Iyi ndiyo pfupiso yevanhu vari muindasitiri kana vachipfupisa dhizaini yekugadzira, asi iri kure nekureruka. Mukuita kubata zvirongwa zvakasiyana, takaona kuti panogara paine mamwe matambudziko ekumisa uye kusungirira mune yekutanga dhizaini. Nenzira iyi, chero hurongwa hutsva hucharasikirwa nekukosha kwayo kunoshanda. Nekungonzwisisa ruzivo rwekutanga rwekumisikidza uye kusungirira tinogona kunyatso kuve nechokwadi chekuvimbika kweiyo dhizaini dhizaini uye kugadzirisa chirongwa.

Ruzivo rwenzvimbo

1, Nheyo yekutanga yekumisikidza kubva kudivi reworkpiece

Paunenge uchimisa kubva kudivi rebasa-chidimbu, iyo-nhatu-nhanho musimboti ndiyo inonyanya kukosha musimboti, sekutsigirwa. Izvi zvakafanana nenheyo yekutsigirwa, iyo inonzi nheyo-nhatu, yakabva pamusimboti we "matatu matatu kwete pamutsetse mumwe chete anosarudza ndege". Matatu emapoinzi mana anogona kuona chiso, saka huwandu hwezviso zvina hunogona kutariswa. Nekudaro, zvisinei kuti unowanikwa sei, zvakaoma chaizvo kuita poindi yechina mundege imwechete.

▲ Pfungwa nhatu

Semuyenzaniso, kana uchishandisa 4 yakatarwa kureba mapoinzi, mapoinzi matatu chete munzvimbo imwechete anogona kubata workpiece, uye mamwe mapoinzi mana akasara achiri mukana wekutadza kubata workpiece.

Naizvozvo, kana uchigadzira chinzvimbo, kazhinji chinobva pamapoinzi matatu, uye chinhambwe chiri pakati pemapoinzi matatu aya chinofanira kuwedzerwa zvakanyanya sezvinobvira.

Uye zvakare, kana uchigadzira chinzvimbo, zvinodikanwa kuti usimbise kutungamira kweiyo inoshandiswa kugadzirisa mutoro mberi. Kutungamira kwemutoro wekugadzirisa zvakare kutungamira kwechibatiso chekushandisa / chishandiso chekufamba. Iyo positioner inogadziriswa pakupera kweiyo feed direction, iyo inogona kukanganisa zvakananga kukwana kwese kweiyo workpiece.

Kazhinji, iyo bhaudhi yemhando inogadziriswa chinzvimbo inoshandiswa kuisa iyo isina chinhu pamusoro peiyo workpiece, uye iyo yakatarwa mhando (iyoCNC Inoshandura Zvikamucontact surface is ground) positioner inoshandiswa kuisa iyo machining pamusoro peiyo workpiece.

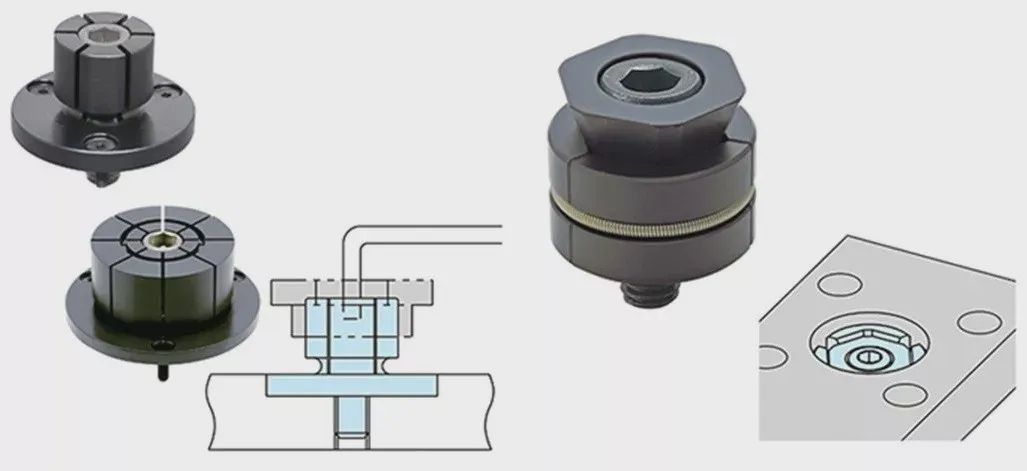

2, Nheyo yekutanga yekumisikidza kubva pagomba rekushanda

Paunenge uchishandisa gomba rakagadziriswa mune yapfuura maitiro eiyo workpiece yekumisikidza, zvinodikanwa kushandisa pini yekushivirira yekumisikidza. Nekufananidza kurongeka kwegomba rekushanda nekurongeka kwepini yepini uye nekubatanidza zvinoenderana nekukodzera kushivirira, iyo yekumisikidza chaiyo inogona kusangana nezvinodiwa chaizvo.

