1. Ndedzipi nzira nhatu dzekusunga maworkpieces?

Pane nzira nhatu dzekusunga maworkpieces anosanganisira:

1) Kusungirira mugadziriso

2) Kutsvaga chaiyo clamp zvakananga

3) Kumaka mutsara uye nekutsvaga iyo chaiyo clamp.

2. Chii chinosanganisa hurongwa hwekugadzirisa?

Iyo yekugadzirisa system inosanganisira maturusi emuchina, workpieces, zvigadziriso, uye maturusi.

3. Ndezvipi zvikamu zve mechanical processing process?

Izvo zvikamu zveiyo mechanic process process ndeye roughing, semi-kupedza, kupedzisa, uye super-kupedza.

4. Mabhenji anoiswa muboka sei?

Benchmarks dzinoiswa sezvizvi:

1. Dhizaini hwaro

2. Maitiro ekutanga: maitiro, kuyerwa, kusangana, chinzvimbo: (yekutanga, yekuwedzera): (hwaro hwakakasharara, hwaro hunogamuchirika)

Chii chinonzi processing accuracy chinosanganisirei?

Kunyatsogadzirisa kunosanganisira kurongeka kwedimensional, kurongeka kwechimiro, uye kurongeka kwenzvimbo.

5. Ko kukanganisa kwepakutanga kunoitika panguva yekugadzirisa kunosanganisira chii?

Iko kukanganisa kwepakutanga kunoitika panguva yekugadziriswa kunosanganisira kukanganisa kwemusimboti, kukanganisa kwekumisikidza, kukanganisa kwechishandiso, chikanganiso chekugadzirisa, muchina wemuchina spindle kutenderera kukanganisa, muchina wedhizaini njanji kukanganisa, muchina chishandiso chekufambisa kukanganisa, process system stress deformation, process system thermal deformation, mudziyo kupfeka, kuyerwa kukanganisa, uye workpiece residual stress kukanganisa kunokonzerwa.

6. Kuomarara kwemaitiro ehurongwa kunokanganisa sei kurongeka kwemachina, senge muchina chishandiso deformation uye workpiece deformation?

Izvi zvinogona kukonzera zvikanganiso zvechimiro cheworkpiece nekuda kwekuchinja kwenzvimbo yekucheka simba rekushandisa, kugadzirisa kukanganisa kunokonzerwa nekuchinja kwehukuru hwesimba rekucheka, zvikanganiso zvekugadzirisa zvinokonzerwa ne clamping simba uye giravhiti, uye kukanganisa kwesimba rekufambisa uye inertial simba. pakugadzirisa kururama.

7. Ndedzipi zvikanganiso mumichina yekushandisa kutungamira uye spindle kutenderera?

Iyo inotungamira njanji inogona kukonzera zvikanganiso zvekusimuka pakati pechishandiso uye workpiece munzira yekukanganisa-inonzwa, nepo spindle ichigona kuve neradial denderedzwa runout, axial circular runout, uye inclination swing.

8. Chii chinonzi "chikanganiso chekudzokorora" chiitiko, uye tingachideredza sei?

Kana iyo process system kukanganisa deformation ichichinja, iyo isina chinhu chikanganiso chinoratidzwa zvishoma pane workpiece. Kuti tideredze mhedzisiro iyi, tinogona kuwedzera huwandu hwezvishandiso zvinopfuura, kuwedzera kuomarara kwehurongwa hwekugadzirisa, kuderedza huwandu hwekudya, uye kugadzirisa iyo isina kujeka.

9. Tinogona sei kuongorora uye kudzikisa kukanganisa kwekutapurirana kwemuchina wekutepfenyura cheni?

Kuongororwa kwekukanganisa kunoyerwa nekutenderera kwekona kukanganisa Δφ yechikamu chekupedzisira cheketani yekutumira. Kuti tideredze zvikanganiso zvekutapurirana, tinogona kushandisa mashoma ekutapurirana zvikamu, kuve neketani pfupi yekutapurirana, shandisa diki diki rekutapurirana reshiyo I (kunyanya pamagumo ekutanga uye ekupedzisira), ita kuti zvikamu zvekupedzisira zvezvikamu zvekutumira zvive zvakarurama sezvinobvira, uye shandisa. mudziyo wekugadzirisa.

