Zvizhinji zvinhu zvinokonzeresa kukanganisa kwezvinhu zvealuminium panguva yekugadzira, zvinosanganisira zvinhu zvemukati, chikamu geometry, uye maparamendi ekugadzira.

Zvinhu zvekutanga zvinosanganisira kushushikana kwemukati mukati mezvakagadzirwa, kukanganisa kunokonzerwa nemagetsi machining masimba uye kupisa, uye deformation inokonzerwa nekudzvanya kumanikidza.

1. Matanho ekugadzirisa kuderedza kushandiswa kwekugadzirisa

1. Deredza kushushikana kwemukati kwechinhu chisina chinhu

Iko kunetsana kwemukati kweiyo mbishi zvinhu kunogona kudzikiswa kuburikidza neakasikwa kana ekugadzira kuchembera uye vibration maitiro. Preliminary processing zvakare inzira inoshanda. Panyaya yezvigadzirwa zvine rupo overhangs uye yakakura protrusions, kukanganisa post-kugadzirisa kwakakosha zvakare.

Kugadzirisa chikamu chakasara chezvakagadzirwa zvisati zvaitika uye kuderedza kuwanda kwechikamu chimwe nechimwe hakungogone kudzikisira kukanganiswa kwemaitiro anotevera, asi zvakare kubvumidza kuti iiswe parutivi kwenguva yakareba mushure mekutanga kugadzirisa, izvo zvinogona kudzoreredza zvimwe zve kukakavara kwemukati.

2. Kuvandudza kugona kwekucheka kwechombo

Simba rekucheka uye kupisa kupisa panguva yekugadzira kunonyanya kukonzerwa nekugadzirwa kwezvinhu uye chimiro chaicho chechishandiso. Kusarudza chishandiso chakakodzera kwakakosha pakuderedza kukanganisa panguva yekugadzira chikamu.

1) Sarudza zvine musoro chishandiso geometric paramita.

①Rake angle inoita basa rakakosha mukucheka mashandiro. Zvakakosha kunyatsosarudza hombe yerake angle uchiona kuti simba reblade rinochengetwa. Iyo hombe rake angle haingobatsire kuwana yakapinza yekucheka mupendero asi zvakare inoderedza kucheka kukanganisa uye inofambisa inobudirira chip kubviswa, zvichitungamira mukudzikiswa kwekucheka simba uye tembiricha. Zvishandiso zvine negative rake angles zvinofanirwa kudzivirirwa nechero muripo.

②Kuyamura kona: Hukuru hweiyo kona yekuyamura inokanganisa zvakanyanya kupfeka padivi uye kunaka kwenzvimbo yakagadzirwa. Kusarudzwa kwekona yekuyamura kunoenderana nehupamhi hwekucheka. Mukugaya kwakashata, uko kune chiyero chakakura chekudya, mutoro unorema wekucheka, uye kugadzirwa kwakanyanya kwekupisa, zvakakosha kuve nechokwadi chekupisa kupisa kubva kuchishandiso. Saka, kona diki yekuyamura inofanira kusarudzwa. Sezvineiwo, pakugaya kwakanaka, inopinza yekucheka mupendero inodiwa kuti uderedze kupokana pakati peflank nenzvimbo yakagadzirwa uye kuderedza elastic deformation. Nekuda kweizvozvo, yakakura clearance angle inokurudzirwa.

③Helix angle: Kuti kugaya kutsetseke uye kuderedza simba rekugaya, helix angle inofanirwa kunge yakakura sezvinobvira.

④ Main deflection angle: Kunyatso kudzikisa iyo main deflection angle inogona kuvandudza kupisa kupisa mamiriro uye kuderedza avhareji tembiricha yenzvimbo yekugadzirisa.

2) Kuvandudza chigadziro chekushandisa.

①Kuvandudza chip evacuation, zvakakosha kudzikisa huwandu hwemazino pane yekugayo cutter uye kuwedzera chip nzvimbo. Nekuda kwehukuru hwepurasitiki hwearuminiyamu zvikamu, kune yakawedzera kucheka deformation panguva yekugadziriswa, ichida yakakura chip nzvimbo. Nekuda kweizvozvo, yakakura yepasi radius yeiyo chip groove uye kudzikiswa kwehuwandu hwemazino ekugaya ekucheka anokurudzirwa.

②Ita kugaya chaiko kwemazino eblade, kuve nechokwadi chekuti kukosha kwekukasha kwechekucheka kuri pazasi Ra = 0.4um. Paunenge uchishandisa banga idzva, zvinokurudzirwa kukuya zvishoma kumberi uye kumashure kwemazino uchishandisa dombo remafuta rakatsetseka kubvisa chero maburrs uye zvidiki zvisiri izvo zvingave zvakakonzerwa nekurodza. Iyi nzira haingodzikisi kupisa kupisa asiwo inoderedza kutema deformation.

