Zvakawanda sei zvaunoziva nezve nzira yesimbi yekucheka shinda?

Simbi yekucheka shinda kunowanzo sanganisira maitiro sekutepa, kugaya shinda, uye imwe-point shinda. Nzira idzi dzinowanzoshandiswa mukugadzira kugadzira tambo dzemukati kana dzekunze pazvikamu zvesimbi.

Kubaya inzira iyo tepi yekushandisa inoshandiswa kucheka shinda kuita maburi asati acherwa. Inowanzoshandiswa kugadzira tambo dzemukati. Thread milling, kune rumwe rutivi, inoshandisa chinotenderera chekucheka chishandiso chine mazino akawanda kuti zvishoma nezvishoma kucheka tambo profile. Iyi nzira inowanzoshandiswa kune zvose mukati uye kunze tambo.

Single-point threading inosanganisira kushandisa chigadziro chekucheka nemucheka mumwechete wekucheka tambo pane workpiece. Iyi nzira inowanzo shandiswa mumachira kana kushandura michina kugadzira shinda chaidzo.

Sarudzo yenzira inotsamira pazvinhu zvakaita serudzi rwezvinhu zviri kugadzirwa, shinda inodiwa mbiri, iko kudiwa kwechokwadi, uye huwandu hwekugadzira. Zvishandiso zvakasiyana, michina, uye matekiniki anogona kushandiswa kune akasiyana maapplication uye zvinodiwa zveindasitiri.

