Iwe unoziva here kuti ingani nzira dziripo dzechaiyo chishandiso kuseta paCNC lathes?

Bata Probe Method: -Iyi nzira inoshandisa probe inobata chishandiso kuyera chinzvimbo chayo maererano nemuchina wekutarisa point. Inopa data rakarurama padhayamita yechishandiso uye kureba.

Tool Pre-Setter:Chishandiso-pre-setter fixture chinoshandiswa kuyera zviyero zvechishandiso kunze kwemuchina. Iyi nzira inobvumira kukurumidza uye kwakaringana kuseta kwechishandiso.

Tool Offset Method:- Munzira iyi, mushandisi anoyera kureba uye dhayamita yechishandiso achishandisa maturusi akadai semacaliper nemamicrometer. Izvo zvakakosha zvinobva zvapinzwa mumuchina wekutonga system.

Laser Tool kuyerwa:Laser masisitimu anoshandiswa kuseta uye kuyera maturusi zviyero. Nekurojera danda relaser mwenje pakucheka kwechishandiso, ivo vanopa chaiyo uye nekukurumidza chishandiso data.

Nzira yekucherechedza mufananidzo:Masisitimu emakombuta epamberi anogona kushandisa tekinoroji yekuziva mifananidzo kuti averenge otomatiki zviyero zvematurusi. Vanoita izvi nekutora mifananidzo yechishandiso, vachiongorora maitiro ayo uye vobva vaverenga zviyero.

Ichi chinyorwa chinobatsira zvikuru. Chinyorwa chinosuma kutanga misimboti uye mazano ari seri kwe "yekuedza-kucheka-chishandiso-kugadzirisa nzira" iyo inowanzoshandiswa neCNC lathes. Inobva yaunza nzira ina dzemanyorero dzekuyedza yekucheka maturusi magadzirirwo eCNC anoshandura masisitimu. Kuti uvandudze kurongeka kwezvigadziriso zvezvishandiso zvayo, chirongwa chinodzorwa otomatiki kuedza kucheka nzira yakavakirwa pa "otomatiki kucheka - kuyera - kukanganisa kukanganisa" yakagadzirwa. Nzira ina dzakarurama dzekuseta maturusi dzakapfupikiswawo.

1. Nheyo uye mazano kuseri kwechishandiso-kugadzirisa nzira yeCNC lathes

Kunzwisisa CNC lathe tool-setting misimboti yakakosha kune vashandisi vanoda kuchengeta pfungwa dzakajeka nezve-turusi-setting, master tool-setting mashandiro, uye kupa mazano matsva. Kugadzika kwechishandiso kutarisisa kwakabva chinzvimbo cheiyo workpiece coordinates system, iyo inochinja kana ichigadzira muchina chishandiso chinoronga system. Kumisikidzwa kwechishandiso kunosanganisira kuwana magadzirirwo emuchina kwekutanga kwechirongwa chereferenzi rekushandisa, uye kuona chishandiso chekugadzirisa chinoenderana nechishandiso ichocho.

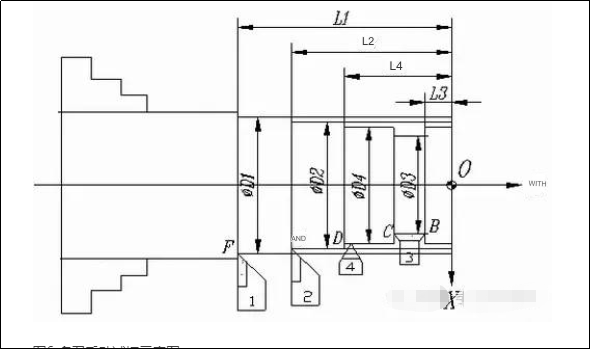

Zvibvumirano zvinotevera zvinoshandiswa kuratidza pfungwa uye mazano ari kumashure kwechigadziro chekushandisa uchishandisa nzira yekucheka yekuedza. Shandisa Hua Medieval Star Teaching Turning System (vhezheni nhamba 5.30 yesoftware software); shandisa iyo yepakati yekurudyi kumagumo kumeso pane yebasa rekutanga chirongwa uye woimisa neiyo G92 command. Diameter programming, workpiece kurongeka kwepurogiramu yekutanga poindi H iri (100,50); isa maturusi mana pachibatiso. The tool No.1 i90deg rough turning tool uye Nha. banga, Kwete. Banga rechina ndiro banga rine shinda ine 60deg angle (mienzaniso munyaya yacho yose yakafanana).

