Munhu wese anoziva nezve thread. Sevamwe vatinoshanda navo muindasitiri yekugadzira, isu tinowanzo kuda kuwedzera tambo zvinoenderana nezvinodiwa nevatengi kana tichigadzira Hardware accessories sengeCNC machining zvikamu, CNC inoshandura zvikamuuyeCNC milling zvikamu.

1. Chii chinonzi thread?

Rwonzi irwonzi runochekwa kuita chirukwa chingave kunze kana mukati. Basa guru re threads ndeiyi:

1. Gadzira chinongedzo chemagetsi nekubatanidza zvigadzirwa zvemukati zveshinda uye zvekunze zvigadzirwa zveshinda.

2. Kuendesa mafambiro nekushandura kutenderera kutenderera kune mutsara mafambiro uye zvinopesana.

3. Wana zvakanakira michina.

2. Thread profile uye terminology

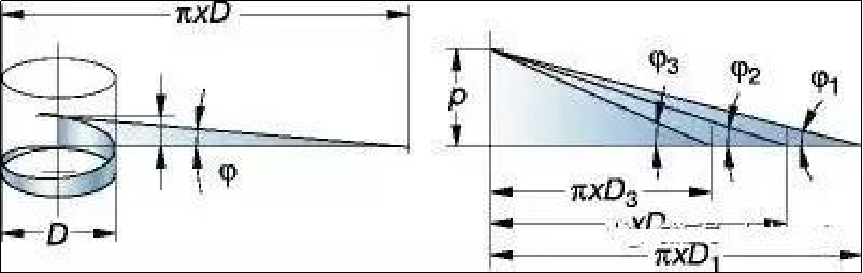

Iyo tambo mbiri inosarudza geometry yeshinda, kusanganisira iyo workpiece dhayamita (hombe, pitch, uye madhayamita madiki); thread profile angle; pitch uye helix angle.

1. Thread terms

① Pazasi: Iyo yepasi pepamusoro inobatanidza mbiri dziri padyo neshinda.

② flank: shinda padivi pepamusoro inobatanidza crest uye pasi pezino.

③Crest: Nzvimbo yepamusoro inobatanidza mativi maviri.

P = pitch, mm kana shinda painch (tpi)

ß = mbiri yekona

ϕ = thread helix angle

d = dhayamita huru yeshinda yekunze

D = dhayamita huru yeshinda yemukati

d1 = dhayamita diki yeshinda yekunze

D1 = Diki dhayamita yeshinda yemukati

d2 = pitch dhayamita yeshinda yekunze

D2 = yemukati shinda pitch dhayamita

Pitch dhayamita, d2/D2

Kubudirira dhayamita yeshinda. Inenge hafu pakati pemadhayamita makuru uye madiki.

Iyo geometry yeshinda yakavakirwa pashinda pitch dhayamita (d, D) uye pitch (P): axial chinhambwe chiri pashinda pane workpiece kubva pane imwe poindi paprofile kuenda kune inowirirana poindi. Izvi zvinogonawo kuonekwa segonyo rinodarika iyo workpiece.

vc = kumhanya kwekucheka (m/min)

ap = kudzika kweshinda yakazara (mm)

nap = kudzika kweshinda yakazara (mm)