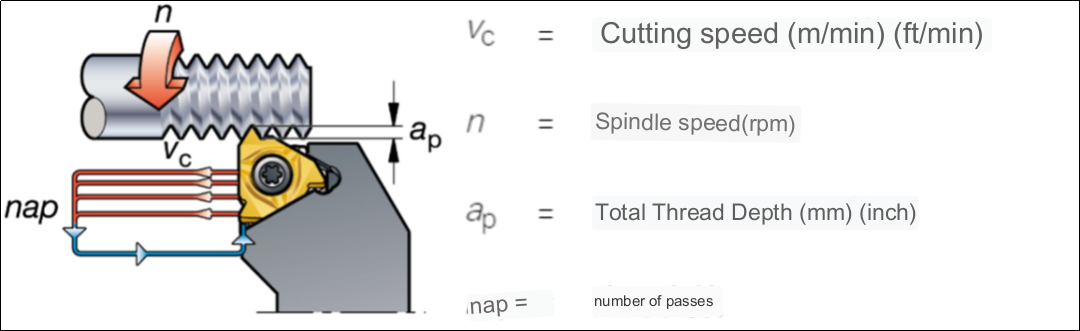

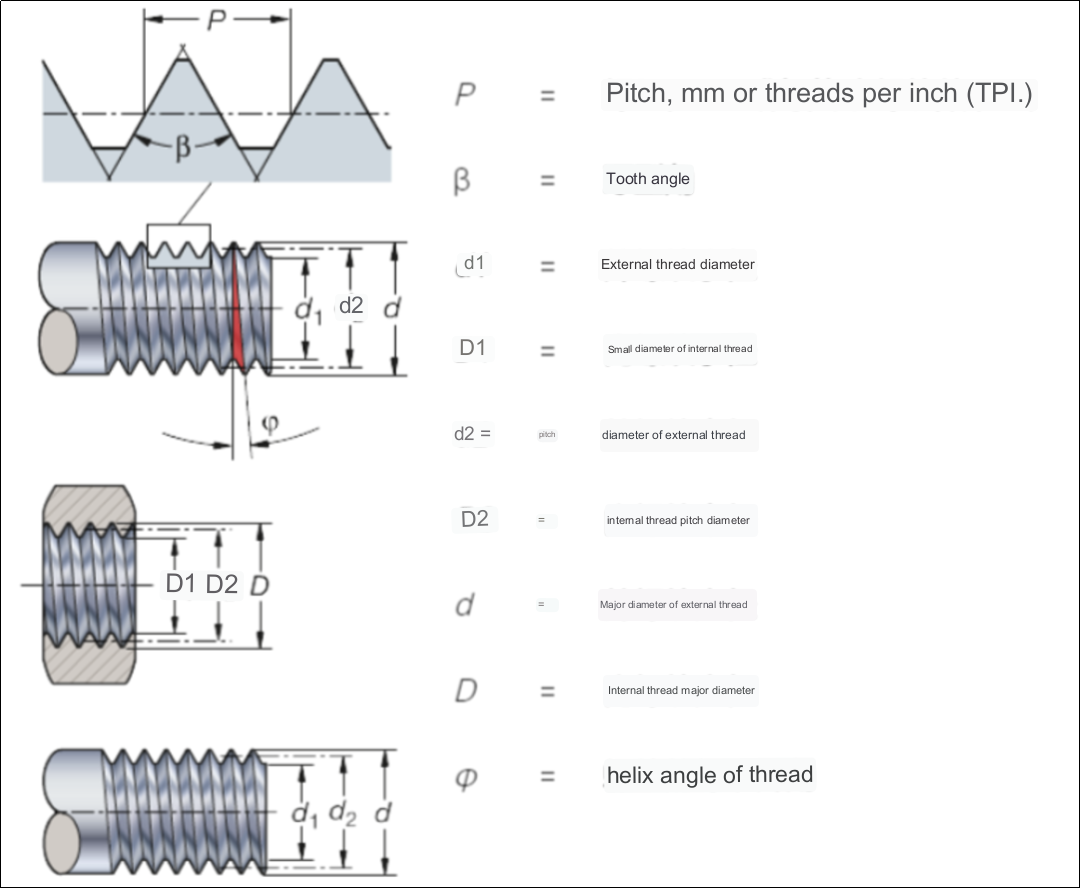

1. Ruzivo rwakakosha rwekutanga shinda

1. Tsanangudzo yemashoko

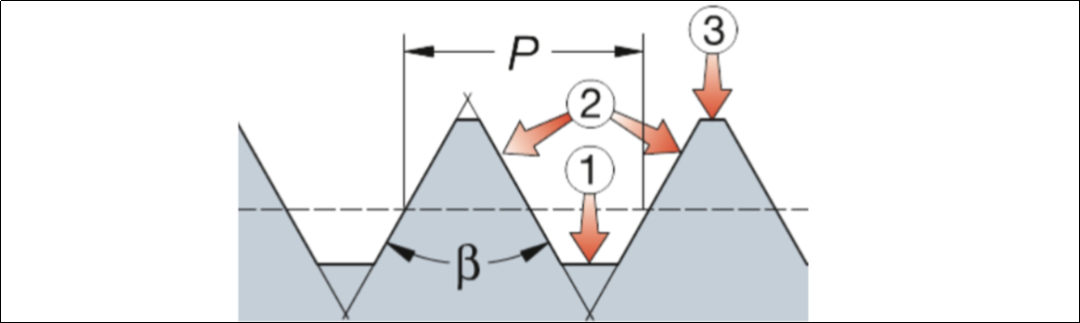

①Pasi pezino ②Kurutivi rwezino ③Pamusoro pezino

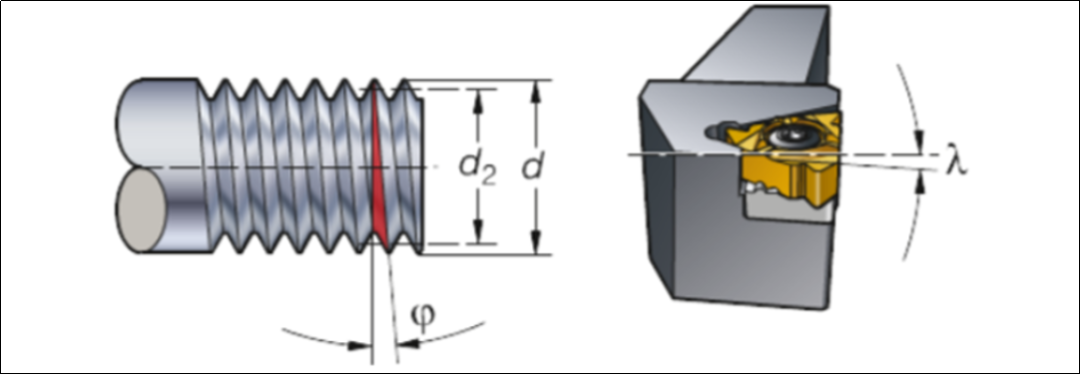

Helix angle:

