1. Pfungwa yesimbi pamusoro roughness

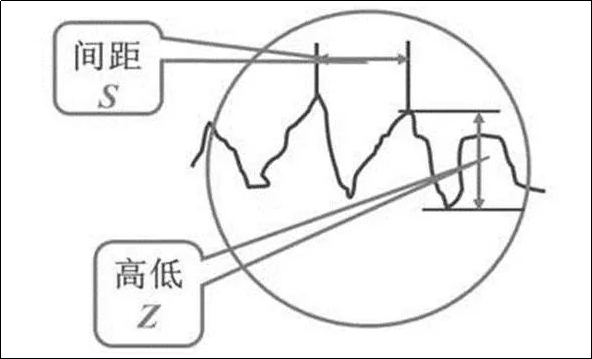

Kukasharara kwepamusoro (Surface roughness) zvinoreva kusaenzana kwenzvimbo diki nenhongonya nemipata ine nzvimbo yakagadzirwa nemichina. Chinhambwe (mufambo wemasaisai) pakati penhongonya mbiri kana zvimwiro zviviri idiki kwazvo (pazasi pe1mm), inova yemicroscopic geometric shape kukanganisa.

Kunyanya, inoreva chiyero chehurefu uye chinhambwe S chezvikomo zvidiki nemipata. Kazhinji yakakamurwa naS:

-

S<1mm ndiko kushata kwepamusoro;

- 1≤S≤10mm is waviness;

- S> 10mm iri f chimiro.

2. VDI3400, Ra, Rmax tafura yekuenzanisa

Chiyero chenyika chinotara kuti zviratidzo zvitatu zvinowanzoshandiswa kuongorora kushata kwepamusoro (chikamu μm): avhareji arithmetic kutsauka Ra yeprofile, avhareji urefu Rz yekusaenzana uye kureba kwepamusoro Ry. Iyo Ra index inowanzoshandiswa mukugadzirwa chaiko. Iyo yakanyanya micro-kureba kutsauka Ry yeprofile inowanzo kuratidzwa neiyo Rmax chiratidzo muJapan nedzimwe nyika, uye iyo VDI index inowanzoshandiswa muEurope uye United States. Pazasi pane VDI3400, Ra, Rmax yekuenzanisa tafura.

VDI3400, Ra, Rmax tafura yekuenzanisa

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

3. Surface roughness kugadzira zvinhu

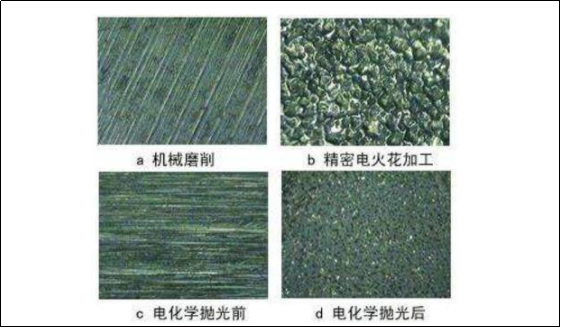

Kushata kwepamusoro kunowanzo kuumbwa nemaitiro ekugadzirisa anoshandiswa uye zvimwe zvinhu, senge kupokana pakati pechishandiso uye pamusoro peiyo.cnc machining chikamupanguva yekugadzira, iyo yepurasitiki deformation yepasi layer yesimbi kana chip ichiparadzaniswa, uye yakakwirira frequency vibration mu process system, magetsi machining magomba ekuburitsa, etc. Nekuda kweakasiyana maitiro ekugadzirisa uye workpiece zvinhu, kudzika, density, chimiro. uye manyorerwo ezvironda zvakasiiwa panzvimbo yakagadziriswa zvakasiyana.

4. Kuratidzwa kukuru kwesimba rekuoma kwepamusoro pazvikamu

1) Kukanganisa kupfeka kusagadzikana. Iyo yakanyanya kukwasharara, iyo idiki iyo inobudirira yekubata nzvimbo pakati penzvimbo dzekusangana, iyo yakakura kudzvanywa, yakakura kupikisa kuramba, uye nekukurumidza kupfeka.

2) Kukanganisa kugadzikana kwekukodzera. Nokuda kwekugadziriswa, iyo yakanyanyisa pamusoro, iyo iri nyore kupfeka, kuitira kuti gaka riwedzere zvishoma nezvishoma panguva yekushanda; simba rekubatanidza.

