1. Wana noungwaru zvitsama zvidiki zvezvokudya uye shandisa mabasa etrigonometric noungwaru

Wana chikafu chidiki nehuchenjeri uye shandisa trigonometric mabasa zvinobudirira.Panguva yekutendeuka, maworkpieces ane mukati nekunze madenderedzwa anoda kururamisa kwakanyanya anogara achigadziriswa. Matambudziko akadai sekucheka kupisa, kukweshana kuchikonzera kupfeka kwechishandiso, uye kudzokororwa chaiko kweskweya mudziyo inobata zvinoita kuti zviome kuve nechokwadi chemhando.

Kuti tigadzirise kudzika kweiyo micro-yekutora, isu tinogadzirisa iyo longitudinal mudziyo inobata pakona zvichienderana nehukama pakati pemativi akapesana uye hypotenuse yeatatu, zvichibvumira kudzika kwakaringana kwakachinjika panguva yekutendeuka. Iyi nzira ine chinangwa chekuchengetedza nguva nekushanda, kuchengetedza mhando yechigadzirwa, uye kuwedzera kushanda zvakanaka.

Muyero wechiyero chechiyero cheC620 lathe tool holder ndeye 0.05mm pachikamu. Kuti uwane kudzika kwe lateral kwe 0.005mm, zvichireva iyo sine trigonometric basa tafura:sinα=0.005/0.05=0.1 α=5º44′Saka, kugadzirisa chibatiso kuti 5º44′ kunogonesa chishandiso chekutendeuka kuti chiwane hudzamu hudiki hwe0.005mm mu inochinjika kutungamira neimwe longitudinal furemu kufamba.

2. Mhosva nhatu dzereverse driving technology

Yakawedzera ruzivo rwekugadzira yakaratidza kuti kushandisa reverse yekucheka tekinoroji mune mamwe maitiro ekuchinja kunogona kuunza mhedzisiro yakanaka. Zviitiko zvemazuva ano zvinosanganisira:

(1) Martensitic Stainless simbi zvikamu zvinoshandiswa sechinhu chekudzosera kumashure tambo dzekucheka.

Paunenge uchishanda pane akarukwa maworkpiece ane mapiche e1.25 uye 1.75mm, zvakajairika kusangana nenyaya dzine chekuita nekudzora kweturusi uye kuputika. Machira akajairika anowanzo shaya yakatsaurirwa buckling dhisiki mudziyo, zvinoda nguva inopedza tsika mhinduro. Nekuda kweizvozvo, kugadzirisa tambo neaya mapiche chaiwo anogona kuve-nguva-yakanyanya uye yakaderera-kumhanya kutendeuka inogona kunge iri iyo yega nzira inoshanda.

Zvisinei, kucheka nekumhanya kwakaderera kunogona kutungamirira kune kuruma kwechishandiso uye kushata kwepamusoro, kunyanya kana uchibata nemartensitic Stainless steel materials se 1Crl3 uye 2 Crl3. Kugadzirisa matambudziko aya, "matatu reverses" nzira yekucheka yakagadzirwa mukugadzira machining.

Iyi nzira, iyo inosanganisira reverse tool loading, reverse cut, and opposite cut directions, yakaratidza kuti inoshanda mukuwana high-speed thread cut with smooth tool retraction. Iyi nzira inonyanya kubatsira sezvo ichibvumira kucheka kwakanaka uye inodzivirira chingangoita chishandiso kutsenga nyaya dzine chekuita nekudzika-kumhanya kutendeuka.

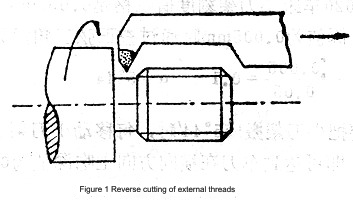

Kana kunze kwemotokari, kugaya mubato wakafanana neyomukati shinda yemotokari banga (Mufananidzo 1);

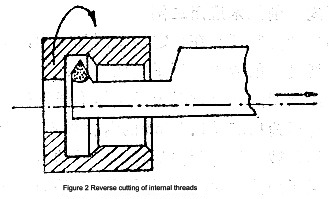

Kana shinda yemukati yemotokari ichikuya, banga rakadzokera shure remukati (Mufananidzo 2).

