Unoziva here kuti ndeapi minda inoda kurongeka kwepamusoro kune zvikamu zvemuchina?

Aerospace:

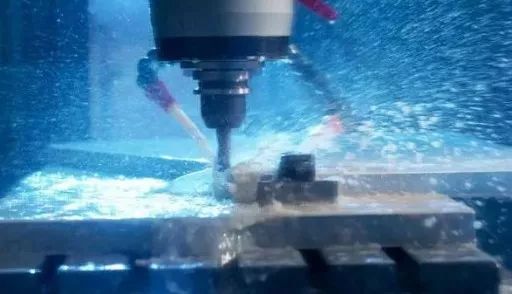

Zvikamu zveindasitiri yemuchadenga senge turbine blades kana zvikamu zvendege zvinoda kugadzirwa zvine hunyanzvi hwepamusoro, uye mukati mekushivirira kwakasimba. Izvi zvinoitirwa kuve nechokwadi chekuita uye kuchengeteka. Injini yejeti blade, semuenzaniso, ingangoda huroyi mukati memicrons kuitira kuchengetedza yakakwana simba rekushandisa uye kuyerera kwemhepo.

Zvishandiso zvekurapa:

Kuve nechokwadi chekuchengetedza uye kuenderana, zvese zvikamu zvakagadzirirwa michina yekurapa senge zvekuvhiya zviridzwa kana zvinoisirwa zvinofanirwa kuve zvakarurama. Kudyarwa kwetsika yemapfupa, semuenzaniso, kungangoda zviyero uye kupedzisa pamusoro kuti ive nechokwadi chekukwana uye kubatanidzwa mumuviri.

Motokari:

Muindasitiri yemotokari, kurongeka kunodiwa kune zvikamu zvakaita sekutumira uye zvikamu zveinjini. Iyo chaiyo-yakagadzirwa-muchina yekufambisa giya kana jekiseni remafuta ingangoda kushivirira kwakasimba kuitira kuti ive nechokwadi chekuita kwakaringana uye kusimba.

Zvemagetsi:

Zvikamu zvemuchina muindasitiri yemagetsi zvinofanirwa kuve zvakanyatsorongeka kune chaiwo dhizaini zvinodiwa. Iyo chaiyo-yakagadzirwa microprocessor imba inogona kuda kushivirira kwakasimba kwekugadzirisa kwakaringana uye kugovera kupisa.

Renewable energy:

Kuti uwedzere kugadzirwa kwesimba, uye kuve nechokwadi chekuvimbika, zvikamu zvemuchina mune inovandudzwa matekinoroji senge solar panel mounts kana mhepo turbine zvikamu zvinoda kunyatso. Iyo chaiyo-yakagadzirwa mhepo turbine giya system inogona kuda chaiyo mazino profiles uye kurongeka kuitira kuwedzera simba rekugadzira magetsi.

Zvakadini nenzvimbo idzo ururami hwezvikamu zvakakandwa zvisinganyanyi kudiwa?

Kuvaka:

Zvimwe zvikamu, zvakadai sezvisungo uye zvimiro zvezvimiro, zvinoshandiswa mumapurojekiti ekuvaka, zvinogona kunge zvisingade kurongeka kwakafanana seyakakosha mekinika zvikamu kana zvinhu zvemuchadenga. Mabhuraketi esimbi mumapurojekiti ekuvaka anogona kunge asingade kushivirira kwakafanana sezvikamu zvemazvo mumachina chaiwo.

Furniture Manufacturing:

Zvimwe zvikamu mukugadzira fenicha, senge yekushongedza trim, mabhuraketi kana Hardware, haifanirwe kuve yakanyanya-chaiyo. Zvimwe zvikamu, senge chakanyatso-machini zvikamu mune zvinogadziriswa fenicha michina inoda kurongeka, ine zvakawanda zvekuregerera kushivirira.

Zvishandiso zvekushandisa pakurima:

Zvimwe zvikamu zvemichina yekurima senge mabhuraketi, zvitsigiro kana zvivharo zvekudzivirira zvinogona kunge zvisingade kubatwa mukati mekushivirira kwakanyanya. Bhaketi rinoshandiswa kuisa chikamu chemidziyo isiri-chaiyo inogona kusada kurongeka sezvikamu mumichina yekurima chaiyo.