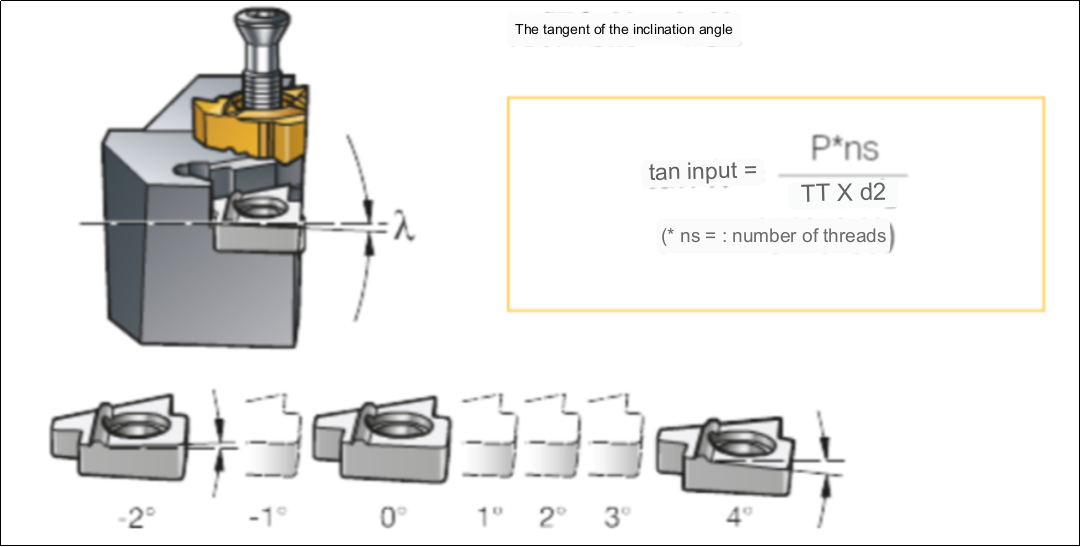

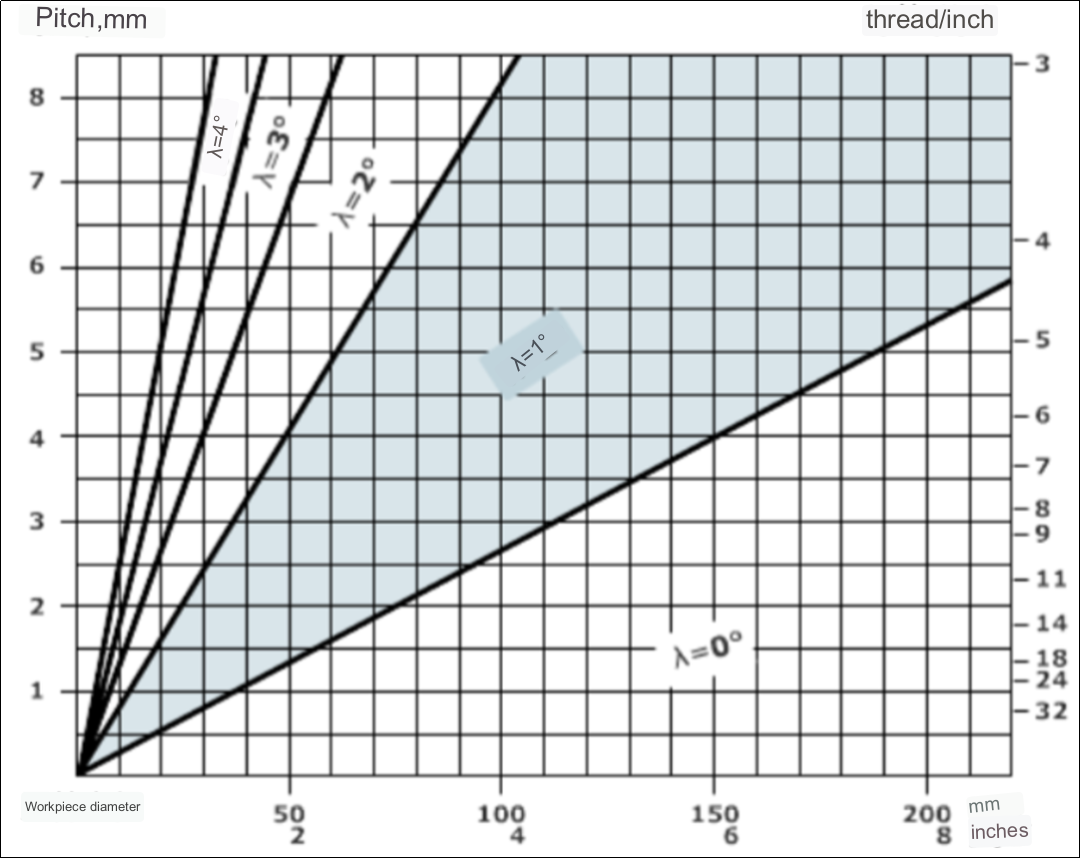

Helix angle inoenderana nedhayamita uye kukwirira kweshinda.

Rongedza kuregedza kweflank yeblade nekuchinja shim.

Iyo blade inclination angle angle ndeye γ. Iyo yakajairika bevel angle ndeye 1 °, iyo inoenderana neyakajairwa shim mune inobata.

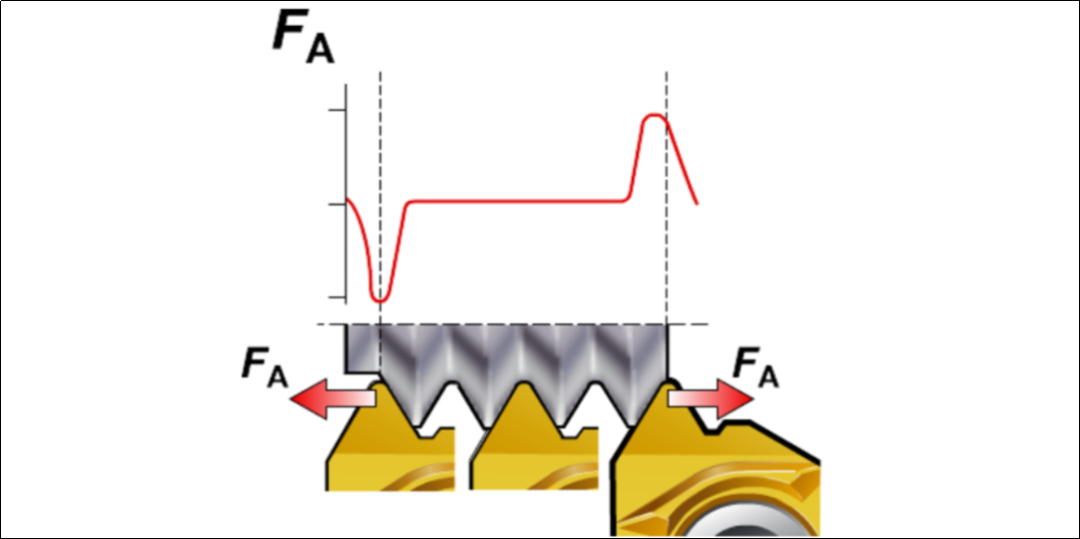

Kucheka masimba kana uchipinda nekubuda mushinda:

Iyo yepamusoro-soro yeaxial yekucheka mauto mu threading mashandiro anoitika panguva yekupinda nekubuda kwechishandiso chekucheka muworkpiece.

Kucheka data yakawandisa kunogona kukonzera kufamba kweiyo isingavimbike yakasungirirwa kuisa.

Gadzirisa blade kuti ubvise:

Iyo bevel angle inogona kuiswa neshim pasi peblade mubato. Tarisa kuchati iri mukatalogi yezvishandiso kuti usarudze kuti shim ipi yekushandisa. Vese vanobata vanouya neakajairika shims akaiswa pa1 ° rake angle.

Sarudza shim zvinoenderana nekona ye bevel. Dhiyamita yeworkpiece uye shinda inonamira zvinokanganisa kona yerake. Sezvinogona kuonekwa kubva pamufananidzo uri pasi apa, dhayamita yecnc lathe zvikamuari 40mm uye pitch i6mm, shim inodiwa inofanirwa kunge iine 3° bevel angle (yakajairwa shim haigone kushandiswa).

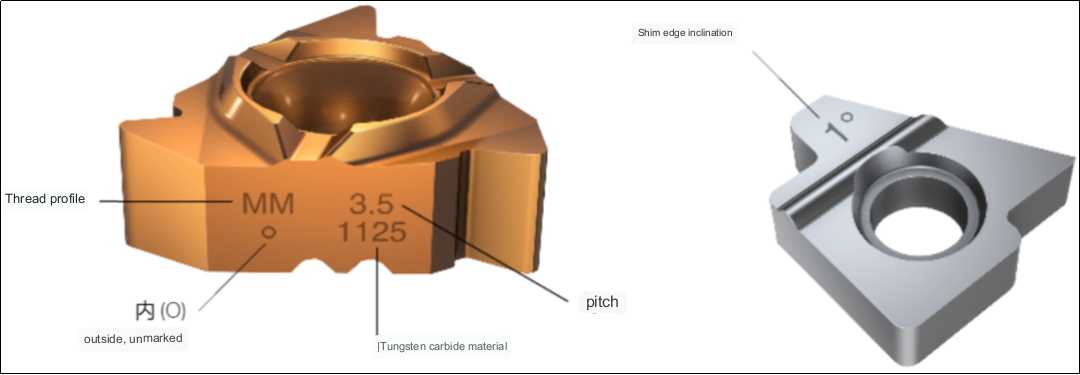

Zvicherechedzo zvekuisa shinda uye shims:

