Chii chaunoziva nezve iyo dimensioning dhizaini mukugadzira mechanika inoda kutariswa?

Zviyero zvechigadzirwa chose:

Ndiwo mativi anotsanangura chimiro nekukura kwechinhu chose. Zviyero izvi zvinowanzomiririrwa senhamba dzenhamba mumabhokisi ane rectangular anoratidza urefu, upamhi uye urefu.

Kushivirira:

Kushivirira ndiyo misiyano inotenderwa yezviyero zvinovimbisa kukwana kwakaringana, kushanda, uye kusangana. Kushivirira kunotsanangurwa nekubatanidza plus uye minus zviratidzo pamwe chete nenhamba. Gomba rine dhayamita gumi +- 0.05mm, semuenzaniso, zvinoreva kuti dhayamita iri pakati pe9.95mm kusvika 10.05mm.

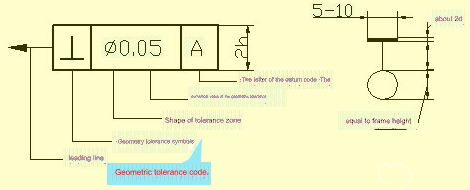

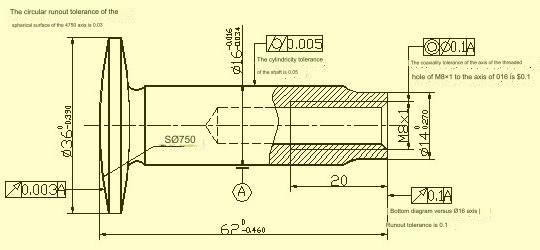

Geometric Dimensions & Tolerances

GD&T inokutendera iwe kudzora uye kutsanangura iyo geometry yezvikamu uye mameseji egungano. Sisitimu iyi inosanganisira mafuremu ekudzora nezviratidzo kudoma zvinhu zvakaita sekuti flatness (kana concentricity), perpendicularity (kana parallelism), zvichingodaro. Izvi zvinopa ruzivo rwakawanda pamusoro pemaumbirwo uye mafambiro ezvimiro kupfuura zviyero zvedimensional.

Surface Finish

Kupedzisa kwepamusoro kunoshandiswa kutsanangura manyorerwo anodiwa kana kutsetseka kwechiso. Kupera kwepamusoro kunoratidzwa uchishandisa zviratidzo zvakaita seRa (arithmetical zvinoreva), Rz(yakanyanya kureba chimiro), uye hukasha hwakakosha.

Threaded Features

Kuti uenzane zvinhu zvakarukwa, semabhaudhi kana masiruu, unofanira kudoma saizi yeshinda, pitch neshinda. Iwe unogona zvakare kusanganisira chero humwe ruzivo, senge shinda kureba, chamfers kana shinda kureba.

Gungano Relationships & Clearances

Dimensioning ruzivo rwakakoshawo pakugadzira ma mechanical magungano kuti utarise hukama pakati pezvikamu, pamwe nekubvumidzwa kunodiwa kuita kwakaringana basa. Izvo zvakakosha kutsanangura mating nzvimbo, kurongeka, mapeji uye chero kushivirira kunodiwa pakushanda.

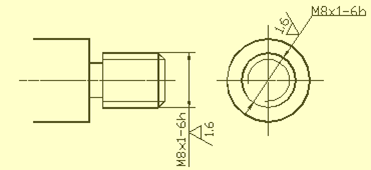

Dimensioning nzira dzezvimiro zvakajairika

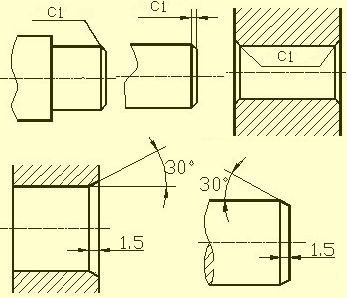

Dimensioning nzira dzemakomba akajairika (makomba mapofu, maburi ane threaded, countersunk makomba, countersunk makomba); dimensioning nzira dzechamfers.

