Stainless simbi yeCNC Machining Zvikamuchimwe chezvinhu zvakajairika zvesimbi mukushanda kwechiridzwa. Kunzwisisa ruzivo rwesimbi isina tsvina kuchabatsira varidzi vezviridzwa zviri nani tenzi sarudzo uye kushandisa.

Stainless Steel ndiko kupfupikiswa kwesimbi isina tsvina uye acid inodzivirira simbi. Simbi inoshingirira kune isina kusimba corrosion media semhepo, chiutsi nemvura kana ine stainless property inonzi stainless steel; Simbi inoshingirira kumakemikari corrosion medium (asidhi, alkali, munyu uye mamwe makemikari etching) inonzi acid inodzivirira simbi.

Stainless Simbi inoreva simbi inoshingirira kune isina kusimba corrosion media semhepo, chiutsi nemvura uye makemikari etching media senge acid, alkali nemunyu, inozivikanwawo seStainless acid resistant steel. Mumashandisirwo anoshanda, simbi inoshingirira kune isina kusimba corrosion yepakati inowanzodaidzwa kunzi Stainless simbi, ukuwo simbi inoshingirira kumakemikari medium inodaidzwa kuti acid resistant simbi. Nekuda kwemusiyano wekuumbwa kwemakemikari pakati pezviviri izvi, yekutanga haifanirwe kurwisa kemikari yepakati corrosion, nepo iyo yekupedzisira kazhinji isina tsvina. Iyo corrosion resistance yesimbi isina tsvina inobva pane alloy zvinhu zviri musimbi.

Common classification

Kazhinji, yakakamurwa kuva:

Kazhinji, zvinoenderana nechimiro chemetallographic, simbi dzakajairwa dzisina tsvina dzakakamurwa kuita mhando nhatu: austenitic simbi isina tsvina, ferritic simbi isina tsvina uye martensitic simbi isina tsvina. Pahwaro hweaya matatu ekutanga metallographic zvimiro, dual phase simbi, kunaya kunoomesa Stainless simbi uye yakakwira alloy simbi ine iron yemukati isingasviki 50% yakatorwa kune chaiyo zvinodiwa uye zvinangwa.

1. Austenitic simbi isina tsvina.

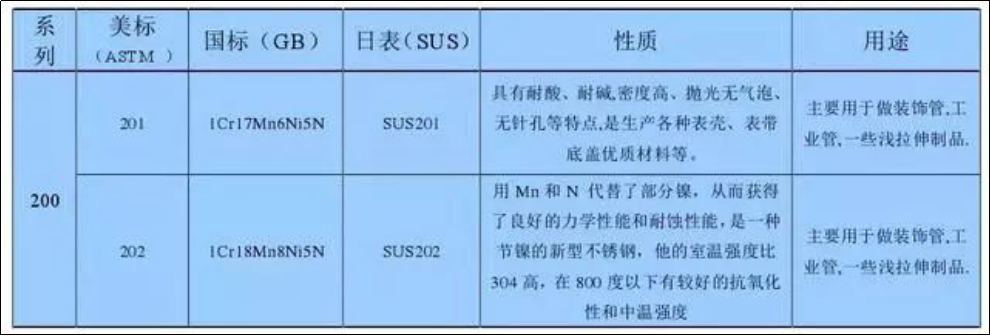

Iyo matrix inonyanya kuita austenitic chimiro (CY chikamu) ine kumeso kwakadzika cubic crystal chimiro, iyo isiri magineti, uye inonyanya kusimbiswa (uye inogona kutungamira kune imwe magnetism) nekushanda kunotonhora. IAmerican Iron and Steel Institute inoratidzwa ne200 uye 300 nhamba dzakatevedzana, dzakadai se304.

