mitengo yekugadzira inofanirwa kutariswa uchive nechokwadi chekugadzirisa mhando. Iwo chaiwo maitiro anofanirwa kutariswa zvinoenderana nemuchina wekushandisa bhuku, kucheka bhuku rekushandisa, uye ruzivo.

Kutanga kubva pakusimba kwechishandiso, kurongeka kwekusarudzwa kwehuwandu hwekucheka ndeye: tanga kuona huwandu hwekucheka kumashure, wozoona huwandu hwekudya, uye pakupedzisira sarudza kukurumidza kucheka.

2. Kutsunga kwehuwandu hwebanga pamusana

Kuwanda kwekucheka kumashure kunotarirwa nekuoma kwechishandiso chemuchina, workpiece uye chishandiso. Kana iyo yakaoma ichibvumira, huwandu hwekucheka kumashure hunofanira kuenzana nemvumo yekugadzira ye workpiece zvakanyanya sezvinobvira. Izvi zvinogona kuderedza huwandu hwezvishandiso zvinopfuura uye kugadzirisa kugadzirwa kwakanaka.

Nheyo dzekutarisa huwandu hwebanga kumashure:

1)

Kana iyo yepamusoro roughness kukosha kweiyo workpiece inodiwa kuve Ra12.5μm ~ 25μm, kana iyo machining mvumo yeCNC machiningiri pasi pe5mm ~ 6mm, imwe yekudya yehukasha machining inogona kusangana nezvinodiwa. Nekudaro, kana iyo margin yakakura, kuomarara kweiyo process system kwakashata, kana simba remuchina wekushandisa harina kukwana, rinogona kupedzwa mune akawanda mafeed.

2)

Kana iyo yepamusoro roughness kukosha kweiyo workpiece inodiwa kuve Ra3.2μm ~ 12.5μm, inogona kukamurwa kuita matanho maviri: roughing uye semi-kupedza. Iyo yekumashure yekucheka chiyero kusarudzwa panguva yakaoma machining yakafanana nekare. Siya muganho we 0.5mm kusvika 1.0mm mushure mekugadzira hutsinye uye woibvisa panguva yekupedza.

3)

Kana iyo yepamusoro roughness kukosha kweiyo workpiece inodiwa kuti ive Ra0.8μm ~ 3.2μm, inogona kukamurwa kuita matanho matatu: roughing, semi-kupedzisa uye kupedza. Iyo yekumashure yekucheka huwandu panguva yehafu-yekupedzisira ndeye 1.5mm ~ 2mm. Munguva yekupedzisa, iyo kumashure yekucheka huwandu hunofanira kuva 0.3mm ~ 0.5mm.

3. Kuverenga kwehuwandu hwekudya

Kuwanda kwekudya kunotarirwa nekururama kwechikamu uye hutsinye hwepamusoro hunodiwa, pamwe chete nepamusoro pezvinhu zvakasarudzwa zvechishandiso uye workpiece. Huwandu hwekudya hunoenderana nekuomarara kwemuchina uye nhanho yekushanda kweiyo feed system.

Nheyo dzekutarisa kumhanya kwekudya:

1) Kana iyo workpiece mhando inogona kuvimbiswa, uye iwe uchida kuwedzera hunyanzvi hwekugadzira, saka kukurumidza kukurumidza kwekudya kunokurudzirwa. Kazhinji, kukurumidza kwekudya kunoiswa pakati pe100m/min uye 200m/min.

2) Kana iwe uchicheka kana kugadzirisa makomba akadzika, kana kushandisa simbi dzepamusoro-soro, zviri nani kushandisa kunonoka kwekudya. Izvi zvinofanira kuva pakati pe20 ne50m/min.

Kana kudiwa kwechokwadi mukugadzira uye kushata kwepamusoro kwakakwira, zviri nani kusarudza diki yekudyisa kumhanya, kazhinji pakati pe20m/min uye 50m/min.

Iwe unogona kusarudza iyo yakanyanya chiyero chekudya chakaiswa neCNC muchina chishandiso system kana chishandiso chisina basa, uye kunyanya "kudzosera zero" chinhambwe.

4. Spindle kumhanya kutsunga

Iyo spindle inofanirwa kusarudzwa zvichienderana nehupamhi hwekucheka kasidhi inobvumidzwa uye dhayamita yebasa rako kana chishandiso. Iyo yekuverenga formula yekumhanyisa kumhanya ndeye:

n=1000v/pD

Kusimba kwechishandiso kunotarisa kukurumidza.

Spindle speed inoyerwa mu r/min.

D -- dhayamita yebasa kana saizi yechishandiso, yakayerwa mumm.

Yekupedzisira spindle kumhanya inoverengerwa nekusarudza kumhanya iyo muchina chishandiso chinogona kuwana kana kuuya padyo, zvinoenderana negwaro rayo.