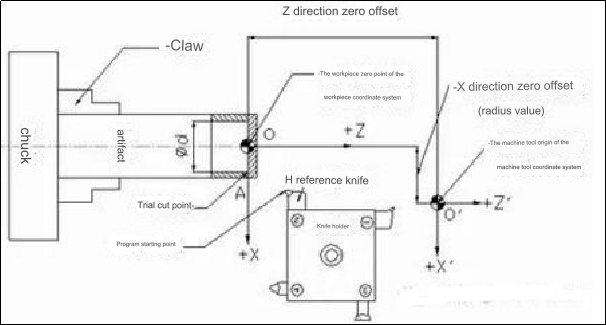

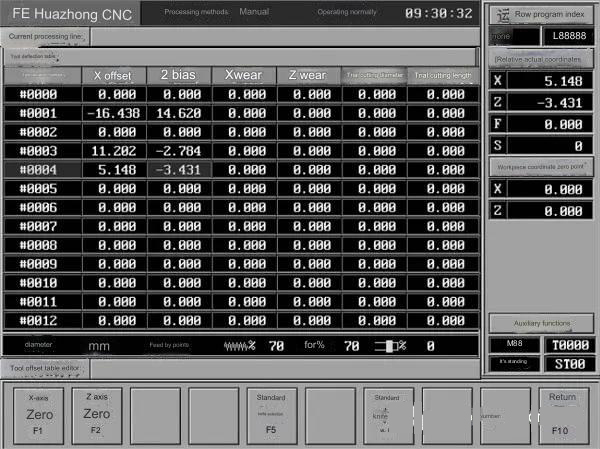

Iyo "chishandiso chemuchina" inorongedzerwa inoshandiswa pakuseta chishandiso. Sezvinoratidzwa mumufananidzo 1, chishandiso chereferenzi "yedzo yemaoko inocheka denderedzwa rekunze uye yekupedzisira kumeso kwechishandiso uye inorekodha XZ muchina wekushandisa kurongeka pachiratidziro. Chishandiso chemuchina chinorongedzerwa chechirongwa cheO chinotorwa kubva pahukama pakati pemakina emuchina anoronga panzvimbo A uye O: XO=XA - Phd, ZO=ZA. Tichishandisa iyo workpiece inorongedzerwa yeH maererano neinongedzo O (100,50), isu tinogona pakupedzisira kutora maturusi emuchina anorongedzerwa point H: XH=100 - Phd, ZH=ZA+50. Iyi workpiece coordinate system yakavakirwa pane chinzvimbo chetipi rekushandisa pane referensi chishandiso.

Mufananidzo 1 Schematic dhayagiramu yemanyorero ekuyedza kucheka uye maturusi marongero

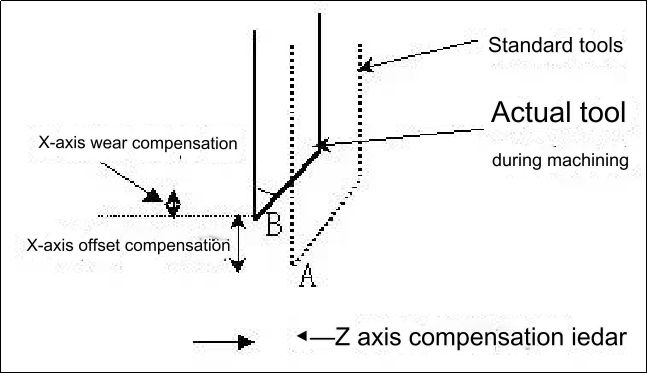

Mumufananidzo 2, kukanganisa pakati pepoindi A nechokushandisa tip B kunoitika nekuda kwekusiyana kwekuwedzera uye zvinzvimbo mu X- uye Z-direction yezvishandiso zvakadzvanywa mumudziyo wemidziyo. Iyo yekutanga coordinate system yeworkpiece haichashanda. Chishandiso chega chega chichapfekawo pachiyero chakasiyana panguva yekushandiswa. Naizvozvo, chishandiso chinobvisa uye kupfeka kukosha kune yega yega chishandiso chinofanira kubhadharwa.