2. Ferritic simbi isina tsvina.

Iyo matrix inonyanya kuita ferrite chimiro (chikamu a) ine muviri wakananga cubic crystal chimiro, iyo ine magineti, uye kazhinji haigone kuomeswa nekupisa kurapwa, asi inogona kusimbiswa zvishoma nekushanda kunotonhora. IAmerican Iron uye Steel Institute yakanyorwa 430 uye 446.

3. Martensitic simbi isina tsvina.

Iyo matrix ndeye martensitic chimiro (muviri wakatarisana cubic kana cubic), magineti, uye ayo emakanika maitiro anogona kugadziriswa kuburikidza nekupisa kurapwa. IAmerican Iron and Steel Institute inoratidzwa nenhamba 410, 420, uye 440. Martensite ine austenitic structure pakupisa kwepamusoro. Kana yakatonhodzwa kusvika kukamuri tembiricha pamwero wakakodzera, iyo austenitic chimiro chinogona kushandurwa kuita martensite (kureva, yakaoma).

4. Austenitic ferritic (duplex) simbi isina tsvina.

Iyo matrix ine zvese austenite uye ferrite maviri-chikamu zvimiro, uye zviri mukati mechikamu chidiki matrix zvinowanzopfuura 15%, iyo ine magineti uye inogona kusimbiswa nekutonhora kushanda. 329 ndiyo yakajairika duplex simbi isina tsvina. Kuenzaniswa neaustenitic Stainless simbi, dual phase simbi ine simba rakakwirira, uye kuramba kwayo kune intergranular corrosion, chloride stress corrosion uye pitting corrosion yakagadziridzwa zvakanyanya.

5. Kunaya kunoomesa simbi isina tsvina.

Simbi isina simbi ine matrix ari austenitic kana martensitic uye inogona kuomeswa nekunaya kwemvura inoomesa marapirwo. The American Iron and Steel Institute yakanyorwa ne600 series manhamba, akadai se630, kureva 17-4PH.

Kazhinji kutaura, kunze kwealloy, austenitic Stainless simbi ine yakanakisa corrosion resistance. Ferritic simbi isina tsvina inogona kushandiswa munharaunda ine yakaderera corrosion. Munharaunda ine ngura yakapfava, martensitic simbi isina tsvina uye kunaya kwemvura inoomesa simbi isina tsvina inogona kushandiswa kana zvinhu zvichidikanwa kuve nesimba rakanyanya kana kuoma.

