1. Inyanzvi kuwana zvishoma zvekudya zvakadzika. Mukuita kutenderedza, basa retriangular rinowanzo shandiswa kugadzira mamwe maworkpiece ane emukati nekunze madenderedzwa pamusoro pechipiri chechokwadi. Nekuda kwekupisa kwekucheka, kupokana pakati pechishandiso nechishandiso chinoita kuti chishandiso chipfeke uye kudzokororwa kwekumisikidza kurongeka kweiyo square tool holder, nezvimwewo, saka mhando yakaoma kuvimbisa. Kugadzirisa iyo chaiyo micro-yakadzika kudzika mukutendeuka, tinogona kushandisa hukama pakati pedivi rakatarisana nedivi rakachinjika regonyo sezvinodiwa kufambisa iyo longitudinal diki inobata banga pakona kuti inyatso kusvika payakachinjika yekudya kudzika kweiyo. micro-moving turning tool. Chinangwa: chengetedza basa uye nguva, chengetedza mhando yechigadzirwa, uye uvandudze kushanda zvakanaka. Iyo yakajairika C620 lathe mudziyo inobata chiyero kukosha ndeye 0.05mm pagidhi. Kana iwe uchida kuwana yakachinjika yekudya kukosha kwe0.005mm, tarisa iyo sine trigonometric basa tafura: sinα=0.005/0.05=0.1 α=5o44′, saka fambisa diki chibatiso. Kana iri 5o44 ', kana uchifambisa dhisiki yakanyorwa kwenguva refu pane diki inobata banga, inogona kusvika kune micro-movement yechishandiso chekucheka nehupamhi hunokosha hwe 0.005mm mu lateral direction.

2. Iko kushandiswa kwereverse turning tekinoroji mumitambo mitatu yenguva refu yekugadzira inoratidza kuti mune chaiyo yekutendeuka maitiro, reverse yekucheka tekinoroji inogona kuwana mhedzisiro yakanaka. Mienzaniso inotevera ndeiyi:

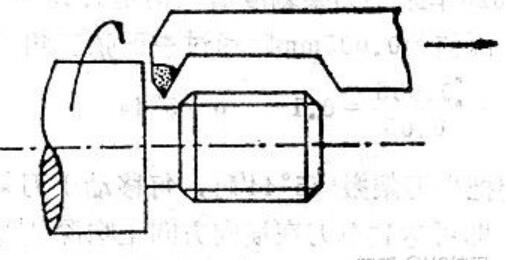

(1) Kana iyo reverse-yekucheka tambo zvinhu iri martensitic Stainless simbi ine mukati nekunze shinda yekushanda ine pitch ye 1.25 uye 1.75 mm kubva papitch yelathe screw inobviswa nenamo yeworkpiece, kukosha kwakawanikwa. is Ukoshi husinga peri. Kana shinda ichigadzirwa nekusimudza mubato wecounter nut, shinda inowanzodambuka. Kazhinji, iyo yakajairika lathe haina dhizaini dhizaini, uye iyo yakazvigadzira yega seti yedhisiki inopedza nguva mukugadzirisa gomo rakadaro. Pakuisa thread, kazhinji. Iyo nzira yakagamuchirwa ndiyo yakaderera-yekumhanya yakatsetseka yekutendeuka nzira nekuti iyo yepamusoro-yekukurumidza nhonga-yepamusoro haina kukwana kudzoreredza banga, saka kugadzirwa kwekuita kwakadzikira, faira rinogadzirwa nyore panguva yeKutendeuka, uye roughness yepasi haina kunaka, kunyanya. mukugadzirisa martensite simbi isina tsvina yakadai se1Crl3, 2 Crl3, nezvimwewo. Kana uchicheka nekumhanya kwakaderera, chiitiko chejeko chinonyanya kuoneka. Iyo reverse-kucheka, reverse-kucheka, uye yakatarisana-yakatarisana "matatu-reverse" nzira dzekucheka dzakagadzirwa mukuita machining dzinogona kuwana yakanaka yekucheka mhedzisiro nekuti iyo nzira inogona kushandura tambo nekumhanya kwakanyanya, uye mafambiro echishandiso. inodzoserwa kubva kuruboshwe kuenda kurudyi, saka hapana chinokanganisa kuti chishandiso hachikwanise kudzoserwa kana uchicheka shinda nekumhanya kukuru. Iyo chaiyo nzira ndeyotevera: Kana iyo yekunze tambo inoshandiswa, geya yakafanana yemukati tambo inoshandura chishandiso (Fig. 1);

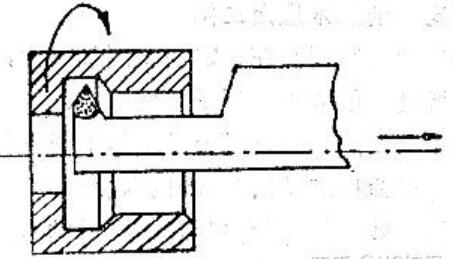

Geya reverse remukati shinda inoshandura chishandiso (Mufananidzo 2).

