Sei tichifanira kubvisa zvigadzirwa zvakagadziriswa?

Safety:

Burrs inogona kugadzira mipendero yakapinza uye protrusions, izvo zvinogona kuisa njodzi kune vashandi pamwe nevashandisi vekupedzisira.

Hunhu:

Nekubvisa maburrs, unogona kuvandudza kunaka uye kutaridzika kwechigadzirwa chako.

Kushanda

Burrs inogona kukanganisa mashandiro ezvikamu uye chimiro chavo nezvimwe zvikamu.

Regulatory Compliance

Mamwe maindasitiri ane mirau yakasimba nezve burr kushivirira mazinga kuitira kuve nechokwadi chekuita kwechigadzirwa uye kuchengetedzeka.

Kuunganidza uye Kubata

Zvigadzirwa zvakabviswa zvinoita kuti zvive nyore kubata uye kuunganidza, izvo zvinoderedza njodzi yekukuvadza.

Burrs inowanzogadzirwa panguva yekucheka simbi. Burrs inogona kuderedza iko kurongeka kwekugadzirisa uye kunaka kwepamusoro kwechishandiso. Zvinokanganisawo kushanda kwechigadzirwa uye, mune dzimwe nguva, zvinokonzera tsaona. Deburring inowanzo shandiswa kugadzirisa nyaya yeburr. Deburring haisi nzira inobudirira. Deburring inzira isina zvibereko. Inowedzera mari, inorebesa kutenderera kwekugadzira uye inogona kutungamira mukurasa chigadzirwa chose.

Chikwata cheAnebon chakaongorora nekutsanangura zvinhu zvinokanganisa kuumbwa kwehuyo. Vakakurukurawo nzira uye matekinoroji aripo ekudzikisa milling burrs uye kuvadzora, kubva padanho rekugadzira kusvika pakugadzira.

1. Kugumisa milling burrs: mhando huru

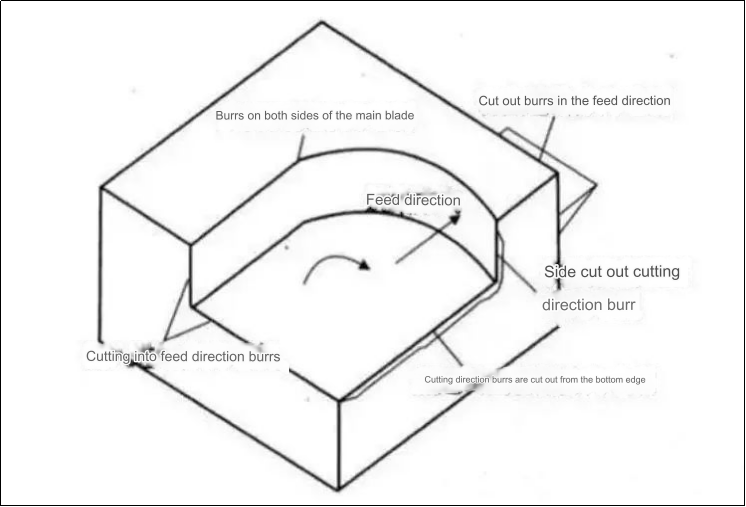

Zvinoenderana nehurongwa hwekugadzika kwemaburrs zvichienderana nekucheka mafambiro uye chishandiso chekucheka mupendero, iwo maburrs makuru anogadzirwa panguva yekupera kwekugaya anosanganisira maburrs ese pamativi enzvimbo huru, maburrs padivi munzira yekucheka, maburrs pazasi. munzira yekucheka, uye cheka mukati nekubuda mafeed. Kune marudzi mashanu emabhura ekutungamirira.

