Zvakawanda sei zvaunoziva nezve mechanical dhizaini?

Mechanical dhizaini ibazi reinjiniya iro rinoshandisa misimboti uye matekiniki akasiyana kugadzira, kuongorora uye kukwenenzvera masystem masisitimu uye zvikamu. Mechanical dhizaini inosanganisira kunzwisisa chinangwa chakanangwa chechikamu kana sisitimu, kusarudza zvinhu zvakakodzera, uchifunga zvakasiyana siyana, senge kushushikana uye kunetsa uye masimba, uye kuve nechokwadi chekuvimbika uye kushanda kwakanaka.

Mechanical dhizaini inosanganisira dhizaini yemuchina, dhizaini yezvimiro, dhizaini dhizaini uye dhizaini yechigadzirwa. Dhizaini yechigadzirwa ine chekuita nekugadzirwa kwezvinhu zvemuviri senge zvinhu zvevatengi, zvigadzirwa zvemaindasitiri nezvimwe zvinobatika. Dhizaini yemuchina, kune rumwe rutivi, inotarisana nekugadzira michina yakaita seinjini, maturbine uye michina yekugadzira. Mechanism dhizaini ine chekuita nekugadzira masisitimu anoshandura zvinopinza kuita zvinodiwa zvinobuda. Magadzirirwo ekugadzira ndiyo danho rekupedzisira. Inosanganisira kuongororwa uye dhizaini yezvivakwa zvakaita semabhiriji, zvivakwa, uye mafuremu esimba rawo, kugadzikana, kuchengetedzeka, uye kusimba.

Iyo chaiyo dhizaini maitiro akaita sei?

Maitiro ekugadzira anowanzo sanganisira matanho akasiyana, sekuzivikanwa kwedambudziko rekutsvagisa uye ongororo, kugadzirwa kwemazano uye dhizaini yakadzama uye prototyping, pamwe nekuyedza uye kujekesa. Muzvikamu izvi mainjiniya anoshandisa hunyanzvi hwakasiyana uye maturusi senge komputa-inobatsira dhizaini (CAD) software, inopera chinhu chekuongorora (FEA) uye simulation kuratidza nekuvandudza dhizaini.

Zvinhu zvipi zvinofanira kufungwa nevagadziri?

Mechanical dhizaini inowanzo batanidza zvinhu zvakaita sekugadzira, ergonomics, mutengo-kushanda pamwe nekuchengetedza. Mainjiniya anoedza kugadzira mamodheru asingangoite uye anoshanda asi, ivo vanofanirwawo kufunga nezvezvinodiwa nemushandisi, kukanganisa kwezvakatipoteredza uye kushomeka kwehupfumi.

Izvo zvakakosha kuti uyeuke kuti iyo ndima yekugadzira mechanic inzvimbo yakakura uye inoramba ichishanduka ine zvinhu zvitsva, matekinoroji uye nzira dziri kugara dzichigadzirwa. Nekudaro, vanogadzira michina vanofanirwa kugara vachivandudza hunyanzvi hwavo neruzivo kuti varambe vari pamberi mukufambira mberi kwetekinoroji.

Anotevera ndiwo mapoinzi eruzivo nezve dhizaini yekugadzira yakaunganidzwa uye yakarongwa neAnebon's engineering timu kuti igovane nevamwe vaunoshanda navo.

1. Izvo zvinokonzeresa kutadza mune zvemakanika zvikamu ndezvi: general kuputsika kana kuwandisa kwasara deformation kukuvara kwepasiprecision yakashandura zvikamu(corrosion wear, friction kuneta uye kupfeka) Kukundikana nekuda kwemigumisiro yemamiriro ekushanda.

2. Zvikamu zvekugadzira zvinofanira kukwanisa kuzadzisa: zvinodiwa zvekudzivisa kukundikana mukati menguva yakatarwa (simba kana kuoma, nguva) uye zvinodiwa zvemaitiro ekugadzirisa, zvido zvehupfumi, pasi pemhando yezvinodiwa, uye zvinodiwa zvekuvimbika.

.

4. Chikamu dhizaini nzira: theoretical dhizaini, empirical dhizaini, muenzaniso bvunzo dhizaini.

5. Inowanzo shandiswa kune mechanical components is Materials for mechanical parts zvinosanganisira ceramic zvinhu, polymer zvinhu uye composite zvinhu.

