Zvakawanda sei zvaunoziva nezve chinzvimbo uye clamping mumachining?

Kuti uwane mhedzisiro uye chaiyo mhedzisiro, chinzvimbo uye clamping zvinhu zvakakosha zvemachining.

Dzidza nezve kukosha kwekumisikidza uye clamping paunenge uchigadzira:

Positioning: Iyi ndiyo chaiyo kuiswa kwechishandiso chekushanda chinoenderana nechigadzirwa chekucheka. Kubatanidza iyo workpiece pamwe nematemo matatu ekutanga (X, Y, Z) inodiwa kuti uwane zviyero zvaunoda uye nzira yekucheka.

Kurongeka kwakakosha kune chaiyo machining:Kubatanidza maworkpieces nenzira kwayo kunogoneka nehunyanzvi hwakadai senge edge finder, zviratidzo uye coordination yekuyeresa muchina (CMM).

Izvo zvakakosha kumisikidza nzvimbo yedatum kana poindi yekumisikidza kunoenderana:Izvi zvinobvumira machining ese anotevera kuve akavakirwa pane yakajairwa pamusoro kana nzvimbo yekunongedza.

Clamping ndiyo nzira yekuchengetedza iyo workpiece pamushini:Inopa kugadzikana uye inodzivirira kuzununguka kana kufamba kunogona kutungamira kune isina kururama machining.

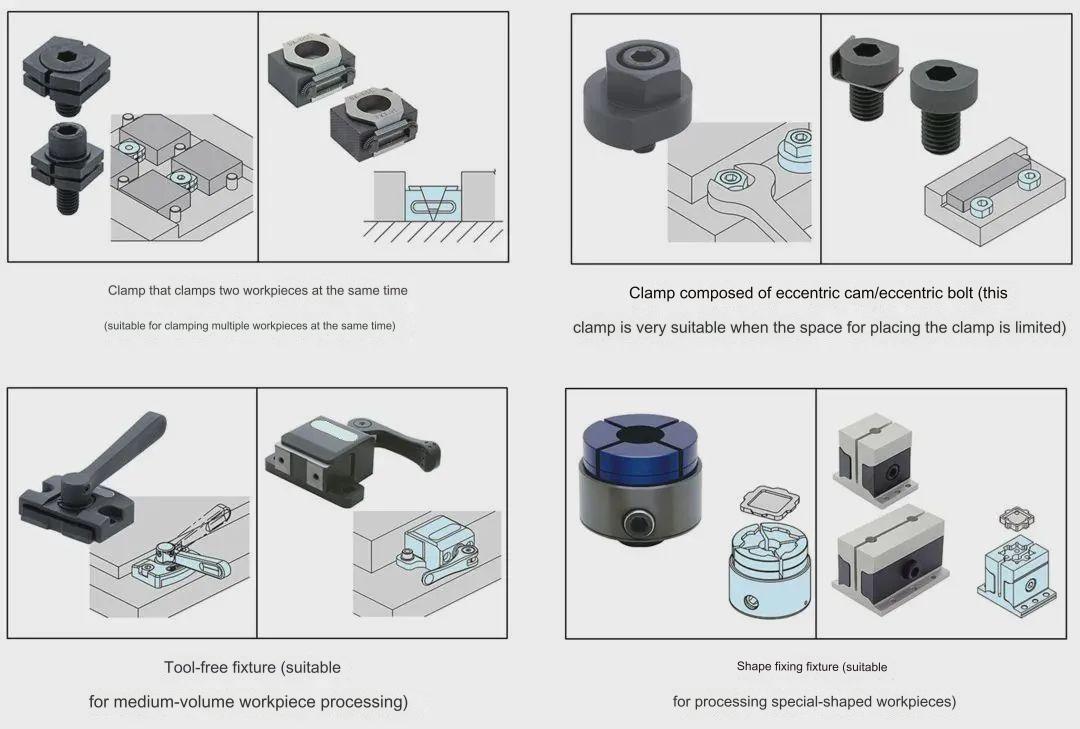

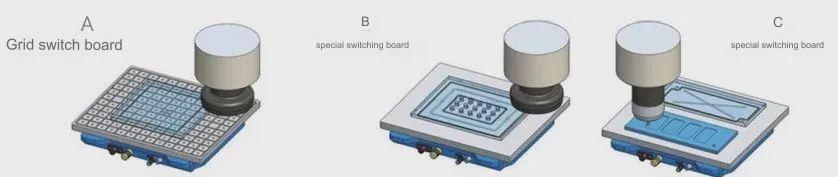

Mhando dzeClamps:Kune akawanda marudzi emaclamps anogona kushandiswa kugadzira. Izvi zvinosanganisira magineti clamps uye pneumatic, hydraulic, kana hydraulic-pneumatic clamps. Sarudzo yenzira dzekurovera dzinobva pazvinhu zvakaita sehukuru uye chimiro, simba rekugadzira, uye nezvinodiwa chaizvo.

