HV, HB, uye HRC ese zviyero zvekuomarara zvinoshandiswa mukuyedzwa kwezvinhu. Ngativaparadze:

1)HV Kuoma (Vickers Hardness): HV kuomarara chiyero chekuramba kwechinhu kune indentation. Inotaridzirwa nekuisa mutoro unozivikanwa pamusoro pezvinhu uchishandisa indenter yedhaimondi uye kuyera saizi yeinoguma indentation. HV kuomarara inoratidzwa muzvikamu zveVickers kuomarara (HV) uye inowanzoshandiswa kuzvinhu zvitete, machira, uye zvikamu zvidiki.

2)HB Kuoma (Brinell Hardness): HB kuoma chimwe chiyero chekuramba kwechinhu kune indentation. Inosanganisira kuisa mutoro unozivikanwa kune zvinyorwa uchishandisa indenter yesimbi yakaomeswa uye kuyera dhayamita yeinoguma indentation. HB kuomarara inoratidzwa mumayuniti eBrinell kuomarara (HB) uye inowanzo shandiswa pazvinhu zvakakura uye zvakakura, zvinosanganisira simbi nemaaloyi.

3)HRC Kuoma (Rockwell Hardness): HRC kuoma chiyero chekuramba kwechinhu kupinza kana kupinda. Inoshandisa zviyero zvakasiyana (A, B, C, nezvimwewo) zvichibva pane chaiyo nzira yekuyedza uye nemhando yeindenter inoshandiswa (dhaimani koni kana simbi yakaoma bhora). Chikero cheHRC chinowanzo shandiswa kuyera kuoma kwezvinhu zvesimbi. Iko kukosha kwekuoma kunomiririrwa senhamba pachiyero cheHRC, senge HRC 50.

Inowanzo shandiswa HV-HB-HRC kuomarara tafura yekuenzanisa:

| Yakajairwa ferrous simbi kuomarara tafura yekuenzanisa (inenge simba shanduko) | ||||