Hunhu uye chinangwa

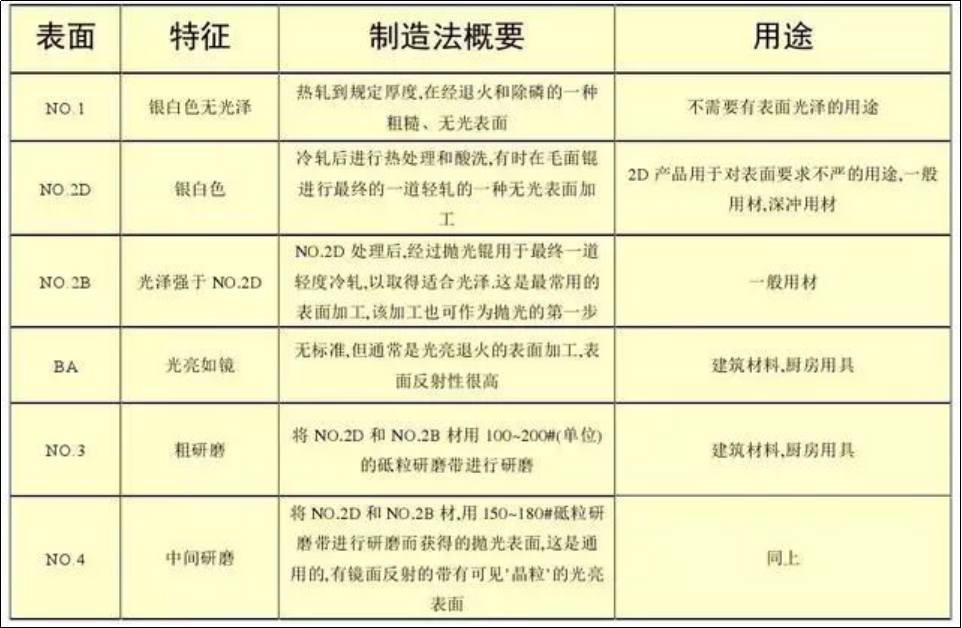

Surface tekinoroji

Kusiyanisa ukuru

1. Nokuti mukukunguruka kwemashini esimbi yesimbi, mupumburu wacho wakakanganiswa zvishoma nekuda kwekupisa, zvichikonzera kutsauka kwehupamhi hweplate yakakungurutswa. Kazhinji, ukobvu hwepakati hwakatetepa kumativi ese. Pakuyera kukora kweplate, chikamu chepakati chemusoro weplate chinofanira kuyerwa maererano nemitemo yenyika.

2. Kushivirira kunowanzo kukamurwa kuita kushivirira kukuru uye kushivirira kudiki zvichienderana nemusika uye kudiwa kwevatengi:

Semuyenzaniso

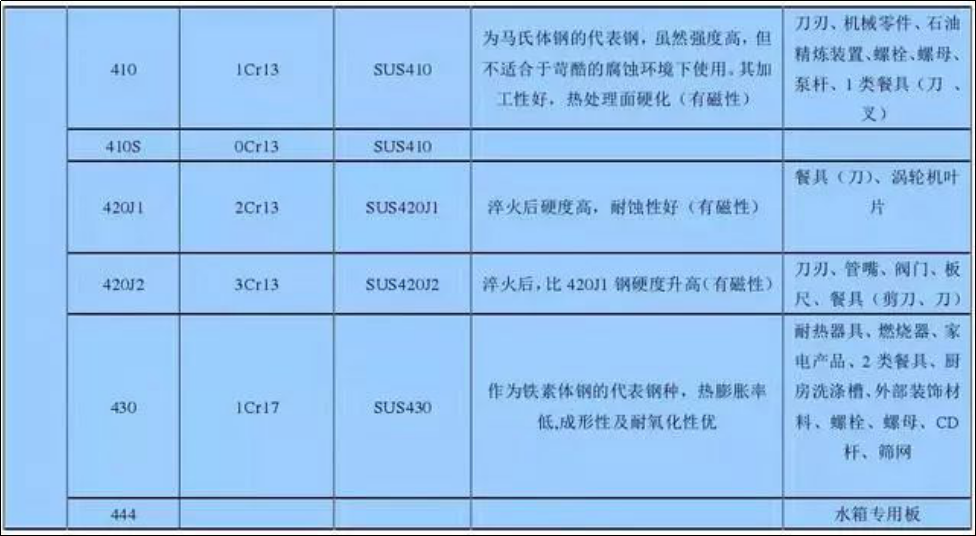

Inowanzo shandiswa Stainless simbi mamakisi uye zvimiro zvezviridzwa

1. 304 simbi isina tsvina. Iyo ndeimwe yeanonyanya kushandiswa austenitic simbi isina tsvina ine huwandu hukuru hwekushandisa. Yakakodzera kugadzira zvakadzika kudhirowa zvikamu zvakaumbwa, mapombi ekutepfenyura acid, midziyo, zvimiro zvezvimiro, akasiyana-siyana ezviridzwa mitumbi, nezvimwewo, pamwe neasiri-magineti uye yakaderera-tembiricha michina uye zvikamu.

2. 304L simbi isina tsvina. Iyo yekupedzisira-yakaderera kabhoni austenitic simbi isina simbi yakagadziridzwa kugadzirisa yakakomba intergranular corrosion maitiro e304 simbi isina tsvina yakakonzerwa nekunaya kweCr23C6 pasi pemamwe mamiriro, yayo inosimudzira intergranular corrosion kuramba iri nani kupfuura 304 simbi isina tsvina. Kunze kwesimba rakaderera, zvimwe zvivakwa zvakafanana ne321 simbi isina tsvina. Iyo inonyanya kushandiswa kune corrosion resistant midziyo uye zvikamu zvinoda welding asi hazvigone kugadziriswa nemhinduro, uye inogona kushandiswa kugadzira akasiyana ezviridzwa mitumbi.

