Simbi isina tsvina isarudzo yakakurumbira yekugadzira zviridzwa. Kudzidza nezve simbi isina tsvina kunogona kubatsira vashandisi vezviridzwa kuti vave nehunyanzvi pakusarudza nekushandisa zviridzwa nemazvo.

Simbi isina tsvina, inowanzopfupikiswa seSS, inokwanisa kushingirira pakusangana nemhepo, chiutsi, mvura, uye zvimwe zvinyoro zvinopisa. Zvichakadaro, simbi inokwanisa kuramba mhedzisiro yekuora kwemakemikari kubva kuzvinhu zvakaita seasidhi, alkali, munyu, uye mamwe makemikari etchants, inozivikanwa seasidhi-resistant simbi.

Simbi isina simbi, inozivikanwawo sesimbi isina simbi isina asidi, inogona kumira nemhepo, chiutsi, mvura, uye zvinhu zvinopisa zvinyoro. Zvisinei, zvakakosha kuti uzive kuti haisi yese simbi isina tsvina inopesana nemakemikari ekuora. Kune rumwe rutivi, acid-resistant simbi yakagadzirirwa kurwisa mhedzisiro yemakemikari media senge acid, alkali, uye munyu. Iyo corrosion resistance yesimbi isina tsvina inotarirwa nealloying elements mukati mesimbi.

Common classification

Kazhinji yakakamurwa ne metallographic organisation:

Munzvimbo yesangano remetallographic, simbi yenguva dzose inogara yakakamurwa mumapoka matatu: Austenitic Stainless simbi, ferritic Stainless simbi, uye martensitic Stainless simbi. Aya mapoka anoumba hwaro, uye kubva ipapo, biphase simbi, kunaya-yakaomeswa simbi isina tsvina, uye yakakwirira alloy simbi ine isingasviki 50% iron yakagadziridzwa kuti isangane nezvinodiwa uye kuita zvimwe zvinangwa.

1, Non-Magnetic Stainless Simbi

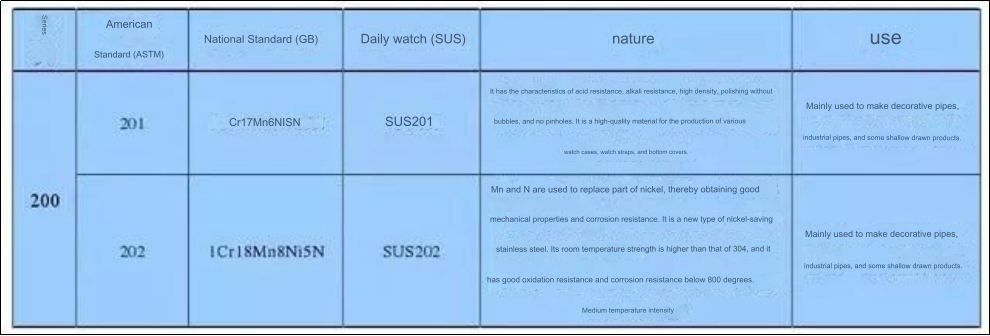

Mhando iyi yesimbi isina tsvina ine crystal structure inozivikanwa se austenitic, iyo inonyanya kusimbiswa kuburikidza nekushanda kunotonhora. Haisi magineti, asi iyo 200 ne300 yakatevedzana nhamba, senge 304, inowanzoshandiswa neAmerican Iron uye Steel Institute kuona iyi simbi.

2, Simbi isina Stainless Yakagadzirwa Kazhinji neSimbi

Iyi mhando yesimbi isina tsvina inonyanya kuve nekristaro chimiro chinodzorwa neferrite (chikamu A), iyo ine magineti. Iyo kazhinji haigone kuomeswa kuburikidza nekudziya, asi kushanda kunotonhora kunogona kukonzera kuwedzera kudiki kwesimba. IAmerican Iron and Steel Institute inotsanangura 430 uye 446 semuenzaniso.