Kuti uone chigadziriso chekushandisa, chishandiso chega chega chinofanirwa kuenderana kune yakatarwa nzvimbo (point A kana B muMufananidzo 1) pane workpiece. Iyo CRT inoratidza maturusi emuchina anorongedzerwa akasiyana kubva kune maturusi ekubvisa ezvisiri-reference maturusi. Nokudaro, vakaiswa panzvimbo imwe chete. Nekushandisa kuverenga kwemaoko kana kuverenga software, makongisheni emuchina anobviswa kubva kune ayo echishandiso chekutarisa. The tool offset inobva yaverengerwa kune yega yega isiri-standard mudziyo.

Mufananidzo 2 Kubhadharwa kwechishandiso chekugadzirisa uye kupfeka

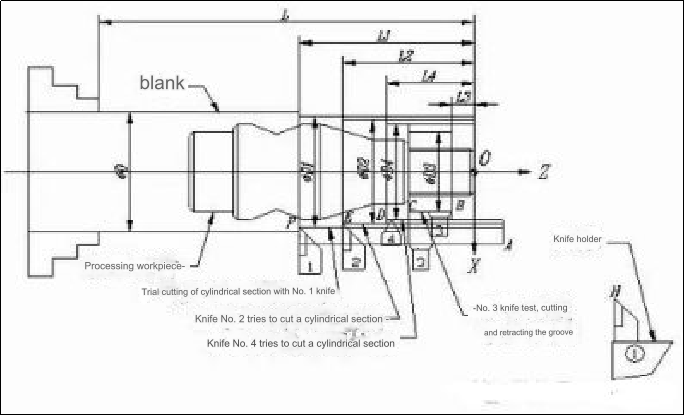

Kurongeka kwemanyorero ekucheka maturusi ezvishandiso ane mashoma. Izvi zvinozivikanwa se rough tooling. Sezvinoratidzwa muFigure 3, kuti uwane mibairo yakanyatsojeka mukati memichina yekubvumidzwa kweiyocnc auto chikamu, iri nyore otomatiki yekucheka chirongwa chekucheka chinogona kugadzirwa. Banga rereferenzi rinoramba richigadziriswa uchishandisa pfungwa ye "otomatiki yekucheka-chiyero-chikanganiso muripo". Chishandiso chekudzikisa uye chirongwa chekutanga cheiyo isiri referensi chishandiso chinoshandiswa kuve nechokwadi chekuti mutsauko uripo pakati pekukosha kwemurayiridzo wekugadzirisa uye kukosha chaiko kwakayerwa kunosangana nezvinodiwa. Precision chishandiso kuseta ndiko kuseta kweturusi kunoitika panguva ino.

Zvakajairika kugadzirisa zvisiri-standard offsets mushure mekugadzirisa kwekutanga. Izvi zvinodaro nekuti kuve nechokwadi chekuti nzvimbo yereferensi yekutangisa ndeyechokwadi chinhu chinodiwa kuti zvigadzirise maturusi chaiwo.

Iyi yakakosha maturusi ekumisikidza maitiro anowanikwa nekubatanidza aya maviri matanho: iwe pachako edza cheka banga nereferensi yekuwana maturusi emuchina anorongedzerwa kwechishandiso kuseta referensi. -Kareta kana otomatiki kuverengera zvigadziriso zvechishandiso chimwe nechimwe chisiri chereferensi. -Banga rereferenzi riri padanho rekutanga rechirongwa. -Iyo banga rereferenzi rinodzokorora kudaidza chirongwa chekucheka bvunzo. Iyo inobata chishandiso inofambiswa muMDI kana nhanho modhi kutsiva zvikanganiso uye kugadzirisa nzvimbo yekutanga. Mushure mekuyera saizi iyo isiri base banga inodzokorodza kudaidza chirongwa chekuyedza-chekucheka. Chishandiso chekubvisa chinogadziriswa zvichibva pane iyi offset. Izvi zvinoreva kuti chishandiso chereferensi chichange chakamira pakutanga chaiko kwechirongwa.