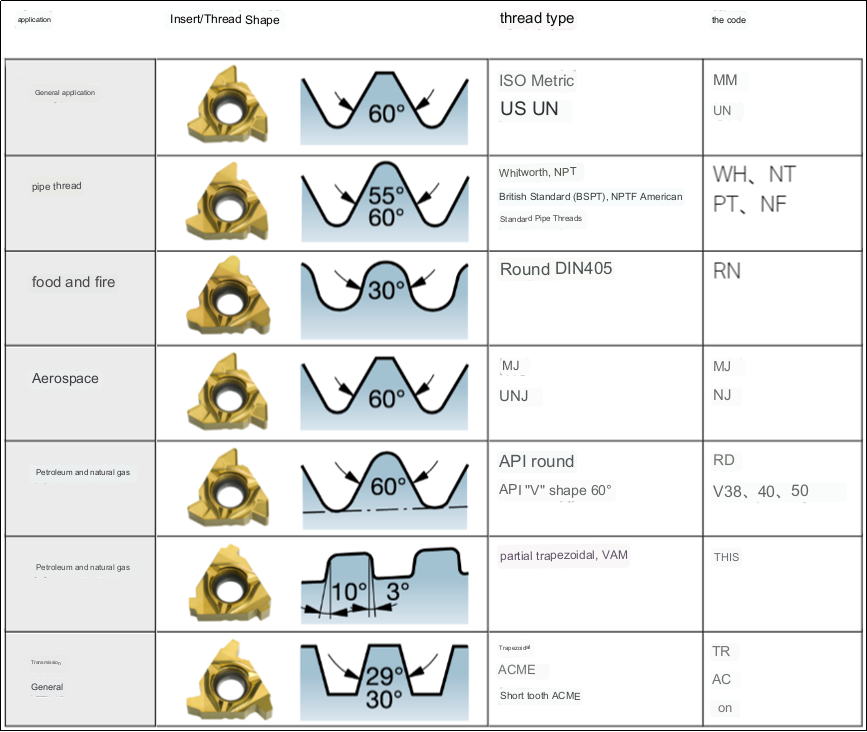

Thread shape uye mashandisirwo ayo:

2. Thread pinza mhando uye clamping chirongwa

1. Multi tooth blade

Advantage:

Deredza nhamba yezvikafu

Kubudirira kwakanyanya

Zvisina kukwana:

Inoda yakagadzikana clamping

Yakakwana nzvimbo yekudzosa inodiwa mushure mekugadzira thread

2. Full profile blade

Advantage:

Kudzora kukuru pane chimiro cheshinda

zvishoma glitches

Zvisina kukwana:

Chipande chimwe chete chinogona kucheka chidimbu chimwe chete

3. V-profile blade

Advantage:

Flexibility, iyo imwechete yekuisa inogona kushandiswa kune akati wandei mapiche.

Zvisina kukwana:

Ichaita kuti maburrs aumbe uye anoda kubviswa.

Clamping solution i-LOCK:

Yakanyanya kuomarara threading ine fixed inoisa

Kutungamirirwa nechitima chekutungamira, blade inoiswa panzvimbo yakarurama

Iyo screw inodzvanya inopinza panjanji inodzokera kune radial kumira pane imwe yekubata kumeso (tsvuku yekubata kumeso) muchigaro chekuisa.

Yakavimbika yekuisa interface inovimbisa hupenyu hurefu hwematurusi uye nepamusoro tambo mhando

Zvibatiso zvakasiyana:

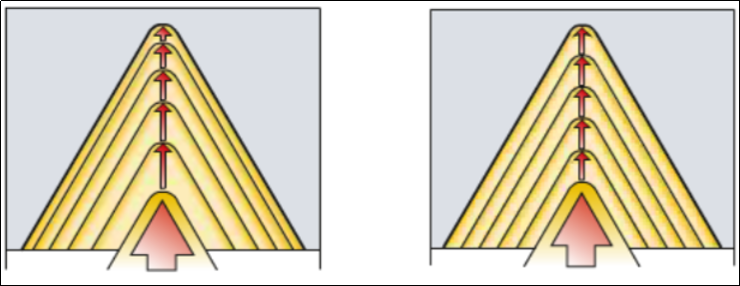

3. Mhando nhatu dzakasiyana dzenzira dzekudyisa

Iyo nzira yekudyisa inogona kuve nemhedzisiro yakakosha pa threading process. Zvinokanganisa: Cheka kudzora, isa kupfeka, shinda yemhando, hupenyu hwekushandisa.