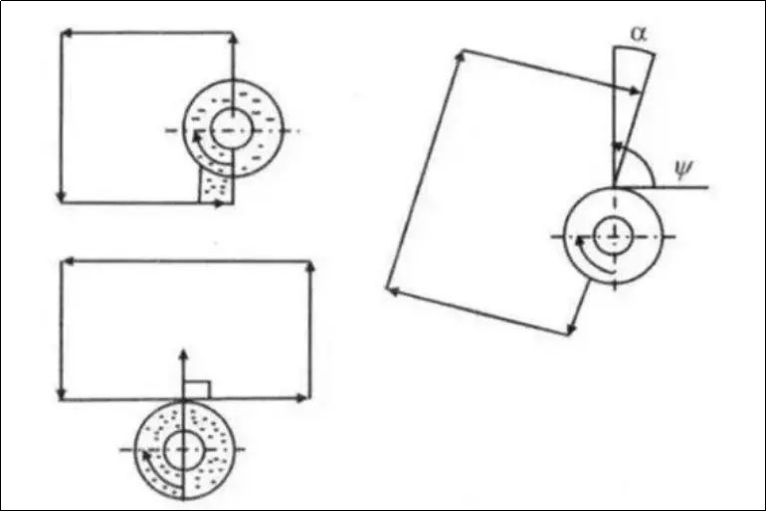

Mufananidzo 1 Burrs inoumbwa nekupera kwekugaya

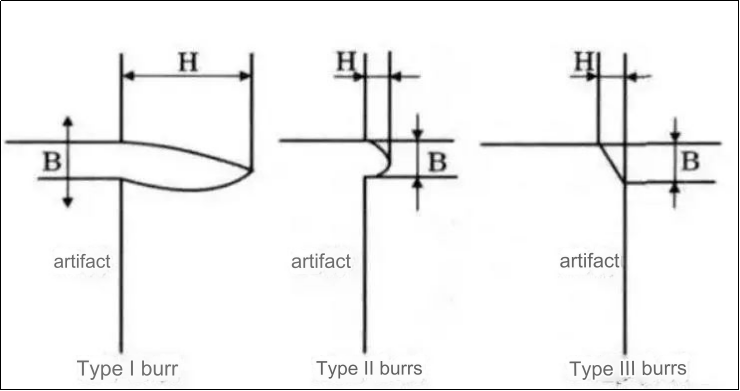

Kazhinji, ukuru hwemaburrs ari munzira yekucheka pamucheto wezasi yakakura uye yakaoma kubvisa. Iri bepa rinotarisa pazasi kumucheto burrs ari mukucheka nzira. Saizi uye chimiro zvinogona kuiswa mumhando nhatu dzakasiyana dzemaburrs anowanikwa mukupedzisira milling yekucheka nzira. Type I burrs inogona kunetsa kubvisa uye inodhura, Type II burrs inogona kubviswa nyore, uye Type III maburrs anogona kunge asina kunaka (sezvinoratidzwa mumufananidzo 2).

Mufananidzo 2 Burrs mhando munzira yekugaya.

2. Izvo zvinhu zvakakosha zvinokanganisa kuumbwa kweburrs pamagumo ekugaya michina

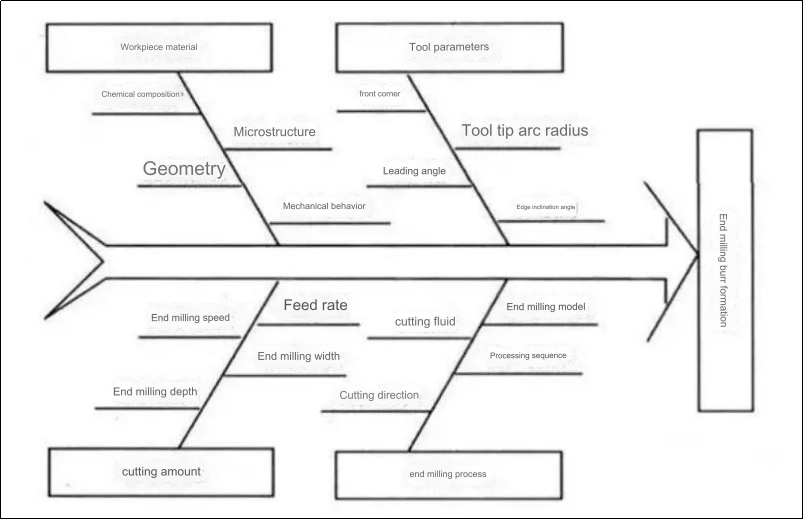

Burr kuumbwa inzira yakaoma ye deformation yezvinhu. Kuumbwa kwemaburrs kunokanganiswa nehuwandu hwezvinhu, zvinosanganisira zvinhu zvemukati zvebasa, geometry yayo, kurapwa kwepamusoro, chishandiso geometry uye nzira yekucheka, kupfeka pamaturusi, kucheka paramita, inotonhorera kushandiswa, nezvimwe. Iyo block diagram iri Mufananidzo 3 inoratidza zvinhu zvinokanganisa kupera milling burrs. Chimiro uye saizi yekupedzisira millings burrs zvinoenderana nekuwedzera mhedzisiro yezvinhu zvakasiyana zvinofurira pasi pemamiriro ekugaya. Nekudaro, zvinhu zvakasiyana zvine maitiro akasiyana pakuumbwa kweburr.