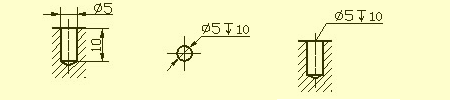

❖ Bofu

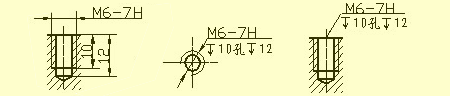

❖ Gomba rine shinda

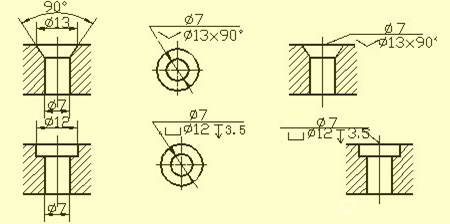

❖ Counterbore

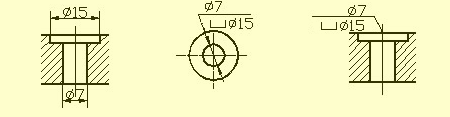

❖ Gomba rinonyura

❖ Chamfer

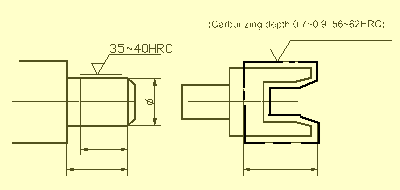

Michina yakagadzirwa pane chikamu

❖ Undercut groove uye grinding vhiri overtravel groove

Kugonesa kubviswa kwechishandiso kubva muchikamu uye kuve nechokwadi chekuti nzvimbo dzezvikamu zvinosangana dzakafanana panguva yekuungana, pre-yakagadziriswa undercut groove, kana mavhiri ekukuya overtravel groove, inofanirwa kuiswa padanho repamusoro. processed.

Kazhinji, saizi ye undercut inogona kuratidzwa se "groove deep x diameter", kana "groove deep x groove width". The overtravel groove yevhiri rekukuya pakukuya kumagumo chiso kana chekunze denderedzwa.

❖Chimiro chekuchera

Mabofu akaboorwa nechibhorani ane 120deg angle kuzasi. Kudzika kwechikamu checylinder ndiko kudzika kwekuchera, kunze kwegomba. Shanduko pakati pegomba rakatsikwa uye 120deg cone inomisikidzwa nekoni ine nzira yekudhirowa, pamwe nedimensional.

Kuve nechokwadi chekucheresa kwakaringana, uye kudzivirira kuputika kwebhiti, zvakakosha kuti akisi yebhiti yedhiri ive perpendicular sezvinobvira kuchiso chemagumo ari kucherwa. Mufananidzo uri pazasi unoratidza maitiro ekugadzirisa zviso zvitatu zvekuchera zviso.

❖Mabhosi nemadimples

Kazhinji, nzvimbo dzinosangana nezvimwe zvikamu kana zvikamu zvinoda kurapwa. Mabhosi uye makomba pane castings anowanzo gadzirirwa kudzikisa nzvimbo yekugadziridza uku uchivimbisa kusangana kwakanaka pakati penzvimbo. Tsigiro dzepamusoro mabhosi uye tsigiro pamusoro pemakomba akasungwa; kuderedza nzvimbo yekugadzirisa, groove inogadzirwa.

