Iyo machining Center inosanganisa oiri, gasi, magetsi, uye nhamba kutonga, uye inogona kuona-imwe-nguva kusungirirwa kweakasiyana zvikamu zvakaoma senge madhisiki, mahwendefa, magomba, makamera, molds, nezvimwewo, uye inogona kupedzisa kuchera, kugaya, kufinha, kuwedzera. , reming, Rigid tapping uye mamwe maitiro anogadziriswa, saka ndiyo yakanakira midziyohigh-precision machining. Ichi chinyorwa chichagovera kushandiswa kwemachina nzvimbo kubva kune zvinotevera zvinhu:

Iyo machining centre inogadzirisa sei chishandiso?

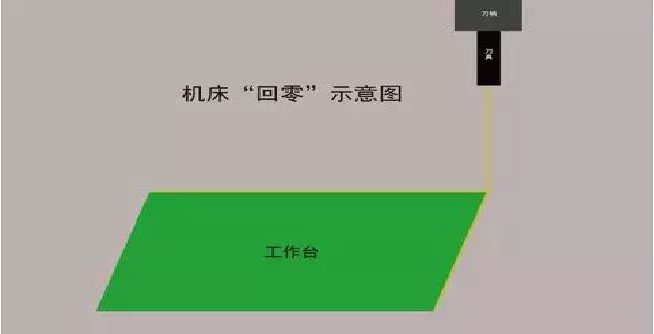

1. Dzokera ku zero (dzokera kumuchina kwakabva)

Pamberi pechigadzirwa chekushandisa, iva nechokwadi chekuita basa rekudzokera kune zero (kudzokera kune kwakabva chigadzirwa chemuchina) kuitira kuti ubvise dhata rekubatanidza rekupedzisira kushanda. Ziva kuti X, Y, uye Z matemo ese anoda kudzokera ku zero.

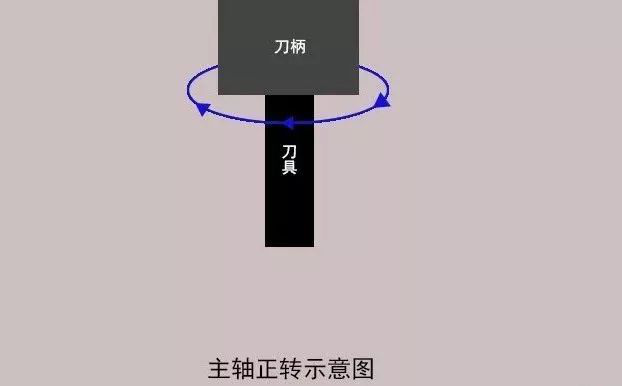

2. Spindle inotenderera mberi

Mu "MDI" modhi, iyo spindle inotenderedzwa kumberi nekuisa kodhi yekuraira, uye inochengetedza ine mwero kutenderera kumhanya. Wobva wachinja kuita "handwheel" modhi, uye fambisa chishandiso chemuchina nekushandura chiyero chekugadzirisa.

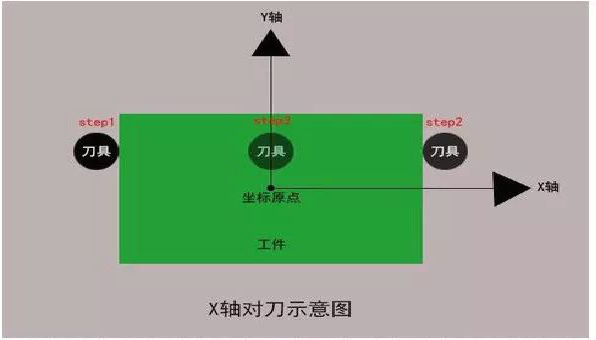

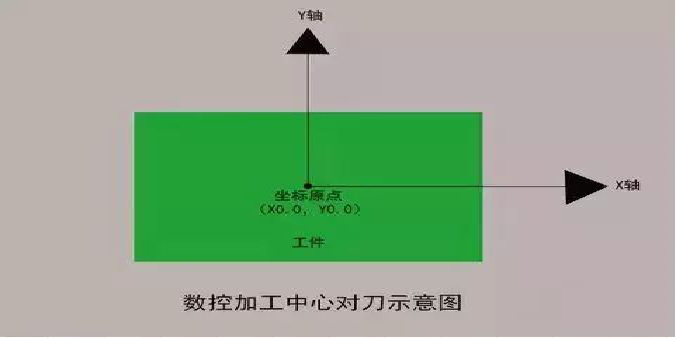

3. X-direction tool setting

Bata zvinyoro-nyoro chishandiso parutivi rwerudyi rwechishandiso kuti ubvise hukama hwehukama hwemuchina chishandiso; simudza mudziyo uchitevedza nzira yeZ, wobva wafambisa chishandiso kuruboshwe rwechishandiso, pasi kusvika pakukwirira kwakafanana nepakutanga, fambisa chishandiso uye workpiece Bata zvishoma, simudza chishandiso, nyora pasi kukosha kweX kwehukama hwehukama. yemuchina wemuchina, fambisa chishandiso kuhafu yehama inoronga X, nyora pasi kukosha kweX kweiyo yakazara kurongeka kwechishandiso chemuchina, uye tinya (INPUT) kuti upinde muhurongwa hwekubatanidza.