3, Yakaoma Stainless Simbi

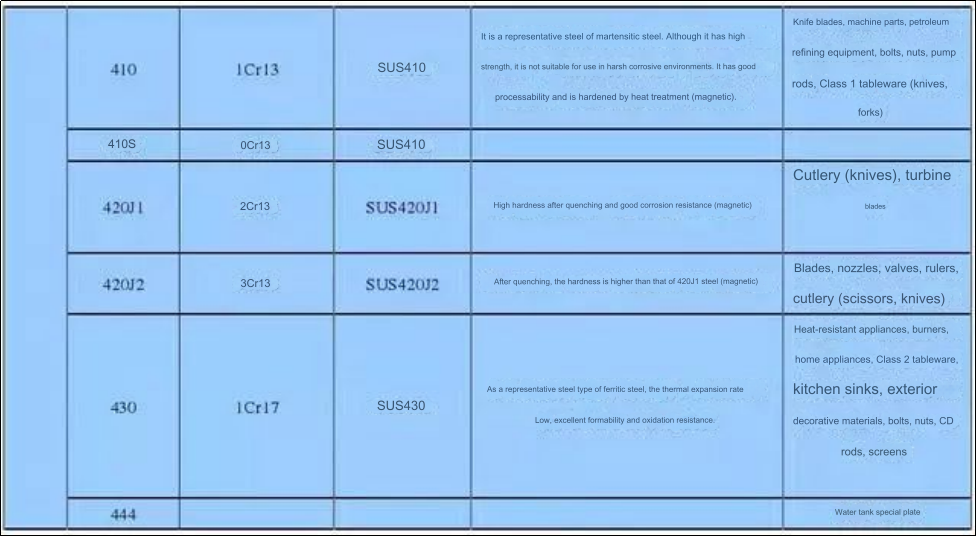

Iyi mhando yesimbi isina tsvina ine crystal structure inonzi martensitic iyo ine magnetic. Iyo mechanical properties inogona kuchinjwa kuburikidza nekupisa kurapwa. The American Iron and Steel Institute inotaura nezvayo se410, 420, uye 440. Martensite inotanga ne austenitic structure pakupisa kwakanyanya uye inogona kushanduka kuita martensite (kureva, inowedzera kuoma) kana ichitonhora nekumhanya kwayo kusvika kune tembiricha yekamuri.

4, Duplex Stainless Simbi

Mhando iyi yesimbi isina tsvina ine musanganiswa we austenitic uye ferritic structures. Chikamu chechikamu chidiki muchimiro chinowanzopfuura 15%, zvichiita kuti ive magineti uye inokwanisa kusimbiswa kuburikidza nekushanda kunotonhora. 329 muenzaniso unozivikanwa werudzi urwu rwesimbi isina tsvina. Kana ichienzaniswa neaustenitic Stainless simbi, duplex simbi inoratidza simba rakakura uye kuwedzera kunoshamisa mukupokana kune intergranular corrosion, chloride stress corrosion, uye point corrosion.

5, Stainless Simbi ine Kunaya Kwemvura Kuomesa Kugona

Iyi mhando yesimbi isina tsvina ine matrix angave austenitic kana martensitic uye inogona kuomeswa kuburikidza nekunaya kwemvura kuoma. The American Iron

uyeSteel Institute inopa mazana matanhatu akateedzana manhamba kune aya masimbi, akadai se630, ayo anozivikanwawo se17-4PH.

Kazhinji, kunze kwealloys, austenitic simbi isina tsvina inopa yakasarudzika corrosion kuramba. Kunzvimbo dzisingaite ngura, ferritic Stainless simbi inogona kushandiswa, nepo munzvimbo dzine ngura zvinyoro-nyoro panodiwa simba rakawanda kana kuoma, martensitic Stainless simbi uye kunaya kwakaomarara simbi isina tsvina ndiyo sarudzo dzakakodzera.