6. Simba rezvikamu zvakagadzirwainorongedzerwa kuita static stress simba pamwe nekushanduka kwesimba rekushushikana.

7. The stress ratio r = -1 is asymmetrical cyclic stress. iyo reshiyo r = 0 inoratidza yakarebesa cyclic kushushikana.

8. Zvinotendwa kuti BC nhanho inozivikanwa sekuneta kuneta (kuderera kutenderera kuneta); CD ndiyo nhanho yekupedzisira yehupenyu kuneta. chikamu chemutsara chinotevera D poindi chinomiririra kusakwana kwehupenyu-kutadza mwero wemuenzaniso. D ndiyo muganhu wekusingaperi kuneta.

9. Matanho ekuvandudza kusimba kwezvikamu kana wakaneta Deredza kukanganiswa kwekushushikana kwekushushikanacnc milled zvikamukusvika pamwero mukuru unobvira (mutoro wekudzikisa groove yakavhurika groove) Sarudza zvinhu zvine simba rekuneta uye tsanangurawo nzira dzekupisa kupisa uye nzira dzekusimbisa dzinowedzera simba rezvinhu zvakaneta.

10. Slide friction: Dry friction boundary frictions, fluid friction, uye kusanganiswa kwakasanganiswa.

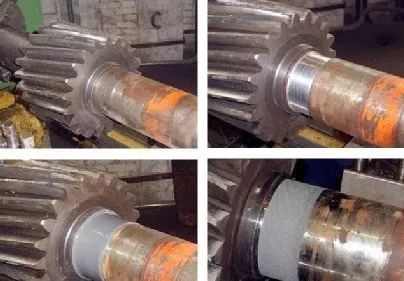

11. Nzira yekupfeka yezvikamu zvinosanganisira kumhanya-mu-nhanho uye yakagadzikana yekupfeka nhanho uye yakasimba yekupfeka nhanho. Nhamburiko dzinofanira kuitwa kuderedza nguva yekumhanya-mukati, kuwedzera nguva yekupfeka kwakagadzikana uye kunonoka kutaridzika kwekupfeka kwakanyanya.

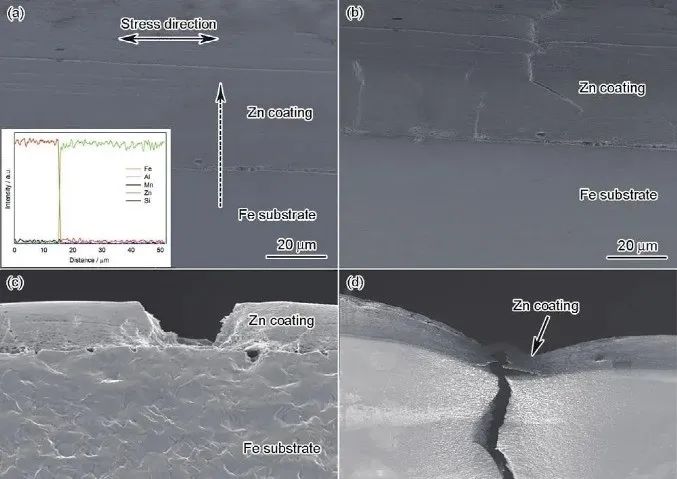

12. Mutsara wekupfeka ndeyeAbrasive wear, adhesive wear uye kuneta corrosion wear, erosion wear uye fretting wear.

13. Mafuta ekuzora anogona kuiswa mumhando ina dziri mvura, gasi semi-yakasimba, yakasimba uye yemvura girizi inorongwa sezvikamu zvitatu: calcium-based greases nano-based greases lithium-based grease, aluminium based grease, uye aluminium-based.

14. Muyero wekubatanidza shinda zino dhizaini ndeye equilateral yegonyo ine yakanakisa yekuzvivharira zvimiro uye kutapurirana kweiyo rectangular transmission shinda inodarika dzimwe shinda. trapezoidal threads ndiyo inonyanya kushandiswa tambo yekutumira.

15. Ruzhinji rwetambo dzekubatanidza dzine zvikwanisiro zvekuzvivharira, saka shinda imwe chete ndiyo inowanzo shandiswa. Tambo dzekutapurirana dzinoda hunyanzvi hwekufambisa uye nekudaro shinda-katatu, kana mbiri-tambo dzinonyanya kushandiswa.