Pamberimachining, gadzirisa kuruka kwe reverse friction plate zvishoma kuti uve nechokwadi chekutenderera kutenderera. Kune yakanaka yekucheka shinda, vhara yekuvhura nekuvhara nati, tanga kumberi uye yakaderera kasi kuenda kune isina sipe sipe, wozoisa shinda inoshandura mudziyo muhudzamu hwakakodzera hwekucheka; unogona kudzorera kutenderera. Panguva ino, chigadziro chekushandura chinosara pakumhanya kukuru. Nekucheka banga kurudyi uye kucheka nhamba yemapanga maererano nenzira iyi, shinda ine hupamhi hwepamusoro uye yakakwirira yepamusoro inogona kugadzirwa.

(2) Muchinyakare chekurovera muitiro wekudzokera kumashure, mafirita esimbi nemarara zvinopinzwa zviri nyore pakati pechishandiso nebanga rekupfumbata, zvichiita kuti workpiece iwedzere kudzvinyirirwa, zvichiita kuti mitsara iunganidzwe, iyo pateni inopwanyika kana kuputswa, nezvimwe, nezvimwe. . Kana iyo nzira itsva yekushanda yeKutendeuka uye kubvongodza kwechipingo che lathe yakagamuchirwa, zvipingamupinyi zvinokonzerwa nekushanda kwekugadzirisa zvinogona kuva zvinodzivirirwa zvinobudirira, uye mugumisiro wakanaka wakazara unogona kuwanikwa.

(3) Reverse kutendeuka kwemukati nekunze taper pombi tambo Paunenge uchitenderedza akasiyana emukati uye ekunze taper pombi shinda nekushomeka kushoma uye kushoma batch, zvinokwanisika kushandisa zvakananga reverse kucheka nekudzosera kumashure kurodha pasina mold mudziyo. Mune nzira itsva yekushanda, paunenge uchicheka rutivi rwechishandiso, chimbo chinotamiswa chakatwasuka kubva kuruboshwe kuenda kurudyi. Iyo faira yakachinjika inoita kuti zvive nyore kubata kudzika kwefaira kubva padhayamita hombe kusvika kudiki dhayamita. Chikonzero ifaira. Kune pre-stress. Huwandu hwemashandisirwo emhando iyi nyowani yereverse inoshanda tekinoroji mukushandura tekinoroji iri kuwedzera kupararira uye inogona kuchinjika kushandiswa kune akasiyana mamiriro chaiwo.

3. Nzira itsva yekushanda uye kushandiswa kwechishandiso chekuchera makomba maduku Mukugadzirisa, kana gomba risingasviki 0.6mm, dhayamita ye drill idiki, kusimba kwakashata, kukurumidza kucheka hakusi kumusoro, uye workpiece zvinhu. isimbi inodzivirira kupisa uye simbi isina simbi, uye kucheka kuramba kwakakura, saka kana kuchera, sekushandiswa kwema mechanical transmission feed, drill iri nyore kutyora. inotevera inotsanangura chishandiso chiri nyore uye chinoshanda uye nzira yekudyisa yemanyorero. Chekutanga, iyo yekutanga drill chuck inoshandurwa kuita yakatwasuka shank inoyangarara mhando. Kana iyo diki yekubooresa yakasungirirwa pane inoyangarara drill chuck, kuchera kunogona kuitwa zvakanaka. Nekuda kwekuti chikamu chekumashure chechibhorani chakati twasu shank inotsvedza, inogona kufamba yakasununguka muruzha rekudhonza. Kana gomba diki radhirowa, iyo drill chuck inogona kubatwa zvinyoro nyoro neruoko, iyo manyorero micro feed inogona kuitika, uye gomba diki rinogona kukurumidza kudhirowa kunze. Hunhu uye huwandu uye kuwedzera hupenyu hwesevhisi yediki drills. Iyo yakagadziridzwa yakawanda-purpose drill chuck inogona zvakare kushandiswa kudiki-dhayamita yemukati tambo yekubaya, reming, zvichingodaro.