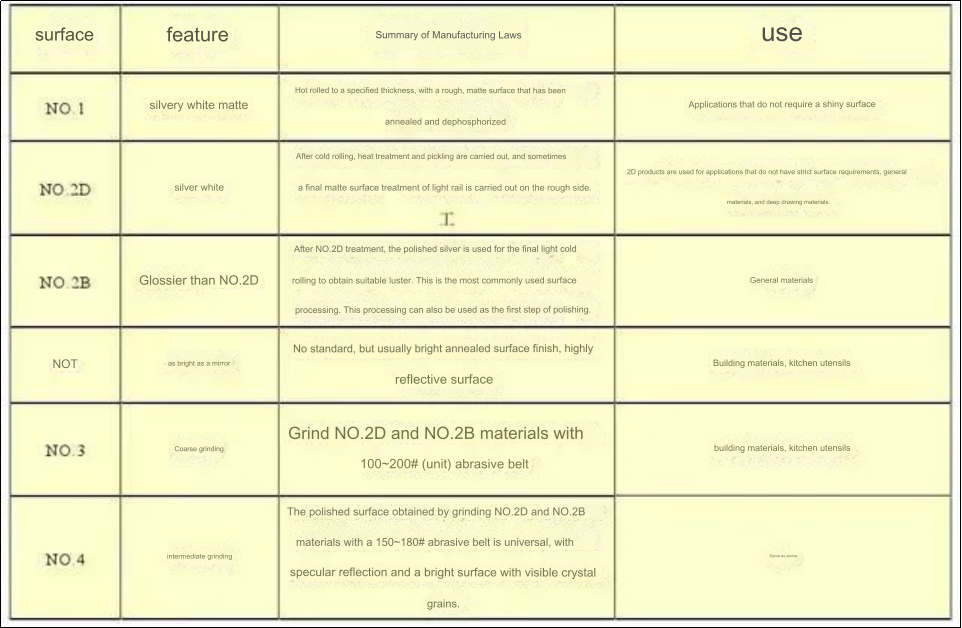

Zvimiro uye nzvimbo dzekushandisa

Surface tekinoroji

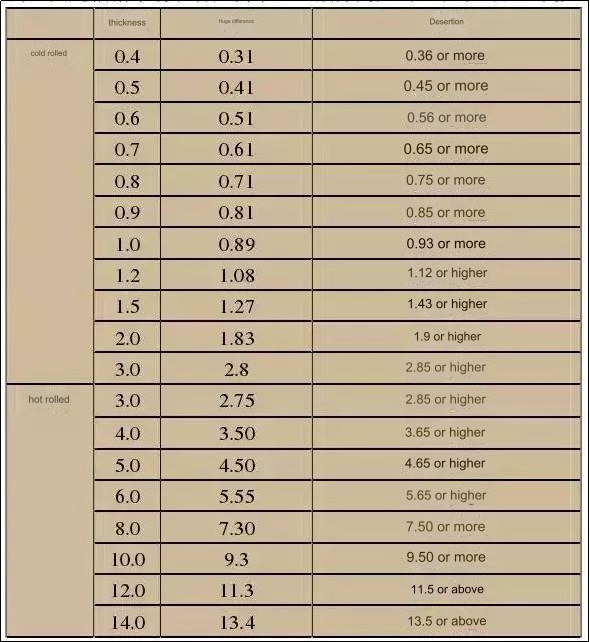

Kusiyanisa ukuru

1, nekuti muchina wesimbi mukugadzira, kupisa kwemupumburu kunoratidzika kushoma, zvichikonzera ukobvu hwekumisikidzwa kwebhodhi kutsauka, kazhinji gobvu pamativi ese ehutete. Pakuyera ukobvu hwebhodhi, nyika inotaura kuti chikamu chepakati chemusoro webhodhi chinofanira kuyerwa.

2, chikonzero chekushivirira chiri maererano nemusika uye kudiwa kwevatengi, kazhinji kwakakamurwa kuva kushivirira kukuru uye kushivirira kudiki: semuenzaniso,

Imhando ipi yesimbi isina tsvina isiri nyore kuita ngura?

Pane zvinhu zvitatu zvakakosha zvinokanganisa simbi isina ngura:

1, zviri mukati me alloying elements.

Impact yeAlloying Elements Kazhinji, simbi ine inokwana 10.5% chromium inoratidza kuramba ngura. Uyezve, simbi isina tsvina ine mazinga epamusoro echromium uye nickel, sezvinowanikwa mu 304 simbi ine 8-10% nickel uye 18-20% chromium, inoratidza yakakwidziridzwa kusaita ngura uye kazhinji inoshingirira kuita ngura mumamiriro ezvinhu chaiwo.