Common Part Structures

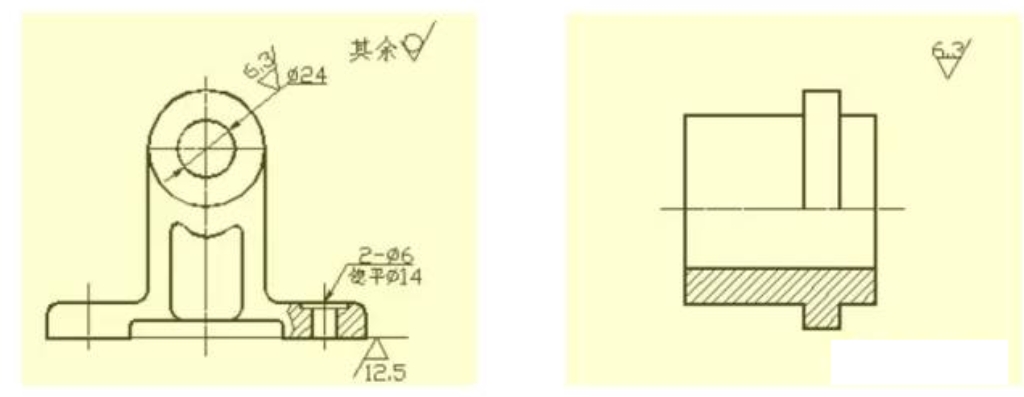

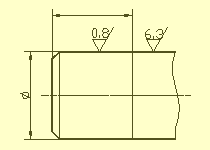

❖Zvikamu zvemaoko

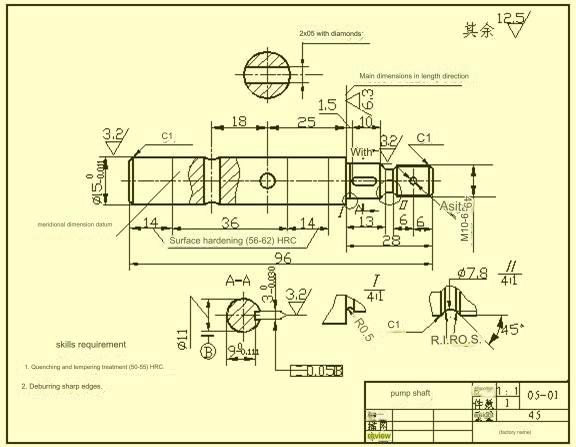

Shafts, bushings, uye zvimwe zvikamu mienzaniso yezvikamu zvakadaro. Chero bedzi maonero ekutanga uye zvikamu zvakayambuka zvichiratidzwa, zvinokwanisika kuratidza maitiro ayo emunharaunda uye maitiro makuru. Iyo axis yekufungidzira inowanzoiswa yakachinjika kuita kuti zvive nyore kuona kudhirowa. Axis inofanira kuiswa pamutsetse weparutivi.

Iyo axis yebushing inoshandiswa kuyera radial dimensions. Izvi zvinoshandiswa kuona F14, uye F11 (ona Chikamu AA), semuenzaniso. Mufananidzo wacho wakadhirowewa. Izvo zvinodikanwa zvekugadzira zvakabatana neiyo process benchmark. Semuenzaniso, kana uchigadzira zvikamu zve shaft pane lathe unogona kushandisa thimbles kusundira gomba repakati peshaft. Munzira yekureba, iyo yakakosha yekupedzisira kumeso kana yekubata kumeso (pafudzi), kana nzvimbo yakagadzirwa nemichina inogona kushandiswa sebhenji.

Mufananidzo wacho unoratidza kuti pfudzi riri kurudyi nekukasharara kwepamusoro Ra6.3, ndiyo inonyanya kutaurwa yezviyero munzira yehurefu. Saizi yakadai se13, 14, 1.5, uye 26.5 inogona kutorwa kubva mairi. Nheyo yekubatsira inotaridza kureba kweshaft 96.

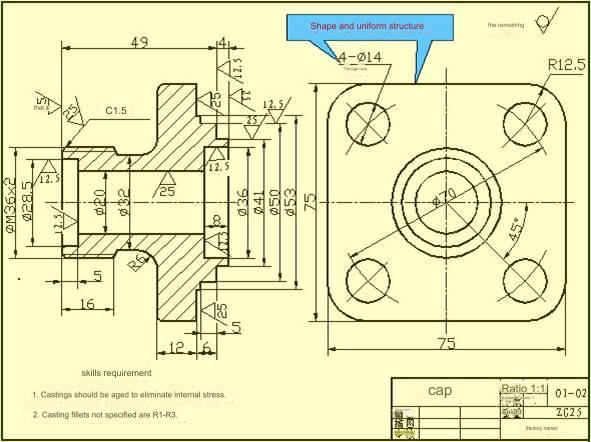

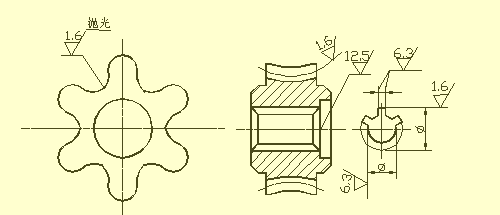

❖Disk chivharo zvikamu

Rudzi urwu rwechikamu kazhinji dhisiki dhisiki. Inosanganisira mavhavha ekupedzisira, chivharo chevhavha, magiya, uye zvimwe zvikamu. Chimiro chikuru chezvikamu izvi muviri unotenderera une maflange akasiyana-siyana uye makomba akatenderera akagoverwa zvakaenzana. Zvivako zvemunzvimbo, zvakaita sembabvu. Semitemo yakawanda, kana uchisarudza maonero unofanira kusarudza chikamu chekutarisa pamwe neaxis kana ndege ye symmetry semaonero ako makuru. Iwe unogona zvakare kuwedzera mamwe maonero kudhirowa (senge kuruboshwe, maonero ekurudyi, kana maonero epamusoro) kuitira kuratidza kufanana kwechimiro uye chimiro. Mumufananidzo unoratidzwa kuti maonero ekuruboshwe akawedzerwa kuratidza square flange, nemakona ayo akakomberedzwa uye akaenzana akagoverwa mana kuburikidza nemakomba.

