Turning Tool

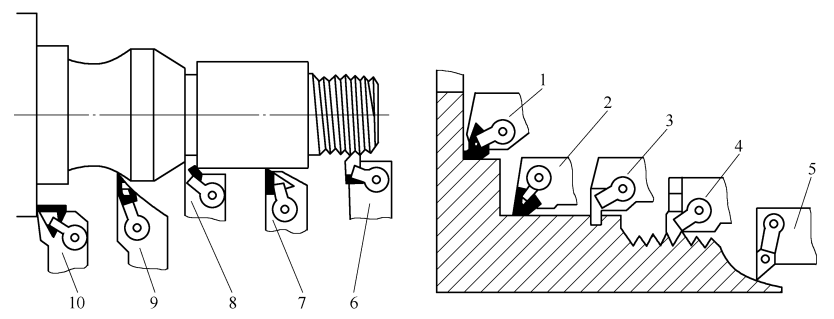

Chishandiso chinowanzo shandiswa mukucheka simbi ndicho chinoshandura. Maturusi ekutenderedza anoshandiswa kucheka madenderedzwa ekunze, maburi pakati, shinda, grooves, mazino, uye mamwe maumbirwo palathes. Mhando dzayo huru dzinoratidzwa muMufananidzo 3-18.

Mufananidzo 3-18 Marudzi makuru ekushandura maturusi

1. 10—End turning tool 2. 7—Outer circle (inner hole turning tool) 3. 8—Grooving tool 4. 6—Thread turning tool 5. 9—Chishandiso

Maturusi ekuchinjisa akaiswa mumapoka zvichienderana nechimiro chawo kuita kutendeuka kwakasimba, welding kutendeuka, muchina chinobatisa kutendeuka, uye indexable maturusi. Indexable inoshandura maturusi ari kuwedzera kufarirwa nekuda kwekuwedzera kwavo kushandiswa. Ichi chikamu chinotarisa kuunza misimboti yekugadzira uye matekiniki eiyo indexable uye welding ekutendeuka maturusi.

1. Welding tool

Iyo welding inoshandura chishandiso inogadzirwa neblade yechimiro chakati uye chibatiso chakabatanidzwa newelding. Mablades anowanzo gadzirwa kubva kumagiredhi akasiyana e carbide zvinhu. Zvishandiso shanks zvinowanzoita 45 simbi uye yakarodzwa kuti ienderane nezvinodiwa panguva yekushandiswa. Hunhu hwematurusi ekuchinjisa maturusi uye kushandiswa kwawo kunoenderana negiredhi blade, iyo blade modhi, chishandiso geometric paramita uye chimiro uye saizi slot. Kukuya kunaka, etc. Kukuya kunaka, nezvimwewo.

(1) Pane zvakanakira uye zvakaipira kune welding inoshandura maturusi

Inoshandiswa zvakanyanya nekuda kweiyo nyore, compact chimiro; high tool kuoma; uye yakanaka vibration kuramba. Iyo ine zvakare yakawanda yakashata, kusanganisira:

(1) Kuita kwekucheka kweblade kwakashata. Kuita kwekucheka kweblade kuchaderedzwa mushure mekunge yave yakasungirirwa pakupisa kukuru. Kupisa kwepamusoro kunoshandiswa kupinza nekupinza kunoita kuti blade iite kushushikana kwemukati. Sezvo mutsara wekuwedzera coefficient ye carbide iri hafu yemuviri wemidziyo, izvi zvinogona kukonzera kutsemuka kuoneke mucarbide.

(2) Chibatiso hachishandiswe zvakare. Raw zvinhu zvakaraswa nekuti chibatiso hachigone kushandiswa zvakare.

(3) Nguva yekubatsira yakarebesa. Chishandiso chekuchinja uye kuseta kunotora nguva yakawanda. Izvi hazvienderane nezvinodiwa zve CNC michina, otomatiki machining masisitimu, kana otomatiki muchina maturusi.