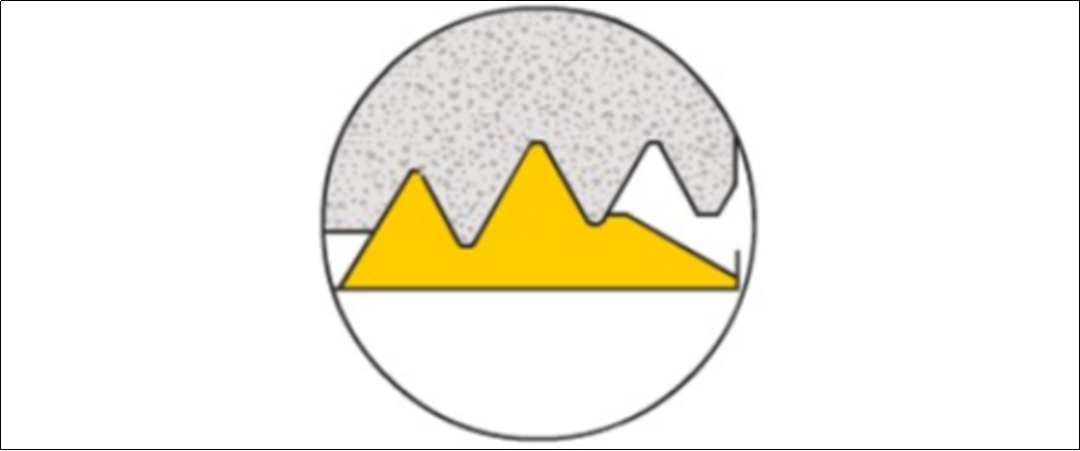

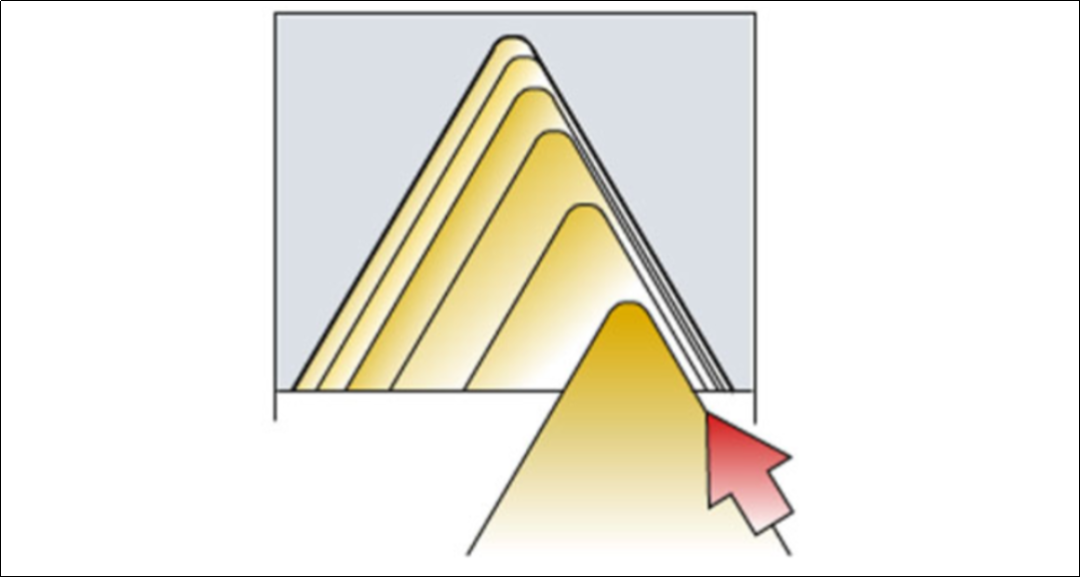

1. Kuvandudzwa kwekudya kweparutivi

Mazhinji CNC muchina maturusi anogona kushandisa nzira iyi yekudyisa kuburikidza nemapurogiramu ekutenderera:

Chips kupesana neakajairwa kutendeuka mhando - nyore kugadzira uye kutungamira

Axial yekucheka simba inoderedza vibration njodzi

Machipisi akakora asi anongobata divi rimwe chete rekupinza

Yakaderedzwa kupisa kupisa kune blade

Sarudzo yekutanga kune mazhinji mashandisirwo ekurukisa

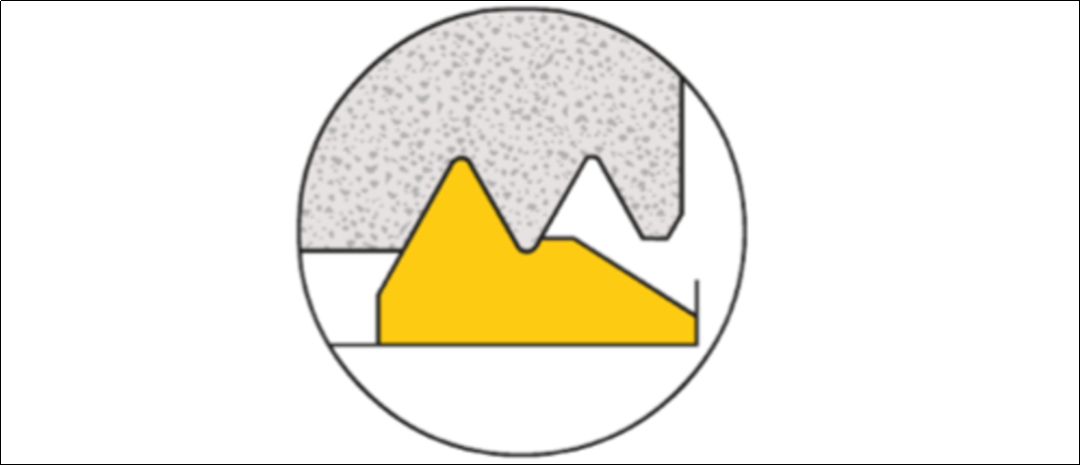

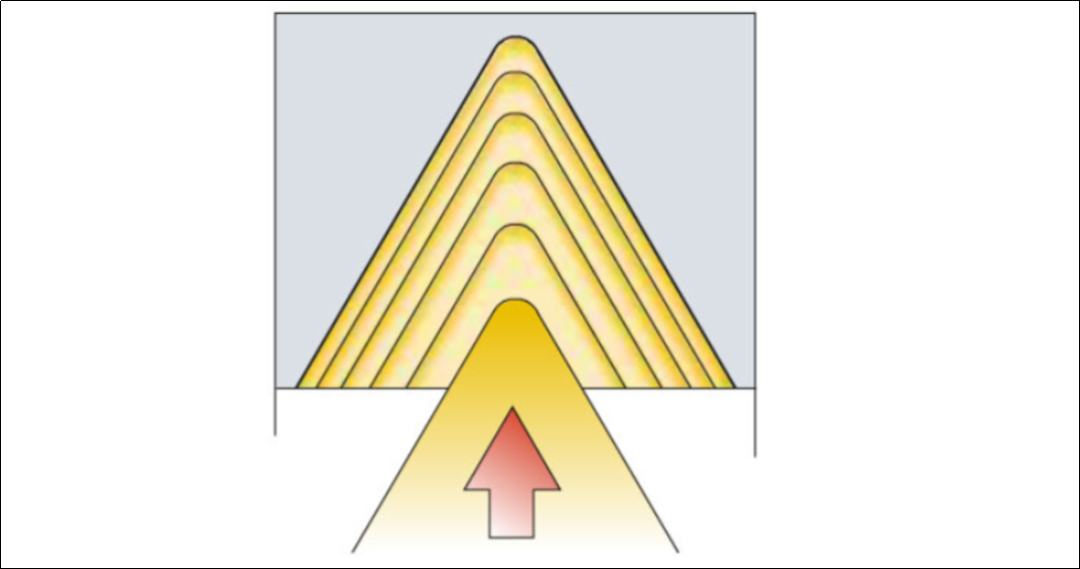

2. Radial infeed

Yakawanda nzira - nzira chete iyo yekare isiri-CNC lathes vanogona kushandisa:

Inogadzira machipisi akaoma "V" akafanana

Uniform Blade Wear

Insert homwe dzinoratidzwa kune tembiricha yakakwira, ichidzikamisa kudzika kwekudya