Mufananidzo 3: Chikonzero uye Mhedzisiro Chati yeMilling Burr Kugadzira

1. Kupinda/kubuda kwechombo

Mabhura anogadzirwa kana chishandiso ichitenderera kubva kune workpiece inowanzova yakakura kupfuura iyo inogadzirwa kana ichitenderera mukati.

2. Bvisa kona kubva mundege

Iyo ndege yakachekwa-makona ine simba guru pakugadzira burrs pamucheto wezasi. Kana iyo yekucheka painotenderera kubva kune terminal pamusoro peiyo workpiece mundege, ichipfuura nepakati peimwe nzvimbo perpendicular axis yekucheka milling panguva iyoyo, musanganiswa wevector we toolspeed uye feedspeed yakaenzana neAkona pakati pekutungamira kwezviso zvekupedzisira workpiece. Iyo yekupedzisira kumeso kweiyo workpiece inomhanya kubva pachishandiso screw in point kune chishandiso kunze point. Mumufananidzo 5, huwandu hwePs, kona inochekwa kubva mundege ndeye 0degPs = 180deg.

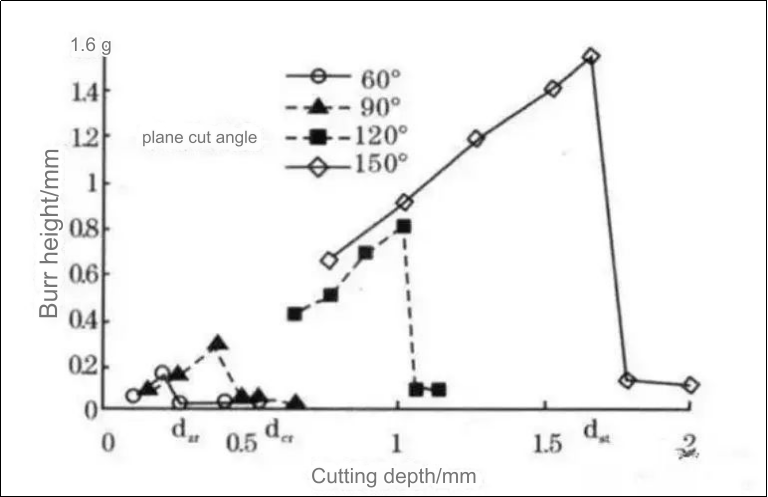

Mhedzisiro yebvunzo inoratidza kuti sekucheka kudzika kunowedzera mabhurari anochinja kubva pamhando I kuenda kumhando II. Kazhinji, hudzamu hwehuyo hunodiwa kugadzira mhando II burrs (inozivikanwawo semuganhu wekucheka kudzika kana dcr) inodaidzwa kudzika kudzika. Mufananidzo 6 unoratidza kukanganisa kwemakona ekucheka ndege uye kucheka kwakadzika pahupamhi hweburr panguva yealuminium alloy machining.

Mufananidzo 6 Ndege yekucheka kona, fomu yeburr uye kudzika kwekucheka

Mufananidzo 6 unoratidza kuti, kana kona yekucheka-ndege yakakura kuti 120deg mhando yeI burrs yakakura uye kudzika kwavanoshandura kumhando II burrs inowedzera. Ndege diki cutout angle ichakurudzira kuumbwa kwemhando II burrs. Chikonzero ndechekuti iyo yakaderera iyo Ps kukosha, iyo yakakura kuomarara kwepamusoro pane iyo terminal. Izvi zvinoita kuti zvive zvishoma kune maburrs.

Iyo yekumhanyisa kwekudya uye kutungamira kwayo kuchapesvedzera kumhanya uye kona yekucheka kwendege uye kuumbwa kwemaburrs. Iyo yakakura chiyero chekudya uye kubviswa kwemupendero pakubuda, a, uye madiki maPs, inonyanya kushanda pakudzvinyirira kuumbwa kwakakura burrs.