Pamusoro pezvo, kana uchishandisa pini yekumisikidza, kazhinji imwe inoshandisa pini yakatwasuka uye imwe inoshandisa pini yedhaimani, saka zvichave nyore kuunganidza nekubvisa chidimbu chebasa. Kashoma kuti workpiece ibatike nepini.

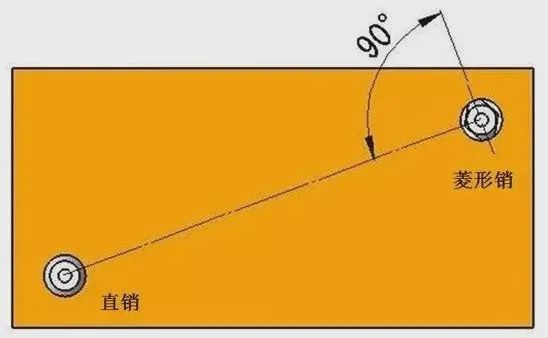

▲ Kumira nepini

Ehezve, zvinogoneka zvakare kushandisa yakatwasuka pini kune ese mapini nekugadzirisa yakakodzera kushivirira. Kuti uwedzere kumira zvakanaka, zvinowanzoita zvakanyanya kushandisa pini yakatwasuka uye pini yedhaimani.

Kana pini yakatwasuka nepini yedhaimani zvichishandiswa, mutsetse wekubatanidza munzira yekumisikidza (apo pini yedhaimani inobata workpiece) yepini yedhaimani inowanzoita 90 ° perpendicular kumutsara wekubatanidza pakati pepini yakatwasuka nepini yedhaimani. Iyi gadziriso ndeyeangular positioning (iyo inotenderera kutungamira kweiyo workpiece).