Clamping Techniques:Kurovera kwakaringana kunosanganisira kugovera zvakaenzana simba rekusunga, kuchengetedza kusimba kusingachinji pane workpiece uye kudzivirira kukanganisa. Kuti udzivise kukanganisa kune workpiece uchichengetedza kugadzikana, zvakakosha kushandisa iyo chaiyo clamping pressure.

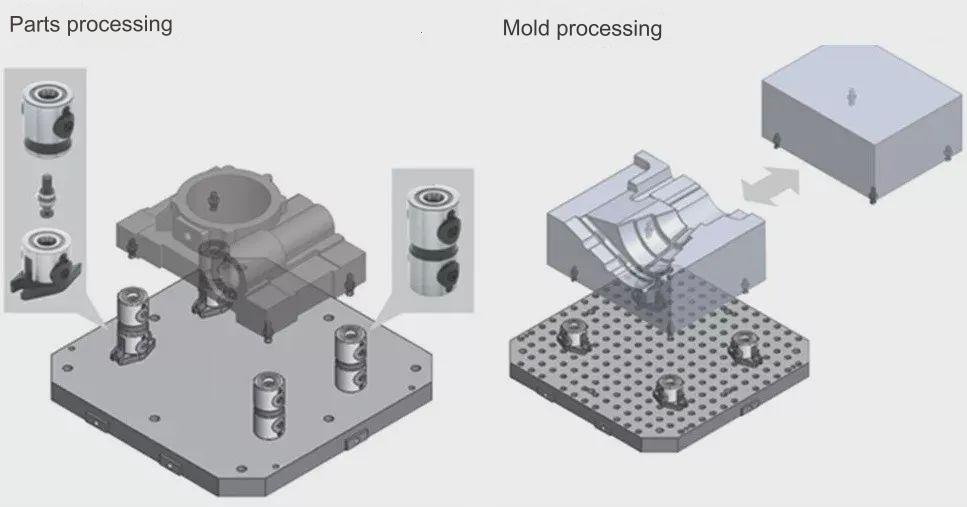

Fixtures maturusi akakosha anosunga uye anoisa maworkpieces:Ivo vanopa rutsigiro, kurongeka uye kugadzikana kune machining mashandiro. Izvi zvinoderedza njodzi yekukanganisa uye inovandudza chibereko.

Fixtures inouya mumhando dzakawanda dzakasiyana, seV-blocks uye angle plates. Vanogonawo kugadzirwa-tsika. Kusarudzwa kwekugadzirisa kwakakodzera kunotsanangurwa nekuoma kwechidimbu uye machining zvinodiwa.

Fixture Dhizaini inosanganisira kunyatsofunga nezvezvinhukufanana workpiece zviyero, uremu, zvinhu uye kuwana zvinodiwa. Iyo yakanaka dhizaini dhizaini inovimbisa yakakwana clamping uye chinzvimbo chekuita machining.

Kushivirira uye Kururamisa:Kumisikidzwa kwakaringana uye kusungirira kwakakosha kuti uwane kushivirira kwakasimba uye iko kurongeka kana uchigadzira. Chikanganiso chidiki mukurovera kana kuisa chinzvimbo chinogona kutungamira mukusiyana kwehukuru uye kukanganisa kunaka.

Kuongorora uye Kuona:Kugara uchiongorora uye kuoneswa kwe clamping uye kurongeka kwechokwadi kwakakosha kuti uve nechokwadi chekuenderana mumhando. Kusimbisa chokwadi chezvikamu zvemuchina, zviyereso zvekuyeresa senge calipers uye micrometers pamwe neCMM zvinogona kushandiswa.

Hazvisi nyore seizvi. Isu takaona kuti yekutanga dhizaini inogara iine mamwe matambudziko ne clamping uye chinzvimbo. Magadzirirwo matsva anorasikirwa nekukosha kwawo. Isu tinogona chete kuve nechokwadi chekutendeseka uye mhando yegadziriso dhizaini nekunzwisisa basic positioning uye clamping ruzivo.