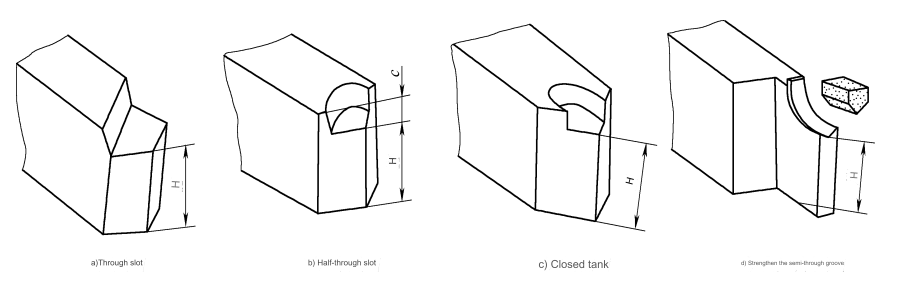

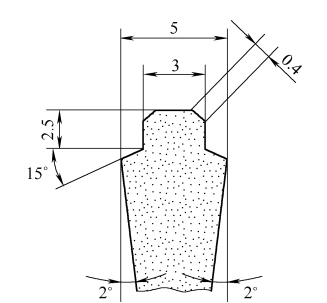

(2) Rudzi rwemudziyo unobata groove

Kune maturusi ekutendeuka maturusi, mudziyo shank grooves unofanirwa kugadzirwa zvinoenderana nechimiro uye saizi yeblade. Chishandiso shank grooves chinosanganisira kuburikidza ne grooves, semi-kuburikidza ne grooves, yakavharwa grooves, uye yakasimbiswa semi-kuburikidza ne grooves. Sezvinoratidzwa Mufananidzo 3-19.

Mufananidzo 3-19 Tool holder geometry

Iyo mudziyo inobata groove inofanirwa kuzadzisa zvinotevera zvinodiwa kuti ive nechokwadi chemhando welding:

(1) Dzora ukobvu. (1) Dzora ukobvu hwekucheka muviri.

(2) Dzora mukaha uripo pakati peblade nemudziyo une groove. Mukaha uripo pakati peshizha nechibatiso chezvishandiso haufanire kunge wakakurisa kana diki, kazhinji 0.050.15mm. Iyo arc yekubatanidza inofanirwa kunge yakafanana sezvinobvira uye iyo yakawanda yenzvimbo gap haifanirwe kudarika 0.3mm. Zvikasadaro, simba re weld richakanganiswa.

(3) Dzora kukosha kwepamusoro-soro kwechibatiso chegiyo. Mugero wezvishandiso une kukwasharara kwepamusoro kweRa=6.3mm. Iyo blade yepamusoro inofanira kuva yakati sandara uye yakatsetseka. Usati wapisa, groove yemudziyo wekushandisa inofanira kucheneswa kana paine chero mafuta. Kuti uchengetedze nzvimbo yewelding yakachena, unogona kushandisa sandblasting kana doro kana peturu kuti uikweshe.

Dzora kureba kweblade. Mumamiriro ezvinhu akajairika, blade yakaiswa mugero rezvishandiso inofanira kubuda ne 0.20.3mm kubvumira kurodza. Iyo girove yemidziyo inogona kuitwa yakareba ne 0.20.3mm kupfuura blade. Mushure mekudzikisira, mudziyo wemudziyo unozoiswa weld. Kuti utaridzike zvakanaka, bvisa chero zvakawandisa.

(3) Kupisa kweblade

Hard solder inoshandiswa kukwenenzvera simende ye carbide blades (yakaoma solder ndeye refractory kana brazing zvinhu zvine tembiricha yekunyungudika yakakwira kupfuura 450degC). Solder inodziya kusvika kune yakanyungudutswa, iyo inowanzoita 3050degC pamusoro penzvimbo inonyungudika. Iyo flux inodzivirira solder kubva pakupinda uye kupararira pamusoro peiyomachined components. Inobvumirawo kupindirana kwe solder ne welded chikamu. Iko kunyunguduka kunoita kuti blade yecarbide isungirwe zvakasimba mukati meiyo slot.

Mazhinji ekudziya ekupisa maitiro aripo, senge gasi murazvo welding uye yakakwirira frequency welding. Electric contact welding ndiyo yakanakisa kudziyisa nzira. Kupikisa panzvimbo yekubatana pakati pemhangura yemhangura, uye musoro wekucheka ndiwo wepamusoro-soro, uye apa ndipo apo kupisa kwepamusoro kuchagadzirwa. Muviri wekucheka unotanga kutsvuka uye ipapo kupisa kunoendeswa kune blade. Izvi zvinoita kuti blade iwedzere kupisa zvishoma nezvishoma uye zvishoma nezvishoma kukwira kwekushisa. Kudzivirira kutsemuka kwakakosha.