2. Kufurira kweSmelting Process paCorrosion Resistance

Iyo corrosion resistance yesimbi isina simbi inogonawo kukanganiswa nekunyungudika muzvivako zvekugadzira. Miti mikuru-yesimbi isina tsvina yakashongedzerwa tekinoroji yepamberi uye michina yemazuva ano inogona kuve yakagadzikana uye yakavimbika mhando yechigadzirwa kuburikidza nekudzora kwakaringana kwealloying zvinhu, kubviswa kwetsvina kunoshanda, uye kutonga kwakaringana kwekutonhora kwekutonhora kwebillet. Izvi zvinoguma nemhando yepamusoro yemukati uye kuderedza kubatwa ne ngura. Sezvineiwo, zvigayo zvidiki zvesimbi zvine midziyo yechinyakare uye tekinoroji inogona kunetseka kubvisa tsvina panguva yekunyungudutswa, zvichitungamira mukuora kusingadzivisike kwezvigadzirwa zvavo.

3. mamiriro ekunze, mamiriro ekunze akaoma uye anofefetedza mhepo haisi nyore kuita ngura.

Mamiriro ekunze kwezvakatipoteredza, kunyanya yakaoma uye inofefetera zvakanaka, haikurudzire kuumbwa kwe ngura. Sezvineiwo, huwandu hwehunyoro hwemhepo, mamiriro ekunze ekunaya kwenguva refu, kana nharaunda dzine pH yakakwira mazinga anogona kutungamirira kukugadzira ngura. Kunyange 304 simbi isina simbi inova ngura kana ichiiswa pasi pemamiriro ekunze akaipa.

Simbi isina tsvina inoita ngura nzvimbo yekubata nayo?

1. Nzira dzemakemikari

Shandisa nzira dzemakemikari dzakaita sepickling paste kana kupfapfaidza kufambisa kupfuudzazve kwenzvimbo dzine ngura, kugadzira chromium oxide firimu rinodzoreredza kusaita ngura. Kutevera pickling, kunyatsogeza nemvura kwakakosha kubvisa zvese zvinosvibisa uye masara easidhi. Pedzisa nzira yekurapisa nekukwenenzvera nemidziyo yakakodzera uye nekusimbisa nenamo. Kune madiki madiki anotaridza ngura, musanganiswa we1: 1 wepeturu nemafuta unogona kuiswa nemucheka wakachena kubvisa ngura.

2. Mechanical nzira

Kushandiswa kwejecha kuputika, girazi kana ceramic particle shot blast, abrading, brushing, uye polishing inzira dzemuviri dzekubvisa hutachiona hwakasiiwa nekumbokwenenzverwa kana kuita abrading. Chero nzira yekusvibiswa, kunyanya yekunze iron particles, inogona kutungamira mukuora, kunyanya munzvimbo dzakanyorova. Saka, zvinokurudzirwa kuita kucheneswa kwepanyama kwenzvimbo pasi pemamiriro akaoma. Izvo zvakakosha kuti uzive kuti kushandiswa kwemaitiro emuviri kunogona chete kubvisa kusvibiswa kwepamusoro uye hakushandure iyo inherent corrosion resistance yezvinyorwa. Nekuda kweizvozvo, zvinokurudzirwa kupedzisa chirongwa ichi nekukwenenzvera nemidziyo yakakodzera uye nekusimbisa newakisi yekupolisha.

