Iyo shinda inonyanya kukamurwa kuita tambo yekubatanidza uye tambo yekutumira

Zvekubatanidza tambo dzeCNC Machining zvikamuuyeCNC Kushandura zvikamu, nzira huru dzekugadzirisa ndeidzi: kubaya, kupinza, kutenderedza, kukunguruka, kukunguruka, etc. Kune tambo yekutumira, nzira huru dzekugadzirisa ndeidzi: rough uye yakanaka kutendeuka ---kugaya, kugaya-chamupupuri---yakaoma uye yakanaka kutendeuka, nezvimwe. .

Nzira dzakasiyana-siyana dzekugadzirisa dzinotsanangurwa pasi apa:

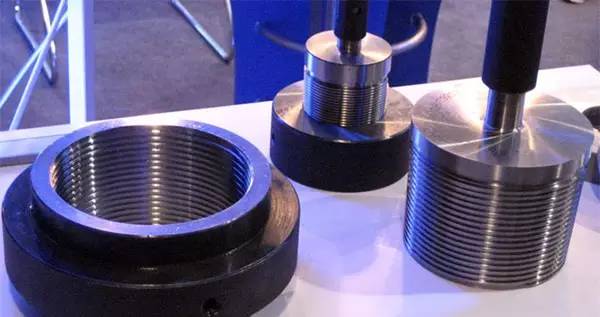

1. Kucheka shinda

Kazhinji inoreva nzira yekugadzira tambo pacnc kushandura zvikamunematurusi ekugadzira kana maturusi ekukuya, kunyanya anosanganisira kutenderedza, kugaya, kubaya, kupinza, kukuya, kugaya uye kucheka kwechamupupuri. Kana uchitenderedza, kugaya uye kugaya tambo, cheni yekufambisa yemuchina wemuchina unova nechokwadi chekuti chishandiso chekutenderedza, chigayo chekucheka kana vhiri rekukuya chinofambisa mutobvu nemazvo uye zvakaenzana padivi peaxis yeworkpiece pese painotenderera workpiece. Kana uchibaya kana shinda, chishandiso (pombi kana kufa) uye workpiece inoita kutenderera kutenderera, uye yekutanga yakaumbwa shinda groove inotungamira chishandiso (kana workpiece) kufamba axially.

Kubatidza shinda pa lathe kunogona kushandisa fomu rekutenderedza kana muzinga weshinda (ona maturusi eshinda). Kushandura tambo nekugadzira maturusi ekushandura inzira yakajairika yeimwe-chidimbu uye diki-batch kugadzirwa kwe threaded workpieces nekuda kweiyo yakapusa sisitimu chimiro; kushandura shinda neshinda dzekucheka zvine hunyanzvi hwekugadzira, asi chimiro cheturusi chakaomarara uye chakakodzera kuchinjika mukati uye hukuru-hukuru kugadzirwa Zvipfupi zvakarukwa workpieces zvine pitch yakanaka. Iko kurongeka kweiyo trapezoidal tambo kutendeutsa payakajairwa lathes inogona chete kusvika mamakisi 8 kusvika 9 (JB2886-81, zvakafanana pazasi); kugadzirisa tambo paakasarudzika shinda lathes kunogona kuvandudza zvakanyanya kugadzirwa kana kurongeka.

2. Kugaya shinda

Kugaya kunoitwa pamushini wekugaya shinda une disc cutter kana comb cutter. Disc milling cutters anonyanya kushandiswa kukuya trapezoidal ekunze shinda pane workpieces akadai sikuruu rods uye makonye. Mucheka wakaita muzinga wekugaya unoshandiswa kugaya mukati nekunze shinda dzakajairwa uye taper shinda. Sezvo yakagayiwa ne-multi-edged milling cutter, kureba kwechikamu chayo chekushanda chakakura kupfuura kureba kweshinda yakagadziriswa, saka workpiece inoda chete kutenderera 1.25 kusvika 1.5 kutendeuka kuti igadzirise. Kukwana, kugadzirwa kwepamusoro. Hurukuro hwekugaya shinda hunogona kusvika giredhi 8-9, uye kushata kwepamusoro iR 5-0.63 microns. Iyi nzira yakakodzera kugadzirwa kwebatch ye threaded workpieces ine general chaiyo kana rough machining isati yakuya.

3. Kukuya shinda

Iyo inonyanya kushandiswa kugadzira tambo dzakasimba dzeakaomeswa workpiece pane shinda grinders. Zvinoenderana nechimiro chemuchinjiko-chikamu chegumbo rekukuya, inogona kukamurwa kuva mhando mbiri: imwechete-mutsara grinding vhiri uye akawanda-line grinding vhiri. Iko kurongeka kweiyo mutsara wekukuya vhiri giredhi 5-6, kushata kwepamusoro iR 1.25-0.08 microns, uye kupfekedzwa kwevhiri rekukuya kuri nyore. Iyi nzira yakakodzerakugaya nemakona ekutungamirira screws, machira eshinda, makonye, mabhechi madiki ezvishandiso zvine shinda uye kurerutsa kukuya mahobho chaiwo. Multi-line grinding wheel grinding yakakamurwa kuita marudzi maviri: longitudinal grinding method uye plunge grinding method. Munzira yokukuya nayo yelongitudinal, kufara kwevhiri kudiki pane kureba kweshinda ichagayiwa, uye shinda inogona kukuyiwa kusvika pakukura kwekupedzisira nekufambisa gumbo kureba kamwe kana kuti kakawanda. Munzira yekugaya, hupamhi hwevhiri rekukuya hwakakura kupfuura kureba kweshinda kuti igayiwe, uye vhiri rekukuya rinocheka mukati meiyo workpiece radially, uye workpiece inogona pasi mushure me 1.25 revolutions. Kugadzirwa kwacho kwakakwira, asi kurongeka kwakadzikira zvishoma, uye kupfekedzwa kwegumbo rekukuya kunowedzera kuoma. Iyo plunge grinding nzira yakanakira yekuyamura mapombi ane mabhechi mahombe uye kukuya dzimwe shinda dzekusimbisa.