Inokodzera kugadzirisa shinda yakanaka

Inogona kuzunguzika uye kushomeka kwechipi control paunenge uchigadzira shinda dzakakasharara

Chekutanga sarudzo yekushanda yakaoma zvinhu

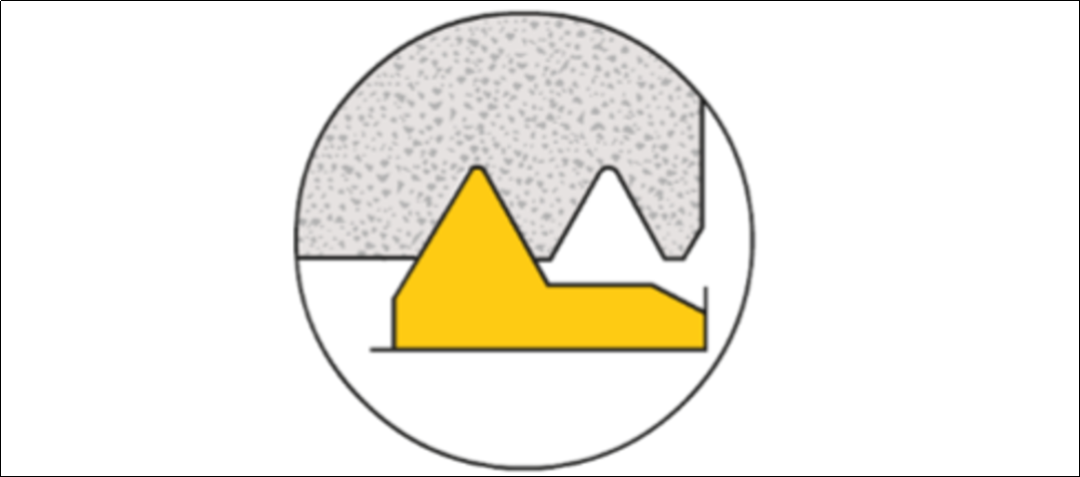

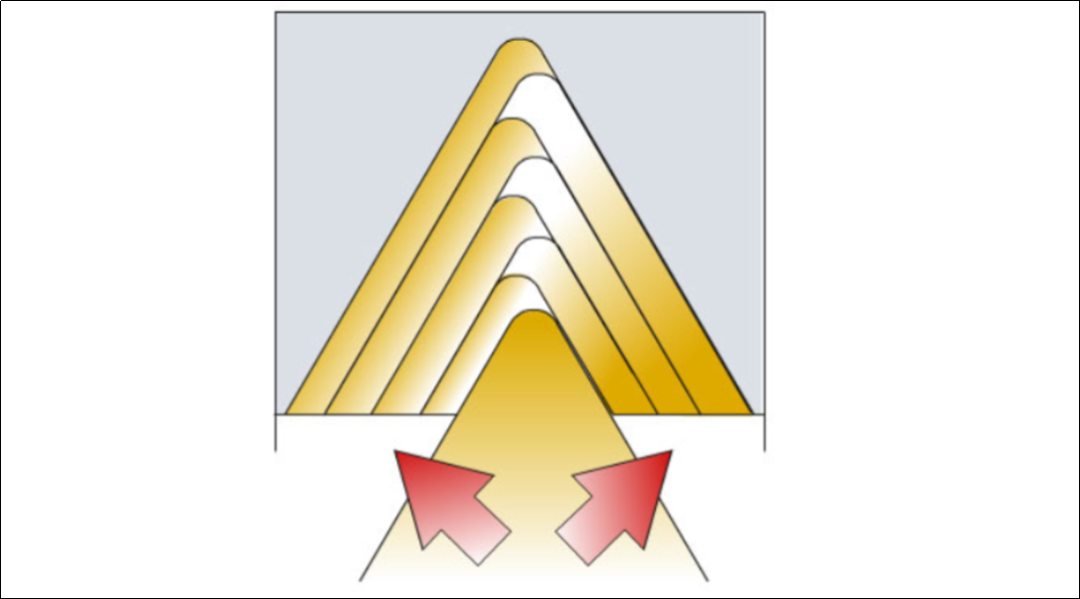

3. Alternate feeding

inokurudzirwa mazino makuru

Uniform yekuisa kupfeka uye hupenyu hwekushandisa zvakanyanya paunenge uchigadzira tambo dzakakura kwazvo

Chips inotungamirirwa mumativi maviri, zvichiita kuti zvive zvakaoma kudzora

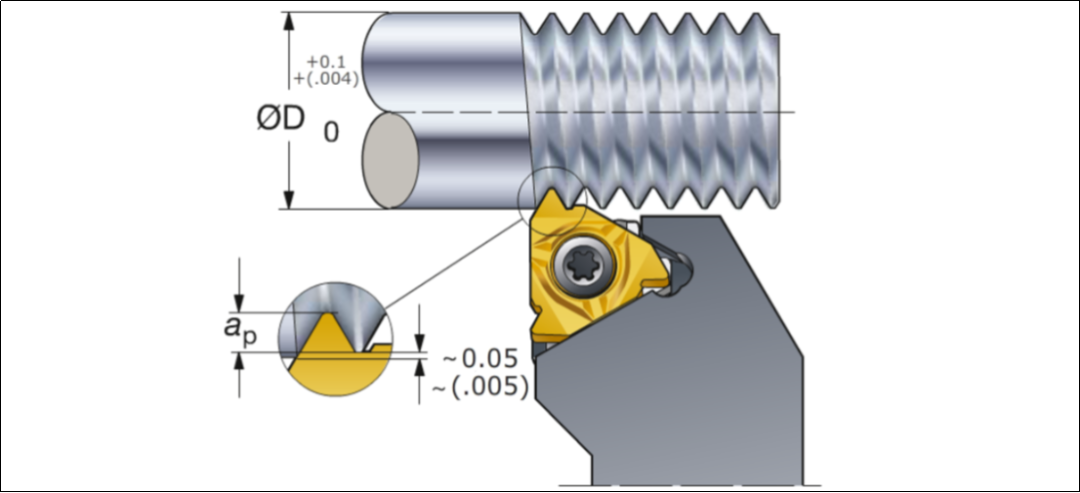

4. Nzira dzekuvandudza migumisiro yekugadzirisa

Kudzikira kudzika kwekucheka (kuruboshwe), kudzika kwakadzika kwekucheka (kurudyi)

1. Kudzika kwekucheka kunodzikira layer ne layer (iyo chip nzvimbo inoramba isina kuchinjika)

Kugona kuwana inogara chip nzvimbo, inova ndiyo inonyanya kushandiswa nzira muzvirongwa zveNC.