Chiridzwa chinowanzoshandiswa Stainless simbi giredhi uye kuita

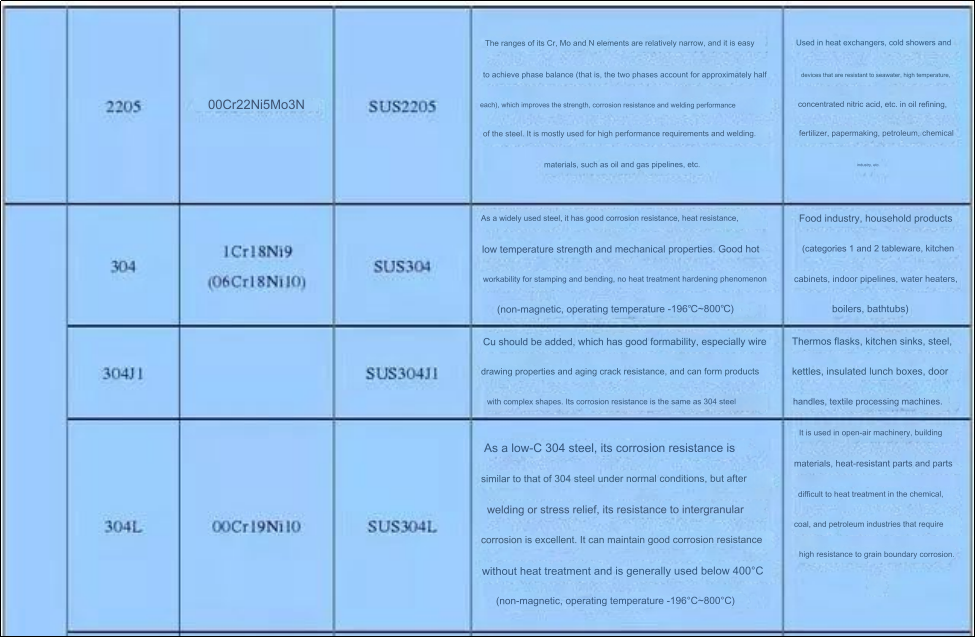

1, 304 simbi isina simbi inoshandiswa zvakanyanya austenitic stainless simbi, yakanakira kugadzira yakadzika-inodhonzwa.cnc machined components, mapaipi ane acid, midziyo, zvikamu zvezvimiro, uye dzakasiyana-siyana midziyo miviri. Pamusoro pezvo, inokwanisa kugadzira isiri-magnetic uye yakaderera-tembiricha michina uye zvikamu.

2, 304L simbi isina tsvina inoshandiswa kugadzirisa intergranular corrosion susceptibility ye304 simbi isina tsvina nekuda kwekunaya kweCr23C6 pasi pemamiriro chaiwo. Mamiriro ekunzwisiswa kweiyi Ultra-yakaderera kabhoni austenitic Stainless simbi inopa yakawedzera kunatsiridza intergranular corrosion resistance kana ichienzaniswa ne304 Stainless simbi. Pamusoro pezvo, nepo ichiratidza simba rakaderera zvishoma, inogovera zvivakwa zvakafanana ne321 simbi isina tsvina uye inonyanya kushandiswa pakunama. Yakanyatsokodzera kugadzirwa kweakasiyana-siyana emidziyo miviri uye inodzivirira corrosion midziyo uye zvikamu zvisingakwanise kurapwa yakasimba mhinduro.

3, 304H simbi isina tsvina. Bazi remukati re304 simbi isina tsvina, kabhoni misa chikamu che 0.04% -0.10%, yakanyanya tembiricha kushanda kuri nani pane 304 simbi isina tsvina.