Kurongeka kwekugadzirisa ndiyo dhigirii yekuenderana kwehukuru hwepasi, chimiro uye chinzvimbo kune geometrical paramita dzakatsanangurwa mudhirowa.

Ivhareji saizi ndiyo yakakodzera geometric parameter yehukuru.

Surface geometry idenderedzwa, humburumbira kana ndege. ;

Zvinogoneka kuve nenzvimbo dzakafanana, perpendicular kana coaxial. Machining kukanganisa ndiwo mutsauko pakati peiyo geometric paramita yechikamu uye yavo yakanaka geometric paramita.

1. Nhanganyaya

Chinangwa chikuru chekugadzira machina ndechekugadzira zvigadzirwa. Ose ari maviri machining kurongeka uye zvikanganiso zvekugadzira mazwi anoshandiswa kuongorora geometric paramita yenzvimbo yakagadzirwa. Kushivirira giredhi rinoshandiswa kuyera machining kururama. Iyo yakakwirira yekururama, iyo idiki giredhi. Iko kukanganisa kwekugadzira kunogona kuratidzwa sehuwandu hwehuwandu. Kuwanda kwenhamba ndikowo kukanganisa kukuru. Inversely, high processing precision inosanganiswa nezvikanganiso zviduku zvekugadzirisa. Kune makumi maviri mazinga ekushivirira, kubva kuIT01 kusvika IT18. IT01 ndiyo nhanho yehunyanzvi hwekugadzira iyo iri pamusoro, IT18 yakaderera, uye IT7 uye IT8 kazhinji ndiwo mazinga ane pakati nepakati. level.

Hazvibviri kuwana chaiwo parameters nekushandisa chero nzira. Chero bedzi kukanganisa kwekugadzirisa kuwira mukati mehutano hwekushivirira hunotsanangurwa nechikamu chekudhirowa uye hachina kukura kudarika basa rechikamu, kunyatsogadzirisa kunogona kunzi kwakavimbiswa.

2. Zvakaenderana

Dimensional kurongeka:

The tolerance zone inzvimbo iyo saizi yechikamu chaiyo uye pakati penzvimbo yekushivirira zvakaenzana.

Shape kunyatsoita:

Iyo dhigirii iyo iyo geometric chimiro chepamusoro pechikamu chakagadzirwa chinoenderana neyakakodzera fomu yejometri.

Kurongeka kwenzvimbo:

Musiyano mukurongeka kwenzvimbo pakati penzvimbo dzezvikamu zviri kugadziriswa.

Kudyidzana:

Paunenge uchigadzira zvikamu zvemuchina uye uchitsanangura kurongeka kwavo kwekugadzira, zvakakosha kudzora kukanganisa kwechimiro nekushivirira kwenzvimbo. Iko kukanganisa kwenzvimbo kunofanirawo kuva diki pane kushivirira kwedimension. Kune zvikamu zvakanyatsorongeka uye nzvimbo dzakakosha, zvinodiwa zvekugadzirisa chimiro zvinofanira kunge zvakakwirira.

3. Kugadzirisa Nzira

1. Kugadzirisa maitiro ekugadzirisa

Kugadzirisa nzira yekucheka muyedzo: Edza saizi, gadzirisa huwandu hwechishandiso chekucheka uye wozocheka. Dzokorora kusvikira wasvika pakukura kwaunoda. Iyi nzira inoshandiswa zvakanyanya kune diki-batch uye imwechete-chidimbu kugadzirwa.

Methode d'ajustement: Kuti uwane saizi yaunoda, gadzirisa zvinzvimbo zvemuchina chishandiso, chigadziriso uye workpiece. Iyi nzira ndeyepamusoro-kubereka uye inonyanya kushandiswa mukugadzirwa kwehuwandu.

2. Deredza zvikanganiso zvemashandisi emuchina

1) Kuvandudza spindle chikamu chekugadzira kunyatsoita

Iko kutenderera kwekutakura kunofanirwa kuvandudzwa.

