Nzvimbo yekugadzira michina, inozivikanwawo seCNC machining Center, chishandiso chine otomatiki uye chakasiyana-siyana chinoshandiswa muindasitiri yekugadzira kune akasiyana machining mashandiro.

-

Pfupiso: Nzvimbo yekugadzira machini inosanganisa akati wandei kuita yuniti imwechete, kusanganisira kugaya, kuchera, kubaya, kufinha, uye dzimwe nguva kutendeuka. Iyo inosanganisa chishandiso chemuchina, chinoshandura chishandiso, uye sisitimu yekudzora kuita imwe chete system yekuwedzera kugona uye kugadzira.

-

Mhando: Machining nzvimbo anouya mumhando dzakasiyana, senge vertical machining nzvimbo (VMC) uye yakachinjika machining nzvimbo (HMC). VMCs ine spindle yakatwasuka, ukuwo HMCs iine shinda yakachinjika. Mhando yega yega ine zvayakanakira uye yakakodzera kune chaiwo maapplication.

-

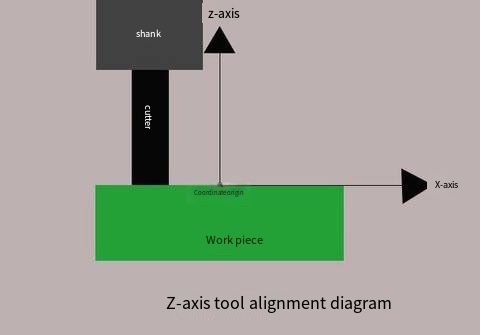

Axes: Machining nzvimbo anowanzo ane matatu kana anopfuura mademo ekufamba. Anonyanya kuzivikanwa ndiwo matatu-axis muchina, ane X, Y, uye Z axes emutsetse wekufamba. Mamodheru epamberi anogona kuve neamwe maaxes ekutenderera (semuenzaniso, A, B, C) kune akawanda-axis machining.

-

CNC Kudzora: Machining nzvimbo dzinodzorwa nekombuta nhamba control (CNC) masisitimu. CNC programming inobvumira kunyatso kudzora kweiyo machining process, inosanganisira kufamba kwezvishandiso, mareti ekudya, kumhanya kwespindle, uye kuyerera kunotonhorera.

-

Tool Changer: Machining nzvimbo ane otomatiki maturusi ekuchinja (ATC) ayo anobvumira kukurumidza uye otomatiki kuchinjana kwekucheka maturusi panguva yekuita machining. Izvi zvinogonesa kugadzirwa kwakanaka uye kusingapindiki.

-

Kubata: Zvishandiso zvinobatwa zvakachengeteka patafura yenzvimbo yekugadzira kana chigadziriso panguva yekushanda kwemuchina. Nzira dzakasiyana-siyana dzekushanda dzinoshandiswa, senge mavhisi, zvisungo, zvigadziriso, uye pallet masisitimu, zvichienderana nekushandiswa uye zvinodiwa.

-

Zvishandiso: Machining nzvimbo anoshandiswa zvakanyanya mumaindasitiri akadai seaerospace, mota, zvekurapa, uye zvakajairika kugadzira. Ivo vanoshandirwa kuita mabasa senge milling yakaoma zvikamu, maburi ekuchera, kugadzira maprofiles chaiwo, uye kuwana kushivirira kwakasimba.

-

Kufambira mberi: Munda wemachining nzvimbo unoramba uchishanduka nekufambira mberi mune tekinoroji. Izvi zvinosanganisira kuvandudzwa kwekugadzirwa kwemuchina, kudzora masisitimu, kucheka maturusi matekinoroji, otomatiki, uye kubatanidzwa nemamwe maitiro ekugadzira.

Iyo machining Center inosanganisa oiri, gasi, magetsi, uye manhamba kutonga, uye inogona kuona-imwe-nguva kusungirirwa kweakasiyana madhisiki, mahwendefa, mabhomba, makamera, mold uye zvimwe zvakaomarara zvikamu uye workpieces, uye inogona kupedzisa kuchera, kugaya, kufinha, kuwedzera, reming, Rigid tapping uye mamwe maitiro anogadziriswa, saka ndiyo yakanakira midziyo yekukwira-chaiyo machining. Ichi chinyorwa chinogovera hunyanzvi hwekushandisa hwemachining nzvimbo kubva kune zvinotevera zvinhu:

Iyo machining centre inogadzirisa sei chishandiso?