Kupasa kwekutanga kwakadzama

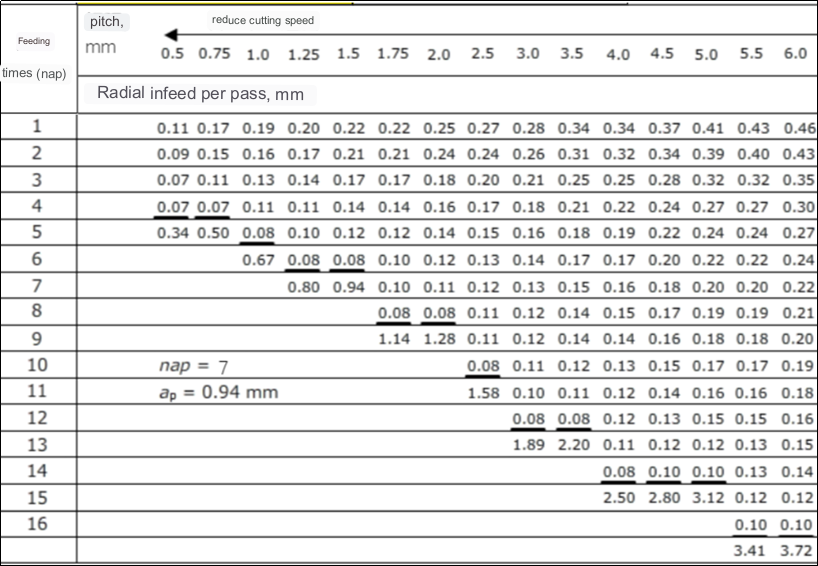

Tevedzera kurudziro patafura yekudyisa mukatalogi

More "yakaenzana" chip nzvimbo

Kupfuura kwekupedzisira kunenge 0.07mm

2. Kudzika kwakadzikama kwekucheka

Kupasa kwega kwega kune hudzamu hwakafanana zvisinei nehuwandu hwekupasa.

Pane zvinodiwa zvepamusoro pane blade

Ita shuwa yakakwana chip control

Haifanirwe kushandiswa kana gomo rakakura kupfuura TP1.5mm kana 16TP

Pedzisa ma thread crests nemamwe stock:

Hapana chikonzero chekushandura stock kusvika dhayamita chaiyo usati waisa shinda, shandisa yakawedzera stock / zvinhu kupedzisa shinda crests. Pakupedzisa kuisirwa crest, iyo yapfuura yekutendeuka maitiro inofanirwa kusiya 0.03-0.07mm yezvinhu kuti ibvumire crest kuumbwa zvakanaka.

Inokurudzirwa yekunze shinda yekudya kukosha (ISO metric system):

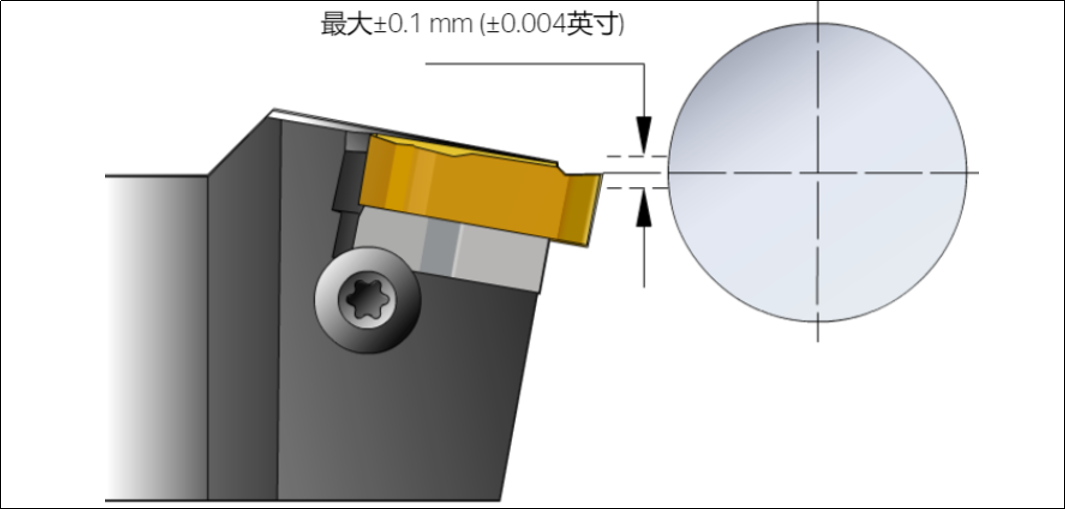

Kuve nechokwadi chekushanda uye kurongeka kwemidziyo:

Shandisa yakanyanya pakati pekutsauka kwe ± 0.1mm. Yakanyanya kukwirira nzvimbo yekucheka uye kona yekuyamura ichaderera uye iyo yekucheka inocherwa (yakatsemuka); yakaderera zvakanyanya nzvimbo yekucheka uye chimiro cheshinda chinogona kunge chisina chokwadi.

5.shinda inoshandura hunyanzvi hwekushandisa kubudirira

1) Usati watendeuka, tarisa kana iyoaluminium machining zvikamudhayamita ine chaiyo machining mvumo, uye wedzera 0.14mm semvumo yekorona.

2) Kumisikidzwa chaiko kwechishandiso mumuchina mudziyo.

3) Tarisa kugadzika kwekucheka kunoenderana nepitch diameter.

4) Ita shuwa kushandisa iyo chaiyo yekuisa geometry (A, F kana C).

5) Ita shuwa kwakakura uye kwakafanana kubvumidzwa (shim-yakatemerwa shim) nekusarudza shim yakakodzera kuti uwane iyo chaiyo flank clearance.