Mufananidzo 3 Schematic Diagram yeTool Setting for Multi-Knife Trial Cutting

Muchidimbu nezve rough mapanga kuseta matekiniki

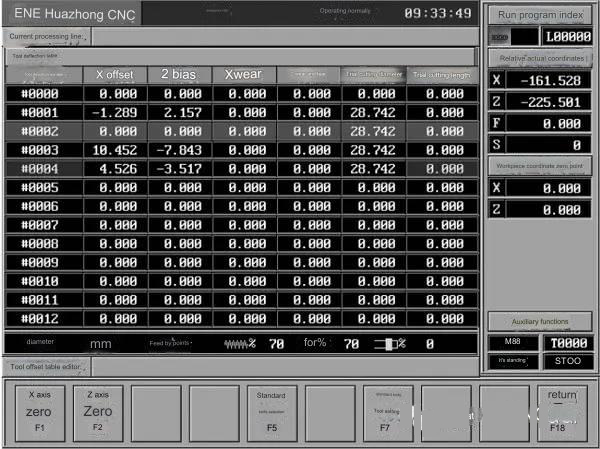

Kuti ugadzirire kuseta-turusi, unogona kushandisa chero ipi yeiyi nzira dzinotevera: dzvanya kiyi yeF2 mune submenu yeMDI system kuti uwane iyo chishandiso offset tafura. Shandisa makiyi kuti ufambise bhara rekusimudzira kuenda kunzvimbo yenhamba yezvishandiso inoenderana nechishandiso chimwe nechimwe uye tinya bhatani reF5. Shandura iyo X uye Z yekubvisa kukosha kwechishandiso chekubvisa nhamba #0000 uye #0001, wobva wadzvanya kiyi F5.

1) Seta otomatiki nzira yekumisa chishandiso nekusarudza chishandiso chereferenzi.

Matanho ekuseta chishandiso anoratidzwa muFigure 1 ne4.

Iyo bhawa yebhuruu yakasimbiswa nemakiyi inogona kufambiswa kuti ienderane nemudziyo wekubvisa #0002 yeNo. Reference tool 2. Kuseta Nha.2, dzvanya kiyi F5. Chishandiso che2 chinozoiswa sechishandiso chekare.

2) Cheka denderedzwa rekunze nereferensi yekushandisa uye cherechedza iyo X muchina-chishandiso chinoronga. Mushure mekudzoreredza chishandiso, misa muchina uye kuyera dhayamita rekunze rechikamu cheshaft.

3) Iyo yereferensi blade inodzokera kunzvimbo A yakanyorwa ne "jog + nhanho" nzira. Pinza PhD uye zero mumakoramu ekucheka dhayamita yebvunzo uye kureba kwekucheka kwebvunzo zvakateerana.

4) Dzorera chishandiso chakajairika uye sarudza nhamba yeisina standard chishandiso. Zvadaro, manually chinja turusi. Chishandiso chekushandisa chega chega chisiri-chiyero chinofanirwa kuenderana nekuona nepoint A uchishandisa "jog + nhanho" nzira. Gadzirisa iyo inoenderana inogadzirisa mushure mekunge chishandiso chaenderana nekuona. Kana iwe ukapinda zero nePhD mumakoramu eyedzo yekucheka kureba uye dhayamita, mapanga anobvisa eese asina-referenzi mapanga anozongoratidzwa muX offset uye Z offset column.

5) Kana chishandiso changodzokera kunzvimbo A, MDI ichamhanya "G91 G00/kana" G01 X[100 PhD] Z50 kuti isvike panotangira chirongwa.

Mufananidzo 4 Schematic dhayagiramu yechishandiso chereferenzi inogadzirisa otomatiki chishandiso chekushandisa cheyakajairwa chishandiso

2. Seta zvinorongeka zvechishandiso chereferenzi kusvika zero panzvimbo yekunongedza chishandiso uye wobva waratidza otomatiki nzira yekubvisa chishandiso.

Sezvinoratidzwa muFigure 1 uye Figure 5, matanho ekugadzirisa maturusi ndeaya anotevera:

1) Zvakafanana nedanho (2) pamusoro.

2) Iyo yereferensi banga inodzokera kune yekuyedza yekucheka point A kuburikidza ne "jog + nhanho" nzira maererano nekukosha kwakanyorwa.