1 Sarudza yakakwirira-chaiyo rolling bearings;

2 Shandisa dynamic pressure bearings ine high precision yakawanda-oiri wedges.

3 Kushandisa yakakwirira chaiyo hydrostatic bearings

Zvakakosha kuvandudza kururamisa kwekutakura zvinhu.

1 Kuvandudza iko kurongeka kwejenari ye spindle uye maburi ekutsigira bhokisi;

2 Kuvandudza kurongeka kweiyo yepamusoro inoenderana nekubereka.

3 Kuyera uye kugadzirisa radial renji yezvikamu kuti zvigadzirise kana kutsiva zvikanganiso.

2) Preload mabhengi zvakanaka

1 Inogona kubvisa mikaha;

2 Wedzera kuomarara

3 Uniform rolling element kukanganisa.

3) Dzivisa kuratidzwa kweiyo spindle kurongeka pane workpiece.

3. Zvikanganiso zveketani dzekutumira: Dzikise

1) Kurongeka kwekufambisa uye nhamba yezvikamu zvakakwirira.

2) Chiyero chekutapurirana idiki kana transmission pair iri pedyo nekumagumo.

3) Iyo yekupedzisira chidimbu kurongeka kunofanirwa kuve kwakakura kupfuura zvimwe zvikamu zvekutapurirana.

4. Deredza Tool Wear

Maturusi ekurodza zvakare anodiwa asati asvika padanho rekupfeka zvakanyanya.

5. Deredza kushungurudza deformation muhurongwa hwekugadzirisa

Zvikuru kubva:

1) Wedzera kuoma uye simba rehurongwa. Izvi zvinosanganisira izvo zvisina kusimba zvinongedzo zvemaitiro system.

2) Deredza mutoro uye kusiyana kwayo

Wedzera kuoma kwehurongwa

1 Inonzwisisika dhizaini yekugadzira

1) Sezvingabvira, deredza huwandu hwenzvimbo dzinobatana.

2) Kudzivirira hukama hwemunharaunda hwekuoma kwakaderera;

3) Izvo zvakakosha zvikamu uye zvinotsigira zvinhu zvinofanirwa kuve zvine musoro chimiro uye chikamu chemuchinjikwa.

2 Kuvandudza kuomarara kwekubatana pane yekubatanidza nzvimbo

1) Kuvandudza kunaka uye kuenderana kwenzvimbo dzinobatanidza zvikamu pamwechete mumashini emidziyo yemidziyo.

2) Kufanorodha zvinhu zvemuchina

3) Wedzera kurongeka kweiyo workpiece chinzvimbo uye kuderedza kushata kwepamusoro.

3 Kutora zvinonzwisisika clamping uye chinzvimbo nzira

Deredza mutoro nemigumisiro yaro

1 Sarudza chishandiso geometry paramita uye yekucheka huwandu kudzikisa simba rekucheka.

2 Iwo ma blank blanks anofanirwa kuunganidzwa pamwe chete uye mvumo yekuagadzirisa inofanira kunge yakafanana nekugadzirisa.

6. Thermal deformation yegadziriro yekugadzirisa inogona kuderedzwa

1 Isolate kupisa masosi uye kuderedza kupisa kugadzirwa

1) Shandisa madiki ekucheka huwandu;

2) Kuparadzanisa roughing uye kupedza kanamilling componentszvinoda kunyatsojeka.

3) Sezvinobvira, patsanura sosi yekupisa uye muchina kuti uderedze deformation yekupisa.

4) Kana zvinopisa zvisingakwanisi kupatsanurwa (zvakadai semaspindle bearings kana screw nut pairs), kunatsiridza friction zvivakwa kubva muchimiro, lubrication uye zvimwe zvinhu, kuderedza kugadzirwa kwekupisa, kana kushandisa kupisa-inodzivirira zvinhu.

5) Shandisa kutonhora kwemhepo yakamanikidzwa kana kutonhora kwemvura pamwe chete nedzimwe nzira dzekupisa kupisa.