Usati watanga maitiro, gadzirisa inotenderedza-inotenderedza friction disc spindle zvishoma kuti uve nechokwadi chekutenderera kana uchitanga kutenderera-kutenderera. Tevere, gadza uye chengetedza tambo yekucheka, tanga kutenderera kumberi nekumhanya kwakaderera, uye enda kune isina chinhu chishandiso groove. Zvadaro, enderera mberi nekuisa tambo yekutenderedza tambo kune yakafanira yekucheka kudzika usati wachinja kutenderera kutenderera. Munguva iyi, chishandiso chekutendeuka chinofanira kutenderera kubva kuruboshwe kuenda kurudyi nekumhanya kwakanyanya. Mushure mekucheka kwakati wandei uchitevera nzira iyi, zvinokwanisika kuwana shinda ine kukwasharara kwepamusoro uye nehupamhi hwepamusoro.

(2) Anti-mota roll maruva

Paunenge uchishandisa yechinyakare rolling lathe, zvakajairika kuti simbi zvimedu nemarara zvipinde muworkpiece uye yekucheka chishandiso. Kushandisa nzira nyowani yekushandisa nelathe spindle kunogona kudzikisira zvinobudirira nyaya dzinosangana panguva yechinyakare kushanda uye kuunza mhedzisiro yakanaka.

(3) Reverse kutendeuka kwemukati nekunze tapered tambo dzepombi

Paunenge uchishanda mukati nekunze tapered tambo dzepombi ine yakaderera chaiyo zvinodiwa uye mumabheji madiki, unogona kushandisa zvakananga nzira nyowani yekudzosera kumashure uye kudzosera dhizaini yekuisa pasina kudiwa kwe template mudziyo, kuchengetedza inoenderera yekucheka maitiro.

Kushanda kwebanga rinotsvaira kubva kuruboshwe kuenda kurudyi kana richitenderedza tambo yepombi yekunze, riri mukukwanisa kudzora kudzika kwebanga rekuchekeresa kubva padhayamita hombe kusvika padhayamita diki nekuda kwe pre-pressure panguva. iyo slicing process. Iko kushandiswa kweiyi nyowani reverse operation tekinoroji mukutendeuka inoramba ichikura uye inogona kuchinjika kuchinjika kune akasiyana chaiwo mamiriro.

3. Kushanda kutsva uye zvishandiso zvitsva zvekuchera makomba maduku

Panguva yekushandura mashandiro, kana makomba ekuchera ari madiki pane 0.6mm, iyo shoma dhayamita uye isina kusimba kusimba kwechiboorero chinodzivirira kuwedzera kwekucheka kukurumidza. Iyo workpiece zvinhu, kupisa-resistant alloy uye simbi isina tsvina, inoratidza yakakwirira yekucheka kuramba. Nekuda kweizvozvo, kushandisa mechanical transmission feeding nzira panguva yekuchera kunogona kutyora dhiri nyore nyore. Mhinduro iri nyore uye inoshanda ndeye kushandisa nzira yekudyisa nemawoko uye mudziyo wakasarudzika.

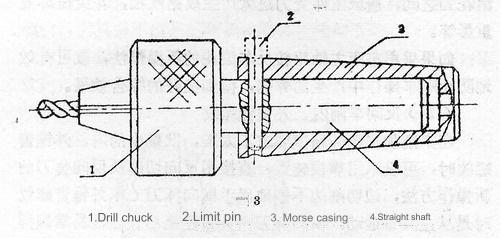

Danho rekutanga rinosanganisira kushandura iyo yekutanga drill chuck kuita yakatwasuka-shank inoyangarara mhando. Nekuroverera kadiki kachibhorani pane inoyangarara drill chuck, kuchera kwakatsetseka kunowanikwa. Iyo yekumashure chikamu che drill bit inobatanidza yakatwasuka mubato uye inotsvedza, inobvumira kusununguka kufamba mukati memudhonza. Zvichakadaro, pakuboora buri diki, zvinyoronyoro zvinyoro-kudyisa neruoko-inobata chibooreso chuck inogonesa kuchera nekukurumidza, kuchengetedza kunaka uye kurebesa hupenyu hwesevhisi yezvimedu zvidiki.

