Kuenzaniswa nekugadziriswa kwekunze kwepamusoro, mamiriro ekugadzirisa gomba akanyanya kuipa, uye zvakanyanya kuoma kugadzira maburi pane kugadzira madenderedzwa ekunze. Izvi zvinodaro nekuti:

1) Saizi yechishandiso chinoshandiswa pagomba machining inoganhurwa nehukuru hwegomba rinofanirwa kugadzirwa, uye kuomarara kwakashata, kunowanzo kukotama deformation uye vibration;

2) Paunenge uchigadzira gomba neyakagadziriswa-saizi chishandiso, saizi yegomba kazhinji inotsanangurwa zvakananga nehukuru hunoenderana nechishandiso, uye kukanganisa kwekugadzira uye kupfeka kwechishandiso kuchakanganisa zvakananga machining egomba;

3) Paunenge uchigadzira maburi, nzvimbo yekucheka iri mukati me workpiece, kubviswa kwechip uye kupisa kupisa mamiriro ezvinhu hazvina kunaka, uye machining akarurama uye pamusoro pehutano hazvisi nyore kudzora.

1. Kuchera uye kugadzirisa zvakare

1. kuchera

Kuchera ndiyo yekutanga maitiro ekugadzira makomba mune yakasimba zvinhu, uye dhayamita remakomba kazhinji isingasviki 80mm. Kune nzira mbiri dzekuchera: imwe ndeyekutenderera kwechibhorani; imwe yacho kutenderera kweworkpiece. Izvo zvikanganiso zvinogadzirwa nenzira mbiri dziri pamusoro dzekuchera dzakasiyana. Muchidhirowa nzira ine drill bit inotenderera, kana iyo drill bit yakatsauka nekuda kweasymmetry yekucheka kwekucheka uye kusakwana kusimba kweiyo drill bit, mutsara wepakati wegomba rakagadzirwa richave rakatsvedza kana kukanganisa. Haina kutwasuka, asi gomba dhayamita harina kuchinjwa; pane zvinopesana, mune nzira yekuchera iyo iyo workpiece inotenderera, kutsauka kwechibooreso chichaita kuti dhayamita yegomba ichinje, nepo gomba repakati richiri rakananga.

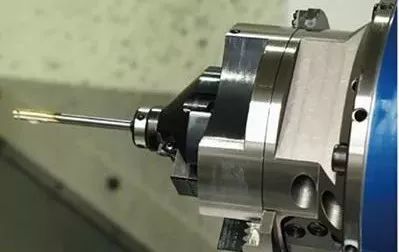

Zvishandiso zvinowanzoshandiswa kuchera zvinosanganisira: twist drill, centre drill, deep gole drill, etc. Pakati pavo, inonyanya kushandiswa ndiyo twist drill, iyo dhayamita yakatarwa ndiyo Image.

Nekuda kwekumisikidza kwemaitiro, kugonda nekuomarara kwechibhorani zvese zvakaderera, zvakasanganiswa nekusadzika kwepakati, iko kuchera kwakadzikira, kazhinji kungosvika IT13 ~ IT11; kushata kwepamusoro kwakakurawo, uye Ra kazhinji kacho 50 ~12.5μm; asi simbi yekubvisa chiyero chekuchera yakakura, uye kucheka kwekucheka kwakakwirira. Kuchera kunonyanya kushandiswa kugadzira makomba ane yakaderera mhando zvinodiwa, senge maburi ebhaudhi, maburi ezasi akaiswa shinda, maburi emafuta, etc. Kune makomba ane yakakwirira machining kurongeka uye pamusoro pemhando yezvinodiwa, anofanirwa kuwanikwa kuburikidza nekugadzirisa zvakare, kugadzirazve, kufinha kana kugaya mukati. machining anotevera.

2. Kuongororazve

Reaming ndiyo imwe yenzira dzekupedzisa dzemakomba, ayo anoshandiswa zvakanyanya mukugadzira. Kumakomba madiki, kurerazve inzira ine mari uye inoshanda pane kukuya mukati uye kufinha.

1. Reamer

Reamers anowanzo kupatsanurwa kuita marudzi maviri: mawoko reamers uye muchina reamers. Mubato wemugadziri wemaoko ibato rakatwasuka, chikamu chekushanda chakareba, uye basa rinotungamira riri nani. Iyo hand remer ine zvimiro zviviri zveakakosha mhando uye inogadziriswa yekunze dhayamita. Kune marudzi maviri emuchina reamers, shank mhando uye sleeve mhando. Reamers haigone kungogadzira makomba akatenderera, asiwo maburi ematepi anogona kugadziriswa ne taper reamer.