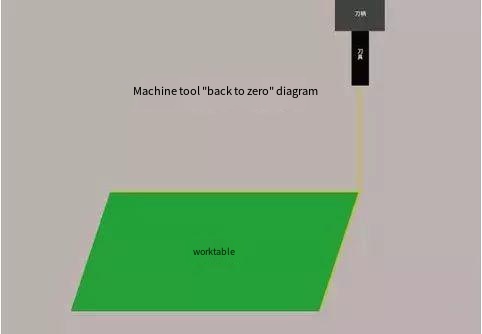

1. Dzokera ku zero (dzokera kune kwakabva mudziyo wemuchina)

Usati wamisa chishandiso, zvinodikanwa kuti udzokere ku zero (dzokera kune kwakabva mudziyo wemuchina) kuitira kuti ubvise kurongeka kwedata rekupedzisira kushanda. Ziva kuti X, Y, uye Z matemo ese anoda kudzokera ku zero.

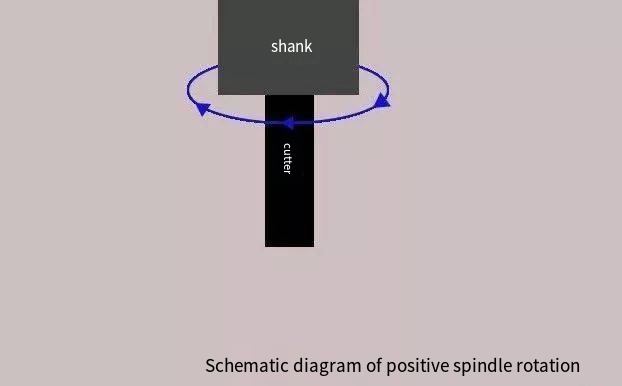

2. Spindle inotenderera mberi

Mu "MDI" modhi, iyo spindle inotenderedzwa kumberi nekuisa macode emirairo, uye kumhanya kwekutenderera kunochengetwa padanho repakati. Wobva wachinja kune "handwheel" modhi, uye ita mashandiro emuchina chishandiso kufamba nekuchinja uye kugadzirisa kumhanya.

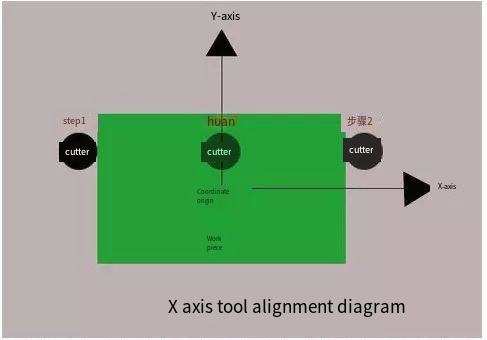

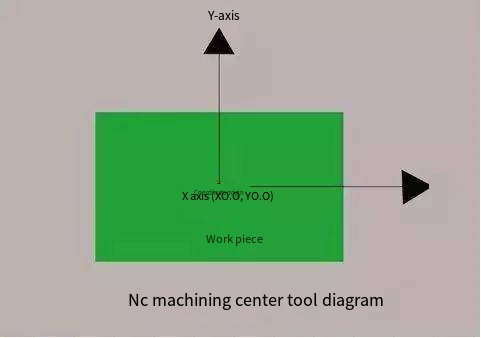

3. X nhungamiro yekushandisa kugadzirisa

Shandisa chishandiso kubata zvishoma ruoko rwerudyi rwechishandiso kuti ubvise hukama hwehukama hwemuchina chishandiso; simudza chishandiso pamwe negwaro reZ, wobva wafambisa chishandiso kuruboshwe rwechishandiso, uye fambisa chishandiso uye workpiece pasi pahurefu hwakafanana nepakutanga. Bata zvishoma, simudza chishandiso, nyora pasi kukosha kweX kwehukama hwehukama hwechishandiso chemuchina, fambisa chishandiso kune hafu yehama inoronga X, nyora pasi kukosha kweX kweiyo mhedziso kurongeka kwechishandiso chemuchina, uye tinya (INPUT. ) kupinda muhurongwa hwekubatanidza.