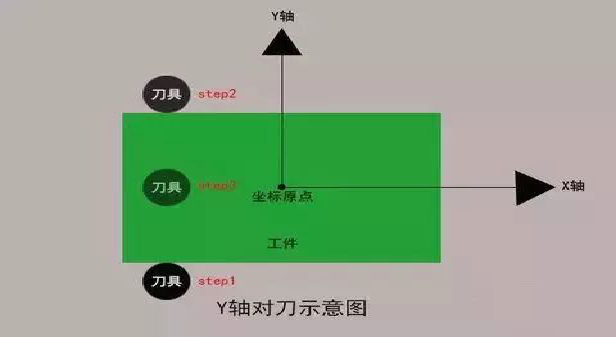

4.Y-direction tool setting

Bata zvinyoro zvinyoro pamberi pechishandiso kuti ubvise hukama hwehukama hwemuchina chishandiso; simudza chishandiso pamwe negwaro reZ, wobva wafambisa chishandiso kuseri kwechishandiso, pasi kusvika pakukwirira kwakafanana nepakutanga, fambisa chishandiso uye workpiece Bata zvishoma, simudza chishandiso, nyora pasi kukosha kweY kwehukama hwehukama hwe. mudziyo wemuchina, fambisa chishandiso kuhafu yehama inorongedzera Y, nyora pasi kukosha kweY kweiyo asolute kurongeka kwechishandiso chemuchina, uye dzvanya (INPUT) kuti upinde muhurongwa hwekubatanidza.

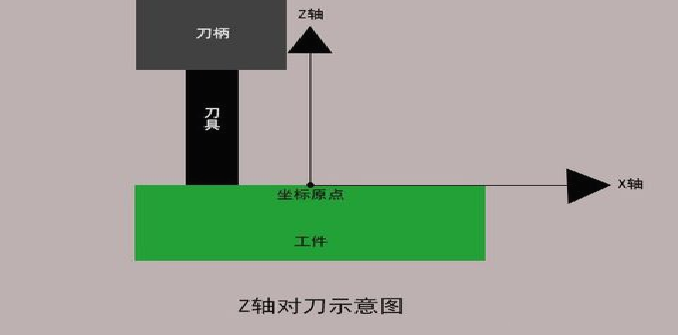

5. Z-direction tool setting

Fambisa chishandiso kumusoro kwechishandiso chinoda kutarisana ne zero point yeZ kutungamira, zvishoma nezvishoma fambisa chishandiso kuti ubate nechepamusoro penzvimbo yebasa, rekodha kukosha kweZ muhurongwa hwekurongeka kwemuchina panguva ino. , wobva wadzvanya (INPUT) kuisa mucoordination system.

6. Spindle stop

Kutanga misa chirungiso, fambisa chinorukwa panzvimbo yakakodzera, fonera chirongwa chekugadzirisa, uye gadzirira kugadziridzwa.

Nzvimbo yekugadzira michina inoburitsa uye kugadzira zvikamu zvinogomara zviri nyore sei?

Kune zvikamu zvine huremu huremu, kusimba kusimba uye simba risina simba, zviri nyore kuremara nechisimba uye kupisa panguva yekugadzira, uye kukwirira kwezvimedu zvekugadzirisa kunotungamirira kukuwedzera kukuru kwemutengo. Kune zvikamu zvakadaro, tinofanira kutanga tanzwisisa zvinokonzera deformation:

Simba deformation:

Zvikamu zvakadaro zvine madziro akatetepa, uye pasi pekuita kwesimba rekuvhara, zviri nyore kuve neakasiyana makubvu mukugadzira uye kucheka nzira, uye elasticity haina kunaka, uye chimiro chezvikamu zvakaoma kupora pachako.

Thermal deformation:

Iyo workpiece yakareruka uye yakaonda, uye iyo radial simba panguva yekucheka ichaita kuti workpiece ive yakaremara nekupisa, nokudaro kuita ukuru hwebasa rekushanda husina kunaka.

Vibration deformation:

Pasi pechiito cheiyo radial yekucheka simba, zvikamu zvinowanzoita vibration uye deformation, iyo inokanganisa dimensional kurongeka, chimiro, kurongeka kwenzvimbo uye kushata kwepamusoro kwechishandiso.