tpi = shinda pa inch

Kudyisa = pitch

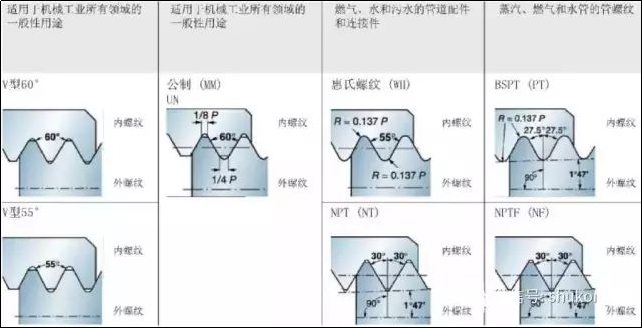

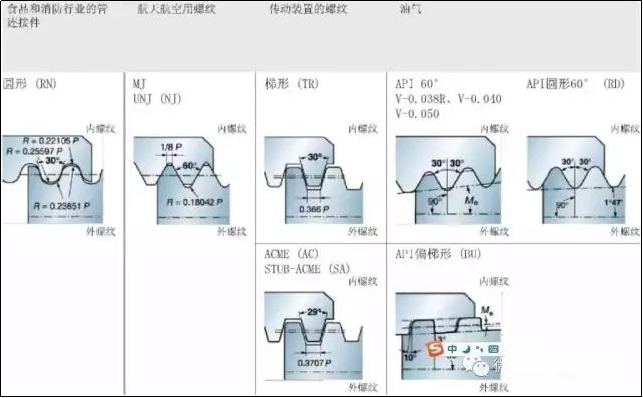

2. Yakajairika thread profile

1. Kuverenga uye kushivirira kwekunze kweshinda pitch dhayamita ye60 ° mazino emhando (yenyika standard GB197/196)

a. Kuverengera kwehukuru hwehukuru hwe pitch diameter

Hukuru hwehupamhi hwedhayamita yeshinda = dhayamita huru yeshinda - pitch × coefficient value.

Formula inomiririra: d/DP×0.6495

2. Kuverenga uye kushivirira kwepitch dhayamita ye60° shinda yemukati (GB197/196)

a.6H level thread pitch dhayamita kushivirira (zvichienderana neshinda inonamira)

Muganho wepamusoro:

P0.8+0.125P1.00+0.150P1.25+0.16P1.5+0.180

P1.25+0.00P2.0+0.212P2.5+0.224

Iyo yakaderera muganho kukosha ndeye "0",

Iyo yepamusoro muganho wekuverenga formula 2+TD2 ndiyo yakakosha saizi + kushivirira.

Semuenzaniso, iyo pitch diameter yeM8-6H yemukati shinda ndeye: 7.188 + 0.160 = 7.348 Upper muganho: 7.188 ndiyo yakaderera muganhu.

b. Kuverengera formula yepitch diameter yeshinda yemukati yakafanana neyekunze kweshinda

Ndiko kuti, D2 = DP × 0.6495, kureva, dhayamita yepakati yeshinda yemukati yakaenzana nehupamhi hukuru hwe thread-pitch× coefficient value.

c.6G kirasi shinda pitch dhayamita basic deviation E1 (zvichienderana neshinda pitch)

P0.8+0.024P1.00+0.026P1.25+0.028P1.5+0.032

P1.75+0.034P1.00+0.026P2.5+0.042

3. Kuverenga uye kushivirira kwedhayamita huru yeshinda yekunze (GB197/196)

a. Muganho wepamusoro we6h yakakura dhayamita yeshinda yekunze

Kureva, iyo dhayamita yedhayamita yemuenzaniso muenzaniso M8 ndeye φ8.00 uye yekumusoro muganho kushivirira ndeye "0".

b. Kushivirira kweiyo yakaderera muganho kukosha kweiyo dhayamita hombe ye6h kirasi yeshinda yekunze (zvichienderana neshinda inoyerera)

P0.8-0.15P1.00-0.18P1.25-0.212P1.5-0.236P1.75-0.265

P2.0-0.28P2.5-0.335

Yekuverengera fomula yemuganho wepasi wedhayamita hombe: d-Td ndiyo chiyero cheiyo dhayamita huru yeshinda - kushivirira.

4. Kuverenga uye kushivirira kwediki dhayamita yemukati shinda

a. Kuverengera kwehukuru hwakakosha hwedhayamita diki yeshinda yemukati (D1)

Hukuru hwehukuru hwediki dhayamita yeshinda = saizi yekutanga yeshinda yemukati - pitch × factor

5. Calculation formula yekukamura musoro single diviing method

Kuverengera formula yeimwe division nzira: n=40/Z

n: nhamba yekuchinja iyo musoro unoparadzanisa unofanirwa kutendeuka

Z: Chikamu chakaenzana cheworkpiece

40: nhamba yakatarwa yekuparadzanisa musoro

6. Kuverengera formula yehexagon yakanyorwa mudenderedzwa

① Tsvaga iyo ine hexagonal yakatarisana divi (S pamusoro) yedenderedzwa D

S=0.866D idhayamita×0.866 (coefficient)

② Verenga dhayamita yedenderedzwa (D) kubva kumativi akasiyana ehexagon (S pamusoro)

D=1.1547S iri opposite side×1.1547 (coefficient)

7. Calculation formula yehexagonal yakatarisana mativi uye diagonals mune inotonhora musoro maitiro

① Tsvaga iyo yakatarisana nekona e kubva kune yakatarisana divi (S) yekunze hexagon

e=1.13s iri opposite side×1.13

②Tsvaga kona yakatarisana (e) kubva kune yakatarisana (s) yemukati hexagon

e=1.14s inotarisana nedivi×1.14 (coefficient)

③ Tsvaga iyo dhayamita yemusoro wekona yakatarisana (D) kubva kune yakatarisana (s) yekunze hexagon.