③Zvakakosha kunyatso tarisisa mapfekero ezviyero zvekucheka maturusi. Sezvo chishandiso chinopera, kukosha kwepamusoro kweiyo workpiece kunokwira, kucheka tembiricha inowedzera, uye workpiece deformation inowedzera kutaurwa. Pamusoro pekusarudza kucheka maturusi ezvishandiso zvine yakanakisa kupfeka kuramba, zvakakosha kuti utevedzere kune yakanyanya kupfekwa yechishandiso muganho we 0.2mm kudzivirira kuitika kwekuvakwa-kumucheto. Panguva yekucheka mashandiro, zvinokurudzirwa kuchengetedza tembiricha yebasa iri pasi pe100 ° C kudzivirira deformation.

3. Kuvandudza clamping nzira ye workpieces

Kune matete-walled aruminiyamu workpieces asina kusimba kusimba, dzinotevera nzira dzekusunga dzinogona kushandiswa kuderedza deformation:

①Paunenge uchishanda neakatetepa-akakomberedzwa nemadziro, kushandisa matatu-shaya-yega-yepakati chuck kana chitubu chuck kusungirira zvikamu radially zvinogona kukonzera workpiece deformation kana yakasunungurwa mushure mekugadzirisa. Mumamiriro ezvinhu akadaro, zvinokurudzirwa kushandisa yakasimba axial end face compression nzira. Tanga nekutsvaga mukati megomba rechikamu, kugadzira tsika yakarukwa mandrel, uye kuipinza mukati megomba. Shandisa chivharo chekuvhara kuti uise kudzvinyirira kune chiso chekupedzisira, uye wozoichengetedza panzvimbo ne nut. Nekushandisa nzira iyi, unogona kudzivirira clamping deformation panguva yekunze denderedzwa kugadzirisa, zvichitungamira kune yakagadziridzwa kugadzirisa kwayo.

②Paunenge uchishanda neatete-walled sheet simbi zvikamu, zvinokurudzirwa kushandisa magineti clamping tekinoroji kuti uwane yunifomu yekurovedzera simba, pamwe chete neakanaka kucheka paramita. Iyi nzira inonyatso kudzikisa njodzi ye workpiece deformation panguva yekugadzirisa.Seimwe nzira, rubatsiro rwemukati runogona kushandiswa kusimbisa kugadzikana kwezvikamu zvakatetepa.

Nekupinza iyo workpiece ine svikiro rinotsigira, senge urea solution ine 3% kusvika 6% potassium nitrate, mukana we deformation panguva ye clamping nekucheka unogona kuderedzwa. Iyi filler inogona kuzonyungudika nekubviswa nekunyudza iyo workpiece mumvura kana doro post-processing.

4. Ronga nzira yacho zvine musoro

Mukati mekucheka-kumhanya-mhanya, kugaya kunowanzoita kuzunguzika nekuda kweyakakura machining mvumo uye kucheka kwepakati, zvichikonzera kukanganisa kwakashata pakurongeka kwemachina uye kushata kwepasi. Nekuda kweizvozvo, iyo CNC yakakwira-kumhanya yekucheka maitiro anowanzo kutenderedza matanho akasiyana, anoti rough machining, semi-kupedza, kuchenesa makona, uye kupedzisa, pakati pezvimwe.

Muzviitiko apo zvikamu zvinoda kunyatsojeka, zvingave zvakafanira kuita semi-kupedzisa kwechipiri kuchiteverwa nekupedzisa. Zvichitevera kune hutsinye machining, zvinobatsira kubvumira zvikamu kuti zvipinde mumhepo inotonhorera kudzikisa kushushikana kwemukati kunokonzerwa nehutsinye machining uye kuderedza deformation. Muganho wakasara mushure mekugadzira machining unofanirwa kudarika mwero we deformation, kazhinji kubva pa1 kusvika ku2 mm.

Uyezve, pakupedzisa kupedzisa, zvinodikanwa kuchengetedza inowirirana machining mvumo pane yakapedzwa pamusoro pechikamu, kazhinji kubva 0.2 kusvika 0.5mm. Iyi tsika inovimbisa kuti chishandiso chinoramba chiri chakagadzikana panguva yekugadziriswa, nekudaro zvakanyanya kudzikisira kucheka deformation, kuwana yepamusoro yepamusoro yekugadzirisa mhando, uye kusimudzira chigadzirwa.