Ruzivo rwenzvimbo

1. Kuisa workpiece kubva parutivi ndiyo nheyo inokosha.

Iyo 3-point musimboti, serutsigiro, ndiyo musimboti wekutanga wekuisa iyo workpiece kubva padivi. Iyo 3-point musimboti wakafanana neiyo yekutsigirwa. Iyi nheyo inobva pakuti "mitsetse mitatu yakatwasuka isingapesane inosarudza ndege." Zvitatu zvezvina zvibodzwa zvinogona kushandiswa kuona ndege. Izvi zvinoreva kuti 4 nzvimbo dzese dzinogona kutariswa. Zvakaoma kuwana poindi yechina mundege imwe chete, zvisinei nekuti mapoinzi akaiswa sei.

▲3-pfungwa musimboti

Semuyenzaniso, pakushandisa mapoinzi mana akareba, matatu chete mapoinzi chaiwo anokwanisa kudhumana nechishandiso, zvichisiya mukana wakakura wekuti yasara yechina poindi haizogadzirise kuonana.

Naizvozvo, paunenge uchigadzirisa locator, tsika yakajairika ndeyekuimisa pamapoinzi matatu uchiwedzera chinhambwe pakati peaya mapoinzi.

Uyezve, panguva yekurongeka kweiyo positioner, zvakakosha kufanosimbisa kutungamira kweiyo inoshandiswa kugadzirisa mutoro. Kutungamira kweiyo machining load inopindirana nekufamba kwechibatiso/chombo. Kuisa chinzvimbo pamagumo eiyo feed direction inobata zvakananga kurongeka kwese kweiyo workpiece.

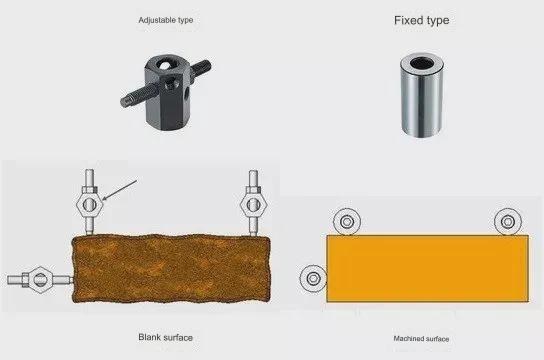

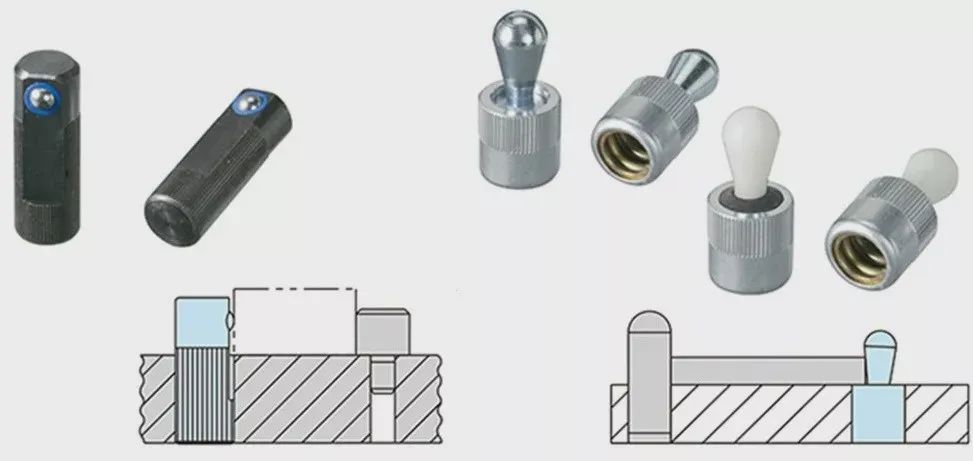

Kazhinji, pakuisa nzvimbo yakaomarara yebasa rekushanda, bhoti-mhando inogadziriswa chinzvimbo inoshandiswa, nepo yakagadziriswa mhando yekumisikidza (ine yepasi workpiece yekubata kumeso) inoshandiswa kumisa iyo yakashongedzwa pamusoro peiyo.machining zvikamu.

2. Misimboti yakakosha yekumisikidza kuburikidza nemaburi eworkpiece

Pakumisa uchishandisa maburi akagadzirwa panguva yakapfuura machining process, mapini ane kushivirira anofanirwa kushandiswa. Nekugadzirisa kurongeka kwegomba rekushanda nekururama kwepini yepini, uye kuvabatanidza zvichienderana nekodzero yekushivirira, kurongeka kwekugadzirisa kunogona kusangana nezvinodiwa chaizvo.