Nenguva pfupi, kukosha kwehuwandu hwekucheka hunogona kuverengwa nekuenzanisa, zvichienderana nekushanda kwemichina, zvinyorwa, uye ruzivo rwehupenyu chaihwo. Spindle kumhanya uye kudzika kwekucheka kunogona kugadziridzwa kune yekudyisa kumhanya kugadzira iyo yakakwana huwandu hwekucheka.

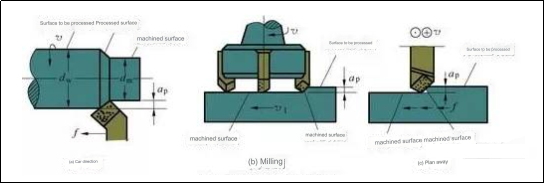

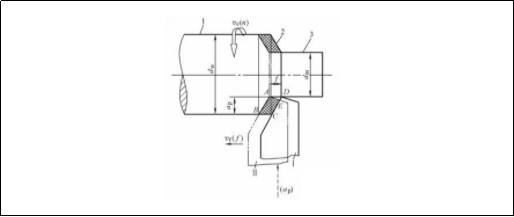

1) Kucheka kumashure huwandu (kucheka kudzika) ap

Kumashure kuchekwa huwandu ndiyo nhambwe yakatwasuka pakati pechiso kuenda kumushini uye nepamusoro pakagadzirwa. Kucheka kumashure ndiko kuwanda kwekucheka kuyerwa perpendicularly kune ndege yebasa kuburikidza neiyo base point. Kudzika kwekucheka ndiko kuwanda kwekucheka kunoitwa nemudziyo wekutendeuka kuita workpiece nefeed yega yega. Huwandu hwekucheka kuseri kwedenderedzwa rekunze hunogona kuverengerwa uchishandisa formula iri pazasi:

ap = (dw — dm) /2

Mune fomula, ap——huwandu hwebanga kumusana (mm);

dw——Iyo dhayamita yepasi ichagadziriswa yeworkpiece (mm);

dm - yakagadzirwa nepamusoro dhayamita yebasa rekushanda (mm).

Muenzaniso 1:Izvo zvinozivikanwa kuti iyo dhayamita yepasi yeworkpiece inofanirwa kugadziriswa ndeye Φ95mm; ikozvino dhayamita iri Φ90mm mune imwe feed, uye huwandu hwekucheka kumashure hunowanikwa.

Mhinduro: ap = (dw — dm) /2= (95 —90) /2=2.5mm

2) Huwandu hwekudya f

Iko kuchinjika kwechishandiso uye workpiece munzira yekudyisa mafambiro kune yega yega shanduko yeworkpiece kana chishandiso.

Zvinoenderana neakasiyana ekudyara madhairekitori, yakakamurwa kuita longitudinal feed huwandu uye transverse yekudya huwandu. Huwandu hwekudyisa hurefu hunoreva huwandu hwekudyisa parutivi rwenzira yelathe bed guide njanji, uye iyo transverse feed yehuwandu inoreva kune iyo nzira perpendicular kune lathe bed guide njanji. Feed rate.

Cherechedza:Iyo feed speed vf inoreva kukurumidza kwekukurumidza kwenzvimbo yakasarudzwa pamucheto wekucheka maererano nekufambisa kwekudya kwechishandiso.

vf=fn

uko vf——kudyisa kumhanya (mm/s);

n——Spindle speed (r/s);

f——huwandu hwekudya (mm/s).

3) Kucheka kumhanya vc

Instantaneous velocity mumutambo mukuru pane imwe nzvimbo pane yekucheka blade maererano ne workpiece. Yakaverengerwa ne:

vc=(pdwn)/1000

Iko vc —-kucheka kumhanya (m/s);

dw = dhayamita yepasi inofanira kurapwa (mm);

-- Kutenderera kumhanya kweiyo workpiece (r/min).

Masvomhu anofanirwa kuitwa zvichibva pahupamhi hwekucheka kumhanya. Maverengero anofanirwa, semuenzaniso, kuitwa zvichienderana nedhayamita uye chiyero chekupfeka kwechiso chiri kugadzirwa.

Tsvaga vc. Muenzaniso wechipiri: Kana uchitenderedza denderedzwa rekunze rechinhu chine dhayamita Ph60mm palathe, sipidhi yespindle yakasarudzwa i600r/min.

Solution:vc=(pdwn)/1000 = 3.14x60x600/1000 = 113 m/min

Mukugadzirwa kwechokwadi, zvakajairika kuziva dhayamita yechidimbu. Kucheka kumhanya kunotemerwa nezvinhu zvakaita senge zvinhu zvechishandiso, zvishandiso zvekushandisa uye zvinodikanwa zvekugadzirisa. Kugadzirisa lathe, kasi yekucheka inoshandurwa kune spindle kasi ye lathe. Iyi fomula inogona kuwanikwa:

n=(1000vc)/pdw

Muenzaniso 3: Sarudza vc kusvika 90m/min uye tsvaga n.