16. Bolt connection yemhando yakajairika (kuburikidza negomba kana maburi ane hinged akazaruka pazvikamu zvakabatanidzwa) zvibatanidza, stud connections screw connection, set screw connection.

17. Chikonzero chekubatanidzwa kwe threaded pre-tightening ndechekuvandudza simba uye kusimba kwekubatanidza. Inobatsirawo kumisa mapundu uye kutsvedza pakati pezvikamu mushure mekurodha. Iyo yekutanga nyaya ye threaded yekubatanidza kusunungura ndeyekudzivirira kutenderera kutenderera mumasruru panguva yakatakura. (Friction yekudzivirira kusunungura, mechanic kuramba kumisa kusunungura, kunyungudutsa screw-pair motion hukama)

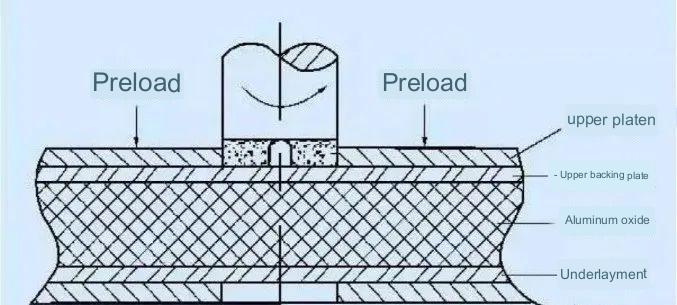

18. Nzira dzekuwedzera simba rekubatanidza threaded Kuderedza amplitude yekushungurudzika kunobata simba rekuneta mubhoti (kuderedza kuoma kwebhoti pamwe nekuwedzera kuoma kwezvikamu zvakabatana) uye kuvandudza kugoverwa kusina kuenzana kwemutoro pamusoro pe mazino eshinda, deredza mhedzisiro kubva mukushushikana kusungirirwa uye shandisa nzira inoshanda yekugadzira.

19. Key connection type Key connection type: flat (mativi ose ane nzvimbo dzekushanda) semicircular key connector wedge key connection the tangential key connection.

20. Kutumira bhandi kunogona kukamurwa kuva marudzi maviri: meshing type uye friction type.

21. Mhedzisiro yepakutanga yepamusoro pabhanhire iri panzvimbo iyo kuguma kwakasimba kwebhanhire kunotanga kutenderera pulley duku. Iko kushushikana kunoshanduka ka4 panguva yekosi pabhanhire.

22. Tensioning yeV-belt transmission: nguva dzose tensioning device, automatic tensioning device, tensioning device uchishandisa tensioning pulley.

23. Kuverengera kweketani yeketani mumaketani anotenderera anowanzo kuenzana (huwandu hwemazino mu sprocket inhamba isinganzwisisike) uye iyo yakawedzera-yakawedzerwa cheni chinongedzo chinoshandiswa kana nhamba yeketani yekubatanidza iri nhamba isinganzwisisike.

24. Chikonzero chekumanikidzika kwecheni drive ndeyekuona kuti meshing haina kukanganisa uye kudzivirira cheni vibration kana sag pamucheto wakasununguka wakakurisa uyezve kuwedzera meshing kureba pakati pecheni pamwe ne sprocket.

25. Chikonzero chekukundikana kwegiya kutsemuka kwemazino, kupfeka pamusoro pemazino (yakazaruka giya) kupinza mazino (yakavharwa giya) Zino pamusoro pegluing uye deformation yepurasitiki (maridges anooneka pamitsetse yekufambisa inooneka chidhiraivho).

26. Magiya ane kuoma kwekupfuura 350HBS uye 38HRS anozivikanwa seakaoma-kumeso kana, kana asina, magiya akapfava.

27. Kuvandudza kurongeka kwekugadzira uye kuderedza ukuru hwegiya kuti udzikise kukurumidza kwainofamba kunogona kuderedza simba rekuita. Kuti uderedze mutoro uyu zvine simba, mudziyo unogona kugadziriswa pamusoro payo. mazino egiya anoumbwa kuita dhiramu kuti awedzere kunaka kwemazino egiya. kurodha kugovera.

.

29. Fambisa giya rehonye. Mushure mekutamiswa iwe uchaona kuti denderedzwa repanji repanji pamwe nedenderedzwa repanji rinopindirana, zvisinei zviri pachena kuti gonye regonye rachinja, uye harichaenderana nedenderedzwa raro.