Iyo blade haina "kupisa" nekuti simba rinovharwa kana zvinhu zvanyunguduka. Magetsi anobata welding akaratidzwa kuderedza kutsemuka kweblade uye desoldering. Brazing iri nyore uye yakagadzikana, ine unhu hwakanaka. Iyo brazing process haina kunyatso shanda pane yakakwira-frequency welds, uye zvakaoma kubhura maturusi ane akawanda edge.

Unhu hwebrazing hunobatwa nezvinhu zvakawanda. Iyo brazing zvinhu, flux uye nzira yekudziya inofanira kusarudzwa nemazvo. Kune carbide brazing tool, zvinhu zvinofanira kuva nekunyunguduka kwakakwirira kudarika tembiricha yekucheka. Icho chinhu chakanaka chekucheka nekuti chinogona kuchengetedza simba rekubatanidza blade uku ichichengetedza fluidity, kunyorova uye kupisa kwemhepo. Izvi zvinotevera brazing zvinhu zvinowanzo shandiswa pakugadzira simende-carbide blades:

(1) Kunyunguduka kwekushisa kwemhangura yakachena kana mhangura-nickel alloy (electrolytic) inenge 10001200degC. Iwo anobvumidzwa tembiricha yekushanda i700900degC. Izvi zvinogona kushandiswa nemidziyo ine basa rinorema.

(2) Copper-zinc kana 105# filler simbi ine tembiricha yekunyunguduka pakati pe900920degC & 500600degC. Inokodzera zvepakati-mutoro tooling.

Nzvimbo yakanyunguduka yesirivha-copper alloy ndeye 670820. Kupisa kwayo kwakanyanya kushanda ndeye 400 degrees. Nekudaro, inokodzera welding chaiyo yekutendeuka maturusi ane yakaderera cobalt kana yakakwira titanium carbide.

Unhu hwebrazing hunonyanya kukanganiswa nekusarudzwa uye kushandiswa kwekuyerera. Iyo flux inoshandiswa kubvisa okisidhi pamusoro pechigadzirwa chebasa chinozove chakashongedzwa, kuwedzera kunyorova uye kudzivirira weld kubva kune oxidation. Maturusi maviri anoshandiswa kugadzira maturusi ecarbide: yakapera mvura Borax Na2B4O2 kana yakaomeswa Borax 25% (massfraction) + boric Acid 75% (massfraction). Kupisa kweBrazing kunobva ku800 kusvika ku1000degC. Borax inogona kuderedzwa nekunyungudutsa borax, uye kuipwanya mushure mekutonhora. Sefa. Kana uchigadzira maturusi eYG, dehydrated borax inowanzova nani. Iwe unogona kuwana mhedzisiro inogutsa paunenge uchigadzira maturusi eYT uchishandisa fomula dehydrated borax (massfraction) 50% + boric (massfraction) 35% + dehydrated potassium (massfraction) fluoride (15%).

Kuwedzerwa kwe potassium fluoride kunovandudza kunyorova uye kugona kunyunguduka kwetitanium carbide. Kuti uderedze welding kushushikana kana brazing yakakwirira-titanium alloys (YT30 uye YN05), yakaderera tembiricha pakati 0.1 uye 0.5mm inowanzoshandiswa. Semuripo gasket pakati pemashizha nemidziyo inobatisa, kabhoni simbi kana iron-nickel inowanzoshandiswa. Kuti uderedze kushushikana kwekupisa, blade inofanirwa kuve insulated. Kazhinji mudziyo wekushandura unoiswa muchoto chine tembiricha ye280°C. Insulate kwemaawa matatu pa320degC, wobva watonhodza zvishoma nezvishoma mungave muchoto, kana muasbestos kana mashanga ehupfu.

(4) Inorganic bonding

Inorganic bonding inoshandisa phosphoric solution uye inorganic copper poda, iyo inosanganisa chemistry, mechanics, uye fizikisi kune bond blades. Inorganic bonding iri nyore kushandisa pane brazing uye haikonzeri kushushikana kwemukati kana kuputika kweblade. Iyi nzira inonyanya kubatsira kune blade zvinhu zvakaoma kupinza, senge ceramics.