Ruzivo rwakakodzera rwe clamp

1, Kurongwa kwevanobata

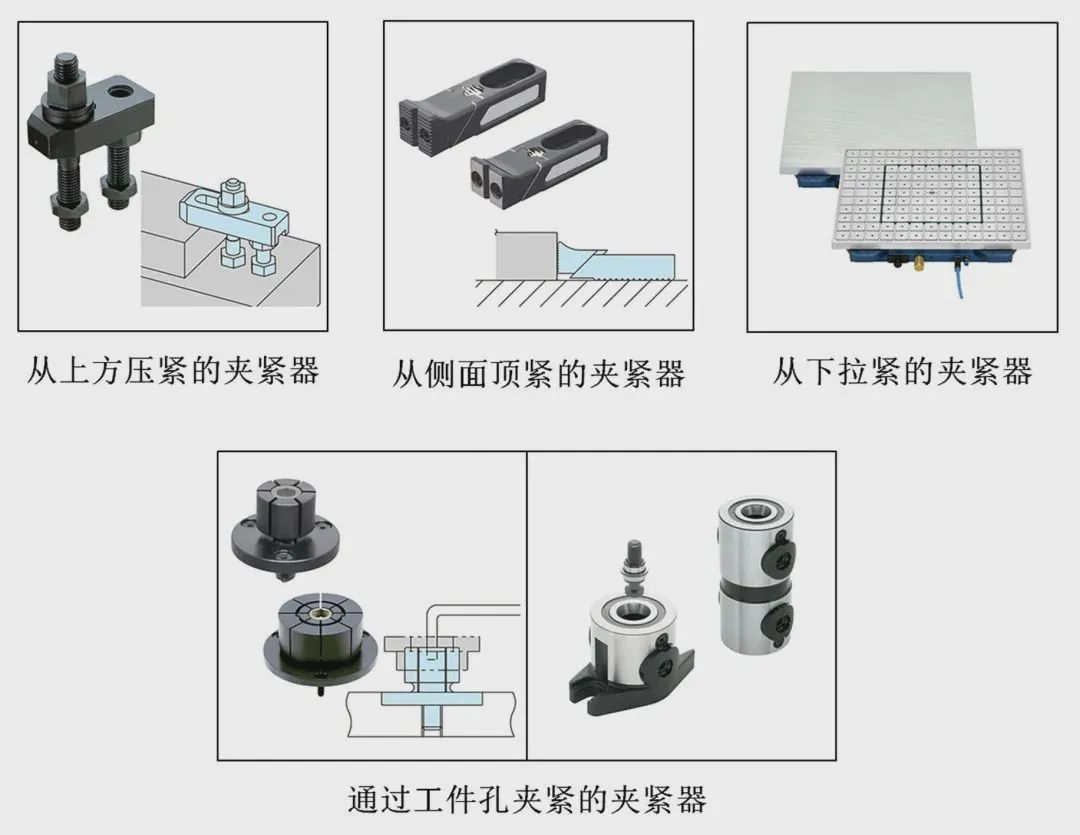

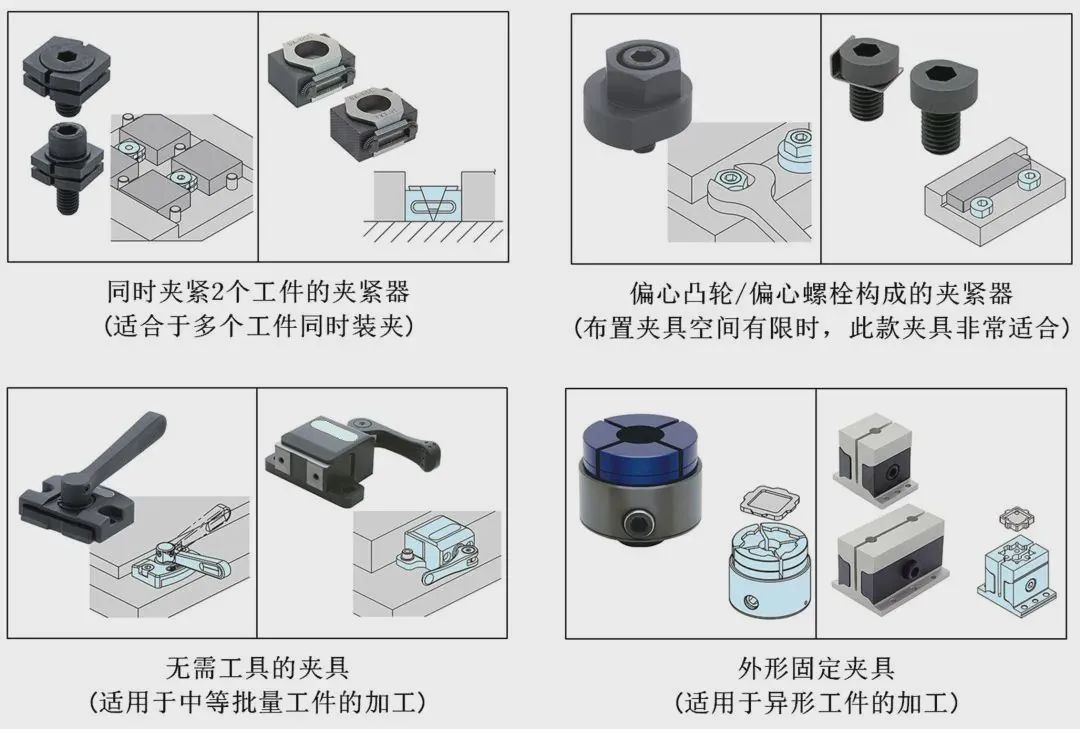

Zvinoenderana neiyo clamping gwara, rinowanzo kupatsanurwa muzvikamu zvinotevera:

Tevere, ngatitarisei maitiro eakasiyana maclamps.

