Iyo Tekinoroji Zvinodikanwa zvemakina madhirowa akaunganidzwa neAnebon timu inovhara zvinotevera zvakakosha dhairekitori:

1. General technical zvinodiwa

2. Chinodiwa chekurapa kwekupisa

3. Kushivirira kunodiwa

4. Chikamu chekona

5. Gungano rinodiwa

6. Kukandira zvinodiwa

7. Coating chinodiwa

8. Piping zvinodiwa

9. Solder kugadzirisa zvinodiwa

10. Forging zvinodiwa

11. Zvinodiwa zvekucheka workpiece

▌ General Technical Requirements

1. Zvikamu zvinobvisa ganda reoxide.

2. Pamusoro pezvikamu zvekugadzirisa, hapafaniri kunge kune zvipembenene, maronda uye zvimwe zvinokanganisa zvinokuvadza pamusoro pezvikamu.

3. Bvisa burrs.

▌ Zvinodiwa Kurapa Kupisa

1. Mushure mekupisa kurapwa, HRC50 ~ 55.

2. Zvikamu zvekudzima kwepamusoro-frequency, 350 ~ 370 ℃ kupisa, HRC40 ~ 45.

3. Carburizing kudzika 0.3mm.

4. High tembiricha kukwegura kurapwa.

▌ Zvinodiwa Zvekushivirira

1. Iyo isina kucherechedzwa chimiro kushivirira ichasangana nezvinodiwa zveGB1184-80.

2. Kutsauka kunobvumirwa kwehurefu husina kuratidzwa huri ± 0.5mm.

3. Iyo yekukanda tolerance zone inofananidzwa kune yekutanga saizi gadziriso yekukanda isina chinhu.

▌ Makona nemapendero ezvikamu

1. Radhiyasi yekona R5 haina kutaurwa.

2. Chamfer isina jekiseni ndeye 2 × 45 °.

3. Makona akapinza / makona akapinza / mipendero yakapinza yakagomara.

▌ Zvinodiwa paGungano

1. Pamberi peungano, chisimbiso chimwe nechimwe chinofanira kunyudzwa mumafuta.

2. Kupisa kwemafuta kunobvumirwa kubhadharisa kupisa kwemabhengi ekutenderera panguva yegungano, nekushisa kwemafuta kusingapfuuri 100 ℃.

3. Kutevera gungano regiya, mapoinzi ekusangana uye backlash pamusoro pemazino anofanira kutevedzera zviyero zvakatsanangurwa muGB10095 uye GB11365.

4. Mumusangano we hydraulic system, kushandiswa kwekuisa chisimbiso filler kana sealant kunobvumirwa, kunze kwekuti ichichengetwa kunze kwegadziriro.

5. Zvosemachining zvikamuuye zvikamu zvinopinda mugungano (kusanganisira izvo zvakatengwa kana kuburitswa kunze) zvinofanirwa kuve nezvitupa kubva kubazi rekuongorora.

6. Pamberi pegungano, zvikamu zvinofanirwa kunyatsocheneswa kuti zvive nechokwadi chekusavapo kwemaburrs, flash, oxide, ngura, machipisi, oiri, zvigadziriso zvemavara, uye guruva.

7. Usati wasangana, zvakakosha kuti uongorore hukuru hwakakwana hwezvikamu nezvikamu, kunyanya kupindirana kwezviyero uye nekunyatsoenderana.

8. Musangano wese, zvidimbu hazvifanirwe kugogodzwa, kubatwa, kukweshwa, kana kutenderwa kuita ngura.

9. Paunenge uchichengetedza screws, bolts, uye nuts, zvakakosha kuti urege kuvarova kana kushandisa zvisina kunaka spanners uye wrenches. Iyo screw slots, nzungu, screws, uye mabhaudhi misoro inofanira kuramba isina kukuvara mushure mekuomesa.

10. Fasteners inoda chaiyo tightening torque inofanirwa kuchengetedzwa uchishandisa torque wrench uye yakasimbiswa zvinoenderana neyakatsanangurwa torque.

11. Paunenge uchisunga chikamu chimwe chete nemakumbo akawanda (mabhoti), anofanirwa kusimbiswa mumuchinjikwa, symmetrical, nhanho-nhanho, uye maitiro akafanana.

12. Kuungana kwemapini ekoni kunofanirwa kusanganisira kupendesa gomba, kuve nechokwadi chekusangana kweasingasviki 60% yehurefu hwekufananidza, hwakagoverwa zvakaenzana.

.