Hunhu mashandiro uye anoshanda makesi emuchina

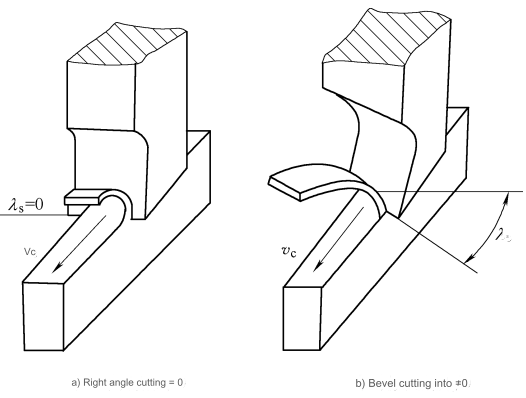

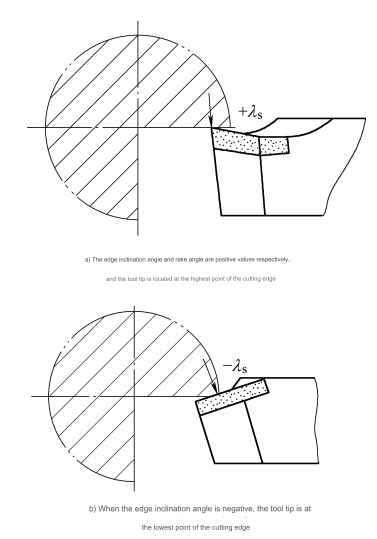

4. Kusarudza kona yeedge inclination uye bevel cut

(1) Kucheka bevel ipfungwa yanga iripo kwenguva yakareba.

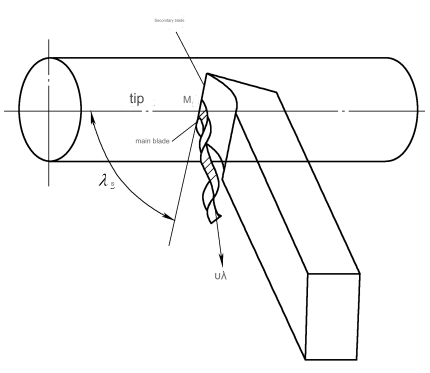

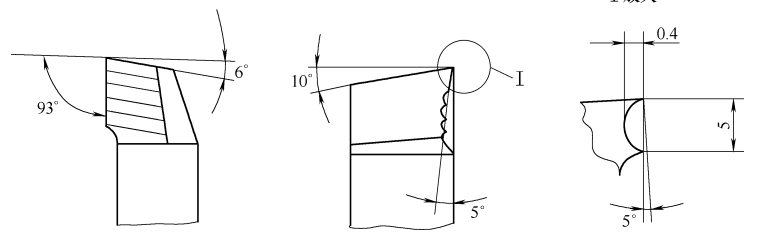

Right-angle kucheka ndiko kucheka umo blade yekucheka yechishandiso inofananidzwa kune iyo nzira iyo kucheka kufamba kunotora. Bevel yekucheka ndeye iyo yekucheka kumucheto kwechishandiso isiri perpendicular nekutungamira kwekucheka kufamba. Sekureruka, mhedzisiro yekudya inogona kuregererwa. Kucheka kuri perpendicular neiyo huru yekufamba kumhanya kana kumucheto inclination angles lss = 0 inoonekwa seyekurudyi kona yekucheka. Izvi zvinoratidzwa mumufananidzo 3-9. Kucheka kusiri perpendicular nekumhanya kukuru kwekufamba kana edge inclination angles lss0, inonzi oblique angle-cutting. Semuenzaniso, Sezvakaratidzwa muMufananidzo 3-9.b, kana imwe chete yekucheka iri kucheka, izvi zvinozivikanwa sekucheka kusununguka. Kucheka kwebevel kunowanikwa zvakanyanya mukucheka simbi.