Pamusoro pezvo, iyo yakagadziridzwa yakawanda-chinangwa drill chuck inogona kushandiswa kune diki-dhayamita yemukati tambo kubaya, kugadzirazve, uye zvakafanana mashandiro. Pamakomba mahombe, kuisa pini yekugumira pakati pemubato wekudhonza uye mubato wakatwasuka unorairwa. Tarisa mufananidzo 3 kuti uwane ruzivo rwekuona.

4. Shockproof yekugadzira gomba rakadzika

Munguva yekugadzira gomba rakadzika, kusanganiswa kwegomba diki dhayamita uye slender boring tool shank inogona kutungamirira kukudengenyeka kusingadzivisiki paunenge uchishandura zvikamu zvine dhayamita yegomba kubva Φ30 kusvika Φ50mm uye yakadzika inenge 1000mm. Kudzikamisa kuzununguka uye kuve nechokwadi chepamusoro-chakadzika gomba kugadzirisa, yakatwasuka uye inoshanda nzira inosanganisira kubatanidza zvitsigiro zviviri, zvakavakwa kubva kune zvinhu zvakaita sejira uye bakelite, kune muviri wetsvimbo.

Izvi zvinotsigira zvinofanirwa kuenderana nehukuru hwegomba dhayamita nemazvo. Nekushandisa bakelite block yakavharwa nejira sechitsigiro chekumisikidza panguva yekucheka, bhara rekushandisa rinodzikamiswa, zvichideredza zvakanyanya mukana wekudedera uye kugonesa kugadzirwa kwemhando yepamusoro yegomba zvikamu.

5. Kudzivirirwa kwekuputsika kwemadiki madhiri epakati

Mukati mekushandura, kuchera buri repakati ridiki pane Φ1.5mm kunoisa njodzi huru yekupwanya chibooreso chepakati. Nzira inoshanda yekudzivirira kutyoka ndeye kudzivirira kukiya tailstock uchiboora buri repakati. Izvi zvinobvumira huremu hwakafa hwemuswe uye friction force pakati payo nemubhedha wemidziyo yemuchina kuti ushandiswe pakuchera. Mumamiriro ezvinhu apo kucheka kuramba kwakanyanyisa, iyo tailstock inozodzora otomatiki, nekudaro ichidzivirira yepakati drill.

6. Dambudziko rekugadzirisa kushandiswa kwezvinhu

Patinenge tichiomerwa nekugadzirisa zvinhu zvakadai se-high-temperature alloy uye kudzima simbi, kushata kwepamusoro kweworkpiece kunodiwa kuva mu RA0.20 kusvika ku0. Pakupedzisira, kushandiswa kwakanaka kunowanzoitwa pamubhedha wekukuya.

7. Kukurumidza kurodha uye kuburitsa spindle

Panguva yekutendeuka, tinowanzosangana neakasiyana siyana ekutakura ane denderedzwa rekunze uye inverted gidhi taper angles. Nekuda kwehukuru hwavo hwebatch, ivo vanoda kurodha uye kurodha mukati mekugadzirisa. Nguva inodiwa pakuchinja kwechishandiso yakareba kudarika nguva chaiyo yekucheka, zvichiita kuti kuderedzwa kwekugadzirwa kwekugadzira.

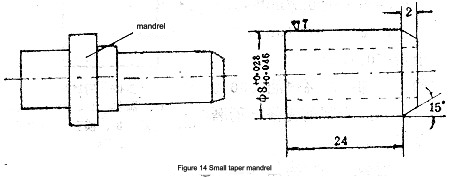

Iko kukurumidza kurodha uye kuburitsa mandrel, pamwe chete ne-single-blade multi-blade (tungsten carbide) inoshandura chishandiso inotsanangurwa pazasi, inogona kuderedza nguva yekubatsira uye kuve nechokwadi chemhando yezvigadzirwa paunenge uchigadzira akasiyana-siyana anotakura sleeve zvikamu. Iyo nzira yekugadzira ndeiyi inotevera: Kugadzira iri nyore diki-taper mandrel, diki taper ye0.02mm inoshandiswa kumashure.