6) Kana iyo tambo isina kukodzera, tarisa iyo yese setup inosanganisira mudziyo wemuchina.

7) Tarisa zviripo NC zvirongwa zvekutenderera shinda.

8) Gadzirisa nzira yekudyisa, nhamba yekupfuura uye saizi.

9) Ita shuwa chaiyo yekucheka kumhanya kusangana nezvinodiwa zvekushandisa.

10) Kana kukwirira kweshinda yeworkpiece isiriyo, tarisa kana gomo remuchina wekushandisa rakarurama.

.

12) Yepamusoro-chaiyo inotonhorera inogona kuwedzera hupenyu hwechishandiso uye kugadzirisa chip control.

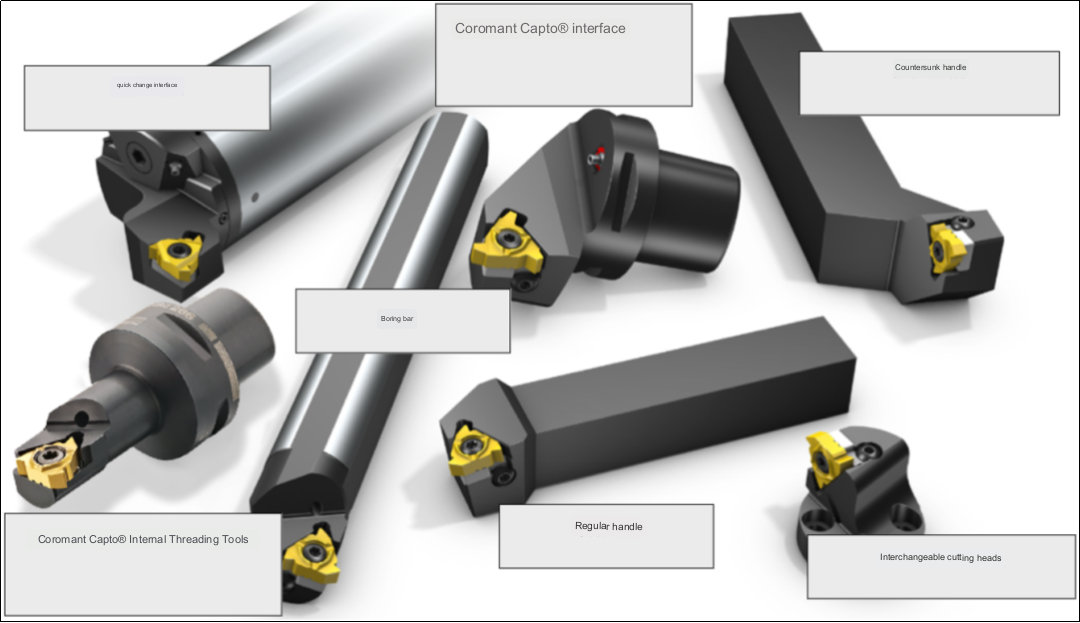

13) Iyo yekukurumidza shanduko sisitimu inovimbisa nyore uye nekukurumidza clamping.

Paunenge uchisarudza maturusi ekutenderedza shinda, funga:

Tarisa overhangs uye chero clearance inodiwa (semuenzaniso bendekete, sub-spindle, nezvimwewo)

Chengetedza kuwandisa kwechishandiso chekukurumidza kuseta

Kune mashoma akaomesesa setups, sarudza anoisa ane mashoma ekucheka masimba

High-precision cnc turningcoolant inowedzera hupenyu hwezvishandiso uye inovandudza kudzora kucheka

Kuwanikwa kuri nyore kune inotonhorera ine plug-uye-kutamba inotonhorera adapta

Kuti uve nechokwadi chekubudirira uye hupenyu hwezvishandiso, kuisirwa-mazhinji-mbiri kunofarirwa, imwe-kumucheto yakazara-yakazara-yakaiswa ndiyo yechipiri sarudzo, uye V-profile yekuisa ndiyo yakaderera kubereka uye mapfupi ehupenyu maturusi sarudzo.

Isa kupfeka uye hupenyu hwezvishandiso:

Feed nzira, optimize nzira yekudyisa, nhamba yekupfuura uye kudzika

Kurerekera kweblade kuve nechokwadi chakakura uye chakafanana kubvumidzwa (shim-yakatemerwa shim)

Isa geometry, ita shuwa kushandisa iyo chaiyo yekuisa geometry (A, F kana C geometry)

Blade zvinhu, sarudza iyo chaiyo zvinhu zvinoenderana nezvinhu uye kuomarara zvinodiwa

Kucheka parameters, kana zvichidikanwa, shandura kukurumidza kucheka uye nhamba yezvinopfuura mukuita kwecnc milling zvikamu.

Anebon inonamatira pakutenda kwako kwe "Kugadzira mhinduro dzemhando yepamusoro uye kugadzira shamwari nevanhu vanobva kumativi ese enyika", Anebon inogara ichiisa kufarira kwevatengi kutanga nayo kuChina Mugadziri weChina aruminiyamu yekukanda chigadzirwa, milling aluminium ndiro, yakagadziridzwa aluminium diki. zvikamu cnc, nechishuwo chakanakisa uye kutendeka, vanoda kukupa iwe neakanakisa masevhisi uye kufambira mberi newe kuti uite ramangwana rakajeka rinoonekwa.

Yekutanga Factory China Extrusion Aluminium uye Profile Aluminium, Anebon ichanamatira kune "Hunhu kutanga,, kukwana nekusingaperi, vanhu-vanotungamirwa, tekinoroji innovation"business philosophy. Kushanda nesimba kuti urambe uchifambira mberi, hunyanzvi muindasitiri, ita zvese kuedza kune yekutanga-kirasi bhizinesi. Isu tinoedza nepatinogona napo kuvaka iyo sainzi manejimendi modhi, kudzidza ruzivo rwakawanda rwehunyanzvi, kugadzira michina yekugadzira yepamusoro uye maitiro ekugadzira, kugadzira yekutanga-kufona mhando zvigadzirwa, mutengo unonzwisisika, mhando yepamusoro yebasa, kukurumidza kutumira, kukupa iwe kugadzira. kukosha kutsva .

Nguva yekutumira: Jun-14-2023