Pfupiso yenzira sere dzekugadzirisa shinda iwe unofanirwa kuziva kana uchigadzira.

.Izwi rechirungu rinoenderana nerokuti Kumesa ndiko Kukurukuru. Zvinorehwa neshoko iri zvachinja zvakanyanya mumazana emakore achangopfuura. Kanenge muna 1725, zvinoreva "kusangana".

Kushandiswa kweiyo tambo musimboti kunogona kurondwa kumashure kune inotenderera mvura-yekusimudza chishandiso chakagadzirwa nenyanzvi yechiGiriki Archimedes muna 220 BC.

Muzana remakore rechina AD, nyika dzeMediterranean dzakatanga kushandisa musimboti wemabhaudhi nenzungu kumichina inoshandiswa mukugadzira waini. Panguva iyoyo, shinda yokunze yaimonerwa netambo pasimbi yobva yatemerwa maererano nechiratidzo ichi, nepo shinda yomukati yaiwanzogadzirwa nokurova shinda yokunze nezvinhu zvakapfava.

Akapoteredza 1500, muchidimbu chetambo yekugadzira tambo yakadhirowewa naItari Leonardo da Vinci, pakanga paine zano rekushandisa Screw yechikadzi uye giya rekuchinjana kugadzirisa tambo dzine mapikisi akasiyana. Kubva ipapo, nzira yekucheka shinda nemichina yakatanga muindasitiri yekugadzira wachi yeEurope.

Muna 1760, hama dzeBritain J. Wyatt naW. Wyatt vakawana patent yekucheka masiruu ehuni neimwe mudziyo. Muna 1778, muBritish J. Ramsden akambogadzira shinda-yekucheka shinda inotyairwa nehonye giya pair, iyo inogona kugadzira shinda refu nehupamhi hwepamusoro. Muna 1797, muRungu H. Maudsley akashandisa Screw uye giya rekuchinjana kushandura tambo dzesimbi dzemapiji akasiyana palathe yake yakavandudzwa, iyo yakaisa nzira yekutanga yekutenderedza shinda.

Mumakore ekuma1820, Maudsley akagadzira matepi ekutanga uye anofa nekuda kweshinda.

Mukutanga kwezana ramakore rechi20, kusimukira kweindasitiri yemotokari kwakawedzera kusimudzira kumisikidzwa kweshinda uye kuvandudzwa kwenzira dzakasiyana-siyana dzakanyatsonaka uye dzakasimba dzekugadzirisa shinda. Yakasiyana-siyana otomatiki yekuvhura misoro yekufa uye matepi anodzikira otomatiki akagadzirwa imwe mushure meimwe, uye shinda yekugaya yakatanga kuiswa.

Mukutanga kwema1930, kukuya kweshinda kwakaonekwa.

Kunyangwe tekinoroji yekutenderedza tambo yaive patent mukutanga kwezana ramakore re19, nekuda kwekuoma kwekugadzira mold, kusimudzira kwakawedzera kusvika Hondo Yenyika Yechipiri (1942-1945) nekuda kwekudiwa kwekugadzirwa kwezvombo uye kusimudzira tekinoroji yekukuya shinda. Dambudziko chairo rekugadzira mold rakakura nekukurumidza.CNC inoshandura chikamu

Shinda dzinonyanya kukamurwa kuita tambo dzekubatanidza uye tambo dzekutumira.

Nzira dzepakati dzekugadzirisa tambo dzekubatanidza tambo, kukanda, kupinza, kukanda tambo, tambo yekutenderedza, nezvimwe.

Nzira dzepakati dzekugadzirisa tambo dzekutumira dzakakasharara uye dzakatsetseka---kugaya, kugaya----yakakora uye kutenderera zvakanaka, nezvimwe.