Mufananidzo 7 Mhedzisiro yenzira yekudya pakugadzirwa kweburr

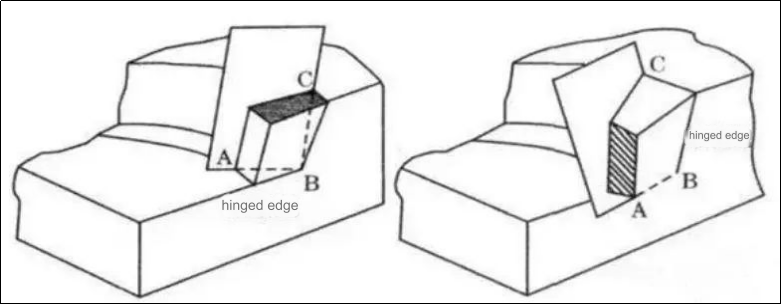

3. Tool tip EOS kubuda kutevedzana

Saizi yeburr inotemerwa zvakanyanya nehurongwa hwekuti tipi rekushandisa rinobuda paguyo rekupedzisira. Mumufananidzo 8, poindi A inomiririra diki rekucheka. Point C inomiririra mativi makuru ekucheka. Uye poindi B inomiririra tip apex. The tool tip radius inofuratirwa nekuti inofungidzirwa kuve yakapinza. Iwo machipisi anozosungirirwa kumusoro kwechigadzirwa chemuchina kana mupendero AB ukasiya workpiece pamberi pemucheto BC. Sezvo maitiro ekugaya achienderera mberi, machipisi anosundirwa kubva kune workpiece achigadzira hombe yepazasi yekucheka burr. Kana mupendero AB ukasiya workpiece pamberi pemupendero BC, machipisi anozosungirirwa panzvimbo yeshanduko. Ivo vanobva vagurwa kubva kune workpiece munzira yekucheka.

Kuedza kunoratidza:

①Iyo yekushandisa tip yekubuda sequence ABC/BAC/ACB/BCA/CAB/CBA inowedzera saizi yeburr mukutevedzana.

②Mhedzisiro yeEOS yakafanana, kunze kwekunge iyo saizi yeburr inogadzirwa mumidziyo yepurasitiki pasi pekutevedzana kwakafanana yekubuda yakakura kupfuura inogadzirwa mune brittle zvinhu. Kutevedzana kwechishandiso chekubuda kwechishandiso hachina hukama kwete chete kune chishandiso geometry asiwo zvinhu zvakaita sereti yekudyisa, milling yakadzika, workpiece geometry, uye mamiriro ekucheka. Burrs inoumbwa nemusanganiswa wakawanda zvinhu.

Mufananidzo 8 Tool tip burr kuumbwa uye kubuda kutevedzana

4. Pesvedzero Yezvimwe Zvinhu

① Milling paramita (tembiricha, nharaunda yekucheka, nezvimwewo). Kuumbwa kweburrs kuchakanganiswawo nezvimwe zvinhu. Pesvedzero yezvinhu zvikuru zvakadai sechikafu chekudya, chigayo chinhambwe, zvichingodaro. Iyo ndege yekucheka kona uye chishandiso tip yekubuda kutevedzana EOS dzidziso dzinoratidzwa mudzidziso yemakona ekucheka ndege. Ini handisi kuzoenda mune zvakadzama pano;

② Iyo yakawanda yepurasitiki zvinhu zvecnc kushandura zvikamu, zvichave nyore kugadzira I type burrs. Kana kupera kugaya brittle zvinhu, hombe dzekudya kana hombe dzekucheka ndege dzinogona kutungamira kune mhando III kukanganisa.

③ Kuwedzera kuomarara kwepasi kunogona kudzvanya kuumbwa kwemaburrs kana kona iri pakati penzvimbo yekupedzisira uye ndege yemuchina inodarika kona yekurudyi.

④ Kushandiswa kwechigayo kunobatsira pakuwedzera hupenyu hwematurusi, kuderedza kusakara uye kubvaruka, kuzora nzira yekugaya uye kuderedza saizi yebhura;

⑤ Kupfeka kwechishandiso kune zvakakosha pakuumbwa kweburr. Iyo arc yetipi inowedzera kana chishandiso chapfekwa kune imwe nhanho. Iyo burr saizi inowedzera munzira yekubuda yechiridzwa, uye zvakare munzira yekucheka. Kuwedzera kudzidza kunodiwa kuti unzwisise mashandiro. Dig deep.

⑥ Zvimwe zvinhu, senge mudziyo wemidziyo, zvinogona zvakare kukanganisa kuumbwa kweburr. Maturusi edhaimani anodzvanya maburrs zviri nani pane mamwe maturusi pasi pemamiriro akafanana.