3) Muchiratidziro chinoratidzwa muMufananidzo 4, shandisa kiyi yeF1 kuti "isa X-axis kusvika zero" uye shandisa kiyi F2 kuti "seta Z-axis kusvika zero". Ipapo "hama chaidzo makongisheni" anoratidzwa neCRT ndeaya (0, 0).

4) Nemaoko shandura iyo isiri-reference tool kuitira kuti chigadziro chayo chekushandisa chionekwe chienderane nechombo A. Panguva ino, kukosha kwe "hukama chaihwo kurongeka" kunoratidzwa paCRT ndicho chigadziro chekugadzirisa kwechigadziro chinoenderana nereferensi yekushandisa. Shandisa ▲ nemakiyi kufambisa yebhuruu Simbisa nhamba yemudziyo wemudziyo wechinhu chisiri chereferensi, rekodha uye woisa panzvimbo inoenderana.

5) Zvakafanana nedanho rekare (5).

Mufananidzo 5 Schematic Dhiagiramu yeTool Offset inoratidzwa otomatiki kana Reference Tool yaiswa pazero mumidziyo yekumisikidza mareferenzi anoronga.

3. Iyo nzira yekubvisa banga inoverengerwa nekuverenga nemaoko kucheka kwekuyedza nemapanga akawanda ekunze denderedzwa shaft segment.

Sezvinoratidzwa mumufananidzo 6, sisitimu inogadzirisa mapanga 1, 2 uye 4 uye inocheka axis. Inobva yarekodha marongedzero emuchina kune magumo ekucheka kwebanga rega rega. (Pfungwa F, D, uye E mumufananidzo 6). Eresa dhayamita nehurefu hwechikamu chimwe nechimwe. Tsiva Nhamba 1 yekucheka banga. Sezvinoratidzwa mumufananidzo, cheka recess yekushandisa. Gadzirisa blade yekucheka neyekurudyi tipi, rekodha marongero epoinzi B uye kuyera L3 nePhD3 maererano nenhamba. Kuwedzera kurongeka kwehukama pakati peF, E uye D mapoinzi pachishandiso chega chega, uye O mavambo anogona kutariswa nekuenzanisa data riri pamusoro.

Zvinogona kuoneka kuti maturusi emuchina anorongedzerwa ari (X2-PhD2+100 uye Z2-L2+50) uye maturusi emuchina anorongedzerwa echirongwa chekutanga chinoenderana nereferenzi chishandiso. Nzira yekuverenga inoratidzwa mune tafura 1. Muzvinyorwa, pinda maitiro akaverengwa uye akanyorwa. Ongorora: Muyedzo wekucheka chinhambwe chinhambwe pakati peiyo coordination zero point yeworkpiece uye yekupedzisira poindi yemuyedzo yakachekwa muZ-direction. Positive and negative directions inotarwa necoordinate axis.

Mufananidzo 6 Schematic dhayagiramu yeakawanda-banga manyore yekuyedza yekucheka

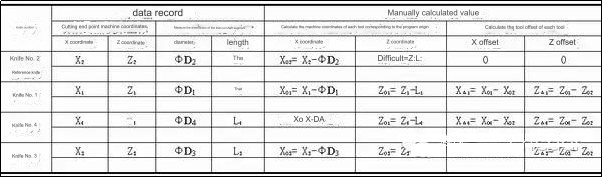

Tafura 1 Kuverengera kwezvishandiso zvigadziriso zvezvisina-standard Zvishandiso

Iyi nzira inobvumira nzira yakapusa yekucheka bvunzo, sezvo inobvisa kudiwa kwekuona kurongedza bvunzo dzekucheka mapoinzi. Nekudaro, iyo yekubvisa banga inofanira kuverengerwa nemaoko. Iwe unogona kuverenga chishandiso chekugadzirisa nekukurumidza kana iwe ukadhinda pepa neformula wobva wazadza izvo zvisina.