Kugadzirisa nzira yezvikamu zviri nyore kuremara:

Izvo zviri nyore kuremara zvikamu zvinomiririrwa neakatetepa-madziro machining anogona kutora chimiro chepamusoro-kumhanya machining nediki diki rekudya uye yakakura yekucheka kumhanya kudzikisa simba rekucheka pane workpiece panguva yekugadzira, uye panguva imwechete inoita yakawanda yekucheka kupisa kubhururuka. kure nemachipisi eiyo workpiece nekumhanya kukuru. Bvisa, nekudaro kuderedza kutonhora kweiyo workpiece uye kuderedza deformation inopisa ye workpiece.

Sei machining center maturusi achifanira kupfuudzwa?

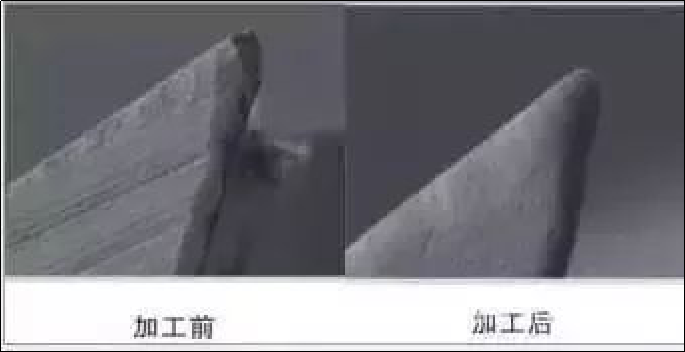

CNC maturusi haana kukurumidza sezvinobvira, saka sei passivate izvozvo? Muchokwadi, kufambisa chishandiso hachisi icho munhu wese anonzwisisa chaizvo, asi nzira yekuvandudza hupenyu hwesevhisi yechishandiso. Natsiridza mhando yemidziyo kuburikidza nematanho akadai sekuyeresa, kupukuta, uye kubvisa. Aya ndiwo maitiro akajairwa mushure mekunge mudziyo wanyatsokuyiwa uye usati wapfekedzwa.

▲ Tool passivation kuenzanisa

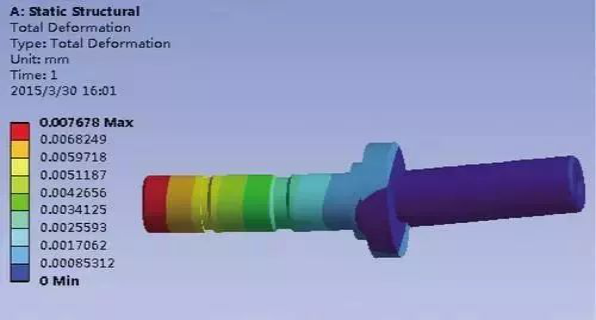

Chishandiso chinozorodzwa nevhiri rekukuya pamberi pechigadzirwa chapera, asi kurodza kwacho kunokonzeresa madhigirii akasiyana emakorokopu. Kana iyo machining centre ichiita yakakwira-kumhanya kucheka, iyo micro-notch ichawedzerwa nyore, iyo inomhanyisa kupfeka uye kukuvara kwechishandiso. Tekinoroji yemazuva ano yekucheka ine zvakaomesesa zvinodikanwa pakugadzikana uye kurongeka kwechishandiso, saka CNC chishandiso chinofanirwa kupfuudzwa chisati chavhara kuti ive nechokwadi chekusimba uye hupenyu hwebasa rejasi. Zvakanakira chishandiso passivation ndezvi:

1. Ramba kupfeka chombo

Munguva yekucheka, pamusoro pechishandiso chichave chichipfekwa zvishoma nezvishoma neworkpiece, uye kucheka kumucheto kunowanikwawo kune deformation yepurasitiki pasi pekushisa kwepamusoro uye kudzvinyirira kwakanyanya panguva yekucheka. Passivation yechishandiso inogona kubatsira kuvandudza kuomarara kwechishandiso uye kudzivirira chishandiso kubva pakurasikirwa nekucheka kuita nguva isati yakwana.

2. Chengetedza kupera kweworkpiece

Burrs pamucheto wekucheka kwechishandiso ichaita kuti chishandiso chipfeke uye pamusoro pechigadzirwa chemuchina chichava chakaomarara. Mushure mekurapa kwekupfuura, iyo yekucheka mupendero wechishandiso ichave yakatsetseka, iyo chipping phenomenon ichaderedzwa zvinoenderana, uye kupedzisa kwepamusoro kwechishandiso kuchavandudzwa zvakare.