Paunenge uchigadzira zviyero zvedhisiki yekuvhara zvikamu axis yekufamba nepakati pegomba reshaft rinowanzo kusarudzwa se radial dimension axis uye yakanyanya kukosha mupendero inowanzosarudzwa seyekutanga dimension datum munzira yehurefu.

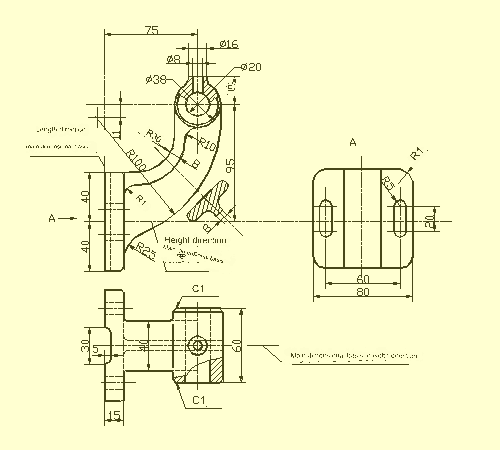

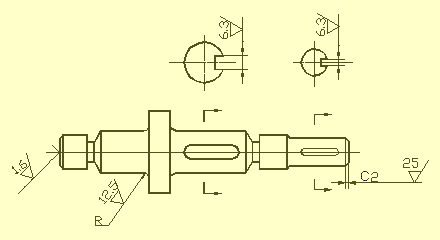

❖ Zvikamu zveFork

Iwo anowanzo sanganisira matanda ekubatanidza uye chinja maforogo anotsigira, uye zvimwe zvakasiyana zvikamu. Nekuda kwenzvimbo dzakasiyana dzekugadzirisa, nzvimbo yebasa uye chimiro chechikamu chinotariswa pakusarudza maonero anozoshandiswa seyekutanga. Kusarudzwa kwemamwe maonero kazhinji kunoda angangoita maviri ekutanga maonero pamwe neakakodzera zvikamu maonero, chidimbu maonero, uye mamwe matauriro emaitiro anoshandiswa kuratidza kuti chimiro chiri munharaunda kune chidimbu. Kusarudzwa kwemaonero anoratidzwa muzvikamu zve pedal seat diagram iri nyore uye iri nyore kunzwisisa. Kuti uratidze hukuru hwembabvu uye kutakura maonero akanaka hazvidiwi, asi kune mbabvu ine T-yakaumbwa zviri nani kushandisa chikamu chemuchinjikwa. zvakakodzera.

Pakuyera zviyero zveforogo-mhando yezvikamu chigadziko chechikamu pamwe nechirongwa chekuenzanisa chechidimbu chinowanzo shandiswa seyeresheni 'reference point. Tarisa dhayagiramu yemaitiro ekuona zviyero.

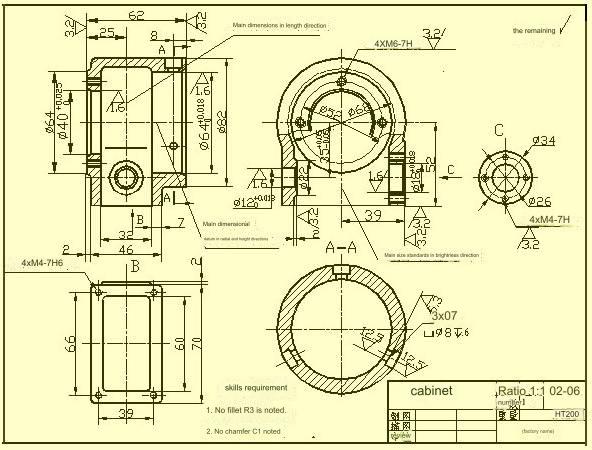

❖Zvikamu zvebhokisi

Kazhinji, chimiro uye chimiro chechikamu chakaoma kupfuura mamwe marudzi matatu ezvikamu. Uyezve, zvinzvimbo zvekugadzirisa zvinoshanduka. Iwo anowanzo sanganisira miviri yevhavha, miviri yepombi inoderedza mabhokisi, uye zvimwe zvakasiyana zvinhu. Paunosarudza maonero ekuona kukuru, zvinonyanya kunetseka ndezvenzvimbo yebasa uye maitiro echimiro. Kana iwe uchisarudza mamwe maonero, akakodzera ebetsero maonero zvikamu zvakadaro kana zvishoma maonero, zvikamu uye oblique maonero zvinofanira kusarudzwa zvichienderana nemamiriro ezvinhu. Vanofanirwa kuburitsa pachena chimiro chekunze uye chemukati chechidimbu.