Kana iyo fani yaiswa, zvikamu zvinodzivirirwa pane mandrel kuburikidza nekukwesha, uyezve imwe-blade yakawanda-yakachinjika inoshandura chishandiso inoshandiswa kushanda pamusoro. Mushure mekutenderedza, kona yekoni inodzoserwa ku15 °, panguva iyo wrench inoshandiswa nekukasira uye nemazvo kuburitsa zvikamu, sezvakaratidzwa mumufananidzo 14.

8. Kutyaira kwekudzima zvikamu zvesimbi

(1) Mumwe wemienzaniso inokosha yokudzimacnc michina yakagadzirwa

①Iyo yakakwirira-yekumhanya simbi W18CR4V kugadziridza uye kugadzirwa patsva (kugadzirisa mushure mekuzorora)

② Homemade Non -Standard Slocculus Standards (Kupera Kwakaoma)

③ Kutyaira kwehardware uye kupfapfaidza zvikamu

④ Inotyairwa yehardware light faces

⑤ Yakakwenenzverwa mwenje wepombi ine high-speed simbi banga

Paunenge uchibata neyakaomeswa hardware uye zvakasiyana-siyana zvinonetsa-kune-muchina zvinhu zvikamu mukugadzirwa kwedu, kunyatsosarudzwa kwezvinhu zvakakodzera zvekushandisa uye huwandu hwekucheka, pamwe nechombo chejiometric angles uye nzira dzekushandisa, zvinogona kuburitsa zvakakosha zvehupfumi. Semuenzaniso, kana sikweya-muromo broach ikatsemuka uye kugadzirwa patsva kuti ishandiswe mukugadzirwa kweimwe square-mouth broach, haingorebesi nguva yekugadzira asiwo inotungamira kumitengo yakakwira.

Maitiro edu anosanganisira kushandisa carbide YM052 uye mamwe matipi eblade kunatsiridza yakatyoka mudzi weiyo yekutanga broach kuita isina kunaka kumberi angle r. = -6 ° ~ -8 °, ichibvumira kuchekwa kuti kudzoserwe mushure mekunyatsokuya newhetstone. Iyo yekucheka kumhanya inoiswa paV = 10 ~ 15m/min. Mushure mekushandura denderedzwa rekunze, groove isina chinhu inochekwa, uye ipapo tambo inoshandurwa (inosanganisira rough uye yakanaka kutendeuka). Kutevera kutendeuka kwakakasharara, mudziyo unofanirwa kurodzwa uye pasi usati wapedza shinda yekunze, uye mushure mezvo, chikamu cheshinda yemukati chinogadzirirwa kubatanidza tie tsvimbo, iyo inozochekwa mushure mekubatanidza. Nekuda kweaya matendeuko maitiro, yakaputsika uye yakaraswa square broach yakagadziriswa uye yakadzoserwa kune yayo yekutanga.

(2) Kusarudzwa kwezvishandiso zvemachini zvakaomeswa Hardware

①Magiredhi matsva ekuisa carbide seYM052, YM053, uye YT05 anowanzo shandiswa pakucheka kumhanya pazasi 18m/min, kuwana workpiece roughness yeRa1.6~0.80μm.

②Iyo FD cubic boron nitride tool inokwanisa kugadzirisa simbi yakadzimwa uye yakapfapfaidzwa-yakapfapfaidza zvikamu pakucheka kumhanya kunosvika 100m/min, zvichikonzera kushata kwepamusoro kweRa0.80~0.20μm. The DCS-F composite cubic boron nitride tool kubva kuhurumende Capital Machinery Factory uye Guizhou No. 6 Grinding Wheel Factory inogovera basa iri. Kunyange zvazvo maitiro ayo ekugadzirisa haasi epamusoro secemented carbide, haina simba rakafanana nekudzika kwekupinda, uye inouya nemutengo wakakwirira uye ine ngozi yekucheka musoro kukuvara kana ikashandiswa zvisina kunaka.

③Ceramic cutting tools inoshanda pakucheka kumhanya kwe40-60m/min asi iine simba rakaderera.Chimwe nechimwe chezvishandiso izvi chinopa maitiro akasiyana-siyana ekugadzira zvikamu zvakadzimwa uye zvinofanira kusarudzwa zvichienderana nemamiriro ezvinhu chaiwo anosanganisira zvinhu uye kuoma kwakasiyana.