4. Anti-vibration mune yakadzika-gomba machining Mukudzika-gomba machining, nekuda kwekaburi kadiki, boring tool bar inotetepa. Izvo hazvidzivisike kugadzira vibration kana gomba dhayamita iri Φ30~50mm, uye gomba rakadzika rinenge 1000mm. Ndiyo inonyanya kushanda uye inoshanda kudzivirira kudengenyeka kwearbor. Iyo nzira ndeyekubatanidza zvitsigiso zviviri (uchishandisa zvinhu zvakaita semucheka bakelite) kumuviri weshank, uye saizi yacho yakangofanana nehukuru hwekuvhura. Munguva yekucheka, iyo arbor hainyanyi kutenderera nekuda kwekumisikidzwa kweiyo slats, uye yakadzika gomba zvikamu zvemhando yakanaka inogona kugadziriswa.

5. Iyo anti-break yediki yepakati drill iri pasi pegomba repakati re Φ1.5mm apo kuchera kuri kuduku pane gomba repakati re Φ1.5mm. Iyo yakapfava uye inoshanda yekurwisa-break nzira ndeyekusakiya tailstock paunenge uchiboora buri repakati asi rega tailstock. Iyo yekuzvirema uye iko kukwesha kunogadzirwa pakati pemuchina wemubhedha wepamusoro unoshandiswa kuchera buri repakati. Kana iyo yekucheka kuramba yakakurisa, iyo tailstock inodzokera yega, nekudaro ichidzivirira yepakati drill.

6. Anti-vibration yekushandura yakaonda-yakakomberedzwa workpieces Panguva yekushandura yakaonda-yakakomberedzwa workpieces, vibrations inowanzogadzirwa nekuda kwekushayikwa kwesimbi zvinhu zveworkpieces; kunyanya kanakushandura simbi isina tsvinauye alloys anodzivirira kupisa, kudengenyeka kunonyanya kuoneka, kushata kwepamusoro kwechishandiso chakashata zvakanyanya, uye hupenyu hwebasa hwechishandiso hunopfupika. Nzira dzakareruka dzekukatyamadza kuzviparadzanisa mune akati wandei zvigadzirwa dzinotsanangurwa pazasi.

(1) Paunenge uchitenderedza denderedzwa rekunze resimbi isina tsvina yakatetepa chubhu workpiece, gomba rinogona kuzadzwa nehuni machipisi uye kuvharwa. Panguva imwecheteyo, migumo yese yebasa inovharirwa nebakelite plug, uye ipapo claw yekutsigira pachibatiso chinotsiviwa neIyo inotsigira melon yezvinhu zvebakelite inogona kugadzirisa arc inodiwa kuita Turning yesimbi isina tsvina. tsvimbo yakaonda. Iyi nzira iri nyore inogona kudzivirira zvinobudirira kuzununguka uye deformation yegomba slender tsvimbo panguva yekucheka.

(2) Kana uchishandura gomba remukati rekudzivirira kupisa (yakakwirira-nickel-chromium) alloy yakatetepa-yakavakirwa workpiece, kuomarara kweiyo workpiece kwakashata, shank iri nhete, uye yakakomba resonance chiitiko chinoitika panguva yekucheka, iyo ine mhosva huru yekukuvadza chishandiso uye kukonzera tsvina. Kana chinhu chinobata kuvhundutsa, chakadai setambo yerabha kana chipanje, chikamonerwa nechekunze kwedenderedzwa rebasa rekushanda, kuvhundutsa kunogona kuitwa zvinobudirira.

(3) Paunenge uchitenderedza denderedzwa rekunze reiyo inodzivirira kupisa-inodzivirira alloy yakatetepa-yakavezwa sleeve workpiece, nekuda kwezvinhu zvakakwana senge kupikisa kwakanyanya kweiyo inodzivirira kupisa alloy, zviri nyore kugadzira vibration uye deformation panguva yekucheka. Kana gomba rerabha kana shinda yekotoni ikaiswa mugomba rekushanda, marara anoshandiswa, ipapo nzira yekuvhara pamigumo miviri inogona kushandiswa kudzivirira zvinobudirira kuzununguka uye deformation yeworkpiece panguva yekucheka, uye iyo yepamusoro-mhando. thin-walled workpiece inogona kugadziriswa.