10. Zvikanganiso zvekugadzirisa zvinorongwa sei? Ndedzipi zvikanganiso zvinogara zviripo, zvakasiyana-siyana zvine hurongwa zvikanganiso, uye zvisina tsarukano kukanganisa?

System kukanganisa:(nguva dzose kukosha system kukanganisa, kusiyanisa kukosha system kukanganisa) kukanganisa kukanganisa.

Constant system error:machining musimboti kukanganisa, kukanganisa kwekugadzira kwematurusi emuchina, maturusi, zvigadziriso, kusagadzikana deformation yegadziriro yekugadzirisa, nezvimwe.

Variable value system kukanganisa:kupfeka kwezvipfeko; thermal deformation kukanganisa kwezvishandiso, zvigadziriso, maturusi emuchina, nezvimwe, pamberi pekupisa kwemafuta.

Random errors:kukopa zvikanganiso zvisina chinhu, zvikanganiso zvekuisa, kusimbisa zvikanganiso, kukanganisa kwekugadziriswa kwakawanda, kukanganisa kwe deformation kunokonzerwa nekusarira kunetseka.

11. Ndedzipi nzira dzekuva nechokwadi nekuvandudza kurongeka kwekugadzirisa?

1) Kukanganisa tekinoroji yekudzivirira: Kushandisa zvine musoro kwehunyanzvi hwepamusoro uye michina kudzikisa zvakananga chikanganiso chepakutanga, kutamisa kukanganisa kwepakutanga, kuenzana kukanganisa kwepakutanga, uye kuenzana kukanganisa kwepakutanga.

2) Kukanganisa muripo tekinoroji: kutariswa pamhepo, otomatiki kuenzanisa uye kugaya kunyange zvikamu, uye kushingaira kutonga kwezvinhu zvinokanganisa kukanganisa.

12. Chii chinonzi processing surface geometry chinosanganisirei?

Geometric roughness, surface waviness, hutungamiri hwezviyo, kukanganisa kwepamusoro.

13. Ndeapi maitiro emuviri uye makemikari emhando dzepamusoro layer zvinhu?

1) Cold basa kuomesa pamusoro pamusoro layer simbi.

2) Metallographic chimiro deformation pamusoro pepamusoro simbi simbi.

3) Residual stress of surface layer metal.

14. Ongorora zvinhu zvinokanganisa kuoma kwepamusoro kwekucheka kugadzirisa.

Iko roughness value inotarirwa nehupamhi hwekucheka nzvimbo yakasara. Zvinhu zvikuru ndeye arc radius yeturusitip, iyo huru declination angle, uye yechipiri declination angle, huwandu hwekudya. Sekondari zvinhu kuwedzera kwekucheka kukurumidza, sarudzo yakakodzera yekucheka mvura, kuwedzera kwakakodzera kwerake angle yechishandiso, uye kuvandudzwa kwemupendero wechishandiso, kukuya kunaka.

15. Zvinhu Zvinokanganisa Kushata kwePamusoro paKugaya Kugadzira:

Zvinhu zveGeometric zvakadai sehuwandu hwekukuya, ukuru hwevhiri rekukuya, uye mapfekero evhiri rekukuya zvinogona kukanganisa kushata kwepamusoro.Zvinhu zvenyama, senge dhizaini yepurasitiki yesimbi yepasi uye kusarudzwa kwemavhiri ekukuya, zvinogona zvakare kukanganisa kushata kwepamusoro.

16. Zvinhu Zvinokonzera Kutonhora Kushanda Kuomarara Kwekucheka Nzvimbo:

Huwandu hwekucheka, iyo geometry yechishandiso, uye zvimiro zvekugadzirisa zvinhu zvinogona kukanganisa basa rinotonhora kuoma kwekucheka nzvimbo.