14. Zvishoma zve 2/3 yemazino emazino anofanira kunge akabatana panguva yekusangana kwe spline, nehuwandu hwekusangana husingasviki 50% pakureba uye kureba kwekutungamira kwemazino anokosha.

15. Pakuungana kwekiyi yeflat (kana spline) yekutsvedza machisi, zvikamu zvechikamu zvinofanirwa kufamba zvakasununguka, pasina kusimba kusina kuenzana kuripo.

16. Kunyanya kunamatira kunofanira kubviswa mushure mekubatana.

17. Iyo semi-denderedzwa gomba remhete yekunze inotakura, chigaro chakazaruka chekutakura, uye chivharo chekutakura hachifanirwe kunamatira.

18. Mhete yekunze inotakura inofanira kuchengetedza kushamwaridzana kwakanaka ne semi-denderedzwa gomba rechigaro chakazaruka chekutakura uye chivharo chekutakura, uye kuratidza yunifomu yekubatana nechigaro chekutakura mukati mehuwandu hwakatarwa panguva yekuongorora kwemavara.

19. Kutevera kuungana, mhete yekunze yebhengi inofanira kuchengetedza yunifomu yakabatana nechekumagumo kwechifukidziro chekumisa.

20. Mushure mekuiswa kwemabheji ekutenderera, kutenderera kwebhuku kunofanira kushanduka uye kugadzikana.

21. Iko kusanganiswa kwepamusoro uye kwepasi kunotakura bushing kunofanira kunamatira zvakasimba uye kuongororwa ne 0.05mm feeler.

22. Paunenge uchigadzirisa ganda rekutakura nepini yekuisa, inofanira kunyudzwa uye kugoverwa kuti ione kurongeka kwakakodzera negomba rakakodzera. Pini haifanire kusunungura mushure mekuiswa.

.

. nzvimbo yekuonana.

25. Chirevo chekupedzisira chiso chegiya (worm gear) uye shaft shoulder (kana kuti chiso chekupedzisira chechigaro chekugadzirisa) inofanira kukwana pasina kubvumira 0.05mm inonzwa kuti ipfuure, kuve nechokwadi cheperpendicularity ne gear reference end face uye axis.

26. Kubatanidzwa kwepamusoro kwebhokisi re gear uye chivharo chinofanira kuchengetedza kushamwaridzana kwakanaka.

27. Pamberi pekusangana, zvakakosha kunyatsoongorora uye kubvisa makona akapinza, maburrs, uye zvidimbu zvekunze zvakasara kubva kune zvikamu zvinogadziriswa, kuve nechokwadi kuti chisimbiso chinoramba chisina kunyorwa panguva yekurodha.

▌ Zvinodiwa Zvekukandira

1. Nzvimbo yekukanda haifanirwe kuratidza yakaderera insulation, fractures, contractions, kana kusakwana senge kusakwana mukukanda (semuenzaniso, kusakwana zvinhu zvakazadzwa, mechanical kukuvadza, nezvimwewo).

2. Kukandwa kunofanirwa kucheneswa kubvisa chero maprotrusion, micheto inopinza, uye zviratidzo zvemaitiro asina kupera, uye gedhi rekudurura rinofanira kucheneswa pamwero nenzvimbo yekukanda.

3. Iyo isiri-yakagadzirwa pamusoro pekukanda inofanirwa kuratidza zvakajeka mhando yekukanda uye yekumaka, ichisangana nekudhirowa zvakatemwa maererano nenzvimbo uye font.

4. Kuomarara kweiyo isiri-yakagadzirwa pamusoro pekukanda, muchiitiko chekukanda jecha R, haifaniri kudarika 50μm.

5. Kukandwa kunofanirwa kubvisirwa sprue, mapurojekiti, uye chero sprue yasara pane isina-machine surface inofanira kuitwa nhanho uye kukwenenzverwa kusangana nepamusoro pemhando yemhando.

6. Kukandwa kunofanirwa kunge kusina jecha rekuumba, jecha repakati, uye core remnants.

7. Zvikamu zvakarerekera uye dimensional kushivirira zone yekukanda kunofanirwa kurongeka zvakarongeka pamwe nendege yakarerekera.

8. Chero jecha rekugadzira, jecha repakati, zvisaririra zvepakati, pamwe chete nejecha rakapfava kana rinonamatira pakukanda, rinofanira kugadziriswa uye kucheneswa.

9. Mhando yezvakanaka nezvakaipa uye chero convex casting kutsauka kunofanirwa kugadziriswa kuti ive nechokwadi chekuchinja kwakanaka uye kuvimbisa kutaridzika kwemhando.