3. Yakanakira groove chip kubviswa

Kuchenesa gorofu yechishandiso kunogona kuvandudza mhando yepamusoro uye chip evacuation performance. Iyo inotsvedzerera iyo groove pamusoro, zviri nani iyo chip evacuation, uye zvakanyanya kuenderana kucheka kunogona kuwanikwa. Mushure mekunge CNC chishandiso chepakati machining chapfuudzwa uye kukwenenzverwa, maburi madiki mazhinji achasiiwa pamusoro. Aya maburi madiki anogona kutora mvura yakawanda yekucheka panguva yekugadzira, iyo inoderedza zvakanyanya kupisa kunogadzirwa panguva yekucheka uye inovandudza zvakanyanya kucheka kwekuita. speed.

Iyo machining centre inoderedza sei kushata kwepamusoro kweiyo workpiece?

Iyo yakaoma pamusoro pezvikamu ndeimwe yematambudziko akajairika eCNC machiningnzvimbo, iyo inoratidzira zvakananga hutano hwekugadzirisa. Nzira yekudzora kushata kwepamusoro kwezvikamu zvekugadzirisa, tinofanira kutanga taongorora zvikonzero zvekushata kwepamusoro, kunyanya zvinosanganisira: zvigadziriso zvezvishandiso zvinokonzerwa nekugaya; thermal deformation kana plastiki deformation inokonzerwa nekucheka kuparadzaniswa; mudziyo uye machined pamusoro friction pakati.

Paunosarudza hutsinye hwepamusoro hwebasa rekushanda, haifaniri kungosangana nezvinodiwa zvekushanda kwepamusoro pechikamu, asiwo funga nezvehutano hwehupfumi. Pachimiro chekugutsa kuita kwekucheka, iyo yakakura yereferensi kukosha kwekuoma kwepamusoro kunofanirwa kusarudzwa zvakanyanya sezvinobvira kuderedza mutengo wekugadzira. Semuiti wenzvimbo yekucheka, chishandiso chinofanira kutarisisa kuchengetedza kwezuva nezuva uye kukuya panguva yakakodzera kuti udzivise kusakwana kwepamusoro roughness inokonzerwa neiyo dull tool.

Chii chandinofanira kuita kana machining centre yapera?

Kazhinji kutaura, iyo machining process mitemo yechinyakare muchina maturusi munzvimbo dzemuchina dzakada kufanana. Musiyano mukuru ndewekuti machining nzvimbo dzinoita kuenderera otomatiki machining kupedzisa ese ekucheka maitiro kuburikidza nekubamba kumwe. Naizvozvo, machining nzvimbo dzinoda kuita mamwe "Aftermath work".

1. Ita kuchenesa kurapwa. Mushure mekunge machining Center apedza basa rekucheka, zvinodikanwa kubvisa machipisi uye kupukuta muchina nenguva, uye kushandisa muchina chishandiso uye nharaunda kuti igare yakachena.

2. Kuti uongorore uye kuchinjwa kwezvishandiso, kutanga kune zvose, teerera kutarisa mafuta ekupukuta ndiro pane njanji yekufambisa, uye kuitsiva munguva kana yakasakara. Tarisa mamiriro emafuta ekuzora uye inotonhorera. Kana turbidity ikaitika, inofanira kuchinjwa munguva, uye chiyero chemvura chiri pasi pechiyero chinofanira kuwedzerwa.

3. Kuti uenzanise nzira yekuvhara, magetsi uye simba guru rekupa papaneti yekushanda yemuchina wekushandisa inofanira kuvharwa. Mukushaikwa kwemamiriro akakosha uye zvakakosha zvinodiwa, musimboti wekudzokera kune zero kutanga, bhuku remanyorero, jog, uye otomatiki rinofanira kuteverwa. Iyo machining Center inofanirwawo kumhanya yakaderera, yepakati kumhanya, uyezve kumhanya kwakanyanya. Iyo yakaderera-yekumhanya uye yepakati-yekumhanyisa nguva yekumhanya haingave isingasviki 2-3 maminetsi isati yave isina mamiriro asina kujairika asati atanga kushanda.

4. Yakajairwa mashandiro, haigone kurova, kururamisa kana kururamisa workpiece pane chuck kana pamusoro, uye inotevera oparesheni inofanira kusimbiswa mushure mekuti workpiece uye chishandiso chakasungwa. Zvishandiso zvekuchengetedza nekuchengetedza pamushini hazvifanirwe kubviswa uye kutamiswa zvisina tsarukano. Iyo inonyanya kushanda kugadzirisa ndeye yakachengeteka kugadzirisa. Sechishandiso chinoshanda chekugadzirisa, kushanda kwenzvimbo yekugadzira machini painovharwa kunofanira kunge yakanyatsogadziriswa, iyo haisi kungochengetedza maitiro ekugadzirisa ikozvino, asiwo kugadzirira kwekutanga kunotevera.

Nguva yekutumira: Sep-19-2022