2 Equilibrium tembiricha munda

3 Tora zvinonzwisisika zviyero zvemuchina chishandiso chechikamu kusangana uye chimiro

1) Kutora iyo thermally-symmetrical chimiro mubhokisi regiya - symmetrically kuronga shafts, mabhengi uye ekufambisa magiya anogona kuderedza deformation yebhokisi nekuona kuti tembiricha yemadziro ebhokisi yunifomu.

2) Sarudza chiyero chegungano chemidziyo yemuchina nehanya.

4 Kurumidza kuchinjisa chiyero chekupisa

5 Kudzora ambient tembiricha

7. Deredza kusara kunetseka

1. Wedzera nzira yekupisa kuti ubvise kushungurudzika mukati memuviri;

2. Ronga nzira yako nenzira inonzwisisika.

4. Zvikonzero zvepesvedzero

1 Machining musimboti kukanganisa

Izwi rekuti "machining musimboti kukanganisa" rinoreva chikanganiso chinoitika kana machining aitwa pachishandiswa fungidziro yekucheka kumucheto, kana hukama hwekutapurirana. Iko kugadzirisa kwenzvimbo dzakaoma, shinda uye magiya zvinogona kukonzera kukanganisa kwekugadzira.

Kuti zviite nyore kushandisa, pachinzvimbo chekushandisa honye yekutanga kuti involute, iyo yakakosha Archimedean worm kana yakajairwa yakatwasuka profiles inoshandiswa. Izvi zvinokonzera kukanganisa muchimiro chezino.

Pakusarudza giya, iyo p kukosha inogona kuverengerwa chete (p = 3.1415) nekuti pane chete nhamba shoma yemazino pane lathe. Chishandiso chinoshandiswa kugadzira iyo workpiece (spiral motion), haizove yakarurama. Izvi zvinotungamira kukanganisa kwepitch.

Kugadziriswa kunowanzoitwa nekufungidzira kugadzirisa pasi pekufungidzira kuti zvikanganiso zvedzidziso zvinogona kudzikiswa kuti zvisangane nekugadzirisa kurongeka kwezvinodiwa (10% -15% kushivirira pazviyero) kuitira kuti uwedzere kubereka uye kuderedza mutengo.

2 kugadzirisa kukanganisa

Kana tichiti mudziyo wemuchina une gadziriso isiriyo, tinoreva kukanganisa.

3 Machine kukanganisa

Izwi rekuti muchina chishandiso kukanganisa rinoshandiswa kutsanangura kukanganisa kwekugadzira, kukanganisa kwekumisikidza, uye kupera kwechombo. Izvi zvinosanganisira kunyanya kukanganisa kwekutungamira uye kutenderera kwemuchina-chishandiso chekutungamira njanji pamwe nekukanganisa kwekutapurirana mucheni yekutapurirana kwemuchina.

Chikanganiso chegwaro remuchina

1. Ndiko kurongeka kwegwara renjanji kutungamira - mutsauko pakati pemafambiro ekufamba kwezvikamu zvinofamba uye nzira yakanaka. Zvinosanganisira:

Nhungamiro inoyerwa nekutwasuka kweDy (ndege yakachinjika) uye Dz (ndege yakatwasuka).

2 Kufanana kwemberi uye kumashure njanji (kukanganisa);

(3) The verticality kana parallelism kukanganisa pakati pe spindle rotation uye gwara renjanji mune ese ari maviri akatwasuka uye akachinjika ndege.

2. Nhungamiro yenjanji inotungamirira kururamisa kune simba guru pakucheka machining.

Izvi zvinodaro nekuti inofunga nezve kutama pakati pechishandiso uye workpiece inokonzerwa nekukanganisa kwenjanji. Kutenderedza (turning) ibasa rekutendeutsa uko kwarinoenda kusingaite kukanganisa. Makanganiso ekwakatwasuka anogona kufuratirwa. Nzira yekutenderera inoshandura nzira iyo chombo chinonzwa kukanganisa. Iyo yakatwasuka gwara ndiro gwara rinonyanya kuona kukanganisa pakuronga. Iyo yakatwasuka yemadhiraivha emubhedha mundege yakatwasuka inotarisisa kurongeka kweflatness uye kutwasuka kwenzvimbo dzakagadzirwa nemichina.