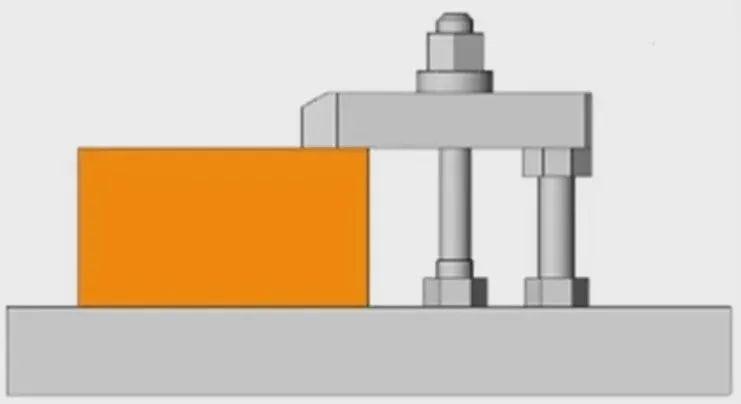

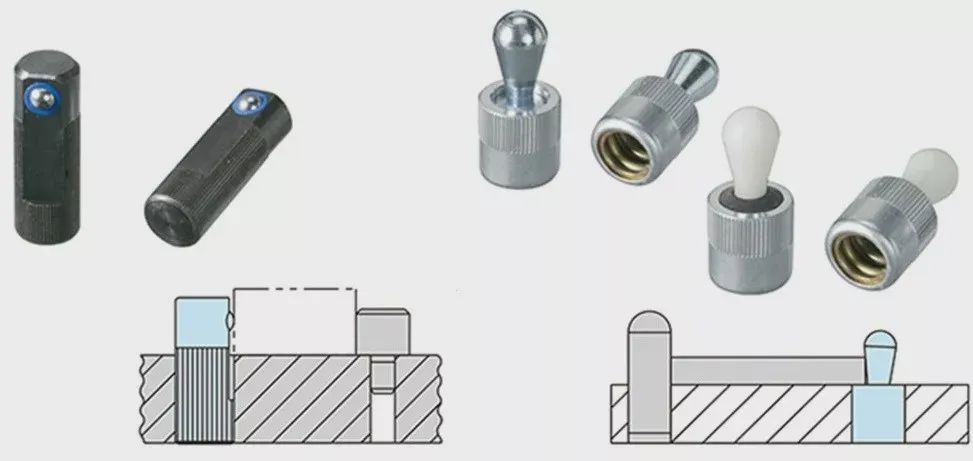

1. Zvisungo zvakadzvanywa kubva kumusoro

Iyo clamping mudziyo unodzvanywa kubva pamusoro peiyo workpiece ine diki deformation panguva ye clamping, uye ndiyo yakanyanya kugadzikana panguva yekugadzira workpiece. Naizvozvo, kazhinji, yekutanga kufunga ndeyekusunga kubva pamusoro peiyo workpiece. Iyo inonyanya kugadzirwa yekutsikirira kubva pamusoro peiyo workpiece ndeye manual mechanical fixture. Semuenzaniso, nhamba inotevera inonzi "loose leaf type" clamp. Chisungiso chakasanganiswa nekutsikirira ndiro, stud bolt, jack nenzungu inonzi "loose leaf" clamp.

Uyezve, mahwendefa ekudhinda ane maumbirwo akasiyana anogona kusarudzwa zvichienderana nechimiro chebasa rekushanda. Zvakaita seCNC Machining Zvikamu, Kushandura Zvikamu uye Zvikamu Zvokugaya.

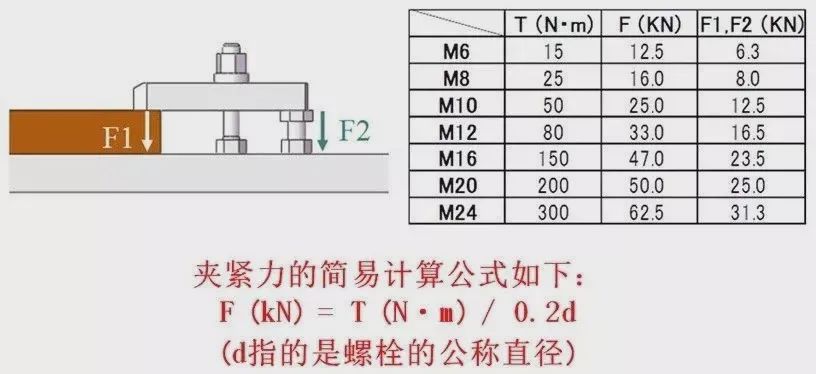

Hukama huri pakati pe torque ne clamping force ye loose leaf type clamp inogona kuverengerwa nekusundidzira simba rebhaudhi.