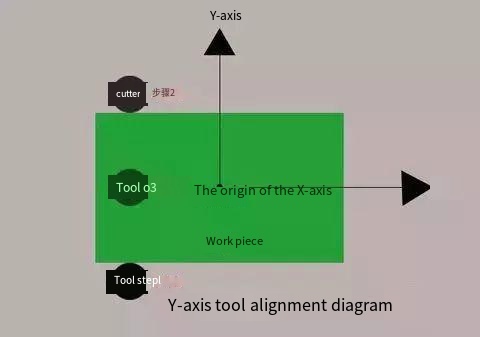

4. Y direction tool setting

Shandisa chishandiso kubata zvinyoro kumberi kwechishandiso kuti ubvise hukama hwehukama hwemuchina chishandiso; simudza chishandiso pamwe negwaro reZ, wobva wafambisa chishandiso kuseri kwechishandiso, uye fambisa chishandiso uye chebasa pasi kusvika pakukwirira kwakafanana nepakutanga. Bata zvishoma, simudza chishandiso, nyora pasi kukosha kweY kwehukama hwehukama hwechishandiso chemuchina, fambisa chishandiso kune hafu yehama yekubatanidza Y, nyora pasi kukosha kweY kweiyo mhedziso kurongeka kwemuchina chishandiso, uye tinya (INPUT ) kupinda muhurongwa hwekubatanidza.

5. Z yekutungamirira mudziyo wekugadzirisa

Fambisa chishandiso pamusoro peiyo workpiece yakatarisana ne zero point munzira yeZ, zvishoma nezvishoma fambisa chishandiso kusvika chabata pamusoro penzvimbo yebasa zvinyoro, rekodha kukosha kweZ muhurongwa hwekurongeka kwemuchina panguva ino. , wobva wadzvanya (INPUT) kuisa mucoordination system.

6. Spindle stop

Misa chirungiso chekutanga, fambisa chinorukwa panzvimbo yakakodzera, fonera chirongwa chekugadzirisa, uye gadzirira kugadzirisa zviri pamutemo.

Iyo machining Center inoburitsa uye kugadzira zvikamu zvinogomara?

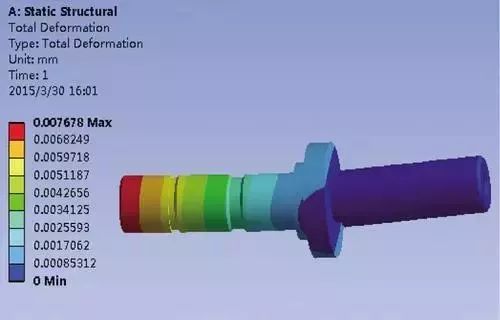

Foraxis cnc machiningzvikamu zvine huremu huremu, kusimba kwakashata, uye simba risina simba, zviri nyore kuremara nechisimba uye kupisa panguva yekugadzira, uye yakakwirira yekugadzirisa zvimedu zvinotungamirira kukuwedzera kukuru kwemutengo. Kune zvikamu zvakadaro, tinofanira kutanga tanzwisisa zvinokonzera deformation:

Deformation pasi pesimba:

Rusvingo rwemhando iyi yezvikamu rwakaonda, uye pasi pekuita kwesimba rekuvhara, zviri nyore kuva nehupamhi husina kuenzana panguva yekugadzira nekucheka, uye elasticity haina kunaka, uye chimiro chezvikamu zvakaoma kudzorera pachako.

Heat deformation:

Iyo workpiece yakareruka uye yakaonda, uye nekuda kweiyo radial simba panguva yekucheka, ichaita kuti kupisa kushanduka kweiyo workpiece, zvichiita kuti ukuru hweworkpiece huve husina kunaka.

Vibration deformation:

Pasi pekuita kweiyo radial yekucheka simba, zvikamu zvinokasira kuvibration uye deformation, izvo zvinokanganisa kurongeka kwedimensional, chimiro, kurongeka kwenzvimbo uye kushata kwepamusoro kweiyo workpiece.

Kugadzirisa nzira yezvikamu zvinogoneka zviri nyore:

Kune zvikamu zvakaremara zvinomiririrwa nezvikamu zvakatetepa-zvakakomberedzwa, kukurumidza-kumhanya machining uye kucheka nediki diki rekudya uye yakakwirira yekucheka kumhanya inogona kushandiswa kudzikisa simba rekucheka pane workpiece panguva yekugadzirisa, uye panguva imwecheteyo, yakawanda yekucheka kupisa. inoraswa nemachipisi ari kubhururuka kubva paworkpiece nekumhanya kukuru. Bvisa, nekudaro kuderedza kutonhora kweiyo workpiece uye kuderedza deformation inopisa ye workpiece.

Sei machining center maturusi achifanira kupfuudzwa?