30. Chikonzero chekukundikana mumotokari yehonye ndeye pitting corrosion uye mazino midzi fractures, zino pamusoro pegluing uye kunyanya kupfeka. Kukundikana kazhinji kunokonzerwa nehonye drive.

31. Simba kurasikirwa kubva kuvharwa worm drive meshing wear loss Kupfeka kurasikirwa kwemabhengi pamwe nekurasikirwa kwemafuta anoputika sezvo zvikamu zvinopinda mutangi yemafuta zvinomutsa mafuta.

32. Kutyaira kwehonye kunofanira kuverenga kuenzana kwekupisa maererano nezvinodiwa kuti kuve nechokwadi chokuti zviyero zve calorific pachikamu chenguva zvakaenzana nehuwandu hwekupisa hunoputika panguva imwe chete yenguva.

Solutions: Wedzera kupisa sinks kuwedzera nzvimbo yekupisa kupisa. isa mafeni padhuze neshaft kuitira kuti uwedzere kuyerera kwemhepo, uye wozoisa masingi ekupisa mukati mebhokisi rekutumira. Vanogona kubatanidzwa kune inotenderera inotonhorera pombi.

33. Zvinodiwa pakugadzirwa kwehydrodynamic lubrication ndezvokuti nzvimbo mbiri dzinotsvedza dzinofanirwa kuumba mukaha wakaita seweji. Nzvimbo mbiri dzakapatsanurwa nefirimu remafuta dzinofanirwa kunge dziine hukama hwakakwana hwekutsvedza, uye kufamba kwayo kunofanira kuita kuti mafuta ekuzora afambe nemumuromo wakakura mumukanwa mudiki. inodiwa kuti mafuta ave nehumwe viscosity uye kupihwa kwemafuta kunodiwa kuve kwakakwana.

.

35. Matatu akarembera anomonereka mabhora mashanu akapinza bhora rakadzika groove bhora 7 ane angular contacts cylindrical roller bearings 01, 02, 01 uye 02 uye 03 zvakateerana. D=10mm, 12mm 15mm, 17,mm zvinoreva 20mm d=20mm uye 12 yakaenzana ne60mm.

36. Hupenyu hweiyo chiyero chekutanga: 10 muzana yemabhengi mukati memhando dzakasiyana-siyana dzemabheyari ari kutambura nekukuvadzwa kwegomba, nepo 90% yemabhengi isingakanganisike nekukuvadzwa kwegomba. Huwandu hwemaawa akashanda ndiyo nguva yeupenyu iyo kutakura.

37. The basic dynamic rating: chiyero icho chinotakura chinokwanisa kutsigira kana chigadziko chemushini chiri chaizvo 106 revolutions.

38. Nzira yekusarudza kugadzirwa kwekutakura: maviri Fulcrums anogadziriswa kune imwe nzira imwe neimwe. Imwe poindi inogadziriswa bidirectionally, nepo imwe fulcrum inoguma yatuhwina mumativi ese, nepo imwe inopera kushambira kuti ipe rutsigiro.

39. Bearings inorongwa maererano nehuwandu hwekutakura shaft (kukotama nguva uye torque) mandrel (nguva yekukotama) uye Transmission shaft (torque).

Anebon inonamatira kune yakakosha pfungwa ye "Hunhu ndiko musimboti webhizinesi uye chimiro chinogona kunge chiri musimboti waro" Kuti uwane mutero wakakura paCustom precision 5 Axis Lathe.cnc machined zvikamu, Anebon ine chivimbo chekuti tichapa zvigadzirwa zvemhando yepamusoro uye masevhisi nemutengo unokwanisika uye yakanakisa mushure mekutengesa sevhisi kune vatengi. Pamusoro pezvo, Anebon ichakwanisa kuvaka hukama hwenguva refu newe.

Chinese Professional China CNC Chikamu uye Metal Machining Zvikamu, Anebon inotsamira pane zvigadzirwa zvemhando yepamusoro, dhizaini yakakwana, yakasarudzika sevhisi yevatengi uye mutengo unodhura kuti uwane kuvimba kwenhamba huru yevatengi vanobva kunze kwenyika nekuUS. Zvizhinji zvezvigadzirwa zvinotumirwa kumisika yemhiri kwemakungwa.

Nguva yekutumira: Aug-02-2023