Machine tool spindle rotation kukanganisa

Iyo spindle yekutenderera kukanganisa ndiyo mutsauko pakati peiyo chaiyo uye yakanaka yekutenderera axis. Izvi zvinosanganisira kutenderera kwechiso chedenderedzwa, spindle denderedzwa radial uye spindle angle tilt.

1, Iyo pesvedzero ye spindle runout denderedzwa pakugadzirisa kurongeka.

① Hapana kukanganisa pane cylindrical pamusoro kurapwa

② Izvo zvinokonzeresa perpendicularity kana flatness chikanganiso pakati pecylindrical axis uye endface kana uchitendeuka nekuifinha.

③ Iko kukanganisa kutenderera kunogadzirwa kana tambo dzakagadzirwa.

2. Pesvedzero ye spindle radial inomhanya pane chokwadi:

① Iko kukanganisa kwekutenderera kwedenderedzwa reradial inoyerwa nerunout amplitude yegomba.

② Iyo radius yedenderedzwa inogona kuverengerwa kubva kumucheto wechishandiso kusvika kune avhareji shaft, zvisinei nekuti shaft iri kushandurwa kana kufinhwa.

3. Pesvedzero yekona yekurerekera kweiyo huru shaft geometric axis pakuita machining

① Iyo geometric axis yakarongedzerwa munzira ine conical ine koni angle, iyo inoenderana neiyo eccentric kufamba kwakatenderedza mean-axis ye geometrical axis kana ichitariswa kubva muchikamu chimwe nechimwe. Iyi eccentric kukosha inosiyana neiyo yeaxial maonero.

② Axis ndeye geometric imwe inotenderera mundege. Izvi zvakafanana neaxis chaiyo, asi iri kufamba mundege mutsetse wakatwasuka.

③ Muchokwadi, kona yeiyo huru shaft's geometric axis inomiririra musanganiswa weaya marudzi maviri ekuzungunuka.

Kutapurirana kukanganisa kwematurusi emuchina wekufambisa cheni

Kukanganisa kwekutapurirana ndiko mutsauko wekufamba pakati pechinhu chekutanga chekufambisa uye chekupedzisira chekufambisa chetani yekufambisa.

④ Kugadzira kukanganisa uye kupfeka pane fixture

Chikanganiso chikuru mukugadzirisa ndechekuti: 1) kukanganisa kwekugadzira kweiyo yekumisikidza chinhu uye chishandiso chinotungamira zvinhu, pamwe neiyo indexing meshini uye clamping kongiri. 2) Mushure mekusangana kwechigadziriso, hukuru hukuru kukanganisa pakati peizvi zvakasiyana zvikamu. 3) Pfeka pamusoro peiyo workpiece inokonzerwa nekugadzirisa. Zviri mukati meMetal Processing Wechat zvakanakisa, uye zvakakodzera kutariswa kwako.

⑤ zvikanganiso zvekugadzira uye kupfeka kwemidziyo

Mhando dzakasiyana dzezvishandiso zvine maitiro akasiyana pakurongeka kwemachina.

1) Kurongeka kwezvishandiso zvine zviyero zvakatarwa (senge zvibooreso, reamers, keyway milling cuts, round broaches, etc.). Kurongeka kwedimensional kunokanganisa zvakananga ne workpiece.

2) Kurongeka kwechishandiso chekugadzira (zvakadai sekushandura maturusi, zvigayo, mavhiri ekukuya, nezvimwewo), zvinokanganisa zvakananga chimiro chechimiro. Kurongeka kwechimiro chebasa rekushanda kunobatwa zvakananga nekururama kwechimiro.

3) Iko kukanganisa kwechimiro mublade yeanocheka akagadzirwa (senge magiya hobs, spline hobos, giya shaper cutters, nezvimwewo). Kurongeka kwechimiro chepamusoro kuchakanganiswa nekukanganisa kweblade.

4) Kurongeka kwekugadzira kwechishandiso hakukanganisi zvakananga kugadzirisa kwayo. Zvisinei, zviri nyore kushandisa.