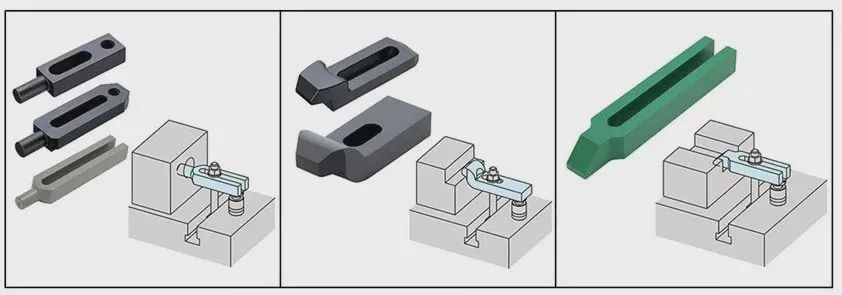

Kuwedzera kune yakasununguka shizha simbi, anotevera mabhanhire akafanana anowanikwa ekusungirira kubva pamusoro peiyo workpiece.

2. Kusunga clamp kubva padivi

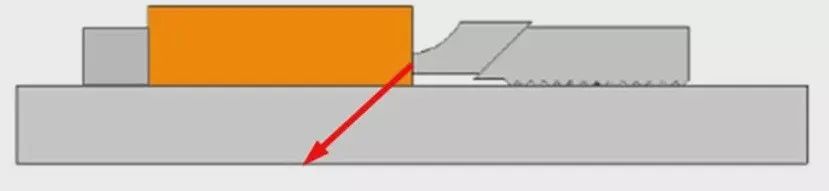

Pakutanga, iyo yekumanikidza nzira yekurovedzera iyo yekushanda-chidimbu kubva kumusoro ndiyo yakanyanya kugadzikana mukurongeka uye hushoma mukugadzirisa mutoro webasa-chidimbu. Nekudaro, kana zvichidikanwa kugadzirisa pamusoro peiyo workpiece, kana isina kukodzera kusungirira kubva pamusoro peiyo workpiece, izvo zvinoita kuti zvisaite kusungirira kubva pamusoro peiyo workpiece, unogona kusarudza kusungirira kubva kudivi reworkpiece. Nekudaro, kutaura, kana workpiece yakasungwa kubva padivi, inoburitsa simba rinoyangarara. Nzira yekubvisa sei simba iri inofanira kubhadharwa paunenge uchigadzira chigadziro.

Sezvinoratidzwa mumufananidzo uri pamusoro, iyo yekubatira yedivi zvakare ine oblique yakadzika simba ichigadzira kusundira, iyo inogona kunyatso kudzivirira workpiece kubva pakuyangarara kumusoro.

Zvisungo zvinosungirira kubva padivi zvakare zvine zvinotevera zvakafanana zvibhamba.

3. Clamping mudziyo wekusimbisa workpiece kubva kudhonza-pasi

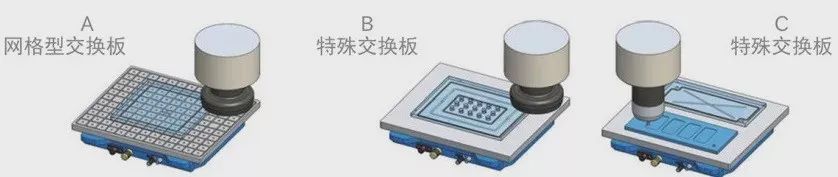

Paunenge uchigadzira nzvimbo yepamusoro yeplate yakaonda workpiece, hazvigoneke chete kuisunga kubva kumusoro, asiwo hazvina musoro kuimanikidza kubva padivi. Iyo chete inonzwisisika clamping nzira ndeye kuomesa workpiece kubva pasi. Kana iyo workpiece yakadzvinyirirwa kubva pazasi, kana yakagadzirwa nesimbi, magineti rudzi clamp inogona kazhinji kushandiswa. Kune asiri-ferrous metal workpieces, vacuum suction cups inogona kazhinji kushandiswa kunetsa.

Muzviitiko zviviri zviri pamusoro, simba rekusunga rinoenderana nenzvimbo yekubata pakati pechishandiso negineti kana vacuum chuck. Kana mutoro wekugadzirisa wakakura zvakanyanya paunenge uchigadzira zvidiki zvebasa, maitiro ekugadzirisa haazove akanaka.