17. Kunzwisisa Kukuya Hasha Kupisa, Kukuya uye Kudzima Kupisa, uye Kukuya Annealing Kupisa:

Kupisa kunoitika kana tembiricha iri munzvimbo yekukuya isingapfuure tembiricha yekuchinja kwesimbi yakadzima asi inodarika tembiricha yekushandurwa kwemartensite. Izvi zvinoguma nechimiro chakapfava nekuoma kwakaderera. Kudzima kunoitika kana tembiricha iri munzvimbo yekukuya ichipfuura tembiricha yekuchinja kwechikamu, uye simbi yepamusoro ine yechipiri quenching martensite chimiro nekuda kwekutonhora. Izvi zvine kuomarara kwepamusoro pane yekutanga martensite muchikamu chayo chepasi uye chimiro chakadziya chine kuomarara kwakaderera pane yekutanga tempered martensite. Anealing inoitika kana tembiricha munzvimbo yekukuya ichipfuura tembiricha yekuchinja kwechikamu, uye hapana chinotonhorera panguva yekukuya. Izvi zvinoguma mune anneal structure uye kudonha kwakapinza mukuoma.

18. Kudzivirira uye Kudzora kweMechanical Processing Vibration:

Kuti udzivise uye udzore mechanical processing vibration, unofanira kubvisa kana kuderedza mamiriro ayo anoibudisa. Iwe unogona zvakare kuvandudza maitiro ane simba eiyo yekugadzirisa sisitimu, kuvandudza kugadzikana kwayo, uye kutora akasiyana-siyana ekudzora vibration zvishandiso.

19. Rondedzera muchidimbu misiyano mikuru uye zviitiko zvekushandisa zvemachining process makadhi, makadhi ekugadzirisa, uye makadhi ekugadzirisa.

Process card:Chidimbu chimwechete uye diki kugadzirwa kwebatch kunoitwa uchishandisa yakajairwa nzira dzekugadzirisa.

Mechanical processing technology kadhi:"Medium batch production" inoreva maitiro ekugadzira apo huwandu hushoma hwezvigadzirwa hunogadzirwa panguva. Nekune rimwe divi, "kugadzirwa kwevhoriyamu yakakura" kunoda basa rakangwarira uye rakarongeka kuti ive nechokwadi chekuti chirongwa chekugadzira chinofamba zvakanaka uye nemazvo. Zvakakosha kuchengetedza matanho akasimba ekugadzirisa maitiro mumamiriro ezvinhu akadaro.

*20. Ndeapi mamisimboti ekusarudza mabhenji akakasharara? Misimboti yekusarudza benchmark yakanaka?

Rough datum:1. Nheyo yekuona kuti mutual chinzvimbo zvinodiwa; 2. Nheyo yekuve nechokwadi chekugovera kwakaringana kwemvumo yemuchina pane iyo machined surface; 3. Nheyo yekufambisa workpiece clamping; 4. Nheyo yekuti rough data kazhinji haigone kushandiswa zvakare

Precision datum:1. Nheyo yedatum coincidence; 2. Nheyo yedatum yakabatana; 3. Nheyo yemutual datum; 4. Nheyo yekuzvimiririra; 5. Nheyo yekubata nyore nyore

21. Ndedzipi nheyo dzekuronga kutevedzana kwemaitiro?

1) Gadzira iyo datum pamusoro pekutanga uye wozogadzira mamwe maficha;

2) Muhafu yemakesi, gadzira pamusoro pekutanga uye wozogadzira maburi;

3) Gadzira iyo huru yekutanga, uye wozogadzirisa iyo yechipiri nzvimbo;

4) Ronga iyo yakaoma machining process kutanga, wozoronga iyo yakanaka machining process. Kugadzirisa matanho

22. Tinoparadzanisa sei matanho ekugadzirisa? Ndeapi mabhenefiti ekuparadzanisa matanho ekugadzirisa?

Diviation yematanho ekugadzirisa: 1. Rough machining stage – semi-finishing stage – finishing stage – precision finishing stage

Kupatsanura matanho ekugadzirisa kunogona kubatsira mukuona nguva yakakwana yekubvisa deformation yekupisa uye kusara kunetseka kunokonzerwa nekukasira machining, zvichikonzera kuvandudzwa kwekutevera kwekugadzirisa kurongeka. Pamusoro pezvo, kana hurema hukawanikwa mune isina chinhu panguva yakaoma machining nhanho, kuenda kune inotevera nhanho yekugadzirisa kunogona kudzivirirwa kudzivirira tsvina.