3. Kudzora milling burrs kuumbwa kuri nyore.

Zvinhu zvakawanda zvinopesvedzera kuumbwa kwekupedzisira-milling burrs. Iyo nzira yekugaya inongova chinhu chimwe chete chinokanganisa kuumbwa kwekupedzisira milling burrs. Zvimwe zvinhu zvinosanganisira geometry yechishandiso, maumbirwo uye saizi workpiece, etc. Kuti uderedze nhamba yekupedzisira milling burrs inogadzirwa, zvakakosha kudzora uye kuderedza burr chizvarwa kubva kumakona akawanda.

1. Inonzwisisika dhizaini yekugadzira

Chimiro che workpiece chinhu chakakosha pakuumbwa kweburrs. Chimiro uye saizi mushure mekugadziriswa kweburrs pamipendero ichasiyanawo zvichienderana neiyo workpiece chimiro. Apo zvinhu uye pamusoro kurapwa kwecnc zvikamudzinozivikanwa, iyo geometry uye mipendero inoita basa guru mukuumbwa kweburrs.

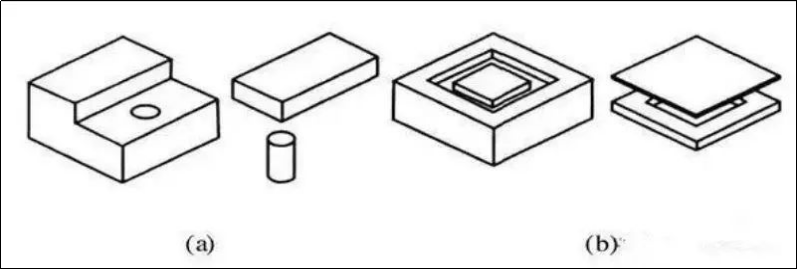

2. Kutevedzana kwekugadzirisa

Kurongeka uko kugadzirisa kunoitwa kunogona zvakare kuve nekukanganisa saizi yeburr uye chimiro. Deburring inokanganiswa nechimiro uye saizi, pamwe nekubvisa mutoro webasa uye mutengo. Kubhadhara mari kunogona kuderedzwa nekusarudza kurongeka kwekugadzirisa.

Mufananidzo 9 Kusarudza kugadzirisa kutevedzana kwekudzora nzira

Kana ndege iri muMufananidzo 10a inotanga kudhirwa uye yobva yagayiwa, ipapo pachange paine milling burrs yakakura yakatenderedza gomba. Zvisinei, kana ikatanga kugayiwa uye yobva yadhirwa, ipapo chete mabhuru madiki ekuchera anoonekwa. Mumufananidzo 10b, kabhura kadiki kanoumbwa kana nzvimbo yeconcave yatanga kukuya, ichiteverwa nekugayiwa kwepamusoro.

3. Dzivisa Tool Exit

Izvo zvakakosha kuti udzivise kubviswa kwechishandiso, sezvo ichi ndicho chikonzero chikuru cheburrs kuumba munzira yekucheka. Mabhura anogadzirwa kana chigayo chikatenderedzwa kubva pachigayo chinowanzova mahombe pane anogadzirwa kana chaiswa mukati. Chigayo chinocheka chinofanirwa kudziviswa panguva yekugadzira zvakanyanya sezvinobvira. Mufananidzo 4 unoratidza kuti burr rakagadzirwa nekushandisa Mufananidzo 4b raive diki pane rakagadzirwa neFigure 4.

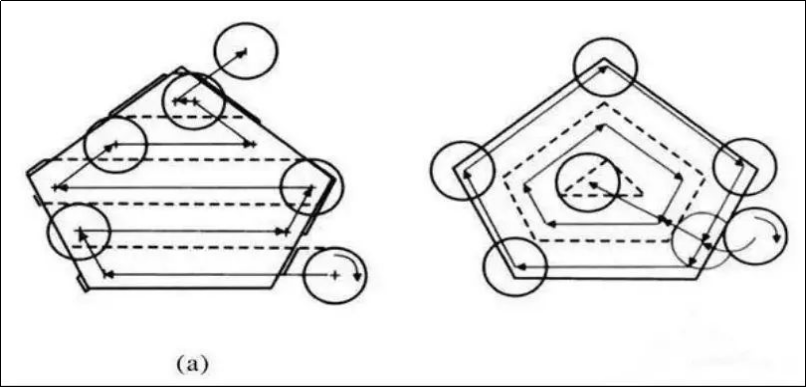

4. Sarudza nzira yakarurama yekucheka

Ongororo yapfuura inoratidza kuti saizi yeburr idiki kana ndege yekucheka kona yakadzikira pane imwe nhamba. Shanduko muhupamhi hwekugaya, kumhanya kwekutenderera uye kumhanya kwekudya kunogona kushandura ndege yekucheka kona. Nekusarudza nzira yakakodzera yekushandisa, zvinokwanisika kudzivirira kugadzira I-type burrs (ona Mufananidzo 11).