Mhinduro: n=(1000v c)/ pdw=(1000×90)/ (3.14×260) =110r/min

Mushure mekuverenga kumhanya kwelathe spindle, sarudza kukosha kuri pedyo nenhamba yenhamba, semuenzaniso, n = 100r/min sekumhanya chaiko kwelathe.

3. Pfupiso:

Kucheka huwandu

1. Banga rekuseri huwandu ap (mm) ap= (dw – dm) / 2 (mm)

2. Huwandu hwekudya f (mm/r)

3. Kucheka kasi vc (m/min). Vc=dn/1000 (m/min).

n=1000vc/d(r/min)

Nekuda kwedu teseCNC aluminium zvikamuvane hanya, ndedzipi nzira dzekudzikisa kugadzirwa kwearuminiyamu zvikamu?

Kugadzirisa Kwakakodzera:

Kugadzirisa workpiece nemazvo kwakakosha kudzikisa kukanganisa panguva yekugadzira. Nekuona kuti maworkpiece akachengetedzwa zvakachengeteka munzvimbo, vibrations uye mafambiro anogona kuderedzwa.

Adaptive Machining

Sensor mhinduro inoshandiswa kugadzirisa maparamita ekucheka zvine simba. Izvi zvinotsiva kusiyana kwezvinhu, uye zvinoderedza deformation.

Kucheka Parameters Optimization

Deformation inogona kudzikiswa nekugadzirisa ma paramita sekucheka kumhanya, feedrate, uye kudzika kucheka. Nekudzikisa masimba ekucheka uye kugadzirwa kwekupisa nekushandisa zvakakodzera kucheka zvimiro, kukanganisa kunogona kuderedzwa.

Kuderedza Kugadzira Kupisa:

Kupisa kunogadzirwa panguva yekugadzira kunogona kutungamira mukupisa kwekupisa uye kuwedzera. Kuti uderedze kugadzirwa kwekupisa, shandisa zvinotonhorera kana mafuta. Deredza kumhanya kwekucheka. Shandisa majasi echishandiso chepamusoro-soro.

Zvishoma nezvishoma Machining

Zviri nani kuita akawanda kupfuura kana uchigadzira aluminium pane imwe inorema kucheka. Kugadzira zvishoma nezvishoma kunoderedza deformation nekudzikisa kupisa uye kucheka masimba.

Preheating:

Preheating aluminium pamberi pekugadzira kunogona kuderedza njodzi yekukanganiswa mune mamwe mamiriro. Preheating inodzikamisa iyo zvinhu uye inoita kuti irambe inopesana nekukanganiswa kana uchigadzira.

Stress Relief Annealing

Stress yekurerutsira annealing inogona kuitwa mushure mekuita machining kuderedza kusara kushushikana. Chikamu chinogona kudzikamiswa nekuchipisa kune imwe tembiricha, wozochitonhodza zvishoma nezvishoma.

Kusarudza Rudyi Tooling

Kuti uderedze deformation, zvakakosha kusarudza maturusi ekucheka akakodzera, ane machira akakodzera uye geometries. Yakagadzirirwa maturusi ealuminium machining anoderedza kucheka masimba, kunatsiridza kupera kwepamusoro, uye kudzivirira kuumbwa kweakavakirwa-mupendero.

Machining mumatanho:

Multiple machining mashandiro kana matanho anogona kushandiswa kugovera mauto ekucheka pane yakaomacnc aluminium zvikamuuye kuderedza deformation. Iyi nzira inodzivirira kushushikana kwenzvimbo uye inoderedza kukanganisa.

Kutsvaga kweAnebon uye chinangwa chekambani kugara chiri "Nguva dzose tichigutsa zvinodiwa nevatengi vedu". Anebon ramba uchiwana uye dhizaini uye gadzira zvinoshamisa zvemhando yepamusoro zvigadzirwa kune yega yega vatengi vedu vekare uye vatsva uye kusvika pakukunda-kuhwina tarisiro yevatengi veAnebon pamwe nesu yeOriginal Factory Profile extrusions aluminium,cnc yakatendeuka chikamu, cnc kugaya naironi. Isu tinogashira nemoyo wese shamwari kuti dzichinjane bhizinesi bhizinesi uye kutanga kushandira pamwe nesu. Anebon inotarisira kurovanisa maoko neshamwari dzepedyo mumaindasitiri akasiyana kuti igadzire inopenya kwenguva refu.

China Mugadziri weChina High Precision uye Metal Stainless Steel Foundry, Anebon iri kutsvaga mikana yekusangana neshamwari dzese kubva kumba nekune dzimwe nyika kuitira kuhwina-kuhwina kubatana. Anebon inotarisira nemoyo wose kuve nekubatana kwenguva refu nemi mose pazvigadziko zvekubatsirana pamwe nekusimudzira kwakafanana.

Kana uchida kuziva zvakawanda, ndapota taura nechikwata cheAnebon painfo@anebon.com.

Nguva yekutumira: Nov-03-2023