2. Unyanzvi hwekushanda kuderedza kushandiswa kwekugadzirisa

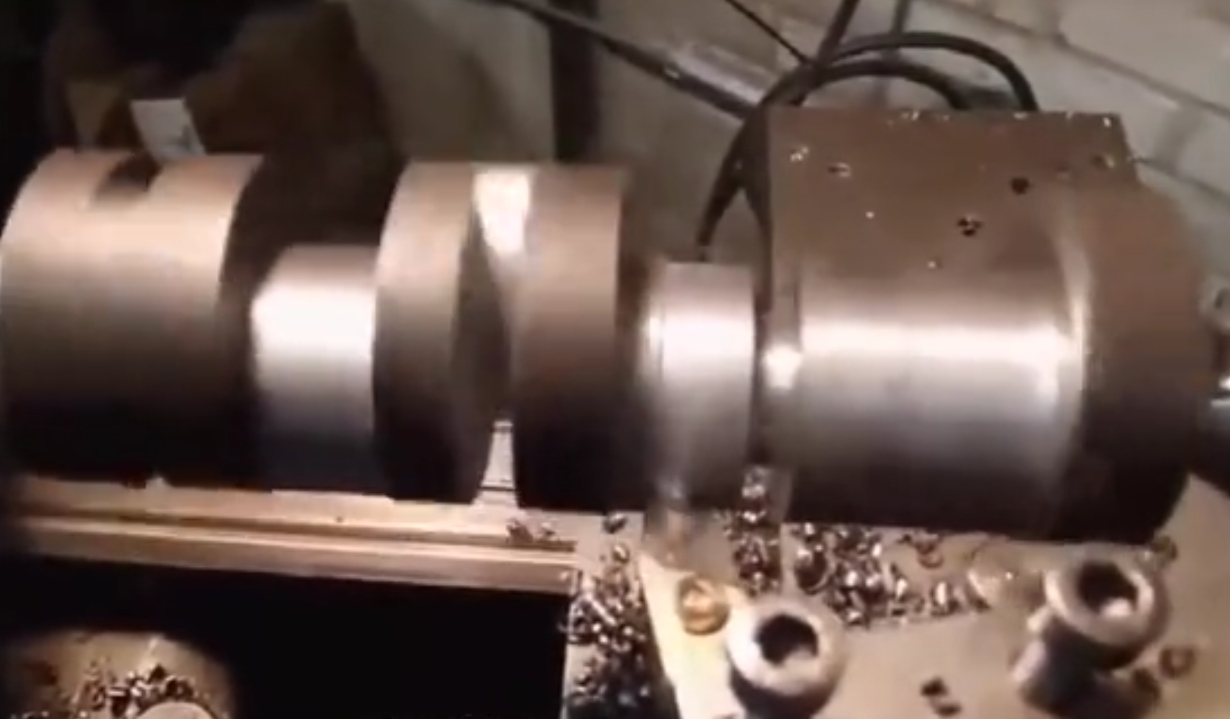

Zvikamu zvakagadzirwacnc machined aluminium zvikamudzakaremara panguva yekugadzirisa. Mukuwedzera kune zvikonzero zviri pamusoro apa, nzira yekushanda inokoshawo mukushanda chaiko.

1. Kune zvikamu zvine mari yakawanda yekubvumidza machining, zvakakosha kushandisa symmetrical kugadzirisa matekiniki kuti uwedzere kupera kwekupisa panguva yekugadzira uye kudzivirira kupisa. Semufananidzo, kana uchidzikisa 90mm gobvu shizha kusvika 60mm, kukuya rimwe divi uye ipapo ipapo kugaya rimwe, richiteverwa nekamwe kekupedzisira saizi process inoguma nekupfava kwe5mm. Mukupesana, kushandisa inodzokororwa symmetrical process, nedivi rega rega rakagayiwa mumatanho maviri, inovimbisa saizi yekupedzisira ine flatness ye0.3mm.

2. Kana pane zvinyorwa zvakawanda pachikamu cheplate, hazvikurudzirwi kushandisa nhanho-nhanho yekugadzirisa nzira kune imwe neimwe indentation. Izvi zvinogona kutungamirira kukusagadzikana kwekunetseka kwekugovera uye kunotevera deformation yechikamu. Pane kudaro, funga kushandisa akaturikidzana kugadzirisa kumichina ese indentations panguva imwe chete pane imwe neimwe layer, usati waenda kune inotevera layer. Izvi zvichabatsira kuve nechokwadi kugovera kwekushushikana uye kuderedza deformation.

3. Kuderedza simba rekucheka uye kupisa, chiyero chekucheka chinogona kugadziriswa. Pakati pematatu ekucheka huwandu zvinhu, kumashure kucheka huwandu kunokanganisa zvakanyanya kucheka simba. Yakawandisa machining mvumo uye simba rekucheka zvinogona kutungamira kune chikamu deformation, kukanganisa muchina chishandiso spindle rigidity, uye kuderedza kusimba kwechishandiso. Kudzikira kwehuwandu hwekucheka kumashure kunogona kuderedza zvakanyanya kugadzirwa. Zvakangodaro, kukurumidza-kumhanya kugaya muCNC machining kunogona kugadzirisa nyaya iyi. Nenguva imwe chete kudzikisira kumashure kwekucheka huwandu uye kuwedzera chikafu uye muchina chishandiso kumhanya, simba rekucheka rinogona kudzikiswa uchichengetedza kugadzirisa kushanda zvakanaka.