Panyaya yedimensioning, iyo axis inodikanwa kuti ishandiswe nedhizaini kiyi yekumisikidza nzvimbo uye Yekusangana nzvimbo (kana process surface) pamwe neiyo symmetry chirongwa (kureba) kweiyo huru chimiro chebhokisi, nezvimwe zvinowanzoshandiswa. sezviyero zvereferensi. Kana zvasvika kune nzvimbo dzebhokisi dzinoda kucheka zviyero zvinofanirwa kucherechedzwa zvakanyatsonaka sezvinobvira kuitira kurerutsa kubata uye kuongorora.

Kushata kwepamusoro

❖ Pfungwa yekushata kwepasi

Hunhu hwejometri ine microscopically hunosanganisira nhongonya nemipata ine maburi madiki pamusoro pepamusoro anozivikanwa sekushata kwepasi. Izvi zvinokonzerwa nemakumbo akasiiwa nematurusi ari pamusoro pemaitiro ekugadzira zvikamu, uye deformation inokonzerwa nepurasitiki yesimbi yesimbi mukugadzira nekucheka uye kupatsanurana.

Kushata kwenzvimbo zvakare chiratidzo chesainzi chekuongorora kunaka kwenzvimbo dzezvikamu. Iyo inokanganisa zvimiro zvezvikamu, kuenderana kwavo kurongeka, kupfeka kusagadzikana corrosion resistance, kuisa chisimbiso chitarisiko uye chitarisiko. chechikamu.

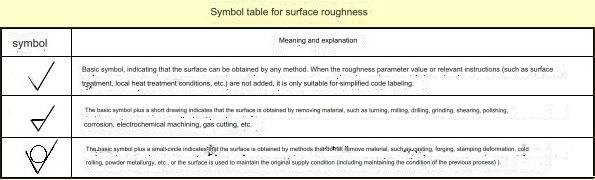

❖ Kukasharara macode zviratidzo, mabhii nezviratidzo

Gwaro reGB/T 131-393 rinotsanangura kodhi yakakasharara pamwe nemaitiro ayo ekunyora. Zviratidzo zvinotaridza kushata kwezvinhu zviri pamusoro pamufananidzo zvinonyorwa patafura inotevera.

❖ Mitemo yekuongorora huru yekushata kwenzvimbo

Maparamita anoshandiswa kuongorora kushata kwenzvimbo yechikamu ndeaya:

1.) Arithmetic zvinoreva kutsauka kwe contour (Ra)

The arithmetic mean yeAbsolute value yecontour offset mukureba. Huwandu hweRa pamwe nehurefu hwesampling hunoratidzwa mutafura ino.

2.) Hurefu hwepamusoro hweprofile (Rz)

Nguva yesampling ndeye mukaha uripo pakati peiyo contour peak yekumusoro neyepasi mitsetse.

Cherechedza: Ra parameter inosarudzwa paunenge uchishandisa.

❖ Zvinodiwa pakutara kushata kwepasi

1.) Muenzaniso wekunyora kodhi kuratidza kushata kwechiso.

Huremu hwepamusoro hwehuremu Ra, Rz, uye Ry zvakanyorwa nenhamba dzenhamba mukodhi, kunze kwekunge zvichikwanisika kusiya iyo parameter kodhi Ra haidiwe panzvimbo yeukoshi hwakakodzera hweparameter Rz kana Ry inofanira kuzivikanwa pamberi. kune chero parameter values. Tarisa Tafura yemuenzaniso wemanyorero.

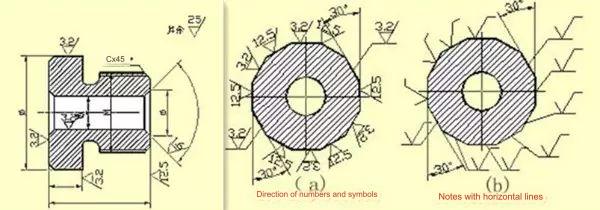

2.) Nzira yekumaka zviratidzo nenhamba panzvimbo dzakashata

❖ Ndinomaka sei kushata kwemavara epamusoro pamifananidzo

1.) Kushata kwepamusoro (chiratidzo) kunofanirwa kuiswa nemitsara yecontour inoonekwa kana mitsetse mitsetse, kana pamitsetse yavo yekuwedzera. Iyo poindi yechiratidzo inofanira kunongedza kubva kunze kwechinhu uye kuenda kumusoro.

2).