7. Iyo yekuwedzera anti-vibration chishandiso inoburitsa nyore kuzununguka nekuda kwehurombo kuomarara kwe elongated shaft-type workpiece panguva ye-multi-groove yekucheka maitiro, zvichikonzera kushata kwepamusoro kweiyo workpiece uye kukuvadzwa kune chishandiso. Seti yekuwedzera anti-vibration maturusi anogona kugadzirisa zvinobudirira dambudziko rekuzunguza rezvikamu zvitete mukuita grooving (ona Mufananidzo 10). Isa iyo yakazvigadzira-yega shockproof chishandiso munzvimbo yakakodzera pane sikweya mudziyo inobata pamberi pebasa. Wobva waisa iyo inodiwa yakaumbwa-yakafanana yekutendeuka chishandiso pane sikweya mudziyo inobata, gadzirisa chinhambwe uye huwandu hwekumanikidza hwechirimo, wobva washanda. Kana iyo yekushandura chishandiso ichicheka mukati meiyo workpiece, iyo yekuwedzera anti-vibration chishandiso inoiswa pamusoro peiyo workpiece panguva imwe chete, iyo yakanaka kune shockproofing. Mhedzisiro.

8. Zvinhu zvakaoma-ku-muchina zvinokudzwa uye zvinopedzwa. Kana isu tiri muzvinhu zvakaoma-ku-machine zvakadai se-high-temperature alloys uye simbi dzakaomeswa, hutsinye hwepamusoro hwebasa rekushanda hunodiwa kuti ive Ra0.20-0.05μm, uye kurongeka kwemaitiro zvakare kwakakwirira. Kupedzisa kwekupedzisira kunowanzoitwa pamushini wekukuya. Itai chigadziriso chakareruka chekugadzira uye vhiri rekukudza, uye gamuchira yakanaka yehupfumi mhedzisiro nekukudza pachinzvimbo chekukuya palathe.

9. Kukurumidza kurodha uye kuburitsa mandrels kunowanzosangana nemhando dzakasiyana dzekutakura seti mukutendeuka. Denderedzwa rekunze uye inverted gwara taper angle yebearing assembly. Nekuda kwehukuru hukuru hwebatch, kurodha uye kurodha nguva inopfuura nguva yekucheka. Yakareba, yakaderera kugadzirwa kwekubudirira. Iyo inokurumidza-kurodha mandrel uye single-banga multi-blade (yakaoma simbi) inotenderedza maturusi anotsanangurwa pazasi anogona kuchengetedza nguva yekubatsira uye kuve nechokwadi chemhando yechigadzirwa mukugadziriswa kweakasiyana akatakura sleeve zvikamu. Nzira yekugadzira ndeyotevera. Ita iri nyore, diki taper mandrel. Nheyo yacho ndeye kushandisa 0.02mm trace ye taper kuseri kwe mandrel. Iyo yekubereka seti yakasimbiswa pane mandrel nekukweshana, uye ipapo banga rimwechete-banga-blade rinoshandura chishandiso rinoshandiswa. Mushure mekutenderera, iyo 15 ° cone angle inodzoserwa shure, uye kupaka kunoitwa kubvisa zvikamu nekukurumidza uye zvakanaka, sezvakaratidzwa mumufananidzo.

10. Kutendeuka kwezvikamu zvesimbi yakaoma

1 yakatsetseka pamusoro peplugging 5 Thread rolling tepi dzakagadzirwa nehigh-speed simbi maturusi Ekudzima. Hardware uye zvakasiyana-siyana zvakaoma zvinhu zvikamu zvakasangana mukugadzirwa kwepamusoro, sarudza iyo yakakodzera chishandiso zvinhu uye kucheka huwandu uye chishandiso makona eJomethrike uye nzira dzekushanda dzinogona kuwana yakanaka yehupfumi mhedzisiro. Semuenzaniso, mushure mekunge square broach yaputsika, kana ikatangwazve kugadzira sikweya broach, kwete chete kutenderera kwekugadzira kwakareba asiwo mutengo wakakwira. Pamudzi webhurochi yepakutanga, tinoshandisa blade yeiyo hard alloy YM052 kuipinza kuita isina kunaka. Kona yekumberi r. =-6 °~-8 °, iyo yekucheka inogona kushandurwa nekunyatsokuya nedombo remafuta. Iko kumhanya kwekucheka ndeye V=10~15m/min. Mushure medenderedzwa rekunze, sipe isina chinhu inochekwa, uye pakupedzisira, shinda inoparadzaniswa kuva yakaoma uye yakanaka. ), mushure mekuomeswa, mudziyo unofanirwa kudzokororwa uye pasi mushure mekurodza kutsva nekukuya. Zvadaro, tambo yemukati yetsvimbo yekubatanidza inofanira kugadzirirwa, uye chibatanidza chinofanira kuderedzwa. Sikweya broach ine zvimedu zvakatyoka yakagadziriswa mushure mekutendeuka, uye yakanga yasakara sechitsva.