2. Reaming tekinoroji uye mashandisiro ayo

Mvumo yekudzorerazve ine pesvedzero huru pamhando yekudzorerazve. Kana iyo mvumo yakakura kwazvo, mutoro weiyo reamer wakakura, kucheka kumucheto kunokurumidza kubvongodzwa, hazvisi nyore kuwana yakatsetseka yemashini kumusoro, uye kushivirira kwedimensional hakusi nyore kuvimbisa; kana iyo mvumo iri diki zvakanyanya, Kana iyo machira echishandiso akasiiwa neyakapfuura maitiro asingakwanisi kubviswa, hazvizogone kuvandudza kunaka kwegomba kugadzirisa. Kazhinji, rough hinge allowance ndeye 0.35 ~ 0.15mm, uye iyo hinge yakanaka ndeye 01.5 ~ 0.05mm.

Kuti udzivise kuumbwa kwemupendero wakavakwa, kudzorerazve kunowanzoitwa pakaderera-kucheka kukurumidza (v <8m / min kune yakakwirira-speed simbi reamers yesimbi uye simbi yakakandwa). Kukosha kwechikafu kune chekuita neaperture inofanirwa kugadziriswa. Iyo yakakura iyo aperture, iyo yakakura kukosha kwekudya. Kana iyo yakakwira-kumhanya simbi inogadzirisa inogadzira simbi nesimbi yakakandwa, chikafu chinowanzo 0.3 ~ 1mm/r.

Paunenge uchigadzira makomba, inofanirwa kutonhodzwa, kudzorwa uye kucheneswa neakakodzera mvura yekucheka kudzivirira yakavakirwa-kumusoro uye kubvisa machipisi nenguva. Kuenzaniswa nekukuya uye kufinha, kudzokorora kune hupfumi hwepamusoro uye zviri nyore kuve nechokwadi chechokwadi chegomba; zvisinei, reming haigoni kugadzirisa chikanganiso chenzvimbo yegomba axis, uye nzvimbo yakarurama yegomba inofanira kuvimbiswa nemaitiro apfuura. Makomba akatsikwa nemabofu haana kukodzera kudzokororwa.

Kurongeka kwedimensional yegomba rekudzoreredza kazhinji IT9~IT7, uye kushata kwepamusoro Ra kunowanzo 3.2~0.8. Kune maburi epakati nepakati ane hunyanzvi hwekuita (senge IT7-level precision makomba), iyo yekuchera-kuwedzera-reaming process ijairika kugadzirisa chirongwa chinowanzoshandiswa mukugadzira.

3. Kufinha

Boring inzira yekugadzira inoshandisa maturusi ekucheka kukudza maburi ekare. Basa rinofinha rinogona kuitwa pamushini unofinha kana lathe.

1. Nzira inofinha

Kune matatu akasiyana machining nzira dzekufinha.

1) Iyo workpiece inotenderera uye chishandiso chinodyisa. Zvizhinji zvekufinha pa lathe ndezvenzira iyi inofinha. Maitiro ekuita ndeaya: iyo axis mutsara wegomba mushure mekugadzira inoenderana neinotenderera axis yebasa rekushanda, kutenderera kwegomba kunonyanya kuenderana nekutenderera kwechokwadi chemuchina wekushandisa spindle, uye axial geometry kukanganisa kwegomba kunoenderana zvakanyanya. pane iyo feed direction yemudziyo unoenderana neaxis yekutenderera yeworkpiece. kururama kwenzvimbo. Iyi nzira inofinha inokodzera kugadzirisa maburi ane coaxiality zvinodiwa nekunze kwekunze.

2) Chishandiso chinotenderera uye workpiece inoita kufamba kwekudya. Iyo spindle yemuchina unofinha inotyaira chishandiso chinofinha kuti chitenderere, uye tafura yekushanda inotyaira iyo workpiece kuti iite kufamba kwekudya.

3) Kana chishandiso chichitenderera uye kuita kufamba kwekudya, iyi nzira yekufinha inoshandiswa kufinha. Iyo overhang kureba kwebhari inofinha inoshandurwa, uye simba uye deformation yebhari inofinha inoshandurwa zvakare. Iyo dhayamita yegomba idiki, ichiita gomba rakapetwa. Pamusoro pezvo, kureba kwekureba kwebhara rinobhowa kunowedzera, uye kubhenda kweiyo shaft huru nekuda kwehuremu hwayo kunowedzerawo, uye axis yegomba rakagadzirwa richakotamiswa saizvozvo. Iyi nzira inofinha inokodzera chete makomba mapfupi.