Muenzaniso wakanaka wekutara kushata kwepasi

Kudhirowa kwakafanana kunoshandiswa kune yega yega nzvimbo inowanzoiswa chiratidzo pachishandiswa chizvarwa chimwe chete (chiratidzo) uye chiri padyo nemutsetse wekuyera. Kana nzvimbo yacho isina kukura zvakakwana kana kuti inonetsa kumaka, zvinokwanisika kutara mutsetse. Kana nzvimbo dzese dziri pachinhu dzichisangana nezvinodiwa pakukasharara kwepasi, mamaki anogona kugadzirwa zvakaenzana nechekumusoro kurudyi kwedhirowa yako. Kana iyo yakawanda yenzvimbo yechidimbu ichigovana zvakafanana pamusoro pekukasharara, iyo inonyanya kushandiswa kodhi (chiratidzo) iri panguva imwe chete, nyora izvi kumusoro kumusoro kuruboshwe kwedhirowa yako. Uyewo, sanganisira "kuzorora" "kuzorora". Zviyero zvezvimiro zvese zvakafanana zvakazivikanwa roughness chiratidzo (zviratidzo) uye tsananguro zvinyorwa zvinofanirwa kunge zvakapetwa ka1.4 kureba kwemakamaka padhirowa.

Kushata kwechiso (chiratidzo) pamusoro penzvimbo inoramba yakakombama yechikamu, pamusoro pezvinhu zvinodzokororwa (zvakadai semazino, maburi migodhi, maburi kana mikororo.) pamwe nenzvimbo inoregedza inobatanidzwa nemitsara mitete yakasimba inongori akaonekwa kamwe chete.

Kana paine mataurirwo akawandisa ekukwasharara kwepasi kwenzvimbo imwe chete mutsetse wakatetepa wakasimba unofanirwa kukweverwa kuratidza mutsara wekupatsanura uye hukasha hwakakodzera uye hukuru hunofanirwa kurekodhwa.

Kana zvakatemwa kuti zino (zino) chimiro hachitevedzerwe pamusoro peshinda, magiya kana mamwe magiya. Kukasharara kwekodhi yepasi (chiratidzo) kunogona kuonekwa mumufananidzo.

Makodhi ehukasha enzvimbo yebasa yegomba repakati, padivi pemakiyi mafiritsi uye machamfers anogona kurerutsa maitiro ekunyora.

Kana iyocnc milled zvikamuinofanira kurapwa nekupisa kana kuvharwa zvishoma (yakavharwa) nzvimbo yose inofanira kuiswa chiratidzo nemitsara yakakora yemitsara ine madoti, uye zviyero zvinoenderana nazvo zvinofanira kunyorwa zvakajeka. Izvo zvinotsanangurwa zvinogona kuoneka pamutsetse wakatwasuka uchitevedza mupendero wakareba wechiratidzo chehukasha.

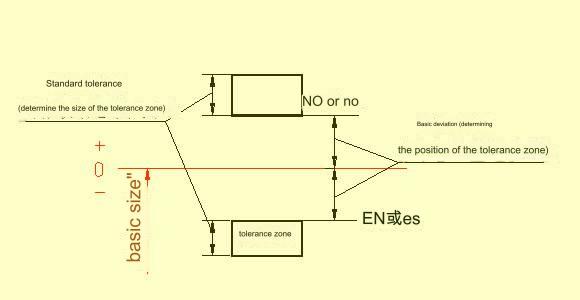

Basic tolerances uye mwero kutsauka

Kufambisa kugadzirwa kunobvumira kudyidzana kwecnc machined componentsuye inosangana nezvinodiwa zvakasiyana-siyana zvekushandisa, chiyero chenyika "Limits and Fits" chinotara kuti nzvimbo yekushivirira inoumbwa nezvikamu zviviri zvinova zvakajairwa kushivirira uye kutsauka kwekutanga. Iyo yakajairwa kushivirira ndiyo inosarudza kuti yakakura sei nzvimbo yekushivirira uye yakakosha kutsauka inosarudza nzvimbo yenzvimbo yekushivirira.

1.) Kushivirira kwakajairika (IT)

Hunhu hweiyo Standard kushivirira huchatemwa nehukuru hwechigadziko uye kirasi. Kirasi yekushivirira chiyero chinotsanangura kurongeka kwezviyero. Yakakamurwa mumatanho makumi maviri, kunyanya IT01, IT0 uye IT1. ,…, IT18. Kurongeka kwezviyero zvedimensional kunodzikira paunofamba kubva kuIT01 kusvika IT18. Kuti uwane mamwe mazinga akajairwa ekushivirira tarisa iwo akakodzera zviyero.