Mufananidzo 7 Schematic dhayagiramu ye otomatiki chishandiso kuseta paCentury Star CNC system

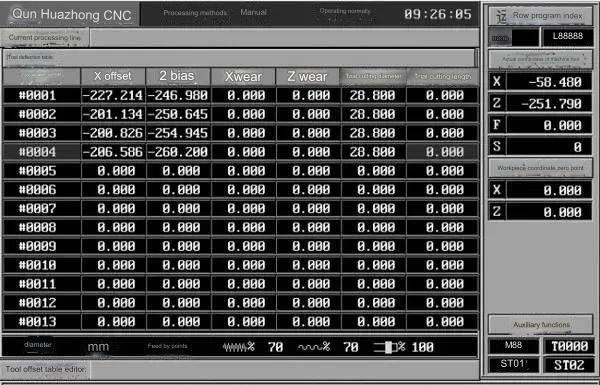

Multi-turusi otomatiki chishandiso seti nzira ye4th Century Star CNC system

Yese nzira dzataurwa pamusoro apa dzekubvisa chishandiso inzira dzine hukama. Mushure mekunge vashandi vehunyanzvi vaita paramende yekumisikidza uye kuyedza system, HNC-21T inobvumira vashandisi kusarudza iyo "absolute offset nzira" pakumisikidza maturusi. Mune machining programming, iyo mhedziso yekushandisa yekubvisa yati siyanei pane yehukama chishandiso off nzira. Izvo hazvifanirwe kushandisa G92 kana G54 kune iyo workpiece kurongedza masisitimu, uye hazvifanirwe kudzima muripo wechishandiso. Ona chirongwa O1005 semuenzaniso. Sezvinoratidzwa mumufananidzo 6, mushure mekunge system yadzokera ku zero, rega banga rega riedze nemaoko kucheka chikamu checylinder.

Dzadza manhamba echishandiso chekubvisa chebanga rega rega mushure mekuyera kureba nedhayamita. Kureba kwekucheka kwekuedza kwakanyorwa mumutsara wekuedza kucheka dhayamita. Iyo system software, uchishandisa nzira inotsanangurwa mu "Multiknife Kucheka kweKunze Shaft Segment - Manual Calculation for Knife Offset", inogona kuverenga otomatiki iyo muchina chishandiso chinorongedzerwa banga rega rega zvichienderana nekwakabva chirongwa. Iyi nzira yekuisa maturusi ndiyo inokurumidza, uye inonyanya kukodzera kugadzirwa kwemaindasitiri.

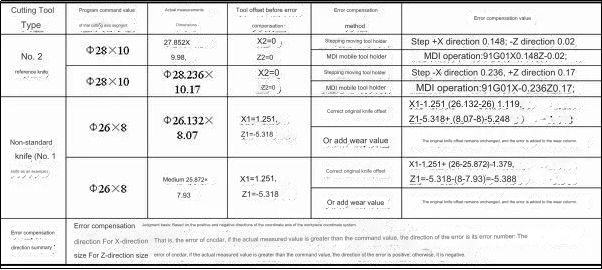

Pfupiso yenzira shanu dzakarurama dzekugadzirisa maturusi

Nheyo yeiyo chaiyo yekumisikidza maturusi ndeye "otomatiki kuyerwa, otomatiki kuedza kucheka uye kukanganisa muripo". Muripo wekukanganisa unogona kukamurwa kuita zvikamu zviviri: Zvereferensi yekushandisa MDI, kana nhanho inofambisa maturusi maturusi kutsiva kwayo chirongwa chekutanga chinzvimbo; uye kune isiri-yakajairwa chishandiso kutsiva chishandiso chayo kubvisa kana kupfeka kukosha. Kuti udzivise kuvhiringidzika, Tafura 2 yakagadzirirwa kuverenga uye kunyora kukosha.

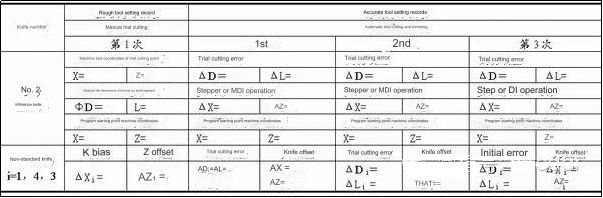

Tafura 2 Tool Setting Record Tafura yeKuedza Kucheka Nzira (Uniti: mm

1. Shandura nzira yekubvisa kune yega yega isiri-yakajairwa chishandiso mushure mekunge mudziyo wekutarisa wagadzirisa panotangira.