Pamusoro pezvo, kana uchishandisa magineti kana vacuum suckers, nzvimbo dzekusangana dzine magineti uye vacuum suckers dzinofanirwa kuitwa kune imwe nhanho yekutsvedzerera dzisati dzashandiswa zvakachengeteka uye zvakajairwa.

4. Clamping mudziyo une maburi

Paunenge uchishandisa 5-axis machining muchina kugadzirisa zviso zvakawanda panguva imwe chete kana kugadzira mold, kuitira kudzivirira kukanganisa kwezvigadziriso uye maturusi pakugadziriswa, zvinowanzo zvakakodzera kushandisa gomba clamping nzira. Kuenzaniswa nenzira yekusungirira kubva kumusoro uye parutivi rwechishandiso, nzira yegomba clamping ine mitoro shoma pane workpiece uye inogona kunyatso kanganisa iyo workpiece.

▲ Yakananga kugadzirisa nemakomba

▲ Seta rivet yekunamatira

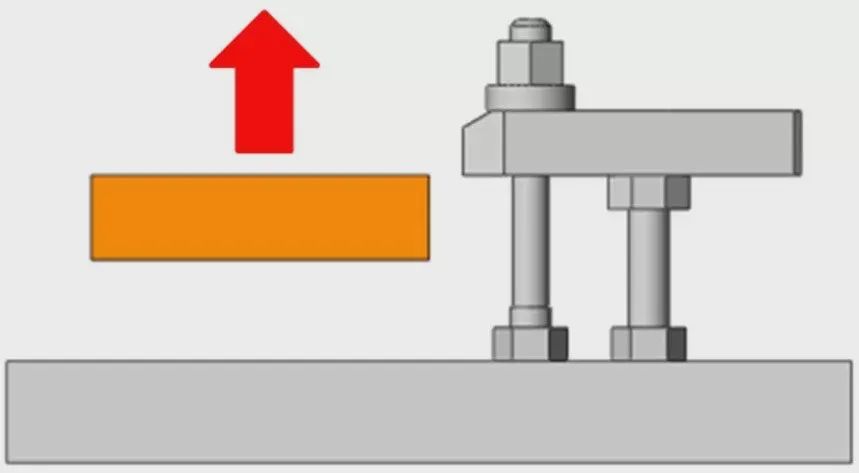

2, Pre clamping

Izvo zviri pamusoro zvinonyanya nezve clamping fixture ye workpiece. Maitiro ekuvandudza kushanda uye kushandisa pre clamping yakakoshawo. Kana iyo workpiece inomira yakamira pachigadziko, iyo workpiece inodonha nekuda kwegiravhiti. Panguva ino, iyo gripper inofanira kushandiswa ichibata workpiece nemaoko.

▲ Pre clamping

Kana ma workpiece akaremerwa kana mazhinji acho akasungwa panguva imwe chete, iko kushanda kuchadzikiswa zvakanyanya uye nguva yekuvhara ichave yakareba kwazvo. Panguva ino, kushandiswa kweichi chitubu pre clamping chigadzirwa kunogona kugonesa iyo workpiece kuti ishandise gripper munzvimbo yakamira, ichivandudza zvakanyanya kushanda uye kuderedza nguva yekusunga yeworkpiece.

3, Chengetedzo kana uchisarudza gripper

Kana akawanda marudzi emachira akashandiswa mune imwechete tooling, maturusi ekusunga & kusunungura anofanirwa kuve akabatana. Semuyenzaniso, sezvakaratidzwa mumufananidzo wekuruboshwe, kana uchishandisa akasiyana maturusi wrenches ye clamping mashandiro, mutoro wese wemushandisi uchave wakakura, uye iyo yakazara clamping nguva yeworkpiece ichave zvakare yakareba. Semuenzaniso, mumufananidzo uri kurudyi pazasi, zvipanera zvematurusi uye saizi yebhaudhi zvakabatana kufambisa vashandisi vemunda.

▲ Workpiece clamping operability

Uye zvakare, kana uchigadzira iyo gripper, zvinodikanwa kufunga nezve operability ye workpiece clamping zvakanyanya sezvinobvira. Kana iyo workpiece ichida kutenderedzwa panguva yekurovera, iyo operability haina kunaka. Mamiriro ezvinhu aya anofanirwa kudziviswa paunenge uchigadzira chigadziriso.

Nguva yekutumira: Oct-24-2022