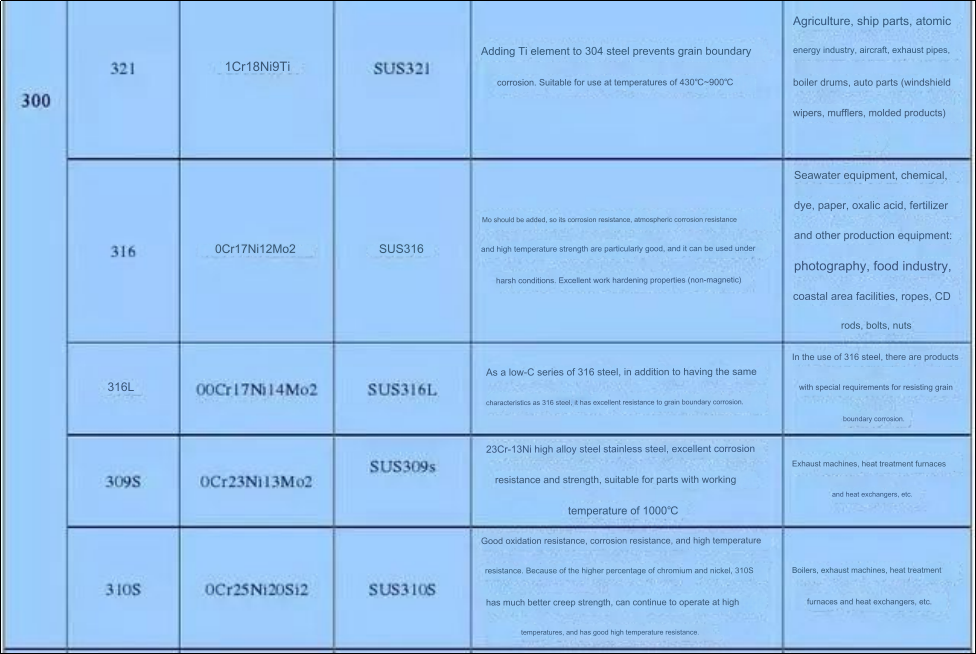

4, 316 simbi isina tsvina. Kuwedzerwa kwe molybdenum pahwaro hwe10Cr18Ni12 simbi inoita kuti simbi ive nekudzivirira kwakanaka kudzikisa midhiya uye point corrosion. Mumvura yegungwa uye mamwe midhiya, corrosion resistance iri nani pane 304 stainless simbi, inonyanya kushandiswa kugadzira pitting resistance materials.

5, 316L simbi isina tsvina. Ultra-yakaderera kabhoni simbi, ine yakanaka kuramba kune sensitized intergranular corrosion, yakakodzera kugadzira welded zvikamu uye midziyo ine gobvu muchinjiko-chikamu saizi, senge ngura isingadziviriri mumidziyo yepetrochemical.

6, 316H simbi isina tsvina. 316 Stainless simbi yemukati bazi, carbon mass chikamu che 0.04% -0.10%, yakakwirira tembiricha kushanda kuri nani pane 316 Stainless simbi.

7, 317 simbi isina tsvina. Pitting uye zvinokambaira kuramba zviri nani pane 316L Stainless simbi, inoshandiswa mukugadzira petrochemical uye organic acid corrosion resistant equipment.

8, 321 Stainless simbi is austenitic Stainless simbi ine titanium kugadzikana. Kuwedzerwa kwetitanium kune chinangwa chekusimudzira kuramba kune intergranular corrosion, uye zvakare inoratidza yakanakira michina zvivakwa pakupisa kwakanyanya. Mumamiriro ezvinhu mazhinji, haikurudzirwe kuti ishandiswe, kunze kwemamiriro ezvinhu akadai sekusangana nekupisa kwakanyanya kana hydrogen-induced corrosion.

9, 347 Stainless simbi is an austenitic Stainless steel alloy iyo yakagadzikana ne niobium. Kuwedzerwa kwe niobium kunoshanda kukwidziridza kuramba kwayo kune intergranular corrosion uye kugona kwayo kushingirira mukuora mu acidic, alkaline, munyu, uye dzimwe hutsinye hwemakemikari nharaunda. Iyo inoratidzawo yakanakisa welding hunhu, ichiita kuti ive yakakodzera kushandiswa seyakaonda-inodzivirira zvinhu uye sesimbi isingadziviriri kupisa. Iyi alloy yesimbi inonyanya kushandiswa mumagetsi ekupisa uye petrochemical maindasitiri kune akasiyana mashandisirwo akadai semidziyo yekugadzira, pombi, zvinopisa kupisa, shafts, uye machubhu echoto muvira remaindasitiri, pamwe nechoto chubhu thermometers.

10, 904L Stainless simbi isimbi yemhando yepamusoro austenitic Stainless steel yakagadzirwa neOUTOKUMPU (Finland) ine nickel inotangira pa24% kusvika 26% uye kabhoni iri pasi pe0.02%. Iyo inozvirumbidza yakasarudzika corrosion resistance uye inoita zvakanaka mune isiri-oxidizing asidhi senge sulfuric acid, acetic acid, formic acid, uye phosphoric acid. Pamusoro pezvo, inoratidza kuramba kwakasimba kune crevice corrosion uye kusagadzikana corrosion. Yakanyatsokodzera kushandiswa ne sulfuric acid munzvimbo dzakasiyana-siyana pazasi 70 ℃ uye inopa yakakwira corrosion resistance muacetic acid uye maasidhi akasanganiswa efomic acid uye acetic acid pane chero kusungwa uye tembiricha pasi pekumanikidzwa kwakajairwa. Pakutanga yakarongedzerwa senge nickel-based alloy pasi peiyo ASMESB-625 standard, yave kudzokororwa sesimbi isina tsvina. Nepo China's 015Cr19Ni26Mo5Cu2 simbi inogovana zvakafanana ne904L, akati wandei vekuEurope vagadziri vezviridzwa vanoshandisa 904L Stainless simbi sechinhu chekutanga kune yavo.cnc zvikamu, senge E+ H misa inoyerera mita yekuyera chubhu uye iyo Rolex wachi yekurinda.