10. Masikirwo ari panzvimbo isina-machine yekukanda haafaniri kudarika yakadzika ye2mm, ine zvishoma zvishoma zve 100mm.

11. Iyo isiri-yakagadzirwa pamusoro pemuchina chigadzirwa castings inofanira kupfurwa peening kana roller kurapwa kuti isangane nehutsanana zvinodiwa zveSa2 1/2.

12. Mishonga inofanira kuomeswa nemvura.

13. Nzvimbo yekukanda inofanira kuva yakatsetseka, uye chero magedhi, protrusions, adhesive jecha, nezvimwewo, inofanira kubviswa.

.

▌ Painting Zvinodiwa

1. Usati wapenda zvikamu zvesimbi, zvakakosha kubvisa chero marara, oxide, grime, guruva, ivhu, munyu, nezvimwe zvinosvibisa kubva pamusoro.

2. Kugadzirira zvikamu zvesimbi zvekubvisa ngura, shandisa zvinonyungudutsa zvechisikigo, caustic soda, emulsifying agents, steam, kana dzimwe nzira dzakakodzera kubvisa mafuta uye tsvina kubva pamusoro.

3. Kutevera pfuti peening kana manual rust kubviswa, nguva yakatarwa pakati pekugadzirira pamusoro uye kushandisa primer haifaniri kudarika maawa matanhatu.

4. Usati wabatanidza, shandisa 30 kusvika 40μm gobvu jasi reanti-corrosion pendi kune nzvimbo dzezvikamu riveted zvinosangana kune mumwe nemumwe. Nama mupendero wejojo yemakumbo nepende, filler, kana adhesive. Kana iyo primer yakakuvadzwa panguva yekugadzira kana welding, shandisazve jasi idzva.

▌ Piping Zvinodiwa

1. Bvisa chero flash, burrs, kana bevels kubva papombi inopera pamberi pegungano. Shandisa mhepo yakamanikidzwa kana nzira yakakodzera yekubvisa tsvina uye yakasara kubva mumadziro emukati emapombi.

2. Usati wasangana, iva nechokwadi chokuti pombi dzose dzesimbi, kusanganisira dzakafanogadzirirwa, dzinobatwa ne degreasing, pickling, neutralization, washing, uye kudzivirirwa kwekuora.

3. Panguva yegungano, sunga zvakasimba tambo dzakasungwa senge pombi dzinosungirira, zvinotsigira, flanges, uye majoini kudzivirira kusunungura.

4. Ita muedzo wekumanikidza pazvikamu zvakasungirirwa zvepombi dzakagadzirirwa.

5. Paunenge uchifambisa kana kutamisa pombi, simbisa pombi yekuparadzanisa pombi netepi yekunamatira kana chivharo chepurasitiki kudzivirira marara kuti asapinda, uye ona kuti yakanyorwa zvinoenderana.

▌ Zvinodiwa zvekugadzirisa zvikamu zvewelding

1. Usati waita welding, zvakakosha kubvisa chero kusakwana uye kuve nechokwadi kuti nzvimbo ye groove yakaenzana uye isina mipendero yakapinza.

2. Zvichienderana nekusakwana kunowanikwa musimbi yakakandwa, nzvimbo yewelding inogona kugadziriswa uchishandisa kuchera, abrasion, carbon arc gouging, gas cutting, kana mechanical procedures.

3. Chenesa nzvimbo dzose dzakapoteredza mukati me 20mm radius ye welding groove, kuve nechokwadi kubviswa kwejecha, mafuta, mvura, ngura, nezvimwe zvinosvibisa.

4. Mukati yose yekugadzira, iyo preheating zone yekukanda simbi inofanira kuchengetedza kutonhora kwete pasi pe350 ° C.

5. Kana mamiriro ezvinhu achibvumira, edza kuitisa welding munzvimbo yakachinjika.

6. Paunenge uchigadzira welding kugadzirisa, gadzirisa zvakanyanya lateral kufamba kwe electrode.

7. Nyatsobatanidza imwe neimwe welding pass, kuve nechokwadi kuti kupindirana kunenge 1/3 yepass wide. Iyo weld inofanira kuva yakasimba, isina kutsva, mitswe, uye zvisizvo zvinoonekwa. Kuonekwa kwe weld kunofanira kufadza, pasina undercutting, yakawandisa slag, porosity, kuputika, spatter, kana zvimwe zvikanganiso. Iyo welding bead inofanira kunge yakafanana.

▌ Kugadzira Zvinodiwa

1. Muromo wemvura uye riser ye ingot inofanira kucheneswa zvakakwana kudzivirira shrinkage voids uye kutsauka kwakakosha panguva yekugadzira.