Pamusoro pezvo, kana uchishandisa mapini ekumisikidza, zvakajairika kushandisa pini yakatwasuka padivi pepini yedhaimani. Izvi hazvingogonese kuungana uye kupatsanurwa kweiyo workpiece asi zvakare inoderedza mukana weiyo workpiece uye pini inonamira pamwechete.

▲Shandisa pini yekumisikidza

Zvirokwazvo, zvinogoneka kuwana kwakaringana kushivirira nekushandisa mapini akatwasuka ezvinzvimbo zvese zviri zviviri. Zvisinei, nokuda kwokururama kukuru mukuisa, kubatanidzwa kwepini yakatwasuka nepini yedhaimani kunoratidza kuva kunobudirira zvikuru.

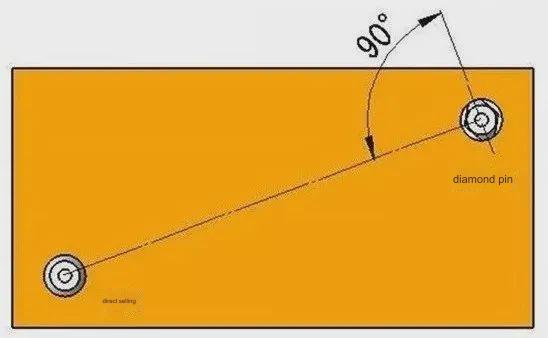

Paunenge uchishandisa zvese pini yakatwasuka nepini yerhombus, zvinowanzokurudzirwa kuisa rhombus pini nenzira iyo mutsara unobatanidza marongero ayo kune workpiece uri perpendicular (pa90 ° angle) kune mutsara unobatanidza pini yakatwasuka uye. pini yerhombus. Kurongeka uku kwakakosha pakuona kona yekumisikidza uye negwara rekutenderera kweworkpiece.

Clamp inoenderana ruzivo

1. Kurongwa kwezvisungo

Zvinoenderana neiyo clamping gwara, rinowanzo kupatsanurwa muzvikamu zvinotevera:

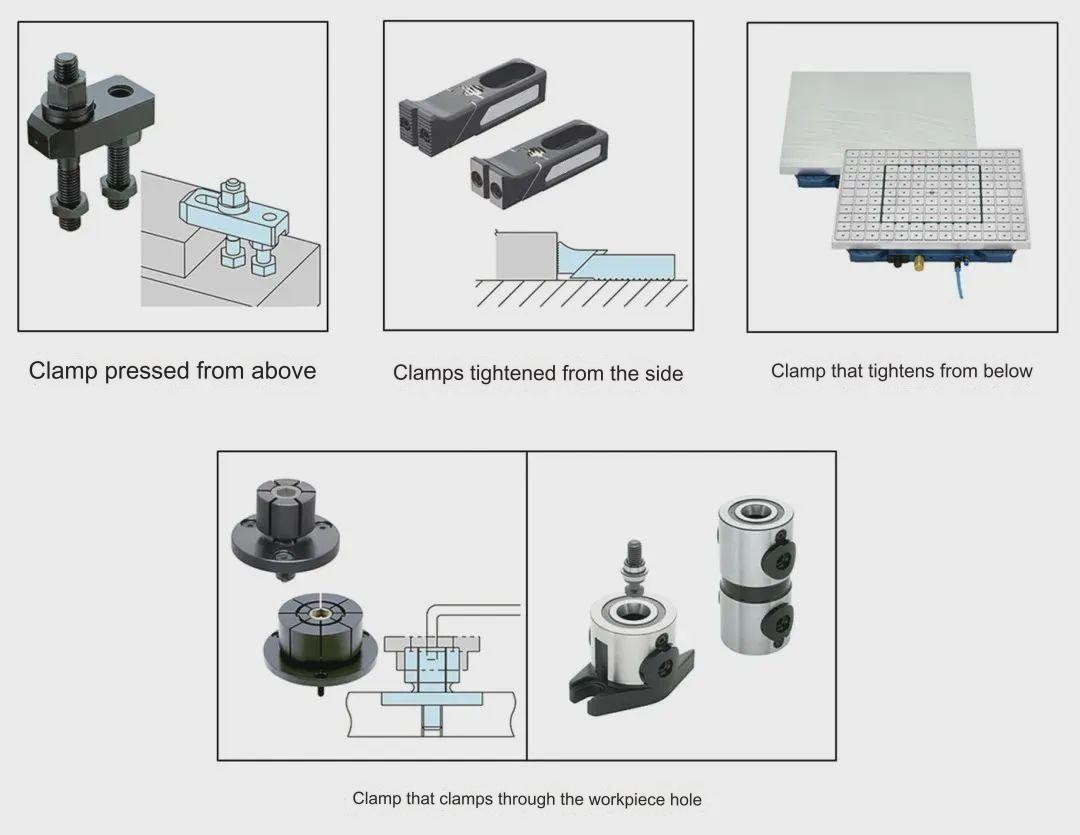

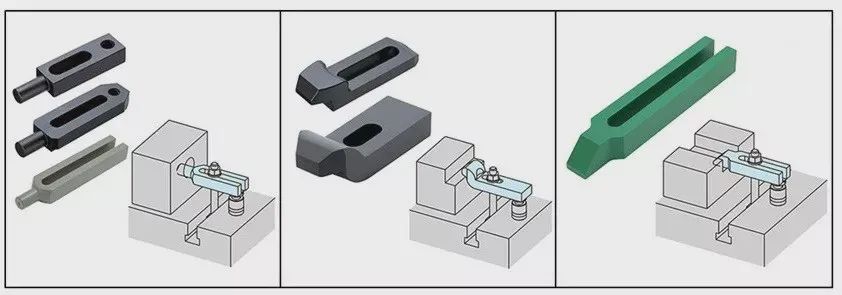

1. Overhead Compression Clamp

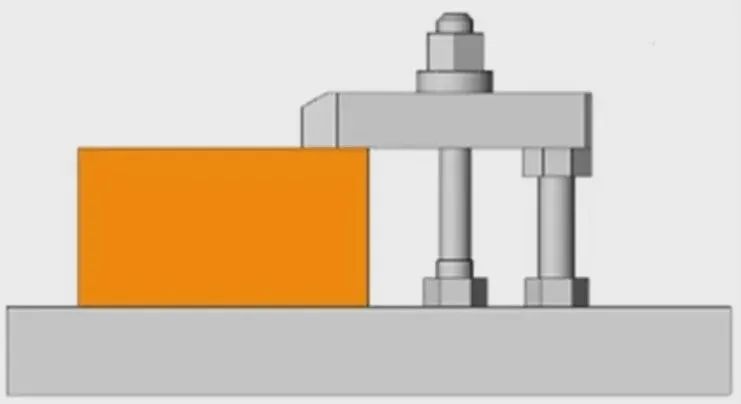

Iyo yekumusoro yekumanikidza yekumanikidza inomanikidza kubva pamusoro peiyo workpiece, zvichikonzera kushoma deformation panguva yekurovera uye kuwedzeredzwa kugadzikana panguva yebasa rekushanda. Nekuda kweizvozvo, kusungirira workpiece kubva kumusoro kunowanzo kukoshesa. Iyo yakanyanya kupararira mhando ye clamp inoshandiswa nenzira iyi ndeye manual mechanical clamp. Semuyenzaniso, chisungiso chine mufananidzo chiri pazasi chinodaidzwa kunzi 'chisungiso chemashizha emupine'. Mumwe musiyano, unozivikanwa se'lose leaf clamp', unosanganisira presure plate, stud bolts, Jacks, and nuts."

Uyezve, zvichienderana nechimiro chebasa rekushanda, une sarudzo yekusarudza kubva kune zvakasiyana-siyana zvekumanikidzika mahwendefa akanyatsogadzirirwa kuti aenderane nemhando dzakasiyana dzebasa.

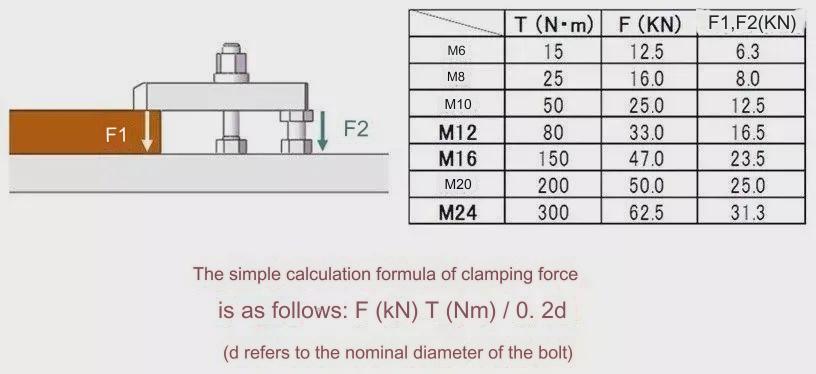

Zvinogoneka kuona kuwirirana pakati pe torque nechisimba chekusunga mushizha rakasununguka rinosunga nekuongorora simba rekusundidzira rinoitwa nebhaudhi.