Mufananidzo 10: Kudzora nzira yekushandisa

Mufananidzo 10a unoratidza nzira yechinyakare yekushandisa. Nzvimbo ine shaded yemufananidzo inoratidza nzvimbo inogona kuitika iyo burrs inogona kuitika munzira yekucheka. Mufananidzo 10b inoratidza yakagadziridzwa chishandiso nzira inogona kuderedza kuumbwa kwemaburrs.

Nzira yezvishandiso inoratidzwa muMufananidzo 11b inogona kunge yakati rebei uye inotora kugaya zvishoma, asi haidi imwe yekuwedzera mari. Mufananidzo 10a, kune rumwe rutivi, inoda kubviswa kwakawanda (kunyangwe pasina mabhura mazhinji munzvimbo ino, muchokwadi, iwe unofanirwa kubvisa ese maburrs kubva kumicheto). Muchidimbu, Mufananidzo 10b's tool nzira inoshanda zvakanyanya pakudzora maburrs pane Figure 10a's.

5. Sarudza yakakodzera milling parameters

Maparamendi ekupera kwekugaya (senge feed-per-zino, kupera milling kureba, kudzika, uye geometric angle) inogona kuve nemhedzisiro yakakura pakuumbwa kwemaburrs. Burrs inobatwa nemamwe ma parameter.

Zvinhu zvakawanda zvinopesvedzera kuumbwa kwe end milling swarfs. Zvinhu zvikuru zvinosanganisira: mudziyo wekupinda / kubuda, ndege yekucheka makona, zvigadziro zvetip sequences, milling parameters etc. Chimiro uye ukuru hwekupedzisira milling burr ndiyo mhedzisiro yezvinhu zvakawanda.

Chinyorwa chinotanga nekugadzirwa kwemaitiro eiyo workpiece, machining process, huwandu hwekugaya uye chishandiso chakasarudzwa. Inobva yaongorora nekukurukura zvinhu zvinopesvedzera milling burrs uye inopa nzira dzekudzora nzira dzekucheka milling, sarudza akakodzera magadzirirwo akateedzana uye kugadzirisa dhizaini. Iwo matekinoroji, nzira, uye maitiro anoshandiswa kudzvanyirira kana kuderedza milling burrs zvinopa zvinogoneka tekinoroji zvigadziriso zvinogona kuiswa mukugayo kugadzirisa kwekuita kudzora kwehukuru hweburr uye mhando, kudzikiswa kwemutengo, uye mapfupi ekugadzira matenderera.

Takura "Mutengi wekutanga, Yepamusoro-mhando yekutanga" mupfungwa, Anebon inoita padhuze nevatengi vedu uye ivape anoshanda uye ane hunyanzvi masevhisi eFactory For.CNC kugaya zvikamu zvidiki, cncakagadzirwa aruminiyamu zvikamuuye Die kukanda zvidimbu. Nekuti Anebon inogara ichigara nemutsara uyu kupfuura makore gumi nemaviri. Anebon yakawana rutsigiro rwevatengesi rwakanyanya kunaka uye mutengo. Uye Anebon yaive nemasora ekubvisa masora asina kunaka. Iye zvino akati wandei mafekitori eOEM akabatana nesu zvakare.

Fekitari YeChina Aluminium Chikamu uye Aluminium, Anebon inogona kusangana nezvinodiwa zvakasiyana zvevatengi kumba nekune dzimwe nyika. Tinogamuchira vatengi vatsva nevakuru kuti vauye kuzobvunza & kutaurirana nesu. Kugutsikana kwako ndiko kukurudzira kwedu! Rega Anebon ishande pamwechete kunyora chitsauko chitsva chinopenya!

Kana uchida kuziva zvakawanda kana kuwana quote, tapota taurainfo@anebon.com

Nguva yekutumira: Zvita-06-2023