3) Kukanganisa simba rekuneta. Kune zvinwiwa zvakakura pamusoro pezvikamu zvakakasharara, izvo zvinonzwa kusungirirwa kwekushushikana senge notchi dzakapinza uye makatsemuka, zvichikanganisa simba rekuneta kwe.kunyatsoita zvikamu.

4) Kukanganisa kusagadzikana kwemarara. Zvikamu zvakakasharara pamusoro zvinogona kuita kuti gasi rinoora kana kuti mvura ipinde mukati memukati mesimbi nemumipata ine microscopic iri pamusoro, zvichikonzera ngura.

5) Kukanganisa kusimba. Nzvimbo dzakakasharara hadzigone kukwana zvakasimba, uye gasi kana mvura inobvinza nepamagapu ari pakati penzvimbo dzekusangana.

6) Inokanganisa kusangana nekuoma. Kuomarara kwekubatana ndiko kugona kweiyo yakabatana pamusoro pezvikamu kurwisa deformation pasi pekuita kwesimba rekunze. Kuoma kwemuchina kunonyanya kutsanangurwa nekuoma kwekubatana pakati pecnc lathe zvikamu.

7) Kukanganisa kuyerwa kwechiyero. Kushata kwepamusoro kwenzvimbo yakayerwa yechikamu uye nzvimbo yekuyeresa yechishandiso chekuyeresa ichakanganisa zvakananga kurongeka kwechiyero, kunyanya mukuyera kwakaringana.

Uye zvakare, kushata kwepamusoro kuchave neakasiyana madhigirii epesvedzero pane yekuputira coating, yekupisa conductivity uye kubata kuramba, kuratidza uye nemwaranzi kuita kwezvikamu, kuramba kumvura uye kuyerera kwegesi, uye kuyerera kwazvino pamusoro pemakondukita.

5. pamusoro roughness evaluation hwaro

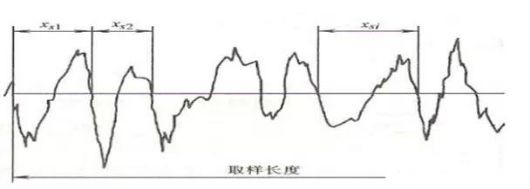

1. Sampling urefu

Urefu hwesampling hurefu hwemutsara wereferensi wakatsanangurwa mukuongororwa kwekushata kwepasi. Zvinoenderana nekugadzirwa uye magadzirirwo enzvimbo chaiyo yechikamu, hurefu hunogona kuratidza hukasha hwepamusoro hunofanirwa kusarudzwa, uye urefu hwesampling hunofanirwa kuyerwa zvichienderana neyakajairwa maitiro eiyo chaiyo yepasi contour. Chinangwa chekudoma nekusarudza hurefu hwesampling kudzikamisa nekunetesa simba rekuti waviness yepasi uye kukanganisa kwemaumbirwo pazviyero zvekuyera kushata kwepasi.

2. Kuyera kureba

Hurefu hwekuongorora hurefu hunodiwa pakuongorora chimiro, uye inogona kusanganisira imwe kana akati wandei sampling kureba. Sezvo kushata kwepamusoro kwechikamu chega chega chepamusoro pechikamu kusiri kwakafanana, imwe nzvimbo yakakasharara haigone kuratidzwa mune imwe sampling urefu, saka zvinodikanwa kutora akati wandei sampling urefu pamusoro kuti uongorore kushata kwepasi. Hurefu hwekuongorora kazhinji hune hurefu hwesampling 5.