Chikamu chekutanga ndechekucheka-shinda

Zvinowanzo reva machining shinda yekugadzira nekugadzira kana abrasive maturusi, kunyanya anosanganisira kutendeuka, kugaya, kubaya nekukuya shinda, kukuya, uye kucheka kwechamupupuri. Pakutenderedza, kugaya, uye kukuya tambo, cheni yekutyaira yemuchina wemuchina unova nechokwadi chekuti chishandiso chekutenderedza, chigayo chekucheka, kana vhiri rekukuya rinofamba nemazvo uye zvakaenzanirana lead imwe padivi peaxis yeworkpiece kune imwe neimwe shanduko yeworkpiece. Kana uchibaya kana shinda, chishandiso (pombi kana kufa) uye workpiece inotenderera kune mumwe nemumwe, uye yakamboumbwa shinda groove inotungamira chishandiso (kana workpiece) kufamba axially.

1. Kutenderedzwa kweshinda

Kubatidza shinda palatheti kunogona kuitwa nemudziyo wekutenderedza kana muzinga weshinda. Kutenderedza tambo nechishandiso chekugadzira inoshandura inzira yakajairwa yeimwe-chidimbu uye diki batch kugadzirwa kweshinda yakashongedzwa workpieces nekuda kweiyo yakapfava chishandiso chimiro; kushandura shinda neshinda yekubatanidza tambo ine yakakwira kugadzirwa kwehunyanzvi, asi chimiro chemidziyo chakaoma, chakakodzera kugadzirwa kwepakati uye hombe batch. Vari kushandura shinda pfupi yekushanda nenamo yakanaka. Iko kurongeka kwakaringana kweakajairwa lathes yekutenderedza trapezoidal shinda kazhinji inogona kungosvika 8 kusvika 9 mamakisi (JB2886-81, zvakafanana pazasi); machining shinda pahunyanzvi shinda lathes inogona zvakanyanya kunatsiridza kugadzirwa kana kurongeka.

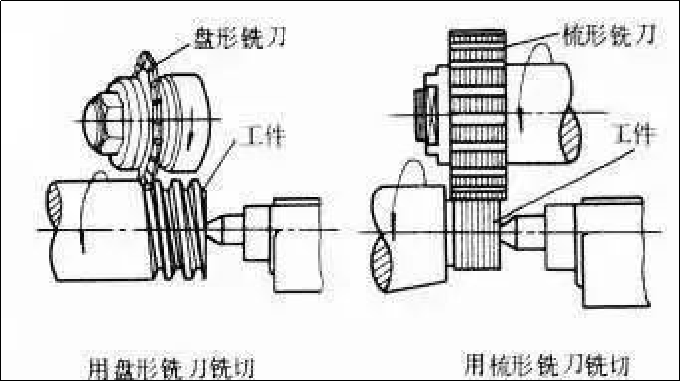

2. Kugaya shinda

Ndaigaya nedisc kana comb cutter pachigayo cheshinda.

Disc milling cutters anonyanya kushandiswa pakugaya trapezoidal ekunze shinda pane workpieces akadai screws uye makonye muzinga-zvakaita milling cutter rinoshandiswa pakugaya mukati uye kunze zvakajairika shinda uye tapered shinda. Sezvo yakagayiwa ne-multi-blade milling cutter uye kureba kwechikamu chayo chekushanda kwakakura kudarika kureba kweshinda, workpiece inoda chete kutenderedzwa 1.25 kusvika ku1.5 inotendeuka kuti igadziriswe uye iitwe nehukuru hwepamusoro. Hurukuro hwekugaya shinda hunogona kusvika pamagiredhi masere kusvika kupfumbamwe, uye kushata kwepamusoro iR5 kusvika 0.63 microns. Iyi nzira yakanakira kugadzira misa-ye threaded workpieces ye general precision kana roughing isati yakuya.