11, 440C simbi isina tsvina. Martensitic Stainless simbi, iyo yakanyanya kuoma musimbi isina tsvina, simbi isina tsvina, kuoma ndeye HRC57. Inonyanya kushandiswa kugadzira nozzles, mabearings, valve spool, chigaro, sleeve, dzinde uye zvichingodaro.

12, 17-4PH simbi isina tsvina inorondedzerwa semartensitic precipitation-yakaoma simbi isina tsvina ine Rockwell kuoma kwe 44. Inopa simba rakasiyana-siyana, kuoma, uye kusagadzikana kwekuora, kunyange zvazvo isingakodzeri kushandiswa pakupisa kunopfuura 300 ° C. Iyi simbi inoratidza kumira kwakanaka kune mamiriro emuchadenga, pamwe neadhiluted acids kana munyu. Kupokana kwayo necorrosion inofananidzwa neiyo ye304 Stainless simbi uye 430 Stainless simbi. Zvikumbiro zvesimbi iyi zvinosanganisira kushandiswa kwayo mukugadzira mapuratifomu ekumahombekombe, turbine blades, mavharuvhu spools, zvigaro, maoko, mavharuvhu madzinde, nezvimwe.

Mumunda wezviridzwa zveunyanzvi, kusarudzwa kweyakajairwa austenitic simbi isina tsvina inotariswa nezvinhu zvakaita sekusiyana-siyana uye mutengo. Iyo inowanzokurudzirwa kutevedzana kwekusarudzwa kwesimbi isina tsvina ndeye 304-304L-316-316L-317-321-347-904L. Zvikurukuru, 317 hainyanyi kushandiswa, 321 haina kufarirwa, 347 inofarirwa yekupisa tembiricha yekudzivirira, uye 904L ndiyo yakasarudzika zvinhu zvezvakati zvinhu zvinogadzirwa nemamwe makambani. Iyo 904L simbi isina tsvina kazhinji haisi iyo yakajairika sarudzo mumagadzirirwo ekugadzira.

Muchiridzwa dhizaini uye kusarudzwa, kazhinji kusangana neakasiyana masisitimu akasiyana, akateedzana, mamakisi esimbi isina tsvina, kusarudzwa kunofanirwa kuve kwakavakirwa pane chaiyo dhizaini midhiya, tembiricha, kudzvanywa, kushushikana kwezvikamu, ngura, mutengo uye zvimwe zvinhu zvekufunga.

Anebon yekutsvaga uye bhizinesi chinangwa ndecheku "Gara tichigutsa zvinodiwa nevatengi vedu". Anebon ramba uchigadzira uye dhizaini nekugadzira zvinhu zvemhando yepamusoro kune ese edu echinyakare uye matsva tarisiro uye nekuona kuhwina-kuhwina tarisiro kune mutengi wedu sezvatinogadzirisa yakakwirira-chaiyo extrusion profiles,cnc inoshandura zvikamu zvealuminiumuyearuminiyamu milling zvikamukune vatengi. Anebon nemaoko akazaruka, yakakoka vatengi vese vanofarira kushanyira webhusaiti yedu kana kutibata isu zvakananga kuti uwane rumwe ruzivo.

Factory Yakagadzirirwa China CNC Machine uye CNC Engraving Machine, chigadzirwa cheAnebon chinozivikanwa zvakanyanya uye chinovimbwa nevashandisi uye chinogona kusangana chichienderera mberi nekuvandudza hupfumi uye magariro zvinodiwa. Anebon inogashira vatengi vatsva uye vekare kubva kumativi ese ehupenyu kuti tibate isu kune ramangwana rehukama bhizinesi uye kuwana kubudirira pamwe chete!

Nguva yekutumira: Jan-23-2024