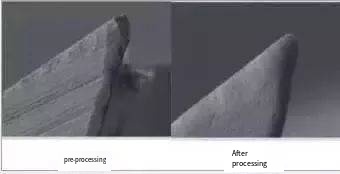

CNC zvishandiso hazvina kukurumidza sezvinobvira, nei passivation kurapwa? Muchokwadi, chishandiso passivation hachisi icho munhu wese anonzwisisa chaizvo, asi nzira yekuvandudza hupenyu hwesevhisi yezvishandiso. Kuvandudza hunhu hwechishandiso kuburikidza nekutsvedzerera, kupukuta, kubvisa uye mamwe maitiro. Aya ndiwo maitiro akajairwa mushure mekunge mudziyo wanyatsokuyiwa uye usati wapfekedzwa.

▲ Kuenzanisa kwechishandiso passivation

Mapanga anorodzwa nevhiri rekukuya pamberi pechigadzirwa chapera, asi kurodza kwacho kunokonzeresa maburi madiki kusvika kune akasiyana. Kana iyo machining Center ichiita yakakwira-kumhanya kucheka, iyo microscopic gap ichawedzera nyore, iyo inomhanyisa kupfeka uye kukuvara kwechishandiso. Tekinoroji yemazuva ano yekucheka ine zvakaomesesa zvinodikanwa pakugadzikana uye kurongeka kwechishandiso, saka CNC chishandiso chinofanirwa kupfuudzwa chisati chavhara kuti ive nechokwadi chekusimba uye hupenyu hwebasa rejasi. Zvakanakira chishandiso passivation ndezvi:

1. Ramba zvokupfeka muviri

Munguva yekucheka, pamusoro pechishandiso chichave chakapfekwa zvishoma nezvishoma netsika cnc workpiece, uye iyo yekucheka inotarisanawo nekugadzirisa kwepurasitiki pasi pekushisa kwepamusoro uye kudzvinyirira kwakanyanya panguva yekucheka. Iyo passivation kurapwa kwechishandiso inogona kubatsira chishandiso kuvandudza kusimba kwayo uye kudzivirira chishandiso kubva kurasikirwa nekucheka kwayo kuita nguva isati yakwana.

2. Chengetedza kupera kweworkpiece

MaBurrs pamucheto wekucheka kwechishandiso anokonzeresa kupfeka kwechishandiso uye pamusoro pechigadzirwa chemuchina chichaita hutsinye. Mushure mekurapa kwekupfuura, iyo yekucheka mupendero wechishandiso ichave yakatsetseka, chipping ichaderedzwa zvinoenderana, uye kupera kwepamusoro kwechishandiso kuchavandudzwa zvakare.

3. Yakanakira groove chip kubviswa

Kupururudza nyere dzematurusi kunogona kuvandudza hunhu hwepamusoro uye chip evacuation performance. Iyo inotsvedzerera iyo nyere pamusoro, zviri nani iyo chip evacuation, uye inopindirana yekucheka maitiro inogona kuwanikwa. Mushure mekufambisa uye kupukuta kweCNC chishandiso munzvimbo yekugadzira, maburi madiki mazhinji achasiiwa pamusoro. Aya maburi madiki anogona kutora yakawanda yekucheka mvura panguva yekugadziriswa, iyo inoderedza zvakanyanya kupisa kunogadzirwa panguva yekucheka uye inovandudza zvakanyanya machining kukurumidza kumhanya.

Iyo machining centre inoderedza sei kushata kwepamusoro kweiyo workpiece?

Kushata kwepamusoro kwezvikamu ndeimwe yematambudziko akajairika eCNC machiningnzvimbo, iyo inoratidzira zvakananga hutano hwekugadzirisa. Nzira yekudzora sei kushata kwepamusoro kwezvikamu zvekugadzirisa, tinofanira kutanga taongorora zvakadzama zvikonzero zvekushata kwepamusoro, kunyanya kusanganisira: zvigadziriso zvezvishandiso zvinokonzerwa panguva yekugaya; thermal deformation kana plastiki deformation inokonzerwa nekucheka kuparadzaniswa; mudziyo uye machined pamusoro friction pakati.

Paunosarudza hutsinye hwepamusoro hwebasa rekushanda, haifaniri kungosangana nezvinodiwa zvekushanda kwepamusoro pechikamu, asiwo funga nezvehutano hwehupfumi. Pasi pechigadziro chekusangana nebasa rekucheka, iyo yakakura yereferensi kukosha kwekuoma kwepamusoro kunofanirwa kusarudzwa zvakanyanya sezvinobvira kuderedza mari yekugadzira. Semuiti weiyo yekucheka machining centre, chishandiso chinofanirwa kutarisisa kugadzirisa kwezuva nezuva uye kukuya nenguva kuti udzivise kusarongeka kwepamusoro kwepamusoro kunokonzerwa nechishandiso chakapusa.