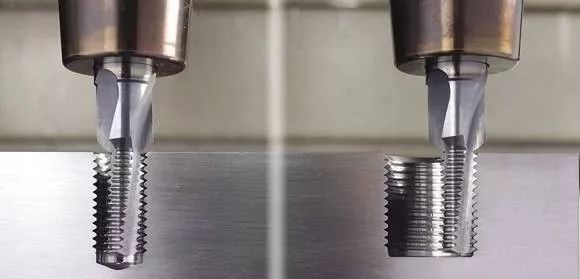

Thread milling cutter yekugadzira shinda dzemukati

3. Kukuya shinda

Inonyanya kushandiswa kugadzira tambo dzemachira akaomeswa pamichina yekukuya-shinda. Chimiro chemuchinjiko-chikamu chegumbo rekukuya chinogona kukamurwa kuva marudzi maviri: mutsara-mutsetse wekukuya vhiri uye yakawanda-mutsara inokuya vhiri. Kurongeka kwepitch kunowanikwa ne-single-line grinding wheel giredhi 5 kusvika 6 mamakisi, uye kushata kwepamusoro iR1.25 kusvika 0.08 microns, iri nyore pakugaya vhiri kupfeka. Iyi nzira yakanakira kukuya zvikukutu, shinda dzegeji, makonye, mabhechi madiki ezvishandiso zvine shinda, uye yekuyamura kugaya chaiko hobho. Multi-line grinding vhiri kugaya yakakamurwa kuita longitudinal uye plunge nzira dzekukuya. Munzira yokukuya nayo yelongitudinal, kufara kwevhiri kuduku pane kureba kweshinda inofanira kukuyiwa, uye vhiri rokukuya rinofamba kureba kamwe kana kuti kakawanda kukuya shinda kusvika pakukura kwekupedzisira. Hupamhi hwevhiri rekugaya nzira yekugaya yakakura kudarika urefu hweshinda ichagayiwa. Gumbo rekukuya rinochekwa radially mukati meiyo workpiece, uye workpiece inogona pasi zvakanaka mushure me 1.25 revolutions. Kugadzirwa kwacho kwakakwira, asi iko kurongeka kwakadzikira zvishoma, uye kupfeka kwegumbo kunowedzera kuoma. Plunge grinding yakakodzera kukuyamura kukuya mabheti mahombe epombi uye nekukuya tambo dzakati dzekusimbisa.aluminium extrusion zvikamu

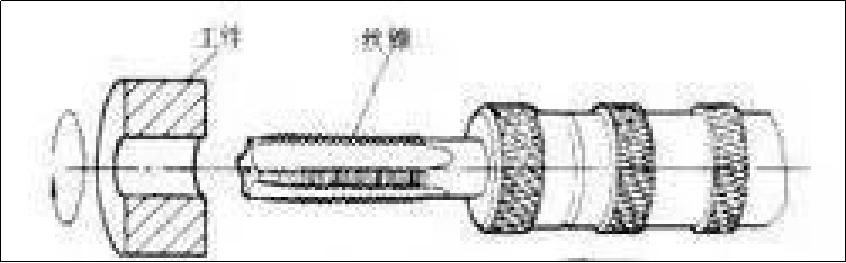

4. Kukuya shinda

Iyo nut-type kana screw-type thread grinder inogadzirwa nezvinhu zvakapfava sesimbi yakakandwa, uye zvikamu izvo shinda ine pitch kukanganisa pane workpiece inoiswa kumberi uye kudzosera kumashure kutenderera kukuya kuti kunatsiridza huronyo. Shinda dzemukati dzakaomeswa dzinowanzoitwa pasi kuti dzibvise deformation uye kunatsiridza kurongeka.

5. Kubata uye kupinza

Tapping

Iko kukwenya pombi mugomba repasi rakafanocherwa pane workpiece ine torque chaiyo yekugadzirisa shinda yemukati.