3. 304H simbi isina tsvina. Kubazi remukati re304 simbi isina tsvina, kabhoni misa chikamu 0.04% - 0.10%, uye tembiricha yakakwira inopfuura 304 simbi isina tsvina.

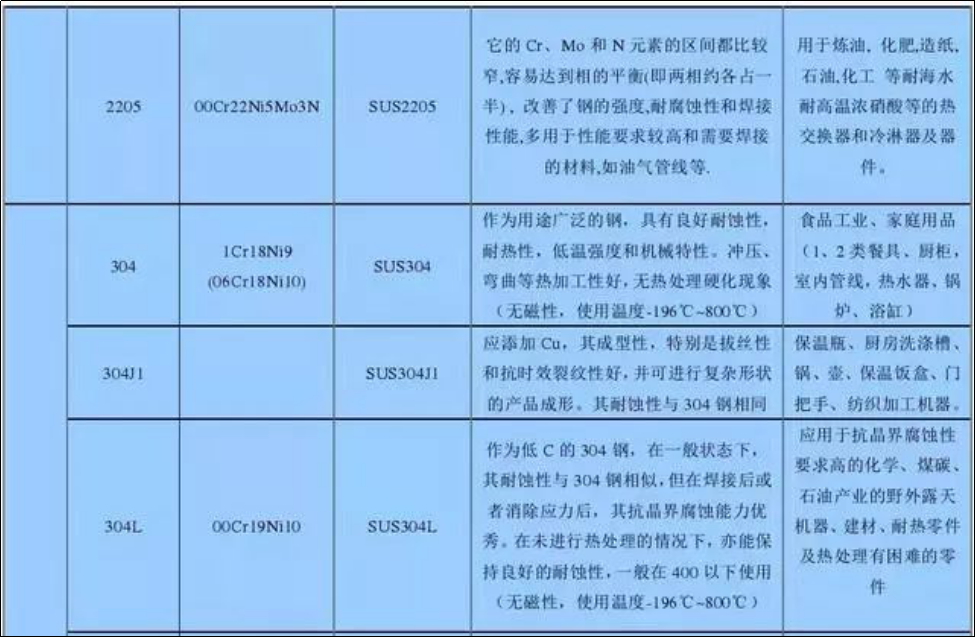

4. 316 simbi isina tsvina. Kuwedzerwa kwe molybdenum pahwaro hwe10Cr18Ni12 simbi inoita kuti simbi ive nekudzivirira kwakanaka kudzikisa kwepakati uye gomba ngura. Mumvura yegungwa nemimwe midhiya, iyo corrosion resistance inokunda 304 simbi isina tsvina, inonyanya kushandiswa kupinza corrosion resistant materials.

5. 316L simbi isina tsvina. Ultra yakaderera kabhoni simbi, ine kumira zvakanaka kune sensitized intergranular corrosion, yakakodzera kugadzira gobvu chikamu saizi yewelding zvikamu nemidziyo, senge anti-corrosion zvinhu mu petrochemical midziyo.

6. 316H simbi isina tsvina. Kubazi remukati re316 simbi isina tsvina, kabhoni misa chikamu 0.04% - 0.10%, uye tembiricha yekushanda yakanyanya kupfuura iyo ye316 simbi isina tsvina.

7. 317 simbi isina tsvina. Kupokana negomba corrosion uye zvinokambaira kwakakwirira kune 316L Stainless simbi. Inoshandiswa kugadzira petrochemical uye organic acid inodzivirira michina.