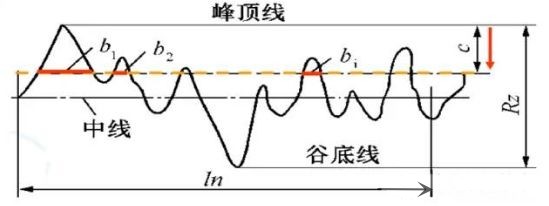

3. Baseline

Mutsara wereferensi ndiyo mutsara wepakati weiyo profil inoshandiswa kuongorora iyo roughness parameters. Kune marudzi maviri emitsara yereferensi: mutsetse diki weskweya wepakati wecontour: mukati meurefu hwesampling, hwerengedzo yema squares e contour offset madaro enzvimbo yega yega pamutsetse wecontour ndiyo idiki, uye ine geometric contour shape. . Iyo arithmetic inoreva mutsetse wepakati wecontour: mukati mekureba kwesampling, nzvimbo dzemakontours kumusoro uye pasi pemutsetse wepakati zvakaenzana. Nechifungidziro, iyo diki-skweya yepakati mutsara ndiyo yakanaka yekutanga, asi yakaoma kuwana mune inoshanda maapplication, saka kazhinji inotsiviwa nearithmetic kureva yepakati mutsara we contour, uye mutsara wakatwasuka une chinhambwe chingashandiswa shandura iyo panguva yekuyera.

6. Surface roughness evaluation parameters

1. Hurefu hunhu parameters

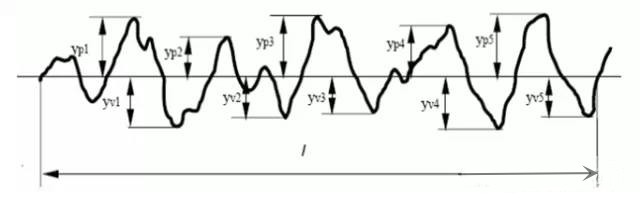

Ra profile arithmetic zvinoreva kutsauka: iyo arithmetic zvinoreva kukosha kwakakwana kwekutsauka kweprofile mukati me sampling urefu (lr). Mukuyera chaiko, kana huwandu hwemapoinzi ekuyerwa kwakawanda, ndiko kuwedzera kwakarurama kweRa.

Rz mbiri yepamusoro kureba: chinhambwe pakati peiyo mbiri peak mutsara uye mupata wepasi mutsetse.

Ra inosarudzwa mune yakajairwa huwandu hweamplitude paramita. Muchiyero chenyika pamberi pe2006, pakanga paine imwe yekuongorora parameter yaive "gumi-point urefu hwe micro-roughness" yakaratidzwa neRz, uye kureba kweiyo contour kwakaratidzwa naRy. Mushure megore ra2006, chiyero chenyika chakadzima hurefu hwemapoinzi gumi ehukukutu, uye Rz yakashandiswa. Inoratidza hurefu hwepamusoro hweprofile.

2. Spacing feature parameters

RsmAvhareji yehupamhi hwe contour elements. Mukati mesampling urefu, avhareji kukosha kwechinhambwe pakati pezvisina kujeka zveiyo profil. Iyo micro-roughness spacing inoreva kureba kweiyo profil peak uye iri padyo neprofile mupata pamutsetse wepakati. Muchiitiko cheiyo Ra kukosha, iyo Rsm kukosha haina kufanana, saka iyo inoratidzwa manyorerwo ichave yakasiyana. Mapeji anoteerera kuumbwa anowanzo teerera kune maviri maratidziro eRa neRsm.

TheRmrchimiro chechimiro paramende inomiririrwa nereshiyo yerutsigiro rwecontour, inova reshiyo yehurefu hwerutsigiro hwecontour kune urefu hwesampling. Kureba kwerutsigiro rweprofile ihwerengedzo yehurefu hwemitsara yechikamu yakawanikwa nekutenderedza chimiro nemutsara wakatwasuka unofambirana nepakati uye chinhambwe che c kubva pamutsetse wepamusoro mukati meurefu hwesampling.

7. Surface roughness measurement method

1. Kuenzanisa nzira

Inoshandiswa kuyera pa-saiti muwekishopu, uye inowanzoshandiswa kuyera nzvimbo dzepakati kana dzakakasharara. Nzira yacho ndeyekuenzanisa nzvimbo yakapimwa nemuenzaniso wekukwasha wamaka nehumwe hukoshi kuti uone kukosha kweiyo yakapimwa kukwasharara.