2. Diamond anofinha

Kuenzaniswa neyakajairwa kufinha, dhaimondi rinofinha rinoratidzwa nekashoma kucheka musana, chikafu chidiki, uye kukurumidza kucheka. Inogona kuwana yakakwirira machining kurongeka (IT7~IT6) uye yakanyanya kutsetseka pamusoro (Ra iri 0.4~ 0.05). Dhaimondi rinofinha rakatanga kugadziriswa nematurusi edhaimani anofinha, uye iko zvino anowanzo gadziriswa necemented carbide, CBN uye maturusi edhaimani ekugadzira. Inonyanya kushandiswa kugadzirisa zvisiri-ferrous simbi workpieces, asiwo kugadzirisa cast cast iron nesimbi.

Izvo zvinowanzo shandiswa kucheka huwandu hwedhaimondi hunofinha ndeiyi: iyo kumashure-yakachekwa huwandu hwe pre-boring ndeye 0.2 ~ 0.6mm, uye yekupedzisira kufinha ndeye 0.1mm; chiyero chekudya chiri 0.01 ~ 0.14mm / r; kumhanya kwekucheka ndeye 100 ~ 250m / min kana machining simbi yakakandwa, uye machining 150 ~ 300m / min yesimbi, 300 ~ 2000m / min yekugadzira simbi isina-ferrous.

Kuti ive nechokwadi chekuti dhaimondi rinofinha rinogona kuwana yakakwira machining kurongeka uye kunaka kwepamusoro, muchina wemuchina (Diamond boring muchina) unoshandiswa unofanirwa kuve nehupamhi hwejometri chaiyo uye kusimba. Iyo huru shaft yemuchina wekushandisa inowanzo tsigirwa neiyo chaiyo angular yekubata bhora mabhengi kana hydrostatic inotsvedza mabhengi, uye yakakwirira-kumhanya inotenderera zvikamu. Inofanira kuva yakanyatsodzikama; uyezve, kufamba kwechikafu chekudya kunofanirwa kuve kwakanyatso kugadzikana kuve nechokwadi chekuti worktable inogona kuita yakagadzikana uye yakaderera-yekukurumidza kufamba kwekudya.

Dhaimondi rinofinha rine kunaka kwekugadzirisa uye kushanda kwepamusoro kwekugadzira, uye rinoshandiswa zvakanyanya mukugadzirisa kwekupedzisira kwemakomba mukugadzirwa kwakawanda, senge maburi einjini, maburi episton, uye maburi eku spindle pamabhokisi emuchina. Nekudaro, zvinofanirwa kucherechedzwa kuti kana uchishandisa madhaimani kufinha kugadzira zvigadzirwa zvesimbi, chete maturusi anofinha akagadzirwa necemented carbide uye CBN anogona kushandiswa, uye maturusi anofinha akagadzirwa nedhaimani haagone kushandiswa, nekuti maatomu ekabhoni ari mudhaimani ane hukama hukuru. ine iron group elements. , hupenyu hwekushandisa hwakaderera.

3. Boring tool

Zvishandiso zvinobhowa zvinogona kukamurwa kuita maturusi emupendero anofinha uye maviri epamucheto anofinha maturusi.

4. Tekinoroji maitiro uye kushandiswa kwakasiyana kwekufinha

Kuenzaniswa nekuchera-kuwedzera-reaming process, dhayamita yegomba haina kuganhurirwa nehukuru hwechishandiso, uye iyo inofinha ine simba rakasimba rekugadzirisa kukanganisa. Iyo inofinha uye yekumisikidza nzvimbo inochengetedza yakakwirira positional kurongeka.

Kuenzaniswa nekunze kwedenderedzwa regomba rinofinha, nekuda kwehurombo husina kusimba uye deformation yakakura yemudziyo wekushandisa, kupisa kwekushisa uye mamiriro ekubvisa chip haana kunaka, uye deformation yekupisa ye workpiece uye chishandiso chakakura. Hunhu hwekugadzira uye kugadzirwa kwegomba rinobhowa hazvina kukwirira seyedenderedzwa rekunze. .