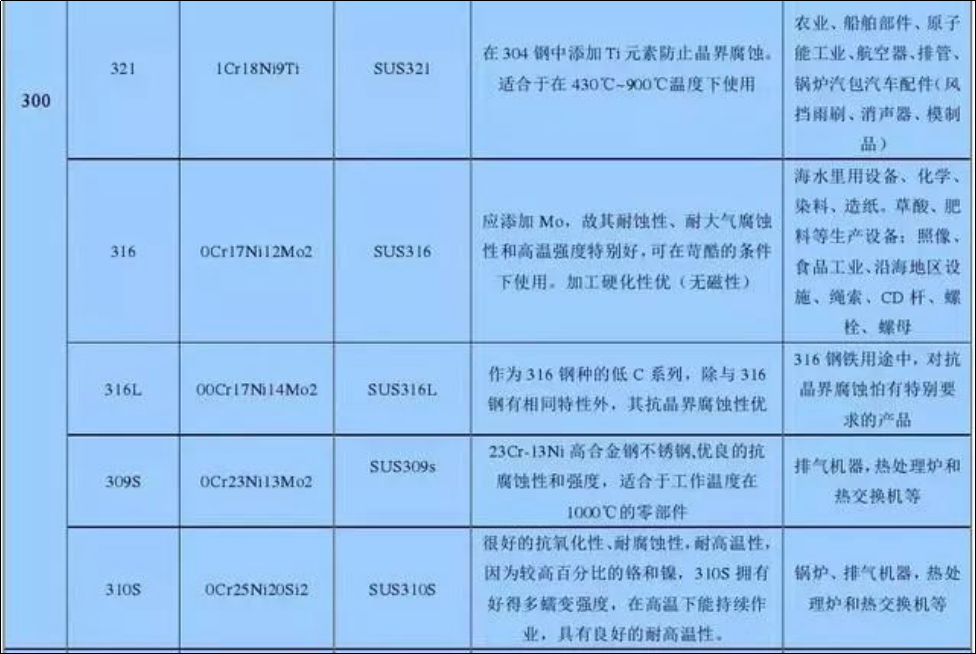

8. 321 simbi isina tsvina. Titanium yakagadzika austenitic simbi isina tsvina inogona kutsiviwa neyekupedzisira-yakaderera kabhoni austenitic simbi isina tsvina nekuda kwekuvandudzwa kwayo intergranular corrosion resistance uye yakanaka tembiricha yekupisa michina. Kunze kwezviitiko zvakakosha senge tembiricha yepamusoro kana hydrogen corrosion resistance, kazhinji hazvikurudzirwe kushandisa.

9. 347 simbi isina tsvina. Niobium yakagadzikana austenitic simbi isina tsvina. Kuwedzerwa kwe niobium kunovandudza intergranular corrosion resistance. Kudzivirirwa kwayo nekuora mu acid, alkali, munyu uye zvimwe zvinosvibisa media zvakafanana ne321 simbi isina tsvina. Nekuita kwakanaka kwewelding, inogona kushandiswa sese zviri zviviri zvinodzivirira ngura uye simbi inodzivirira kupisa. Inonyanya kushandiswa mumagetsi ekupisa uye petrochemical minda, sekugadzira midziyo, mapaipi, kupisa kupisa, shafts, machubhu echoto muchoto cheindasitiri, uye choto chubhu thermometers.