⑥ Process system stress deformation

Pasi pesimba re clamping simba uye giravhiti, sisitimu inozokanganisa. Izvi zvinotungamira mukukanganisa kwekugadzirisa uye zvichakanganisa kugadzikana. Iwo makuru ekutarisisa ndeye deformation yezvishandiso zvemuchina, deformation yezvishandiso uye deformation yakazara yegadziriro yekugadzirisa.

Kucheka simba uye machining kururama

Iko kukanganisa kwecylindricity kunogadzirwa kana chikamu chakagadzirwa chakakora pakati uye chakatetepa kumagumo, zvichibva pane deformation yakakonzerwa nemuchina. Nekugadziriswa kwezvikamu zveshaft, chete deformation uye kushushikana kweiyo workpiece inofungidzirwa. Iyo workpiece inoratidzika gobvu pakati uye yakatetepa kumigumo. Kana iyo chete deformation iyo inofungidzirwa kugadziriswa kwecnc shaft machining zvikamundiyo deformation kana chishandiso chemuchina, ipapo chimiro chebasa mushure mekugadzirisa chichapesana neyakagadziriswa shaft zvikamu.

Mhedzisiro ye clamping simba mune machining kunyatsoita

Iyo workpiece icharemara kana yakasungirirwa nekuda kwekudzika kwayo kuomarara kana zvisina kufanira clamping simba. Izvi zvinokonzera kukanganisa kugadzirisa.

⑦ Thermal deformation in process systems

Iyo process system inodziya uye kuremara panguva yekugadziriswa nekuda kwekupisa kunogadzirwa nekunze kwekupisa sosi kana yemukati kupisa sosi. Thermal deformation inokonzeresa 40-70% yezvikanganiso zvemachining mune yakakura workpiece uye chaiyo machining.

Kune marudzi maviri ekupisa kwekupisa kweiyo workpiece iyo inogona kukanganisa goridhe kugadzirisa: kupisa yunifomu uye kupisa kusina kuenzana.

⑧ Residual Stress mukati me Workpiece

Kugadzira Stress mune yasara mamiriro:

1) Kushungurudzika kwakasara kunogadzirwa panguva yekupisa uye maitiro ekugadzira embryo;

2) Kururamisa kunotonhora kwebvudzi kunogona kukonzera kusara kunetseka.

3) Kucheka kunogona kukonzera kusara kunetseka.

⑨ Kugadzirisa kukanganiswa kwenzvimbo

Iko kunowanzo kune akawanda madiki masimbi particles panzvimbo yekugadzirisa. Aya machipisi esimbi anozokanganisa kurongeka kwekugadzira chikamu kana chiri padhuze nenzvimbo yegomba kana pamusoro pegomba.kushandura zvikamu. Simbi machipisi idiki kuti ione ichave nemhedzisiro mukurongeka mukugadzirwa kwepamusoro-chaizvo. Zvinonyatsozivikanwa kuti ichi pesvedzero chinhu chinogona kuve dambudziko, asi zvakaoma kubvisa. Hunyanzvi hwemushandisi zvakare chinhu chikuru.

Chinangwa chikuru cheAnebon chichava chekupa iwe vatengi vedu hukama hwebhizinesi hwakakomba uye hune mutoro, uchipa kutarisisa kwemunhu kune vese kweNew Fashion Design yeOEM Shenzhen Precision Hardware Factory Custom Fabrication CNC milling process, precision casting, prototyping service. Unogona kuburitsa mutengo wakaderera pano. Zvakare iwe uchawana yakanaka mhando zvigadzirwa uye mhinduro uye inonakidza sevhisi pano! Haufanire kuzeza kubata Anebon!

Nyowani Yemafashoni Dhizaini yeChina CNC Machining Service uye TsikaCNC Machining Service, Anebon ine nhamba dzemapuratifomu ekutengeserana kunze kwenyika, anoti Alibaba,Globalsources,Global Market,Made-in-china. "XinGuangYang" HID mhando zvigadzirwa nemhinduro zvinotengeswa zvakanyanya muEurope, America, Middle East nemamwe matunhu anopfuura makumi matatu nyika.

Kana iwe uchida kutora zvikamu zvemuchina, ndapota inzwa wakasununguka kutumira madhirowa kuAnebon official Email: info@anebon.com

Nguva yekutumira: Zvita-20-2023