Mufananidzo 3-9 Kucheka kona yekurudyi uye kucheka bevel

(2) Mhedzisiro yekucheka bevel pane nzira yekucheka

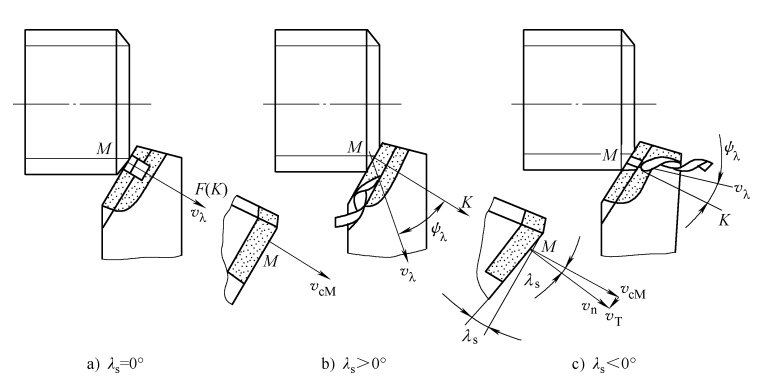

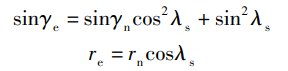

1. Kupesvedzera kutungamira kwechip outflow

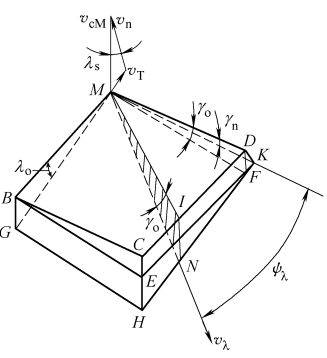

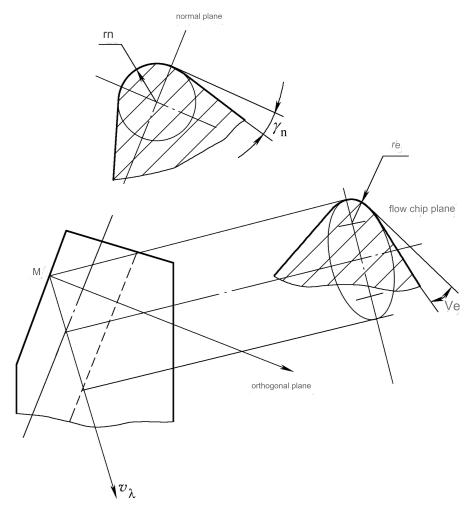

Mufananidzo 3-10 unoratidza kuti chigadziriso chekunze chinoshandiswa kushandura pombi. Kana chete iyo huru yekucheka inobatanidzwa mukucheka, chidimbu cheM muchikamu chekucheka (chichifunga kuti chakaenzana kureba sepakati pechikamu) inova chip pasi peiyo extrusion pamberi pechishandiso uye inoyerera ichienda mberi. Hukama huri pakati peiyo chip kuyerera kwegwara uye kumucheto inclination angle ndeyekubvuta unit body MBCDFHGM ine orthogonal ndege nendege yekucheka uye ndege mbiri dzakafanana navo kuburikidza nepoindi M.

Mufananidzo 3-10 Mhedzisiro ye λs pane inoyerera chip nzira

MBCD ndiyo yekutanga ndege muMufananidzo 3-11. Kana ls = 0, MBEF iri kumberi muMufananidzo 3-11, uye ndege MDF iine orthogonal uye yakajairika ndege. Point M ikozvino iri perpendicular yekucheka kumucheto. Kana machipisi aburitswa, M inhengo yevelocity pamwe negwara rekucheka kumucheto. Iyo MF inoenderana nepakati pekucheka. Sezvinoratidzwa muMufananidzo 3-10a, panguva ino, maChips akakomberedzwa kuita chitubu-sechimiro kana kuti anoyerera mumutsara wakatwasuka. Kana ls ine kukosha kwakanaka saka ndege yeMGEF iri pamberi uye iyo huru yekufambisa kutema kasi vcM haina kufanana nekucheka MG. The particle M velocitycnc kushandura zvikamuvT inoenderana nechishandiso munzira yekucheka kumucheto kunongedza kuMG. Kana point M ikashandurwa kuita chip inoyerera ichienda kumberi uye ichikanganiswa nevT chip's velocity vl inotsauka kubva kune yakajairika ndege MDK pa chip angle ye psl. Kana ls ine kukosha kukuru, machipisi anoyerera akananga kugadziriso yepasi.