10. 904L simbi isina tsvina. Super yakakwana austenitic Stainless simbi ndeye super austenitic Stainless simbi yakagadzirwa neOUTOKUMPU Kambani yeFinland. Chikamu chayo che nickel mass 24% - 26%, uye carbon mass chikamu chiri pasi pe0.02%. Iyo ine yakanakisa corrosion resistance. Iyo ine yakanaka corrosion resistance mune asiri oxidizing acids akadai sesulfuric acid, acetic acid, formic acid uye phosphoric acid, pamwe nekuramba kwakanaka kune crevice corrosion uye kusagadzikana ngura. Inoshanda kune dzakasiyana siyana dze sulfuric acid pazasi 70 ℃, uye ine yakanaka corrosion kuramba kune acetic acid yechero kusungirirwa uye tembiricha pasi pekumanikidzwa kwakajairwa uye kune yakasanganiswa asidhi yefomic acid uye acetic acid. Iyo yekutanga chiyero ASMSB-625 yakaiisa senickel base alloy, uye chiyero chitsva chakaiisa sesimbi isina tsvina. MuChina, pane chete mhando yakafanana ye015Cr19Ni26Mo5Cu2 simbi. Vagadziri vezviridzwa vashoma vekuEurope vanoshandisa 904L simbi isina tsvina sechinhu chakakosha. Semuenzaniso, chubhu yekuyeresa yeE + H mass flowmeter inoshandisa 904L simbi isina tsvina, uye nyaya yeRolex wachi dzinoshandisawo 904L simbi isina tsvina.

11. 440C simbi isina tsvina. Kuomarara kwemartensitic Stainless simbi, kuomarara simbi isina tsvina uye simbi isina tsvina ndiko kwakakwirira, uye kuomarara ndiko HRC57. Inonyanya kushandiswa kugadzira nozzles, mabearings, valve cores, valve seats, sleeves, valve stems, nezvimwe.

12. 17-4PH simbi isina tsvina. Martensitic precipitation inoomesa simbi isina tsvina, nekuoma kweHRC44, ine simba rakawanda, kuoma uye kusagadzikana kwemarara, uye haigone kushandiswa patembiricha inodarika 300 ℃. Iyo ine yakanaka corrosion resistance kumhepo uye diluted acid kana munyu. Kupokana kwayo nekuora kwakafanana ne304 simbi isina tsvina uye 430 simbi isina tsvina. Inoshandiswa kugadziraCNC Machining Zvikamu, turbine blades, mavharuvhu cores, zvigaro zvevharuvhu, maoko, madzinde evharuvhu, nezvimwe.

Muchishandiso chezviridzwa, pamwe chete nepasirese uye nyaya dzemitengo, iyo yakajairika yekusarudzwa kurongeka kweaustenitic stainless simbi ndeye 304-304L-316-316L-317-321-347-904L simbi isina tsvina, iyo 317 isinganyanyi kushandiswa, 321 haina. inokurudzirwa, 347 inoshandiswa kune yakakwirira tembiricha corrosion kuramba, 904L ndiyo yakasarudzika zvinhu zvimwe zvikamu zvevagadziri vega, uye 904L haina kunyatsosarudzwa mukugadzira.

Mukugadzira uye kusarudzwa kwezviridzwa, pane kazhinji nguva apo chiridzwa chakasiyana kubva kune iyo pombi zvinhu, kunyanya mune yakanyanya tembiricha yekushanda mamiriro, kutarisisa kwakanyanya kunofanirwa kubhadharwa kuti sarudzo yemidziyo inosangana nekushisa kwekugadzira uye dhizaini yedhizaini. kugadzira michina kana pombi. Semuenzaniso, iyo pombi ndeyepamusoro tembiricha chromium molybdenum simbi, nepo chiridzwa chiri simbi isina tsvina. Muchiitiko ichi, matambudziko anogona kuitika, uye iwe unofanirwa kubvunza tembiricha uye yekumanikidza geji yezvinhu zvinoenderana.

Mukuita kwekugadzira chiridzwa uye kusarudzwa kwemhando, isu tinowanzosangana nesimbi isina tsvina yemhando dzakasiyana masisitimu, akatevedzana uye mabhureki. Pakusarudza mhando, isu tinofanirwa kufunga nezvematambudziko kubva kune akati wandei maonero akadai seakananga process media, tembiricha, kudzvanywa, kumanikidzwa zvikamu, ngura uye mutengo.

Nguva yekutumira: Oct-17-2022