(2) Kusarudzwa kwezvinhu zvekushandisa zvekutendeuka nekudzima Hardware 1 Magiredhi matsva akadai seyakaoma alloy YM052, YM053, YT05, nezvimwewo, iyo general yekucheka kumhanya iri pazasi 18m/min, uye kushata kwechishandiso kunogona kusvika Ra1.6 ~0.80μm. 2 cubic boron nitride tool FD inogona kugadzirisa marudzi ese esimbi yakaoma uye yakapfapfaidzwa zvikamu, kucheka kukurumidza kusvika 100m / min, kushata kwepamusoro kusvika kuRa0.80 ~ 0.20μm. Iyo composite cubic boron nitride tool DCS-F inogadzirwa neState Capital Machinery Plant uye Guizhou No.6 Grinding Wheel Factory inewo kuita uku. Iyo yekugadziridza mhedzisiro yakaipisisa kupfuura iyo yecemented carbide (asi iyo simba haina kufanana neiyo yakaoma alloy; yakadzika uye yakachipa kupfuura yakaoma alloy, uye iri nyore kukuvadza kana ikashandiswa zvisina kunaka). Zvipfumbamwe zveceramic zvishandiso, kucheka kumhanya kwe40 ~ 60m / min, simba racho rakashata. Zvose zviri pamusoro pezvishandiso zvine maitiro avo mukutendeuka nekudzima zvikamu uye zvinofanirwa kusarudzwa maererano nemamiriro chaiwo ekushandura zvinhu zvakasiyana uye kuoma kwakasiyana.

(3) Kusarudzwa kwemhando dzakasiyana dzesimbi dzakaomeswa zvikamu uye midziyo yemidziyo Zvinhu zvakasiyana zvezvikamu zvesimbi zvakaomeswa pasi pekuomarara kwakafanana, zvinodiwa zvekushandisa kwechishandiso zvakasiyana zvachose, zvakakura sezvikamu zvitatu zvinotevera: 1 high alloy simbi: inoreva alloying. zvinhu Tool simbi uye die simbi (kunyanya akasiyana-siyana high-speed steels) ane huremu hunopfuura 10%. 2 alloy simbi: inoreva simbi yechishandiso uye inofa simbi ine alloying chinhu zviri mukati me2 ~ 9%, senge 9SiCr, CrWMn, uye yakakwirira simba alloy simbi yekugadzira. Matatu kabhoni simbi: anosanganisira akasiyana kabhoni maturusi mapepa esimbi uye carburized simbi seT8, T10, 15 simbi, kana makumi maviri gauge simbi carburizing simbi. Kune kabhoni simbi, iyo microstructure mushure mekudzima martensite ine huturu hwemartensite uye shoma shoma yecarbide, yakaoma bvudzi HV800 ~ 1000, kupfuura kuomarara kweWC neTiC mune simende carbide uye A12D3 mumaturusi e ceramic. Iyo yakadzikira zvakanyanya, uye haina kupisa-yakaoma pane martensite isina alloying zvinhu uye kazhinji haipfuure 200 °C. Sezvo zviri mukati meiyo alloying zvinhu musimbi zvinowedzera, iyo carbide yemukati yesimbi mushure mekudzima uye kupisa kunowedzera, uye mhando yecarbide inova yakaoma. Kutora high-speed simbi semuenzaniso, zviri mukati carbides ari microstructure pashure quenching uye tempering anogona kusvika 10-15% (vhoriyamu reshiyo) uye ine carbides pamusoro MC, M2C, M6 M3, 2C, etc. High kuoma (HV2800) yakakwira zvakanyanya kupfuura kuomarara kwechikamu chakaomarara mune zvakajairika zvishandiso zvekushandisa. Pamusoro pezvo, nekuda kwekuvapo kwenhamba yakawanda yealloying zvinhu, kuomarara kwekupisa kwemartensite ine zvinhu zvakasiyana-siyana zvealloying kunogona kuwedzera kusvika pa600 ° C. Iko kushanda kwakaoma kwesimbi dzakaomeswa neiyo microhardness yakafanana haina kufanana, uye musiyano wakakura kwazvo. Asati ashandura simbi dzakaoma, dzinoongororwa kuti ndedzechikamu ichocho. Tenzi hunhu uye sarudza akakodzera maturusi emidziyo, kucheka huwandu, uye chishandiso geometry. Iko kona inokwanisa kupedzisa kusungirirwa kwezvikamu zvesimbi yakaoma.

Anebon Metal Products Limited inogona kupa CNC Machining, Die Casting, Sheet Metal Fabrication service, ndapota inzwa wakasununguka kutibata nesu.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Nguva yekutumira: Aug-30-2019