Iyo ndege MIN, sezvakaratidzwa muFigure 3-10b uye 3-11, inozivikanwa sekuyerera kwechip. Kana ls ine kukosha kwakashata chikamu chevelocity vT munzira yekucheka inodzoserwa, ichinongedza kuGM. Izvi zvinoita kuti machipisi asiyane kubva kune yakajairika ndege. Kuyerera kuri mukupesana kwakananga pamusoro pemuchina. Sezvinoratidzwa mumufananidzo 3-10.c. Iyi nhaurirano ndeye chete nezve mhedzisiro yels panguva yemahara yekucheka. Kuyerera kwepurasitiki yesimbi pachokushandisa tipi, diki yekucheka mupendero, uye chip groove zvese zvine chekuita negwara rekubuda kwemachipisi panguva chaiyo machining maitiro ekushandura madenderedzwa ekunze. Mufananidzo 3-12 unoratidza kubatika kwemaburi nemaburi akavharika. Kufurira kwekucheka kumucheto kurerekera pane chip kuyerera. Kana uchibaya shinda isina buri, kukosha ls kwakanaka, asi kana uchibaya imwe negomba, kukosha kwakashata.

Mufananidzo 3-11 Oblique yekucheka chip kuyerera nzira

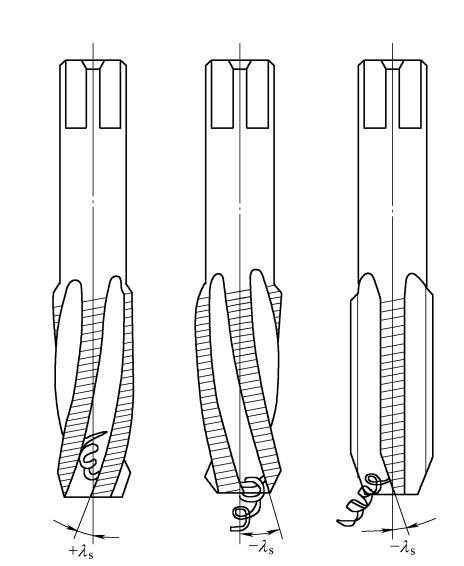

2. Iyo chaiyo rake uye obtuse radii inobatwa

Kana ls = 0, mukucheka kwemahara, makona erake mu orthogonal plane uye chip flow plane dzinenge dzakaenzana. Kana ls isiri zero, inogona kunyatso kanganisa kupinza kwekucheka uye kupikisa kuramba kana machipisi asundirwa kunze. Mune chip flow plane, iyo inoshanda rake angles ge uye yekucheka kumucheto obtuse radii re inofanirwa kuyerwa. Mufananidzo 3-13 inoenzanisa geometry yeimwe ndege yakajairika inopfuura neM-point yemucheto mukuru ne obtuse radii re ye chip flow plane. Muchiitiko chemupendero wakapinza, ndege yakajairika inoratidza arc yakagadzirwa ne obtuse radius rn. Zvisinei, muhuwandu hwekuyerera kwechip, kucheka chikamu che ellipse. Iyo radius ye curvature pamwe neakisi refu ndiyo chaiyo yekucheka kumucheto obtuse radius re. Iyo inotevera fungidziro fomula inogona kuverengerwa kubva kune geometric hukama manhamba muFigure 3-11 uye 3-13.

Iyo fomula iri pamusoro inoratidza kuti inowedzera zvakare sezvo kukosha kwakakwana ls kunowedzera, nepo ge ichiderera. Kana ls=75deg, uye gn=10deg ine rn=0.020.15mm saka ge inogona kunge yakakura se70deg. re inogona zvakare kuve diki se 0.0039mm. Izvi zvinoita kuti mupendero wekucheka uwedzere kupinza, uye unogona kuwana micro-kucheka (ap0.01mm) nekushandisa chidimbu chidiki chekucheka kumashure. Mufananidzo 3-14 inoratidza nzvimbo yekucheka yechishandiso chekunze kana ls yakaiswa pa75deg. Mheto huru uye yechipiri yechishandiso yakagadziridzwa mumutsara wakatwasuka. Kucheka kwechishandiso kwakapinza zvakanyanya. Mucheka wekucheka hauna kugadziriswa panguva yekucheka. Iyo zvakare ine tangent neyekunze cylindrical pamusoro. Kuisa uye kugadzirisa zviri nyore. Chishandiso ichi chakashandiswa zvinobudirira kune yakakwirira-kumhanya kutendeuka kupedzisa kwekabhoni simbi. Inogonawo kushandiswa kupedzisa kugadzirisa zvakaoma-ku-muchina zvinhu zvakadai sesimbi yakasimba.