Zvakare, michina inogona kushandiswa zvine hungwaru nekushandisa yakaderera-chaiyo muchina maturusi ekukasharara machining uye kuchengetedza chaiwo emuchina maturusi ekupedzisa kuchengetedza iwo nhanho chaiyo. Zvishandiso zvevanhu zvinogonawo kurongeka nemazvo, nevashandi vepamusoro-tekinoroji vanonyanya hunyanzvi uye hwekupedzisira-chaizvo machining kuti vaone zvese zviri zviviri.zvikamu zvesimbikunaka uye nhanho nhanho yekuvandudza, izvo zvakakosha zvinhu.

23. Ndezvipi zvinhu zvinokanganisa process margin?

1) Iyo dimensional kushivirira Ta yeiyo yapfuura maitiro;

2) Hurukuro hwepamusoro Ry uye hurema hwepamusoro hudzamu hwakagadzirwa nemaitiro apfuura;

3) Iko kukanganisa kwenzvimbo kwakasiiwa nemaitiro apfuura

24. Koti yeawa yekushanda inosanganisirei?

T quota = T imwe chidimbu nguva + t chaiyo yekupedzisira nguva / n nhamba yezvimedu

25. Ndedzipi nzira dzehunyanzvi dzekuvandudza kubereka?

1) Pfupisa nguva yekutanga;

2) Deredza kupindirana pakati penguva yekubatsira nenguva yakakosha;

3) Deredza nguva yekuronga basa;

4) Deredza nguva yekugadzirira uye yekupedzisa.

26. Ndezvipi zviri mukati memitemo yegadziriro yegungano?

1) Ongorora zvigadzirwa zvakadhirowa, patsanura zvikamu zvegungano, uye sarudza nzira dzegungano;

2) Gadzira kutevedzana kwegungano uye kupatsanura maitiro egungano;

3) Verenga nguva yegungano;

4) Sarudza iyo gungano tekinoroji zvinodiwa, nzira dzekutarisa mhando, uye maturusi ekuongorora ega ega maitiro;

5) Sarudza nzira yekufambisa yezvikamu zvegungano uye midziyo inodiwa uye maturusi;

6) Sarudza uye dhizaini maturusi, zvigadziriso, uye yakakosha michina inodiwa panguva yekusangana

27. Chii chinofanira kutariswa muhurongwa hwekusangana kwechimiro chemuchina?

1) Chimiro chemuchina chinofanira kukwanisa kukamurwa kuita mayuniti egungano akazvimirira;

2) Deredza kugadzirisa uye machining panguva yegungano;

3) Chimiro chemuchina chinofanira kunge chiri nyore kuunganidza uye kupatsanura.

28. Kururama kwegungano kunosanganisirei?

1. Kurongeka kwenzvimbo; 2. Mutual kufamba kwakarurama; 3. Kudyidzana kwakarurama

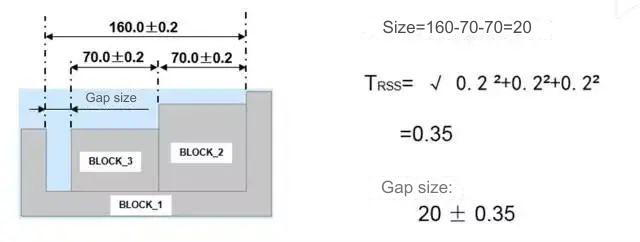

29. Inhaui dzinofanira kucherechedzwa pakutsvaka cheni dzemagungano?

1. Rerutsa gungano dimension cheni sezvinodiwa.

2. Iyo yegungano dimension cheni inofanira kunge ine chidimbu chimwe chete uye imwe link.

3. The assembly dimension chain ine directionality, zvichireva kuti muchimiro chegungano chimwechete, panogona kunge paine misiyano yeassembly accuracy in different positions and directions. Kana zvichidikanwa, cheni yedhisheni yegungano inofanirwa kutariswa nenzira dzakasiyana.