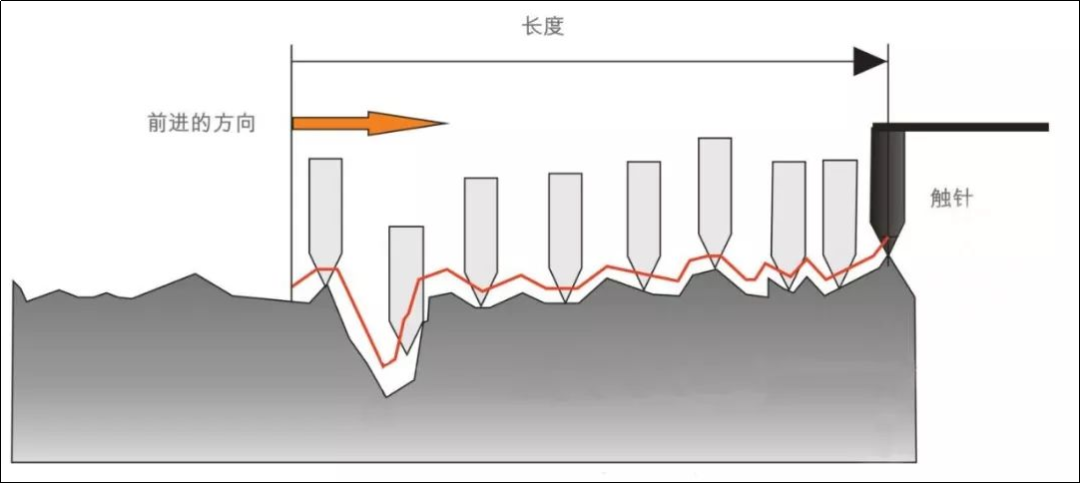

2. Stylus nzira

Kukasharara kwepamusoro kunoshandisa chinyoreso chedhaimani chine tip curvature radius inosvika 2 microns kutsvedza zvishoma nezvishoma panzvimbo yakayerwa. Iyo kumusoro nekudzika kusimuka kwedhaimani stylus inoshandurwa kuita chiratidzo chemagetsi nemagetsi kureba sensor, uye inoratidzwa nechiridzwa chekuratidzira mushure mekukwidziridzwa, kusefa, uye kuverenga. Iyo yepamusoro roughness kukosha inogona kuwanikwa, uye rekodha inogona zvakare kushandiswa kurekodha iyo mbiri curve yechikamu chakayerwa. Kazhinji, chiyereso chinongokwanisa kuratidza kukosha kwehukukutu hunodaidzwa kunzi chiyereso chepamusoro, uye icho chinogona kurekodha chikwiriso chepamusoro chinodaidzwa kunzi face roughness profiler. Aya maturusi maviri ekuyera ane maseketi ekuverenga emagetsi kana makomputa emagetsi, ayo anogona kungoverengera arithmetic zvinoreva kutsauka Ra ye contour, iyo gumi-point urefu Rz ye microscopic kusaenzana, kureba kwepamusoro Ry ye contour uye mamwe ma paramita ekuongorora, ane yakakwirira. kuyerwa kwekuita uye kwakakodzera Kuoma kwepamusoro kweRa ndeye 0.025-6.3 microns inopimwa.

Zvitsva zveAnebon zvekusingaperi ndiwo maitiro e "kutarisira musika, tarisa tsika, tarisa sainzi" uye dzidziso ye "mhando yekutanga, vimba yekutanga uye manejimendi epamberi" yeHot sale Factory OEM Service High Precision CNC Machining zvikamu zve otomatiki. indasitiri, Anebon quote yekubvunza kwako. Kuti uwane rumwe ruzivo, ndapota taura nesu, Anebon ichakupindura ASAP!

Kupisa kutengesa Factory China 5 axis cnc machining zvikamu, CNC yakashandura zvikamu uyekugaya mhangura chikamu. Tikugashirei kushanyira kambani yedu, fekitori uye yedu showroom inoratidzira zvakasiyana siyana zvekutengesa bvudzi zvinosangana nezvaunotarisira. Zvichakadaro, zviri nyore kushanyira webhusaiti yeAnebon, uye vashandi vekutengesa kweAnebon vanoedza nepavanogona napo kuti vakupe sevhisi yakanakisa. Ndokumbira utaure neAnebon kana iwe uine rumwe ruzivo. Chinangwa cheAnebon ndechekubatsira vatengi kuona zvinangwa zvavo. Anebon yanga ichiita nhamburiko huru kuti iwane iyi win-win mamiriro.

Nguva yekutumira: Mar-25-2023