4. Kuchenjerera kunofanirawo kupiwa kune kutevedzana kwekucheka. Mukukasharara machining, chinotariswa chiri pakusimudzira mashandiro ekugadzirisa uye kuyedza kubviswa kwezvinhu zvakanyanya pachikamu chenguva. Kazhinji, kukwira kumusoro kunodiwa. Izvi zvinoreva kuti izvo zvakasara zviri pamusoro peiyo workpiece zvinobviswa nekumhanya kwakanyanya uye munguva pfupi inogoneka kumisikidza inodiwa geometric rondedzero yekupedzisa. Nekune rimwe divi, maitiro ekupedzisa anokoshesa kurongeka kwepamusoro uye hunhu hwepamusoro, saka kudzika kunokurudzirwa. Sezvo ukobvu hwekucheka kwechishandiso huchidzikira zvishoma nezvishoma kubva pahukuru kusvika zero panguva yekugaya, inoderedza zvakanyanya kuoma kwebasa uye kuderedza chikamu deformation.

5. Deformation yeatete-walled workpieces anokonzerwa ne clamping panguva yekugadzirisa inyaya isingadzivisiki, kunyange mushure mokunge apera. Kuti uderedze workpiece deformation, zvinokurudzirwa kusunungura kudzvanywa usati wapedza kuzadzisa zviyero zvekupedzisira. Izvi zvinobvumira workpiece kuti idzokere kumamiriro ayo epakutanga. Mushure mezvo, kudzvanywa kunogona kusimbiswa nekuchenjera kudzamara iyo workpiece yanyatsosungirirwa, ichiwana yaunoda kugadzirisa maitiro. Nenzira yakanaka, iyo clamping force inofanira kushandiswa kune inotsigira pamusoro, inoenderana nekuoma kweworkpiece. Ndichiri kuona kuti workpiece inoramba yakachengeteka, zviri nani kushandisa mashoma clamping simba.

6. Paunenge uchigadzira zvikamu zvine nzvimbo isina mhango, zvinokurudzirwa kudzivirira mucheki wekugaya kupinda akananga muchikamu chakafanana nechibooreso panguva yekuita. Izvi zvinogona kutungamira kune yakaderera chip nzvimbo yeanocheka milling, yakakanganisa chip evacuation, uye zvinokonzeresa kupisa, kuwedzera, uye kuparara kwezvikamu. Zviitiko zvisingafadzi zvakadai sekukanganiswa uye kuputsika kwezvishandiso zvinogona kuitika. Zvinokurudzirwa kutanga kushandisa chibooreso chehukuru hwakaenzana kana kuti chihombe pane chinocheka chigayo kuti uboore gomba uye wozoshandisa chigayo chekucheka pakugadzira. Neimwe nzira, chirongwa chekucheka chespiral chinogona kugadzirwa uchishandisa CAM software.

Dambudziko rekutanga rinopesvedzera iko kurongeka kwealuminium chikamu chekugadzira uye kunaka kwekupedza kwayo kwepamusoro ndiko kukanganiswa kwezvikamu izvi kukanganisa panguva yekugadziriswa. Izvi zvinoda kuti mushandisi ave nehumwe nhanho yehunyanzvi hwekuita uye hunyanzvi.

Anebon inotsamira pane yakasimba tekinoroji simba uye inogara ichigadzira tekinoroji yakasarudzika yekusangana nezvinodiwa zve cnc simbi machining,5 axis cnc kugayauye motokari yekufambisa. Ese maonero uye mazano achaongwa zvikuru! Kudyidzana kwakanaka kunogona kuvandudza isu tose mukusimudzira zvirinani!

ODM Mugadziri ChinaYakagadzirirwa aluminium CNC Zvikamuuye michina yekugadzira zvikamu, Parizvino, zvinhu zveAnebon zvakatengeswa kune nyika dzinopfuura makumi matanhatu uye nzvimbo dzakasiyana, dzakadai seSoutheast Asia, America, Africa, Eastern Europe, Russia, Canada etc. Anebon inotarisira nemoyo wose kumisa kusangana kwakakura nevose vangangove vatengi. zvese muChina nekune dzimwe nyika.

Kana iwe uchida kuziva zvakawanda nezvedu kana uchida kubvunza, ndapota tumira e-mail kuneinfo@anebon.com

Nguva yekutumira: Feb-02-2024