30. Ndedzipi nzira dzekuva nechokwadi chekuti gungano rakarurama? Nzira dzakasiyana-siyana dzinoshandiswa sei?

1. Kuchinjana nzira; 2. Nzira yekusarudza; 3. Kushandura nzira; 4. Kugadzirisa nzira

31. Ndezvipi zvikamu uye mabasa ezvigadzirwa zvemichina?

A machine tool fixture mudziyo unoshandiswa kubatisa workpiece pamuchina. Iyo gadziriso ine akati wandei zvinhu, zvinosanganisira zvigadziriso zvekuisa, zvigadziriso zvekushandisa, clamping midziyo, yekubatanidza zvinhu, clamp body, uye zvimwe zvishandiso. Basa rezvikamu izvi nderokuchengeta workpiece iri munzvimbo yakarurama maererano nemudziyo wemuchina uye kucheka turusi uye kuchengetedza nzvimbo iyi panguva yekugadzira machining.

Mabasa makuru echigadziriso anosanganisira kuve nechokwadi chekugadzirisa mhando, kuvandudza kushanda zvakanaka kwekugadzira, kuwedzera huwandu hwetekinoroji yechishandiso chemuchina, kuderedza kusimba kwevashandi, uye kuve nechokwadi chekuchengetedza kugadzirwa. Izvi zvinoita kuti ive yakakosha chishandiso mune chero machining process.

32. Zvigadziriso zvematurusi zvemuchina zvinorongedzerwa sei zvichienderana nerudzi rwekushandisa?

1. Universal fixture 2. Special fixture 3. Adjustable fixture and group fixture

33. Iyo workpiece yakaiswa pane imwe ndege. Ndezvipi zvinowanzoshandiswa zvimiso?

Uye ongorora mamiriro ekubvisa madhigirii erusununguko.

Iyo workpiece inoiswa pane imwe ndege. Zvishandiso zvinowanzoshandiswa zvinosanganisira tsigiro yakagadziriswa, tsigiro inogadzirika, tsigiro yekuzvimisa, uye tsigiro yekubatsira.

34. Iyo workpiece yakaiswa ne cylindrical gomba. Ndezvipi zvinowanzoshandiswa zvimiso?

Iyo workpiece yakaiswa ne cylindrical gomba. Ndeapi Anowanzo shandiswa ekumisikidza zvikamu zveworkpiece ine cylindrical gomba zvinosanganisira spindle nepini yekumisikidza. Mamiriro ezvinhu ekubvisa madhigirii erusununguko anogona kuongororwa.

35. Kana uchiisa workpiece pane yekunze denderedzwa pamusoro, ndezvipi zvinowanzoshandiswa zvigadziriso zvikamu? Uye ongorora mamiriro ekubvisa madhigirii erusununguko.

Iyo workpiece inoiswa pane yekunze denderedzwa pamusoro. Inowanzo shandiswa chinzvimbocnc yakashandura zvikamusanganisira V-shape blocks.

Anebon yakazvipira kuwana kugona uye kuvandudza matanho ayo kuti ive yepamusoro-giredhi uye yepamusoro-tech bhizinesi padanho repasirese. SeChina Gold Supplier, isu tine hunyanzvi mukupa masevhisi eOEM,tsika CNC machining, masevhisi ekugadzira simbi, uye masevhisi ekugayo. Tinodada nekupa kune zvinodiwa nevatengi vedu uye tinoedza kuzadzisa zvavanotarisira. Bhizinesi redu rine madhipatimendi akati wandei, anosanganisira kugadzira, kutengesa, kutonga kwemhando, uye nzvimbo yebasa.

Isu tinopa precision zvikamu uyezvikamu zvealuminiumizvo zvakasiyana uye zvakagadzirirwa kuzadzisa zvaunoda. Chikwata chedu chichashanda padhuze newe kugadzira yakasarudzika modhi yakasiyana nedzimwe nzvimbo dziripo pamusika. Isu takatsaurirwa kukupa iwe sevhisi yemhando yepamusoro yekuzadzisa zvese zvaunoda. Usazeze kutibata paAnebon uye tizivise kuti tingakubatsira sei.

Nguva yekutumira: Kubvumbi-01-2024