Chii chinofanira kuitwa neMachining Center mushure mekupedza basa?

Kazhinji kutaura, iwo echinyakare muchina maturusi ekugadzirisa maitiro enzvimbo dzemachining akafanana. Musiyano mukuru ndewekuti machining Center inopedzisa ese ekucheka maitiro kuburikidza-imwe-nguva clamping uye inoenderera otomatiki machining. Naizvozvo, nzvimbo yekugadzira machining inoda kuita mamwe "Basa rekutevera".

1. Ita kuchenesa kurapwa. Mushure mekunge machining Center apedza basa rekucheka, zvinodikanwa kubvisa machipisi nenguva, kupukuta mwari wemuchina, uye kuchengetedza mudziyo wemuchina uye nharaunda yakachena.

2. Kuti uongorore uye kuchinjwa kwezvimwe zvinhu, kutanga kune zvose, teerera kutarisa mafuta ekutsvaira panzira yekufambisa, uye kuitsiva munguva kana yakasakara. Tarisa mamiriro emafuta ekuzora uye anotonhorera. Kana turbidity ikaitika, inofanira kutsiviwa nenguva. Kana chiyero chemvura chakaderera kudarika chikero, chinofanira kuwedzerwa.

3. Nzira yekuvhara inofanira kuenzaniswa, uye magetsi uye simba guru rekushandisa pamushini wekushanda kwemuchina unofanirwa kudzimwa. Mukushaikwa kwemamiriro akakosha uye zvakakosha zvinodiwa, musimboti wekudzokera kune zero kutanga, bhuku remanyorero, inching, uye otomatiki rinofanira kuteverwa. Iyo machining Center inofanirwawo kumhanya yakaderera, yepakati kumhanya, uyezve kumhanya kwakanyanya. Iyo yakaderera-yekumhanya uye yepakati-yekumhanyisa nguva haifanirwe kunge iri pasi pe2-3 maminetsi isati yatanga kushanda.

4. Simbisa kushanda. Hazvibvumirwi kugogodza, kururamisa kana kugadzirisa workpiece pane chuck kana kumusoro. Izvo zvinodikanwa kusimbisa kuticnc milling zvikamuuye chishandiso chinosungwa chisati chaenda kune chinhanho chinotevera. Inishuwarenzi uye kuchengetedza midziyo yekudzivirira pamushini wemuchina haifanire kubviswa uye kutamiswa zvisina tsarukano. Iyo inonyanya kushanda kugadzirisa ndeye yakachengeteka kugadzirisa. Sechishandiso chinoshanda chekugadzirisa, kushanda kwenzvimbo yekugadzira kunofanirwa kuve kwakadzikama uye kwakamisikidzwa kana ichivharwa. Izvi hazvisi chete kuchengetedzwa kwemaitiro akapedzwa ikozvino, asiwo kugadzirira kwekutanga kunotevera.

Anebon inogona kupa zviri nyore mhinduro dzemhando yepamusoro, kukosha kwemakwikwi uye yakanakisa kambani yevatengi. KwaAnebon kwakanangana "Iwe unouya pano nekunetseka uye tinokupa kunyemwerera kuti utore" kune Vakanaka Wholesale Vendors Precision Chikamu CNC Machining Hard Chrome Plating Gear, Kuomerera kune diki bhizinesi musimboti wezvakanakira mutual, ikozvino Anebon yawana mukurumbira wakanaka pakati pedu. vatengi nekuda kwemakambani edu epamusoro, zvinhu zvemhando yepamusoro uye makwikwi emitengo. Anebon gamuchirai noushamwari vatengi kubva kumba kwenyu uye mhiri kwemakungwa kuti tibatane nesu kune zvakajairika.

Vatengesi Vakanaka Vekutengesa China vakagadzira simbi isina tsvina, chaiyo 5 axis machining chikamu uye cnc milling masevhisi. Zvinangwa zvikuru zveAnebon ndezvekupa vatengi vedu pasi rese nemhando yakanaka, mutengo wemakwikwi, kuendesa kugutsikana uye masevhisi akanaka. Mutengi kugutsikana ndicho chinangwa chedu chikuru. Tinokugamuchira iwe kuti ushanyire showroom yedu uye hofisi. Anebon yanga ichitarisira kumisa hukama hwebhizinesi newe.

Nguva yekutumira: May-22-2023