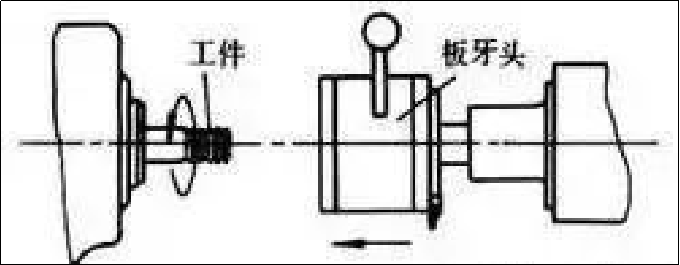

Thread

Cheka shinda yekunze pabhari (kana pombi) workpiece ine difa. Kurongeka kwemachina ekutepa kana kupinza kunoenderana nekurongeka kwepombi kana kufa.zvikamu zvealuminium

Kunyangwe paine nzira dzakawanda dzekugadzirisa tambo dzemukati nekunze, diki-dhayamita dzemukati tambo dzinogona kungogadziriswa nemapombi. Kurovera nekurukisa kunogona kuitwa nemaoko, pamwe chete nemichina, michina yekutepfenyura, nemichina inopinza.

Chikamu chechipiri: Thread rolling

Iyo nzira yekugadzirisa yeplastically deforming iyo workpiece ine yekugadzira rolling die kuti uwane shinda. Thread rolling inowanzoitwa pamuchina weThread rolling kana otomatiki lathe ine otomatiki kuvhurika uye kuvhara Thread rolling musoro, tambo yekunze yekugadzirwa kwakawanda kwemafasteners akajairwa, uye mamwe machira akasungwa. Iyo dhayamita yekunze yeiyo yakakungurutswa Thread isThreadally isingasviki 25 mm, kureba hakuna kupfuura 100 mm, iyo tambo yechokwadi inogona kusvika padanho 2 (GB197-63), uye dhayamita reiyo isina chinhu yakashandiswa inokwana kuenzana nedhayamita yepitch. ye Thread yakagadziriswa. RTthread kazhinji haigone kugadzira tambo dzemukati, asi kune zvekushandisa zvine zvinyoro zvinyoro, tepi isina grooveless extrusion inogona kushandiswa kutonhora-inoburitsa tambo dzemukati (iyo yakakwira dhayamita inogona kusvika 30 mm). Nheyo yekushanda yakafanana neyekutapa. Iyo torque inodiwa pakutonhora kuwedzeredzwa kwetambo dzemukati yakakura kakapetwa ka1 pane iyo yekutepa, uye iko machining echokwadi uye epamusoro mhando yakakwira zvishoma pane iyo yekutepa.

Zvakanakira zve Thread rolling:

①Kushata kwepamusoro idiki pane kupinduka, kukuya, nekukuya;

②Pamusoro peThread afThreadlling inogona kuvandudza kusimba uye kuoma nekuda kwekutonhora kwebasa kuoma;

③Chiyero chekushandiswa kwezvinhu chakakwira;

④Kubereka kwakapetwa kaviri zvichienzaniswa nekucheka, uye zviri nyore kuziva otomatiki;

⑤ Hupenyu hwekukunguruka hwakareba. Nekudaro, rolling Thread reThread kuti kuoma kweiyo workpiece zvinhu hakupfuuri HRC40; kurongeka kwedimensional kwechisina chinhu kwakakwirira; iyo chaiyo uye kuoma kweiyo rolling die zvakare yakakwirira, uye zvakaoma kugadzira iyo die; haina kukodzera kukungurutsa shinda ine asymmetric mazino chimiro.

Zvinoenderana neyakasiyana-siyana inofa, Thread inogona kupatsanurwa kuita mhando mbiri: Thread rolling uye Threadthreadd.

6. Thread rolling

Mahwendefa maviri eshinda anokunguruka ane shinda yemazino maumbirwo akarongwa akatarisana neimwe neimwe ine 1/2 pitch; iyo static plate inogadziriswa, uye ndiro inofamba inofamba mumutsara unodzokorora wekufamba uchienderana neiyo static plate. Kana workpiece inotumirwa pakati pemahwendefa maviri, ndiro inofamba inoenda mberi uye inokwesha workpiece kuti plastically deform pamusoro kuumba shinda (Figure 6 [Screwing]).