(3) Chishandiso Chekuita Zvinodiwa ZveZvishandiso Zvakasiyana zveSimbi Yakadzimwa Zvikamu zvezvinhu zvakasiyana zvinoda kushanda kwechishandiso chakasiyana pasi pekuoma kwakafanana uye zvinogona kuiswa muzvikamu zvitatu zvinotevera:

High alloy simbi:Izvi zvine chekuita nesimbi yemidziyo uye simbi inofa (zvikurukuru zvakasiyana-siyana zvekumhanya-mhanya) ine yakazara alloying element yemukati inodarika 10%.

Alloy simbi:Izvi zvinosanganisira simbi yekushandisa uye die simbi ine alloy element yemukati kubva pa2 kusvika 9%, semuenzaniso, 9SiCr, CrWMn, uye yakakwirira-yakasimba alloy simbi yekugadzira.

Carbon steel:Izvi zvinosanganisira zvakasiyana-siyana carbon tool steels uye carburized steels zvakadai seT8, T10, No. 15 simbi kana No. Izvi zvinoguma nekuoma kwehV800 ~ 1000, iyo yakakwirira kudarika iyo yeWC neTiC mune simende carbide uye A12D3 mumaturusi eceramic.

Pamusoro pezvo, kuoma kwayo kunopisa kwakadzikira pane kwemartensite isina alloy element, kazhinji isingadarike 200°C.

Kuwedzera kuvepo kwealloying zvinhu musimbi kunotungamirira kune inowirirana kuwedzera kwecarbide zviri mukati mesimbi mushure mekudzima uye kupisa, zvichikonzera kusanganiswa kwakaoma kwemhando dzecarbide. High-speed simbi inoshanda semufananidzo, apo iyo carbide yemukati mune microstructure mushure mekudzima uye kupisa inogona kusvika 10-15% (volume ratio). Izvi zvinosanganisira marudzi akasiyana-siyana emacarbides akadai seMC, M2C, M6, M3, 2C, nemamwe, ane VC inoratidza kuomarara kwepamusoro (HV2800), inopfuura nekure kuoma kwezvinhu zvekushandisa.

Uyezve, kuomarara kwekupisa kwemartensite ine akawanda alloying zvinhu zvinogona kusimudzwa kusvika pa600°C. Nekuda kweizvozvo, iyo machinability yesimbi yakadzimwa ine yakafanana macro kuomarara inosiyana zvakanyanya. Usati wagadzira chikamu chesimbi chakadzimwa, zvakakosha kuti utange waongorora chikamu chayo, unzwisise maitiro ayo, uye sarudza akakodzera maturusi emidziyo, kucheka ma paramita, uye chishandiso geometry. Nekufunga kwakakodzera, kutenderedzwa kwesimbi dzakaomarara kunogona kuitwa pamakona akasiyana.

Anebon inodada kubva mukuzadzikiswa kwepamusoro kwemutengi uye kugamuchirwa kwakakura nekuda kweAnebon iri kuramba ichitsvaga zvemhando yepamusoro zvese pachigadzirwa uye sevhisi yeEC Sitifiketi Yakagadzirirwa Yemhando yepamusoro Kombuta Zvikamu.CNC Zvikamu zvekugadziraMetal, Anebon yanga ichidzingirira WIN-WIN mamiriro nevatengi vedu. Anebon gamuchirai noushamwari mutengi kubva kumativi ese enyika achiuya zvakapfuura pakushanya uye nekumisikidza hukama hwerudo hunogara kwenguva refu.

CE Certificate China cnc yakagadzirwa nealuminium zvikamu,CNC Yakashandura Zvikamuuye cnc lathe zvikamu. Vese vashandi mufekitori, muchitoro, uye muhofisi yeAnebon vari kunetsekana nechinangwa chimwe chete chekupa mhando nesevhisi zviri nani. Bhizinesi chairo kuwana win-win mamiriro. Tinoda kupa rubatsiro rwakawanda kune vatengi. Gamuchirai vatengi vakanaka kuti vataure nezve zvigadzirwa zvedu uye mhinduro nesu!

Kana iwe uchida kuziva zvakawanda kana uine kubvunza, ndapota taurainfo@anebon.com.

Nguva yekutumira: Feb-18-2024