Zvichienderana nekuongorora kuri pamusoro, zvinogona kuoneka kuti kufinha kune yakafara dhizaini renji, uye inogona kugadzirisa maburi ehukuru hwakasiyana uye mazinga akasiyana echokwadi. Kune maburi uye maburi masisitimu ane madhayamita akakura uye akakwira dimensional uye positional kunyatsoita zvinodiwa, kufinha kunenge ndiko chete kugadzirisa. nzira. Iko machining iko kufinha kuri IT9~IT7, uye kushata kwepamusoro Ra ndiko . Boring inogona kuitwa pamaturusi emuchina senge muchina unofinha, lathes, uye muchina wekugaya. Iine zvakanakira kushanduka uye inoshandiswa zvakanyanya mukugadzira. Mukugadzirwa kwakawanda kweCNC machining zvikamu, kuitira kuvandudza kushanda kunofinha, kufa kunofinha kunowanzoshandiswa.

4. makomba ekuchera

1. Honing musimboti uye honing musoro

Kucherekedza inzira yekupedza gomba nerukudzo netsvimbo (whitstone). Panguva yekukudza, iyo workpiece inogadziriswa, uye honing musoro unofambiswa nerukudzo rwemuchina kuti utenderere uye uite inodzosera mutsara kufamba. Muchigadziro chekugadzira, bhari rekukuya rinoshanda pamusoro pebasa rekushanda nehumwe dzvinyiriro, uye rinocheka chidimbu chakaonda kwazvo chezvinyorwa kubva pamusoro pebasa rekushanda, uye nzira yekucheka ndeye mesh yakayambuka. Kuti uite mafambiro ekufamba kweabrasive tsanga dzejecha rejecha kusadzokororwa, marevolutions paminiti yekutenderera kwemusoro wehoning uye nhamba yekudzokororwa kwekurohwa paminiti yemusoro wehoning inofanira kunge iri nhamba huru yeumwe neumwe.

Iyo mharadzano kona Mufananidzo weiyo honing track ine hukama neinodzokorora kumhanya Mufananidzo uye peripheral sipidhi Mufananidzo wemusoro wekukudza. Saizi yeChifananidzo chekona inokanganisa kunaka kwekugadzirisa uye kugona kwehoning. Kazhinji, Mufananidzo ° unoshandiswa kuita rough honing, uye Image ° inoshandiswa pakukudza zvakanaka. Kuti ufambise kuburitswa kweakaputsika abrasive particles uye machipisi, kuderedza tembiricha yekucheka uye kuvandudza kunaka kwekugadzirisa, mvura yekucheka yakakwana inofanira kushandiswa panguva yekukudza.

Kuti uite kuti rusvingo rwegomba rugadziriswe zvakafanana, kurova kwejecha rejecha kunofanira kudarika kuwanda kwepamusoro pamagumo ose egomba. Kuti ive nechokwadi chekubvumidza yunifomu yekukudza uye kudzikisira pesvedzero yemuchina wekushandisa spindle kutenderera kukanganisa pakurongeka kwemuchina, mizhinji yemisoro yekukudza uye masipidhi emuchina wemuchina akabatanidzwa nekuyangarara.

Iyo radial yekuwedzera uye kuchinjika kugadziridzwa kweiyo honing musoro grinding bar ine akasiyana masisitimu mafomu akadai semanyorero, pneumatic uye hydraulic.

2. Maitiro maitiro uye kushandiswa siyana honing

1) Honing inogona kuwana yakakwira dimensional kurongeka uye kurongeka kwechimiro. Kurongeka kwekugadzira ndeye IT7~IT6. Iko kutenderera uye cylindricity zvikanganiso zvemakomba zvinogona kudzorwa mukati memhando ye, asi kukudza hakugone kuvandudza mamiriro eiyoCNC machined zvikamu'makomba.

2) Kukudza kunogona kuwana hupamhi hwepamusoro, kushata kwepamusoro Ra is Image, uye kudzika kwemetamorphic defect layer yesimbi yepamusoro idiki zvakanyanya (Mufananidzo).

3) Kuenzaniswa nekumhanya kwekukuya, kunyangwe kumhanya kweparipheral kwemusoro wehoning hakuna kukwirira (vc = 16 ~ 60m / min), asi nekuda kwenzvimbo huru yekubatana pakati pejecha bar uye workpiece, iyo inodzokorodza kukurumidza yakakwira zvakanyanya. (va=8~20m/min). min), saka kukudza kuchiri nekubudirira kwepamusoro.

Honing inoshandiswa zvakanyanya mukugadzira ejini silinda makomba uye nemakomba chaiwo mune akasiyana hydraulic zvishandiso mukugadzirwa kwakawanda. Nekudaro, kukudza hakuna kukodzera kugadzira maburi pane asiri-ferrous simbi workpieces ane hombe plastiki, uye haigone kugadzira maburi ane kiyi grooves, spline maburi, nezvimwe.