2. Mafirita anofanirwa kuumbwa pachidhina chine huwandu hwakakwana kuti ive nechokwadi chekubatana kwemukati.

3. Kuvepo kwekuonekwa kwemafissures, creases, kana zvimwe zvisingaoneki zvinokanganisa kushanda hazvibvumirwi mukugadzira. Zvikanganiso zvemunharaunda zvinogona kugadziriswa, asi kudzika kwekugadzirisa hakufaniri kudarika 75% yemvumo yekugadzira. Zvikanganiso pane unmachined surface inofanira kubviswa uye kusandurwa pasina musono.

4. Forgings inorambidzwa kuratidza mavara akadai semavara machena, mukati mekuputika, uye zvakasara shrinkage voids.

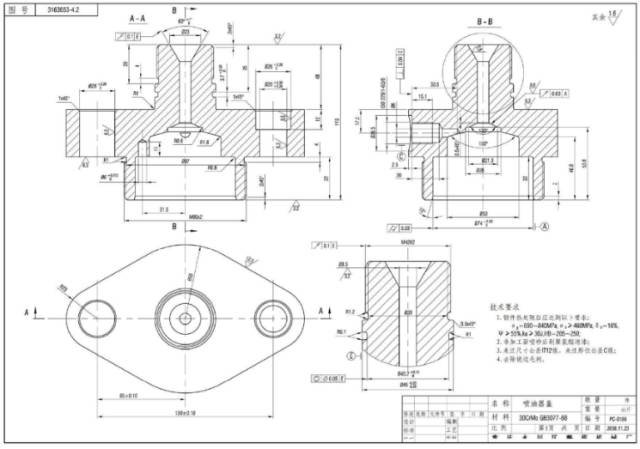

▌ Zvinodiwa zvekucheka workpiece

1. Precision yakashandura zvikamuinofanirwa kuongororwa uye kubvumidzwa mukuenderana nemaitiro ekugadzira, kuve nechokwadi chekufambira mberi kune rinotevera nhanho chete pakusimbiswa kubva mukuongororwa kwapfuura.

2. Zvikamu zvakapedzwa hazvifanirwe kuratidza zvisizvo nenzira yeprotrusions.

3. Zvidimbu zvakapedzwa hazvifanirwe kuiswa zvakananga pasi, uye inodiwa kutsigirwa uye matanho ekuchengetedza anoda kuitwa. Kuve nechokwadi chekushaikwa kwe ngura, ngura, uye chero kukanganisa kwekuita, hupenyu hurefu, kana kutaridzika, kusanganisira mazino, mavanga, kana kumwe kukanganisa, kwakakosha kune yakapedzwa.

4. Iyo yepamusoro inotevera rolling yekupedzisa maitiro haifanire kuratidza chero peeling zviitiko post rolling.

5. Zvikamu zvinotevera kune yekupedzisira kupisa kurapwa hazvifanirwe kuratidza chero nzvimbo oxidation. Pamusoro pezvo, kukwirana uye mazino anotarisana mushure mekupedzwa kunofanirwa kugara pasina chero annealing.

6. Kumusoro kweshinda yakagadziridzwa haifaniri kuratidza kusakwana kwakadai semavara matema, kuputika, kuputika kusina kukwana, kana kuputika.

Kugadzira mamwe mabhenefiti kune vatengi iAnebon's bhizinesi uzivi; shopper kukura isimba rekushanda reAnebon. ZveZvigadzirwa Zvitsva Zvinopisa Durable aluminiumcnc machining zvikamuuyendarira milling partsuye netsika yekutsikisa zvikamu, uchiri kutsvaga chigadzirwa chemhando yepamusoro icho chinoenderana nemufananidzo wako wesangano wakanaka uchiwedzera musika wechinhu chako? Funga nezvekutengesa kwakanaka kweAnebon. Sarudzo yako icharatidza kuve nehungwaru!

Zvitsva Zvitsva Zvigadzirwa China Girazi uye Acrylic Girazi, Anebon inovimba nezvinhu zvemhando yepamusoro, dhizaini yakakwana, sevhisi yevatengi yakanakisa uye mutengo wemakwikwi kuhwina kuvimba kwevatengi vazhinji kumba nekune dzimwe nyika. 95% zvigadzirwa zvinotengeswa kune dzimwe nyika kumisika.

Kana iwe uchida kuziva zvakawanda kana uchida kubvunza, ndapota taurainfo@anebon.com.

Nguva yekutumira: Jan-30-2024