Mufananidzo 3-12 Kurudziro yeedge inclination angle pane chip flow direction panguva yekubaya shinda

Mufananidzo 3-13 Kuenzanisa kwern uye re geometries

3. Impact kuramba uye kusimba kwechishandiso tipi zvinokanganiswa

Kana ls isina kunaka, sezvakaratidzwa muFigure 3-15b, iyo tipi rekushandisa ichave yakaderera poindi parutivi rwekucheka. Kana machende ekucheka akacheka mukatiprototype zvikamupfungwa yekutanga yekushanda ne workpiece ndiyo tooltip (kana kuenda kune kukosha kwakanaka) kana mberi (kana kusina kunaka) Izvi hazvingodziviriri uye zvinosimbisa chidimbu, asi zvinobatsirawo kuderedza dambudziko rekukuvara. Maturusi mazhinji ane hombe rake angle anoshandisa negative edge inclination. Ivo vese vanogona kuwedzera simba uye kuderedza kukanganiswa kwechishandiso tipi. The back force Fp iri kuwedzera panguva ino.

Mufananidzo 3-14 Yakakura blade angle inotenderedza chishandiso isina yakagadziriswa muromo

4. Inokanganisa kugadzikana kwekucheka mukati nekunze.

Kana ls = 0, iyo yekucheka inocheka mukati uye kunze kweiyo workpiece inenge imwe chete, simba rekucheka rinoshanduka kamwe kamwe, uye kukanganisa kwakakura; kana ls isiri zero, iyo yekucheka inocheka zvishoma nezvishoma mukati uye kunze kweiyo workpiece, iyo inokonzeresa idiki, uye kucheka kuri nyore. Semuyenzaniso, hombe helix angle cylindrical milling cutters uye maguyo ekupedzisira ane akapinza ekucheka macheto uye akatsetseka kucheka kupfuura ekare akajairwa milling cutter. Kubudirira kwekugadzira kunowedzerwa ne2 kusvika ku4 nguva, uye iyo yepamusoro roughness kukosha Ra inogona kusvika isingasviki 3.2 mm.

5. Kucheka kumucheto chimiro

Iyo yekucheka kumucheto chimiro chechishandiso chimwe chezvakakosha zviri mukati mezvinonzwisisika geometric parameters yechishandiso. Shanduko mune blade chimiro chechishandiso chinoshandura chimiro chekucheka. Iyo inonzi inonzi cutting pattern inoreva kurongeka uye chimiro umo simbi yesimbi inofanira kugadziriswa inobviswa nekucheka. Iyo inokanganisa saizi yemutoro wekucheka, mamiriro ekushushikana, hupenyu hwezvishandiso uye mhando yemuchina. wait. Zvishandiso zvakawanda zvepamberi zvine hukama zvakanyanya nekusarudzwa kwakaringana kwema blade maumbirwo. Pakati pezvishandiso zvepamberi zvinoshanda, maumbirwo eblade anogona kupfupikiswa mumhando dzinotevera:

(1) Wedzera chimiro cheblade chekucheka. Ichi chimiro cheblade chinonyanya kusimbisa simba rekucheka, kuwedzera kuchekwa kwekona, kuderedza mutoro paurefu hwechikwata chekucheka, nekuvandudza mamiriro ekupisa. Pamusoro pematurusi akati wandei maumbirwo anoratidzwa muMufananidzo 3-8, kune zvakare arc edge maumbirwo (arc edge inotenderedza maturusi, arc edge hobbing face milling cutters, arc edge drill bits, nezvimwewo), akawanda anopinza edge maumbirwo (drill bits. , etc.))mirira;