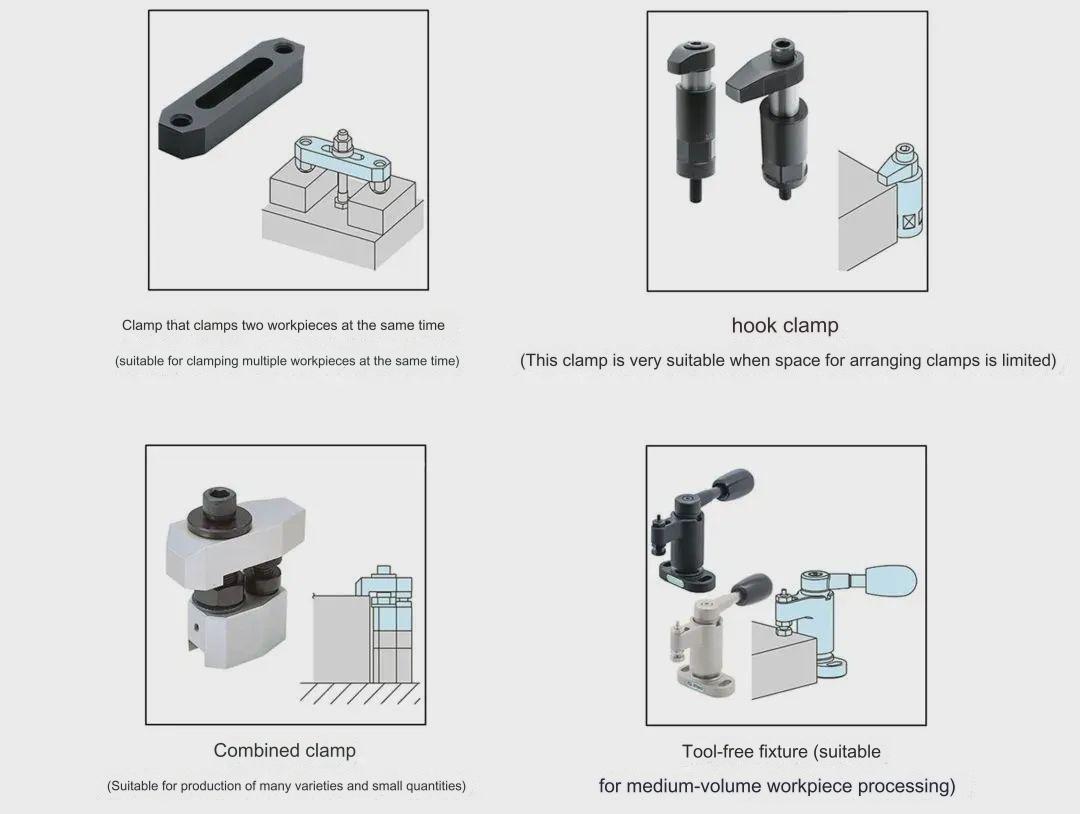

Kunze kweiyo yakasununguka mashizha rudzi clamp, kune zvakare mamwe machira anowanikwa anochengetedza workpiece kubva kumusoro.

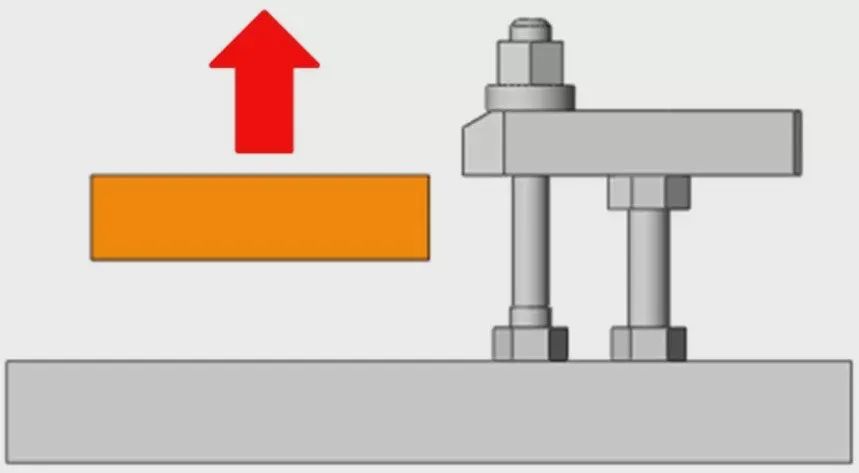

2. Side clamp ye workpiece clamping

Iyo yakajairwa clamping nzira inosanganisira kuchengetedza iyo workpiece kubva kumusoro, ichipa kugadzikana kwepamusoro uye kushoma kugadzirisa mutoro. Nekudaro, mamiriro ezvinhu anogona kumuka apo kusungirira kwepamusoro kusingakodzeri, senge kana iyo yepamusoro inoda machining kana kana kumusoro kusungirira kusingagoneke. Mumamiriro ezvinhu akadaro, kusarudza padivi clamping kunodiwa.