7. Thread rolling

Kune marudzi matatu eiyo radial Thread roThread, tangential Thread roThread, uye inotenderedza musoro shinda.

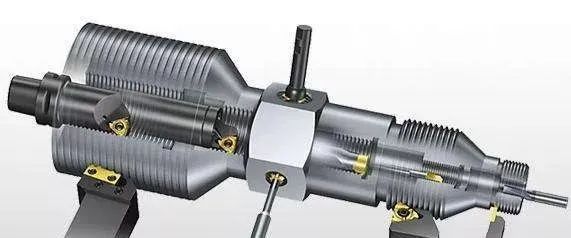

①Radial Threathreadad 2 (kana 3) shinda inotenderedza mavhiri ane shinda profiles akaiswa pane anowirirana shafts; iyo workpiece inoiswa pachitsigiro pakati pemavhiri maviri, uye mavhiri maviri anotenderera nenzira imwechete uye panguva imwechete (Mufananidzo 7). [Radial Thread rolling]), imwe yematenderedzwa, inoitawo radial feed motion. Iyo tambo inotenderedza vhiri inotenderedza iyo workpiece, uye pamusoro pacho inokwidibirwa neradially kuita shinda. Kune mamwe masikuru ekutungamirira ayo asingade kunyatsojeka, nzira yakafanana inogona kushandiswawo kugadzira roll.

②Tangential Thread roThread Inozivikanwawo seplanetary Thread roThread, chishandiso chinotenderedza chine chinotenderera chepakati chetambo chinotenderedza vhiri uye matatu akagadzika arc-shaped mahwendefa eshinda (Fig. 8 [Tangential Thread rolling]). Iyo workpiece inogona kuramba ichidyiswa panguva yeTread thread, saka chibereko chakakwira kupfuura icho che Thread roThreadand radial Thread thread.

③ Thread yakadzokororwazve: Inoitwa pane otomatiki lathe uye inowanzo shandiswa kugadzira mapfupi shinda pane workpiece. Pane 3 kusvika 4 shinda inomonereka mavhiri akagovaniswa padivi pekunze kweiyo workpiece mumusoro unomonereka (Fig. 9 [Thread rethreaded rolling]). Munguva yekutenderedzwa kweshinda, iyo workpiece inotenderera, uye iyo inotenderedza musoro inodyisa axially kukungurutsa workpiece kubva muThread.

Thread threading

Kugadziriswa kwetambo dzakajairwa kunowanzo shandisa machining nzvimbo kana tepi michina uye maturusi; dzimwe nguva, kubata nemaoko kunogonekawo. Nekudaro, mune zvimwe zviitiko zvakasarudzika, iyo nzira iri pamusoro haisi nyore kuwana yakanaka yekugadzirisa mhedzisiro, senge kudiwa kwemuchina tambo mushure mekupisa kurapwa kwezvikamu nekuda kwekuregeredza kana nekuda kwekumanikidza kwezvinhu, sekuda kwekubaya zvakananga pane carbide workpieces. . Panguva ino, zvakakosha kufunga nezvepEDM yekugadzirisa nzira.

Kuenzaniswa nemaitiro ekugadzira, chirongwa che EDM chiri muhutano hwakafanana: gomba rezasi rinoda kutanga, uye hupamhi hwegomba rezasi hunofanira kugadziriswa maererano nemamiriro ekushanda. Iyo electrode inoda kugadzirwa kuita shinda chimiro, uye electrode inoda kukwanisa kutenderera panguva yekugadzira machining.

Anebon Metal Products Limited inogona kupa CNC Machining, Die Casting, Sheet Metal Fabrication service, ndapota inzwa wakasununguka kutibata nesu.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Nguva yekutumira: Kubvumbi-15-2022