Matanho ekuseta chishandiso anoratidzwa muMufananidzo 3.

Mushure mekuita rough tool calibration, chishandiso chereferensi chinofanira kunge chiri pakutanga kwechirongwa. Pinda iyo yekubvisa yega yega isiri-yakajairwa chishandiso munzvimbo yakakodzera yetafura.

Shandisa chirongwa cheO1000 kugadzirisa PhD2xL2 kuitira kuti ucheke muyedzo.

Zvadaro, kuyera dhayamita uye kureba kwechikamu chekucheka shaft, zvienzanise nekukosha muchirongwa chekuraira, uye ona chikanganiso.

Shandura nzvimbo yekutanga yechirongwa kana iyo MDI kukanganisa kukosha kana nhanho kufamba yakakura kupfuura iyo MDI kukanganisa kukosha.

5) Shandura iyo O1000 yekuraira kukosha zvine simba zvichibva pane yakayerwa zviyero uye chengetedza chirongwa. Dzokorora nhanho (2) kusvika nzvimbo yekutanga yereferensi yekushandisa iri mukati meiyo renji renji. Ziva kurongeka kwemuchina-chishandiso chekutanga chirongwa chakagadziriswa. Isai macoordinates pa zero.

6) Dhonza iyo O1001 (banga no. 1, No. O1002 (banga no. 3) yega yega yekuedza kucheka, uye kuyera urefu Li (i = 1, 2, 3) uye dhayamita PhDi yechikamu chimwe nechimwe.

7) Kutsiva zvikanganiso uchishandisa tafura 3 nzira.

Dzokorora nhanho 6 kusvika ku7 kusvika zvikanganiso zvekugadzira zviri mukati mehuwandu hwechokwadi uye chigadziro chekutsvaga chinomiswa pakutanga kwepurogiramu uye hachifambi.

Tafura 3 Muenzaniso wekukanganisa muripo weotomatiki kuyedza kucheka kwecylindrical shaft zvikamu (unit: mm).

2. Kugadzirisa nzvimbo yekutanga yechishandiso chimwe nechimwe

Iyi nzira yekumisikidza dhizaini ndeyekuti chishandiso chega chega chinogadzirisa nzvimbo yayo yekutanga chirongwa, nekudaro ichienderana neyakafanana nzvimbo yekutanga.

Matanho ekuseta chishandiso anoratidzwa muMufananidzo 3.

Mushure mekugadzirisa zvigadziriso zvematurusi, Nha. Mushure mekugadzirisa zvigadziro zvekugadzirisa uye kurekodha zvigadziriswe, Nhamba ye2 yereferensi inofanira kunge iri pakutanga kwepurogiramu.

Matanho 2) kusvika (5) ekutanga akarurama-maturusi ekugadzirisa maitiro akafanana.

Shandisa chirongwa cheO1000 kuita muyedzo wekucheka. Edza kureba Li uye dhayamita PhDi yechikamu chimwe nechimwe.

Iyo nhanho yekufambisa chishandiso kana MDI mudziyo inobata inotsiva zvikanganiso uye inogadzirisa yega yega chirongwa chekutanga.

Dzokorora nhanho (6) kusvika nzvimbo yekutanga yega yega isiri-standard chirongwa chekushandisa chiri mukati mehuwandu hwechokwadi hunobvumidzwa.

The tool offset table inogona kuwanikwa nekuisa hukama hwehukama hunoratidzwa paCRT mu X offset uye Z offset column inoenderana nenhamba yemudziyo wekugadzirisa. Iyi nzira iri nyore uye iri nyore. Iyi nzira iri nyore uye yakanakira.

3. Shandura nzira dzose dzekugadzirisa kune zvisiri-standard zvishandiso panguva imwe chete mushure mekugadzirisa nzvimbo yekutanga yepurogiramu yereferensi yekushandisa.

Mutoo wacho wakafanana neyekutanga kwakarurama kwekushandisa-setting method. Misiyano chete pakati pezviviri ndeyokuti muchikamu chechinomwe, chirongwa cheO1003 chinonzi, chinoshevedza mapanga matatu panguva imwe chete (O1004 inobvisa Nha.