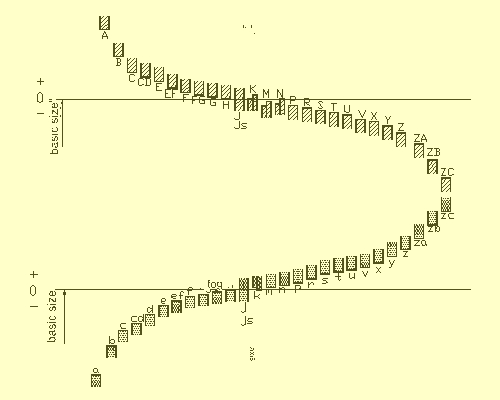

Basic Kutsauka

Kutsauka kwekutanga ndiko kutsauka kwepamusoro kana kuzasi kune zero mumiganho, uye kazhinji inoreva kutsauka pedyo ne zero. Kutsauka kwekutanga kwakadzikira kana nzvimbo yekushivirira yakakwira kupfuura zero mutsara; zvikasadaro zviri kumusoro. Iwo 28 misiyano yakakosha yakanyorwa nemavara echiLatin ane uppercase kumakomba uye madiki kumiririra mashaft.

Pamufananidzo wekutsauka kwekutanga, zviri pachena kuti gomba rekutanga kutsauka AH uye shaft basic deviation kzc inomiririra kutsauka kwepasi. Gomba rekutanga kutsauka KZC rinomiririra kutsauka kwepamusoro. Kutsauka kwepamusoro uye kuzasi kwegomba uye shaft zvakateerana +IT/2 uye -IT/2. Iyo yekutanga kutsauka dhizaini hairatidze saizi yekushivirira, asi nzvimbo yayo chete. Kushivirira kwakajairwa ndiko kwakatarisana nemagumo ekuvhura pamagumo enzvimbo yekushivirira.

Zvinoenderana netsanangudzo yedimensional tolerances, iyo yekuverenga fomula yeyakakosha kutsauka uye chiyero ndeiyi:

EI = ES + IT

ei=es+IT kana es=ei+IT

Iyo yekushivirira nzvimbo kodhi yegomba uye shaft inoumbwa nemakodhi maviri: yekutanga kutsauka kodhi, uye yekushivirira giredhi.

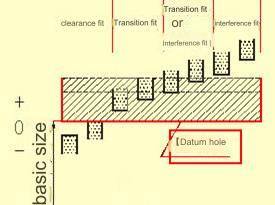

Batira pamwe

Fit hukama pakati penzvimbo yekushivirira yemakomba nemashafts ane chiyero chakafanana uye akasanganiswa pamwechete. Kukwana pakati pe shaft negomba kunogona kusimba kana kuregedzera zvichienderana nezvinodiwa zvekushandisa. Naizvozvo, chiyero chenyika chinotsanangura marudzi akasiyana ekukwana:

1) Clearance kukwana

Gomba uye shaft zvinofanirwa kuenderana pamwe nedikidiki clearance ye zero. Iyo gomba yekushivirira nzvimbo yakakwirira kupfuura iyo shaft yekushivirira zone.

2) Kubatana kwekuchinja

Panogona kunge paine mikaha pakati pegomba negomba kana zvaunganidzwa. Nzvimbo yekushivirira kwegomba inopindirana neiyo shaft.

3) Kupindira kwakakodzera

Pakuunganidza shaft uye gomba, pane kukanganisa (kusanganisira kupindira kuduku kwakaenzana ne zero). Iyo yekushivirira nzvimbo ye shaft yakaderera pane yekushivirira nzvimbo yegomba.

❖ Benchmark system

Mukugadzirwa kwecnc machined zvikamu, chikamu chinosarudzwa sedhamu uye kutsauka kwayo kunozivikanwa. Iyo datum system inzira yekuwana akasiyana marudzi ekukwana ane akasiyana zvivakwa, nekushandura kutsauka kwechimwe chikamu chisiri datum. Miyero yenyika inotsanangura maviri mabhenji masisitimu zvichienderana nezvinodiwa chaizvo zvekugadzira.

1) Iyo yakakosha hole system inoratidzwa pazasi.

Basic hole system (inodaidzwawo kuti basic hole system) igadziriro inogara nzvimbo dzekushivirira dzegomba rine kumwe kutsauka kubva pachiyero uye nzvimbo dzekushivirira dzeshaft dzine kutsauka kwakasiyana kubva kune yakajairwa fomu dzakasiyana siyana. Pazasi pane tsananguro yeiyo basic hole system. Tarisa kumufananidzo uri pasi apa.