Zvakadaro, zvakakosha kuziva kuti kusungirira workpiece kubva padivi kunoburitsa simba rinoyangarara. Kuchenjerera kunofanirwa kupihwa pakubvisa simba iri panguva yekugadzira dhizaini kuti ive nechokwadi chekushanda kwakakwana.

Kufunga kunogona kusanganisira kubatanidza nzira dzinorwisa simba rekuyangarara, sekushandisa imwe rutsigiro kana kudzvanywa kudzikamisa workpiece. Nekunyatsogadzirisa simba rinoyangarara, yakavimbika uye yakachengeteka yedivi clamping mhinduro inogona kuwanikwa, ichiwedzera kuchinjika kweworkpiece kugadzirisa.

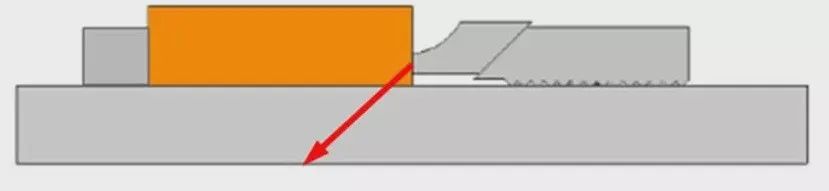

Kune zvakare mabhanhire epadivi aripo, sekuratidzwa pamufananidzo uri pamusoro. Aya mabhanhire anoshandisa simba rekukanda kubva padivi, richigadzira oblique inodzika pasi. Iyi chaiyo mhando ye clamp inoshanda zvakanyanya mukudzivirira iyo workpiece kubva pakuyangarara kumusoro.

Zvakafanana neaya mabhambure ekumativi, kune mamwe masimbi anoshandawo kubva padivi.

Workpiece Clamping kubva Pazasi

Paunenge uchibata chidimbu cheplate-tete uye ichida kugadzirisa pamusoro payo, nzira dzechinyakare dzekusunga kubva kumusoro kana kubva padivi dzinoratidza kusashanda. Mumamiriro ezvinhu akadaro, mhinduro inoshanda ndeyekumanikidza workpiece kubva pazasi. Kune maworkpiece akagadzirwa nesimbi, magineti rudzi clamp inowanzokodzera, nepo isiri-ferroustsika yesimbi yekugayaworkpieces inogona kuchengetedzwa uchishandisa vacuum suction cups.

Mune ese ari maviri ataurwa pamusoro, iyo clamping simba inoenderana nenzvimbo yekubatana pakati pebasa rekushanda uye magineti kana vacuum chuck. Izvo zvakakosha kucherechedza kuti kana iyo yekugadzirisa mutoro padiki workpiece ikava yakawandisa, inodiwa yekugadzirisa mhedzisiro inogona kusawanikwa.

Pamusoro pezvo, zvakakosha kuve nechokwadi chekuti nzvimbo dzekusangana dzemagineti uye vacuum suction kapu dzakanyatso tsetseka kuitira kushandiswa kwakachengeteka uye kwakaringana.