5. Dhonza gomba

1. Broaching uye broaching

Hole broaching inzira inobereka kwazvo yekupedzisa iyo inoitwa pamushini webroaching ane yakakosha broach. Kune marudzi maviri emubhedha webroaching: wakachinjika mubhedha webroaching uye vertical broaching bed, nehorizontal broaching bed inonyanyozivikanwa.

Paunenge uchibhuroka, iyo broach inongoita yakaderera-kumhanya mutsara kufamba (main motion). Nhamba yemazino ebroach inoshanda panguva imwe chete inofanira kunge isiri pasi pe3, kana zvisina kudaro broach haigoni kushanda zvakanaka, uye zviri nyore kubudisa annular ripples pamusoro pebasa rekushanda. Kuti udzivise broach kubva pakutyoka nekuda kwesimba rakawandisa rebroach, kana broach iri kushanda, nhamba yemazino anoshanda kazhinji haifanirwe kudarika 6 kusvika 8.

Pane nzira nhatu dzakasiyana dzekubhuroka dzekubhuroka, dzinotsanangurwa sezvizvi:

(1) Layered broaching Hunhu hweiyi nzira yekubhuroka ndeyekuti broach inocheka workpiece machining allowance layer ne layer sequentially. Kuitira kufambisa kutsemuka kwechipi, mazino anocheka anogayiwa nemigero yekuparadzanisa chip. Iyo broach yakagadzirirwa maererano neyakaiswa broaching nzira inonzi yakajairika broach.

(2) Block broaching Iyi nzira yebroaching inotaridzwa pakuti rimwe nerimwe resimbi riri pamusoro pemuchina rine boka remazino ane hukuru hwakafanana asi mazino akadzedzereka (kazhinji boka rimwe nerimwe rine mazino maviri-3) akabviswa. Zino rimwe nerimwe rinongocheka chikamu chechidimbu chesimbi. Iyo broach yakagadzirwa maererano ne block broaching nzira inonzi vhiri-cut broach.

(3) Comprehensive broaching Iyi nzira inotarisisa zvakanakira zve layered and segmented broaching. Zino rakagozha rinotora kupatsanurwa kwezvikamu, uye zino nyoro rinotora mucheka. Nenzira iyi, kureba kwebhurochi kunogona kupfupiswa, kubereka kunogona kuvandudzwa, uye kunaka kwepamusoro kunogona kuwanikwa. Iyo broach yakagadzirwa maererano nehuwandu hwebroaching nzira inonzi "comrehensive broach".

2. Maitiro maitiro uye kushandiswa kwechiyero chekudhonza gomba

1) Iyo broach chishandiso che-multi-blade, chinogona kutevedzana kupedzisa roughing, kupedzisa uye kupedzisa kwegomba mune imwe broaching sitiroko, ine yakanyanya kugadzirwa kunyatsoita.

2) Kurongeka kwebroaching kunonyanya kuenderana nekururama kwebroach. Mumamiriro ezvinhu akajairika, kurongeka kwebroaching kunogona kusvika IT9 ~ IT7, uye kushata kwepamusoro Ra kunogona kusvika 6.3 ~ 1.6 μm.

3) Paunenge uchidhonza gomba, iyo workpiece inomisikidzwa negomba rakagadzirwa pachayo (iyo inotungamira chikamu chebroach ndiyo yekumisikidza chinhu cheiyo workpiece), uye hazvisi nyore kuve nechokwadi chekuwirirana kwechimiro chegomba uye mamwe maficha; Mukugadziriswa kwenhengo dzemuviri, maburi anowanzo kudhirowa kutanga, uyezve mamwe maficha anogadzirwa achishandisa maburi sereferensi yekumisikidza.

4) Iyo broach haigone kungogadzira makomba akatenderedza, asi zvakare kugadzira maburi uye spline maburi.

5) Iyo broach ndeye yakagadziriswa-saizi chishandiso chine chimiro chakaoma uye mutengo wakakwira, iyo isina kukodzera kugadzirisa makomba makuru.

Makomba ekuchera anowanzoshandiswa mukugadzirwa kwemazhinji kuti agadzirise kuburikidza nemakomba pazvikamu zviduku uye zvepakati nepakati nehupamhi hwe Ф10 ~ 80mm uye kudzika kwegomba kusingapfuuri 5 nguva yehupamhi hwegomba.

Nguva yekutumira: Sep-26-2022