(2) Chimiro chemupendero chinoderedza nzvimbo yakasara. Ichi chimiro chemupendero chinonyanya kushandiswa kupedzisa maturusi, senge maturusi makuru ekutenderedza uye kumeso ekuchekesa macheki ane wiper, maturusi anoyangarara anofinha uye maturusi akajairwa anofinha ane cylindrical wipers. Reamers, nezvimwewo;

Mufananidzo 3-15 Mhedzisiro yeedge inclination angle pane yekukanganisa kana uchicheka chishandiso

(3) Chimiro cheblade chinogovera zvine mutsindo chikamu chekucheka uye chinoburitsa machipisi zvakanaka. Hunhu hwemhando iyi yeblade chimiro ndechekuti inopatsanura yakafara uye yakatetepa yekucheka musara mune akati wandei machipisi, ayo asingangobvumiri machipisi kuti abudiswe zvakanaka, asi zvakare anowedzera mwero wepamberi. Ipa huwandu uye kuderedza chikwata chekucheka simba. Semuyenzaniso, kana tichienzanisa neakajairwa akatwasuka-kumucheto mapanga ekucheka, maviri-nhanho ekucheka ekucheka mapanga anokamura iyo huru yekucheka muganho muzvikamu zvitatu, sezvakaratidzwa muMufananidzo 3-16. Iwo machipisi zvakare akakamurwa kuita matatu mitsetse zvinoenderana. Iko kukakavara pakati pemachipisi nemadziro maviri kwakaderedzwa, izvo zvinodzivirira machipisi kubva kuvharwa uye zvakanyanya kuderedza simba rekucheka. Sezvo kudzika kwekucheka kunowedzera, kuderera kunowedzera, uye mhedzisiro yacho iri nani. Panguva imwecheteyo, kupisa kwekucheka kunoderedzwa uye hupenyu hwekushandisa hunovandudzwa. Kune akawanda maturusi erudzi urwu rwema blade shape, akadai seanocheka nhanho, anocheka edge milling cutter, staggered edge saw blades, chip drill bits, akadzedzereka mazino anocheka chibage, uye wave edge end mills. Uye mavhiri-akacheka broaches, nezvimwewo;

Mufananidzo 3-16 Banga rekucheka rakapetwa kaviri

(4) Mamwe maumbirwo anokosha. Special blade maumbirwo mablade maumbirwo akagadzirirwa kusangana nemamiriro ekugadzirisa echikamu uye maitiro ayo ekucheka. Mufananidzo 3-17 unoratidza chimiro chekumberi chewashboard chinoshandiswa kugadzira lead-brass. Iyo huru yekucheka kumucheto kweiyi blade yakaumbwa mune akawanda matatu-dimensional arches. Poindi imwe neimwe iri pamucheto wekucheka ine kona yekurerekera inowedzera kubva kune isina kunaka, kuenda ku zero uyezve kuenda kune yakanaka. Izvi zvinoita kuti marara acho asvinirwe kuita machipisi akaita seribhoni.

Anebon alyways inotsigira huzivi hwe "Iva No.1 muhutano hwepamusoro, midzi pachikwereti uye kuvimbika kwekukura". Anebon icharamba ichishandira zvakapfuura uye zvitsva tarisiro kubva kumba nekumhiri kwemakungwa zvizere-kupisa kune Ordinary Discount 5 Axis Precision Custom Rapid Prototype.5 axis cnc kugayaKushandura Machining, kuAnebon nemhando yepamusoro yekutanga semotto yedu, tinogadzira zvigadzirwa zvakagadzirwa zvachose muJapan, kubva pakutenga zvinhu kusvika pakugadzirisa. Izvi zvinogonesa vatengi vanobva kumativi ese enyika kuti vashandise nerunyararo rwepfungwa.

China yekugadzira maitiro, simbi yekugaya masevhisi uye nekukurumidza prototyping sevhisi. Anebon inotarisa "mitengo inonzwisisika, nguva yekugadzira inoshanda uye yakanaka mushure mekutengesa-sevhisi" setsika yedu. Anebon inotarisira kushanda pamwe nevatengi vakawanda mukusimudzira pamwe nekubatsirikana. Tinogamuchira vangango tenga kuti vatibate.

Nguva yekutumira: Zvita-14-2023