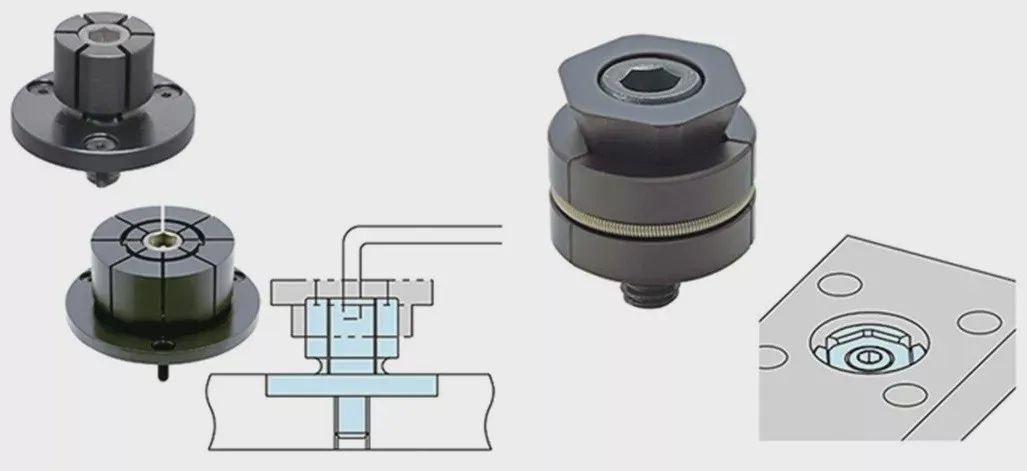

Kushandisa Hole Clamping

Paunenge uchishandisa 5-axis machining muchina wekuita senge panguva imwe chete-yakawanda-kumeso kugadzirisa kana kugadzira mold, zvinokurudzirwa kuti usarudze gomba clamping sezvo ichibatsira kudzikisira kukanganiswa kwezvigadziriso uye maturusi pakugadzirisa maitiro. Kuenzaniswa nekusungirira kubva kumusoro kana kudivi reworkpiece, gomba clamping inoshanda kushoma kudzvanywa uye zvinobudirira kuderedza workpiece deformation.

▲Shandisa maburi ekugadzirisa zvakananga

▲Rivet Kuiswa kweClamping

Pre-clamping

Ruzivo rwapfuura rwunonyanya kutarisa pane workpiece clamping zvigadziriso. Izvo zvakakosha kuti utarise maitiro ekusimudzira usability uye kuvandudza mashandiro kuburikidza ne-pre-clamping. Kana uchiisa workpiece yakatwasuka pachigadziko, giravhiti rinogona kuita kuti workpiece iwire pasi. Mumamiriro ezvinhu akadaro, zvinova zvakakosha kubata nemaoko chigadziriso paunenge uchishanda chibatiso kuitira kudzivirira chero kutamiswa netsaona.

▲ Pre-clamping

Kana iyo workpiece ichirema kana zvidimbu zvakawanda zvakasungwa panguva imwe chete, zvinogona kukanganisa zvakanyanya kushanda uye kurebesa nguva yekurovera. Kugadzirisa izvi, kushandisa chitubu-yemhando pre-clamping chigadzirwa chinobvumira iyo workpiece kuti isungirwe ichiramba yakamira, ichiwedzera kushanda nesimba uye kuderedza clamping nguva.

Pfungwa pakusarudza clamp

Paunenge uchishandisa akawanda marudzi ekusungirira mune imwechete tooling, zvakakosha kushandisa maturusi mamwechete kune ese ari maviri kusungirira uye kusunungura. Semuyenzaniso, mumufananidzo wekuruboshwe pazasi, kushandisa akawanda maturusi mawrench ekusunga maoperation kunowedzera mutoro wakazara pamushandisi uye kuwedzera nguva yekusunga. Kune rimwe divi, mumufananidzo wekurudyi pazasi, kubatanidza zvikwiriso zvechishandiso uye saizi yebhaudhi inorerutsa maitiro evashandisi vepa-saiti.

▲Kushanda Kwekushanda kweWorkpiece Clamping

Uyezve, kana uchigadzirisa chigadziro chekuvhara, zvakakosha kufunga nezvekushanda kwekushanda kwe workpiece clamping. Kana iyo workpiece ichida kusungirirwa pakona yakarerekera, inogona kukanganisa zvakanyanya mashandiro. Naizvozvo, zvakakosha kuti udzivise mamiriro ezvinhu akadaro paunenge uchigadzira fixture tooling.

Kutsvaga kweAnebon uye chinangwa chekambani kugara chiri "Nguva dzose tichigutsa zvinodiwa nevatengi vedu". Anebon ramba uchiwana uye dhizaini uye gadzira zvinoshamisa zvemhando yepamusoro zvigadzirwa kune yega yega vatengi vedu vekare uye vatsva uye kusvika pakukunda-kuhwina tarisiro yevatengi veAnebon pamwe nesu yeOriginal Factory Profile extrusions aluminium,cnc yakatendeuka chikamu, cnc kugaya naironi. Isu tinogashira nemoyo wese shamwari kuti dzichinjane bhizinesi bhizinesi uye kutanga kushandira pamwe nesu. Anebon inotarisira kurovanisa maoko neshamwari dzepedyo mumaindasitiri akasiyana kuti igadzire inopenya kwenguva refu.

China Mugadziri weChina High Precision uye Metal Stainless Steel Foundry, Anebon iri kutsvaga mikana yekusangana neshamwari dzese kubva kumba nekune dzimwe nyika kuitira kuhwina-kuhwina kubatana. Anebon inotarisira nemoyo wose kuve nekubatana kwenguva refu nemi mose pazvigadziko zvekubatsirana pamwe nekusimudzira kwakafanana.

Nguva yekutumira: Sep-25-2023