6. Mapanga mana anogona kugadziriswa kamwechete uchishandisa nzira iyi

Kuti uwane mhosho yekugadzira, pima dhayamita yechikamu chimwe nechimwe, PhDi, uye kureba kwechikamu chimwe nechimwe, Li (i=2, 1, 4), uchishandisa nzira yakabatana-yekugadzirisa. Shandisa MDI kana nhanho kufamba kune iyo inobata chishandiso chereferenzi chishandiso. Shandura purogiramu yekutanga. Pazvishandiso zvisina mwero, tanga wagadzirisa chigadziriso uchishandisa yekutanga offset. Wobva waisa iyo itsva offset. Iko kutadza kwekugadzira kwechishandiso chereferensi kunofanirwawo kuiswa mune inopfeka column. Fonera iyo O1005 muyedzo yekucheka chirongwa kana iyo yakakwana chishandiso kumisa ichishandiswa kuyera chishandiso. Zvadaro, dzorera kukanganisa kwekugadzira kwezvishandiso mumakoramu ezvipfeko zvenhamba dzavo dzekushandisa.

Ndeipi mhedzisiro inosarudza iyo chaiyo chishandiso kuseta nzira yeCNC lathes ine pamhando yeCNC machining zvikamu?

Kururama uye nemazvo:

Zvishandiso zvekucheka zvichave zvakanyatsoenderana kana chigadziro chikaiswa zvakanaka. Izvi zvinokanganisa zvakananga kurongeka uye kurongeka mumabasa emuchina. Kurongeka kweturusi kusiri iko kunogona kukonzera kukanganisa kwedimensional, kushata kwepamusoro kupera, uye kunyange zvimedu.

Kuenderana:

Consistant maturusi marongero anovimbisa kufanana kwekuita kwemuchina uye kunoenderana mhando muzvikamu zvakawanda. Inoderedza misiyano pakupedzisa kwepamusoro uye zviyero, uye inobatsira kuchengetedza kushivirira kwakasimba.

Upenyu hweTool uye Toolwear:

Nekuve nechokwadi chekuti chishandiso chakanyatsobatanidzwa neworkpiece, iyo chaiyo yekumisikidza chishandiso inogona kuwedzera hupenyu hwechishandiso. Zvisizvo zvigadziriso zvematurusi zvinogona kukonzera kupfeka kwakanyanya uye kuputsika kwezvishandiso, izvo zvinoderedza hupenyu hwematurusi.

Kubudirira uye Kubudirira

Maitiro ekugadzirisa maturusi anogona kuderedza nguva yekumisikidza muchina uye kuwedzera nguva. Inowedzera chibereko nekuderedza nguva dzisina basa uye nekuwedzera nguva yekucheka. Izvi zvinobvumira kukurumidza kuchinja chishandiso uye kuderedza yakazara machining nguva.

Operator Safety

Kuchengetedzeka kwemushandisi kunogona kukanganiswa nekusarudza iyo nzira yekumisikidza chishandiso. Dzimwe nzira dzakadai sekuzivikanwa kwemufananidzo kana laser tool kuyerwa zvinobvisa kudiwa kwekubata maturusi nemaoko, kuderedza mukana wekukuvara.

Chinangwa cheAnebon ndechekunzwisisa kukanganisa kwakanyanya kubva mukugadzira uye kupa rutsigiro rwepamusoro kune vatengi vekune dzimwe nyika nevekunze nemoyo wese 2022 Yemhando yepamusoro Stainless Steel Aluminium Yakakwira Precision Yakagadzirwa.CNC Turning, Kugaya,cnc spare partsyeAerospace, Kuti tiwedzere musika wedu wepasirese, Anebon inonyanya kupa vatengi vedu vekunze Kwemhando yepamusoro yekuita mamechani zvikamu, milled parts uye cnc turning service.

China wholesale China Machina Zvikamu uye CNC Machining Service, Anebon inosimudzira mweya we "innovation, kuwirirana, kushanda kwechikwata uye kugovana, nzira, pragmatic kufambira mberi". Tipei mukana uye tichave tichiratidza kugona kwedu. Nerubatsiro rwako rwemutsa, Anebon tenda kuti tinogona kugadzira ramangwana rakajeka newe pamwe chete.

Nguva yekutumira: Oct-19-2023