①Basic hole system

2) Iyo yakakosha shaft system inoratidzwa pazasi.

Basic shaft system (BSS) - Iyi ihurongwa uko nzvimbo dzekushivirira dze shaft negomba, imwe neimwe iine akasiyana ekutanga kutsauka, inoumba akasiyana anokwana. Pazasi pane tsananguro yeiyo basic axis system. Iyo datum axis ndiyo axis mune yakakosha axis. Yayo yekutanga kutsauka kodhi (h) ndeye h uye kutsauka kwayo kwepamusoro ndeye 0.

②Basic shaft system

❖ Mitemo yekushandira pamwe

Fit kodhi inoumbwa neyekushivirira nzvimbo kodhi yegomba uye shaft. Yakanyorwa muchidimbu. Kodhi yekushivirira yegomba iri munhamba, nepo kodhi yekushivirira yeshaft iri mudhinomineta. A basic axis chero musanganiswa une h senumerator.

❖ Kumaka kushivirira uye kukodzera pamifananidzo

1) Shandisa iyo yakasanganiswa yekumaka nzira yekumaka kushivirira uye kukwana pakudhirowa kwegungano.

2) Mhando mbiri dzakasiyana dzekumaka dzinoshandiswa pamachining zvikamumifananidzo.

Geometric kushivirira

Pane zvikanganiso zvejometri uye zvikanganiso mukuwirirana chinzvimbo mushure mekunge zvikamu zvagadziriswa. Silinda inogona kunge iine saizi yakakodzera asi yakakura kune imwe mugumo pane imwe, kana kukora nepakati, asi yakatetepa kune chero kumagumo. Inogonawo kunge isina kutenderera muchikamu-chikamu, chiri chikanganiso chechimiro. Mushure mekugadzirisa, matemo echikamu chimwe nechimwe anogona kuve akasiyana. Uku kukanganisa kwenzvimbo. Shape kushivirira ndiyo mutsauko unogona kuitwa pakati pechakanaka uye chimiro chaicho. Position tolerance ndiyo mutsauko unogona kuitwa pakati peiyo chaiyo uye yakanaka zvinzvimbo. Ose ari maviri anozivikanwa se geometric tolerances.

Mabara ane Geometric Tolerance

❖ Makodhi ekushivirira kwezvimiro nezvinzvimbo

Iyo yenyika standard GB/T1182-1996 inotsanangura makodhi ekushandisa kuratidza chimiro uye kushivirira chinzvimbo. Kana iyo geometric kushivirira isingakwanisi kuratidzirwa nekodhi mukugadzirwa chaiko, tsananguro yemavara inogona kushandiswa.

Geometric tolerance codes dzinosanganisira: mafuremu ekushivirira kwejometri, mitsara yegwara, kukosha kwejometri yekushivirira, uye zvimwe zviratidzo zvinoenderana. Saizi yefonti mufuremu ine hurefu hwakafanana nehwemavara.

❖ Geometric tolerance marking

Mashoko ari pedyo nekushivirira kwejometri anoratidzwa mumufananidzo anogona kuwedzerwa kutsanangura pfungwa kumuverengi. Hazvifanirwe kuverengerwa mumufananidzo.

Anebon inodada kubva mukuzadzikiswa kwemutengi wepamusoro uye kugamuchirwa kwakakura nekuda kweAnebon kuramba achitsvaga zvemhando yepamusoro zvese pachigadzirwa uye sevhisi yeEC Sitifiketi Yakagadzirirwa Yemhando yepamusoro Kombuta Zvikamu CNC Yakatendeuka Zvikamu Zvigaya Metal, Anebon yanga ichichengeta WIN-WIN mamiriro nevatengi vedu. . Anebon gamuchirai noushamwari mutengi kubva kumativi ese enyika achiuya zvakapfuura pakushanya uye nekumisikidza hukama hwerudo hunogara kwenguva refu.

CE Certificate China cnc yakagadzirwa nealuminium zvikamu,CNC Yakashandura Zvikamuuye cnc lathe zvikamu. Vese vashandi mufekitori, muchitoro, uye muhofisi yeAnebon vari kunetsekana nechinangwa chimwe chete chekupa mhando nesevhisi zviri nani. Bhizinesi chairo kuwana win-win mamiriro. Tinoda kupa rubatsiro rwakawanda kune vatengi. Gamuchirai vatengi vakanaka kuti vataure nezve zvigadzirwa zvedu uye mhinduro nesu!

Kana iwe uchida kuziva zvakawanda kana kuda quote, ndapota taurainfo@anebon.com

Nguva yekutumira: Nov-29-2023