Iyo dhayamita yedenderedzwa (D) inofanirwa kuverengerwa zvichienderana ne (yechipiri fomula mu6) iyo hexagonal yakatarisana nedivi (s surface), uye iyo offset centre kukosha kunofanirwa kuwedzerwa zvakakodzera, kureva, D≥1.1547s. Huwandu hweoffset centre hunogona kungofungidzirwa.

8. Kuverengera formula yeskweya yakanyorwa mudenderedzwa

① Denderedzwa (D) kuti uwane divi rakatarisana nekona (S pamusoro)

S=0.7071D idhayamita×0.7071

② Tsvaga denderedzwa (D) kubva kumativi akasiyana echikwere (S pamusoro)

D=1.414S iri opposite side×1.414

9. Calculation formula yeskweya mativi akatarisana nemakona akapesana mukutonhora kwemusoro

① Tsvaga yakatarisana nekona (e) kubva kune yakatarisana (S) yekunze sikweya

e=1.4s ndiro divi rakapesana (s)×1.4 parameter

② Tsvaga yakatarisana nekona (e) kubva kune yakatarisana divi (s) yemukati sikweya

e=1.45s ndiro divi rakapesana (s)×1.45 coefficient

10. Muitiro wekuverenga huwandu hwehexagon

s20.866×H/m/k zvinoreva divi rakapesana×rinopesana×0.866×urefu kana ukobvu.

11. Calculation formula yehuwandu hwefrustum (cone) muviri

0.262H(D2+d2+D×d) i 0.262×hurefu×(musoro muhombe dhayamita×musoro dhayamita dhayamita+musoro dhayamita diki×mumusoro dhayamita+mumusoro dhayamita×musoro dhayamita diki).

12. Kuverengera formula yehuwandu hwemuviri wakatenderedzwa (senge semicircular musoro)

3.1416h2(Rh/3) iri 3.1416×urefu×urefu×(radius-urefu÷3).

13. Calculation formula ye machining dimensions ematepi emukati shinda

1. Kuverengera kwepombi yakakura dhayamita D0

D0=D+(0.866025P/8)×(0.5~1.3) ndiwo musimboti wesaizi yepombi yakakura dhayamita shinda + 0.866025 pitch ÷ 8×0.5 kusvika 1.3.

Ongorora: Sarudzo ye0.5 kusvika 1.3 inofanirwa kusimbiswa zvinoenderana nehukuru hwepitch. Iyo yakakura kukosha kwepitch, iyo diki coefficient inofanira kushandiswa. Pane zvinopesana, iyo idiki kukosha kwepitch, iyo inowirirana yakakura coefficient inofanira kushandiswa.

2. Kuverengera kwetap pitch dhayamita (D2)

D2=(3×0.866025P)/8, kureva, tepi dhayamita=3×0.866025×pitch÷8

3. Kuverengera kwepombi dhayamita (D1)

D1=(5×0.866025P)/8 ndiyo dhayamita yepombi=5×0.866025×pitch÷8

14. Kuverengera formula yehurefu hwezvinhu zvinoshandiswa kutonhora musoro kuumba mune akasiyana maumbirwo

Zvinozivikanwa kuti vhoriyamu formula yedenderedzwa idhayamita×dhayamita×0.7854×kureba kana radius×radius×3.1416×kureba. Kureva, d2×0.7854×L kana R2×3.1416×L

Pakuverenga, vhoriyamu X÷diameter÷diameter÷0.7854 kana X÷radius÷radius÷3.1416 yezvinyorwa zvinodiwa pakugadziriswa.cnc machining zvikamuuyecnc kushandura zvikamundiko kureba kwechinhu.

Column formula = X/(3.1416R2) kana X/0.7854d2

X mune fomula inomiririra kukosha kwevhoriyamu yezvinhu zvinodiwa;

L inomiririra kukosha kwehurefu hwekudya chaiko;

R/d inomiririra radius kana dhayamita yekudyisa chaiko.

Nguva yekutumira: Jan-11-2023