4. Kukuya shinda

Iyo nut-type kana screw-type thread grinder inogadzirwa nezvinhu zvakapfava sesimbi yakakandwa, uye zvikamu zveshinda dzakagadzikiswa dzine zvikanganiso zvenamo zvinogadzikwa kumberi uye neshure kwenzira kuvandudza kunaka kwenzwi. Iyo yakaomeswa shinda yemukati inowanzobviswa zvakare nekukuya kuti ivandudze kurongeka.

5. Kubata uye kupinza

Kubaya ndiko kushandisa imwe torque kukwenya pombi mugomba repazasi rakacherwa kare pane workpiece kugadzirisa shinda yemukati. Kurukwa ndiko kushandiswa kwemafa kucheka tambo dzekunze pabhara (kana pombi) workpieces. Kurongeka kwemachina ekutepa kana kupinza kunoenderana nekurongeka kwepombi kana kufa. Kunyangwe paine nzira dzakawanda dzekugadzirisa tambo dzemukati nekunze, diki-dhayamita dzemukati tambo dzinogona kungogadziriswa nemapombi. Kutepa nekukaruka kunogona kuitwa nemaoko, kana kuti lathes, muchina wekuchera, muchina wekutepfenyura uye muchina weshinda.

Nheyo yeshinda inoshandura kucheka huwandu hwekusarudza

Sezvo kukwirira (kana kutungamirira) kweshinda kunotsanangurwa nemuenzaniso, kiyi yekusarudza chiyero chekucheka paunenge uchishandura shinda ndeyekuona iyo spindle speed n uye yekucheka kudzika ap.

1. Kusarudzwa kwespindle speed

Zvinoenderana nemagadzirirwo ekuti spindle inotenderedza 1 revolution uye chishandiso chinodyisa 1 lead kana uchitenderedza shinda, kukurumidza kwekudya kweCNC lathe kana uchitenderedza shinda inotarwa neyakasarudzwa yekumhanyisa kumhanya. Iyo tambo inotungamira yakarairwa mushinda yekugadzira tambo (shinda yeshinda ndiyo tambo-yekutanga), iyo yakaenzana nechiyero chekudya vf chinomiririrwa nehuwandu hwekudya f (mm/r)

vf = nf (1)

Zvinogona kuoneka kubva kuformula kuti chiyero chekudya vf chakaenzana nechiyero chekudya f. Kana iyo spindle yekumhanyisa yemuchina wemuchina yakasarudzwa yakakwira zvakanyanya, iyo yakashandurwa chiyero chekudyisa inofanirwa kudarika yakayerwa chiyero chekudya chemuchina chishandiso. Naizvozvo, pakusarudza spindle yekumhanyisa shinda yekutenderedza, iyo parameter yekumisikidza ye feed system uye kugadzika kwemagetsi kwechishandiso chemuchina kunofanirwa kutariswa kudzivirira chiitiko che "chaotic mazino" eshinda kana mbiru padyo nenzvimbo yekutanga / yekupedzisira. kusazadzisa zvinodiwa.

Pamusoro pezvo, zvakakosha kucherechedza kuti kana tambo yekugadzira yatangwa, iyo spindle yekumhanyisa kukosha kazhinji haigone kuchinjika, uye kumhanya kwespindle kunosanganisira kupedzisa machining kunofanirwa kutevedzera kukosha kwakasarudzwa pakudya kwekutanga. Zvikasadaro, iyo CNC sisitimu ichaita kuti tambo ive "chaotic" nekuda kwe "overshoot" huwandu hwe pulse encoder reference pulse sign.

2) Kusarudzwa kwekudzika kwekucheka

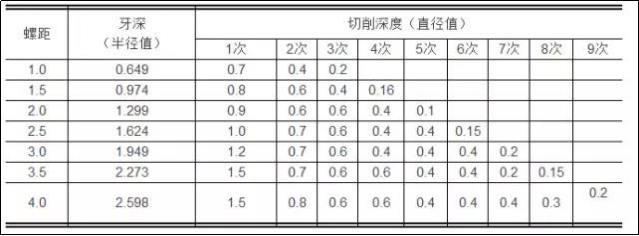

Sezvo tambo yekushandura nzira iri kugadzira kutendeuka, simba rekushandisa harina kunaka, uye chikafu chekucheka chakakura, uye simba rekucheka pachishandiso rakakura zvakare. Naizvozvo, mafractional feed processing anowanzo kudiwa, uye kudzika kwakadzikama kunosarudzwa zvinoenderana nemaitiro ari kudzikira. Tafura 1 inodonongodza mareferensi enguva dzekudya uye kudzika kwekucheka kwezvakajairwa metric thread yekucheka kune referensi yevaverengi.

Tafura 1 Kudyisa nguva uye kudzika kwekucheka kwezvakajairwa metric thread yekucheka

Nguva yekutumira: Zvita-10-2022