| Hukukutu classification | Kusimba simba N/mm2 | |||

| Rockwell | Vickers | Brinell | ||

| HRC | HRA | HV | HB | |

| 17 | - | 211 | 211 | 710 |

| 17.5 | - | 214 | 214 | 715 |

| 18 | - | 216 | 216 | 725 |

| 18.5 | - | 218 | 218 | 730 |

| 19 | - | 221 | 220 | 735 |

| 19.5 | - | 223 | 222 | 745 |

| 20 | - | 226 | 225 | 750 |

| 20.5 | - | 229 | 227 | 760 |

| 21 | - | 231 | 229 | 765 |

| 21.5 | - | 234 | 232 | 775 |

| 22 | - | 237 | 234 | 785 |

| 22.5 | - | 240 | 237 | 790 |

| 23 | - | 243 | 240 | 800 |

| 23.5 | - | 246 | 242 | 810 |

| 24 | - | 249 | 245 | 820 |

| 24.5 | - | 252 | 248 | 830 |

| 25 | - | 255 | 251 | 835 |

| 25.5 | - | 258 | 254 | 850 |

| 26 | - | 261 | 257 | 860 |

| 26.5 | - | 264 | 260 | 870 |

| 27 | - | 268 | 263 | 880 |

| 27.5 | - | 271 | 266 | 890 |

| 28 | - | 274 | 269 | 900 |

| 28.5 | - | 278 | 273 | 910 |

| 29 | - | 281 | 276 | 920 |

| 29.5 | - | 285 | 280 | 935 |

| 30 | - | 289 | 283 | 950 |

| 30.5 | - | 292 | 287 | 960 |

| 31 | - | 296 | 291 | 970 |

| 31.5 | - | 300 | 294 | 980 |

| 32 | - | 304 | 298 | 995 |

| 32.5 | - | 308 | 302 | 1010 |

| 33 | - | 312 | 306 | 1020 |

| 33.5 | - | 316 | 310 | 1035 |

| 34 | - | 320 | 314 | 1050 |

| 34.5 | - | 324 | 318 | 1065 |

| 35 | - | 329 | 323 | 1080 |

| 35.5 | - | 333 | 327 | 1095 |

| 36 | - | 338 | 332 | 1110 |

| 36.5 | - | 342 | 336 | 1125 |

| 37 | - | 347 | 341 | 1140 |

| 37.5 | - | 352 | 345 | 1160 |

| 38 | - | 357 | 350 | 1175 |

| 38.5 | - | 362 | 355 | 1190 |

| 39 | 70 | 367 | 360 | 1210 |

| 39.5 | 70.3 | 372 | 365 | 1225 |

| 40 | 70.8 | 382 | 375 | 1260 |

| 40.5 | 70.5 | 377 | 370 | 1245 |

| 41 | 71.1 | 388 | 380 | 1280 |

| 41.5 | 71.3 | 393 | 385 | 1300 |

| 42 | 71.6 | 399 | 391 | 1320 |

| 42.5 | 71.8 | 405 | 396 | 1340 |

| 43 | 72.1 | 411 | 401 | 1360 |

| 43.5 | 72.4 | 417 | 407 | 1385 |

| 44 | 72.6 | 423 | 413 | 1405 |

| 44.5 | 72.9 | 429 | 418 | 1430 |

| 45 | 73.2 | 436 | 424 | 1450 |

| 45.5 | 73.4 | 443 | 430 | 1475 |

| 46 | 73.7 | 449 | 436 | 1500 |

| 46.5 | 73.9 | 456 | 442 | 1525 |

| 47 | 74.2 | 463 | 449 | 1550 |

| 47.5 | 74.5 | 470 | 455 | 1575 |

| 48 | 74.7 | 478 | 461 | 1605 |

| 48.5 | 75 | 485 | 468 | 1630 |

| 49 | 75.3 | 493 | 474 | 1660 |

| 49.5 | 75.5 | 501 | 481 | 1690 |

| 50 | 75.8 | 509 | 488 | 1720 |

| 50.5 | 76.1 | 517 | 494 | 1750 |

| 51 | 76.3 | 525 | 501 | 1780 |

| 51.5 | 76.6 | 534 | - | 1815 |

| 52 | 76.9 | 543 | - | 1850 |

| 52.5 | 77.1 | 551 | - | 1885 |

| 53 | 77.4 | 561 | - | 1920 |

| 53.5 | 77.7 | 570 | - | 1955 |

| 54 | 77.9 | 579 | - | 1995 |

| 54.5 | 78.2 | 589 | - | 2035 |

| 55 | 78.5 | 599 | - | 2075 |

| 55.5 | 78.7 | 609 | - | 2115 |

| 56 | 79 | 620 | - | 2160 |

| 56.5 | 79.3 | 631 | - | 2205 |

| 57 | 79.5 | 642 | - | 2250 |

| 57.5 | 79.8 | 653 | - | 2295 |

| 58 | 80.1 | 664 | - | 2345 |

| 58.5 | 80.3 | 676 | - | 2395 |

| 59 | 80.6 | 688 | - | 2450 |

| 59.5 | 80.9 | 700 | - | 2500 |

| 60 | 81.2 | 713 | - | 2555 |

| 60.5 | 81.4 | 726 | - | - |

| 61 | 81.7 | 739 | - | - |

| 61.5 | 82 | 752 | - | - |

| 62 | 82.2 | 766 | - | - |

| 62.5 | 82.5 | 780 | - | - |

| 63 | 82.8 | 795 | - | - |

| 63.5 | 83.1 | 810 | - | - |

| 64 | 83.3 | 825 | - | - |

| 64.5 | 83.6 | 840 | - | - |

| 65 | 83.9 | 856 | - | - |

| 65.5 | 84.1 | 872 | - | - |

| 66 | 84.4 | 889 | - | - |

| 66.5 | 84.7 | 906 | - | - |

| 67 | 85 | 923 | - | - |

| 67.5 | 85.2 | 941 | - | - |

| 68 | 85.5 | 959 | - | - |

| 68.5 | 85.8 | 978 | - | - |

| 69 | 86.1 | 997 | - | - |

| 69.5 | 86.3 | 1017 | - | - |

| 70 | 86.6 | 1037 | - | - |

HRC/HB Mazano Anoda Kushandurwa

Kuoma kwacho kwakakwira kupfuura 20HRC, 1HRC≈10HB,

Hukukutu hwakaderera pane 20HRC, 1HRC≈11.5HB.

Mazano: Pakucheka kugadzirwa, inogona kunyatso kushandurwa zvakafanana 1HRC≈10HB (kuoma kwechigadzirwa chebasa chine shanduko yekuchinja)

Kuoma kwezvinhu zvesimbi

Kuomarara zvinoreva kugona kwechinhu kuramba deformation yenzvimbo, kunyanya deformation yepurasitiki, indentation kana kukwenya. Indekisi yekuyera kupfava nekuoma kwezvinhu.

Zvinoenderana neakasiyana maitiro ekuyedza, kuomarara kwakakamurwa kuva marudzi matatu.

①Scratch kuoma. Inonyanya kushandiswa kuenzanisa kupfava uye kuoma kwemaminerari akasiyana. Nzira yacho ndeyekusarudza tsvimbo ine mugumo wakaoma uye imwe mugumo yakapfava, kupfuudza zvinhu kuti zviedzwe pamwe chete netsvimbo, uye kuona kuoma kwezvinhu kuti zviedzwe maererano nechinzvimbo chekukwenya. Mukutaura kwehunhu, zvinhu zvakaoma zvinogadzira makwara akareba uye zvinhu zvakapfava zvinogadzira zvikwambo zvipfupi.

②Indentation kuoma. Inonyanya kushandiswa kumidziyo yesimbi, iyo nzira ndeye kushandisa imwe mutoro kudzvanya iyo yakatsanangurwa indenter muzvinhu kuti zviedzwe, uye enzanisa kupfava uye kuoma kwezvinhu kuti zviedzwe nehukuru hwenzvimbo yepurasitiki deformation pamusoro zvinhu. Nekuda kwekusiyana kweindenter, kuremerwa uye kuremerwa kwenguva, kune akawanda marudzi ekuomarara kwemukati, kunyanya kusanganisira Brinell kuomarara, Rockwell kuomarara, Vickers kuomarara uye microhardness.

③Rebound kuoma. Inonyanya kushandiswa kumidziyo yesimbi, iyo nzira ndeyekugadzira nyundo diki diki inodonha yakasununguka kubva kune imwe nzvimbo kureba kuti ibate sampu yechinhu chinofanirwa kuongororwa, uye kushandisa huwandu hwesimba rekumanikidza rakachengetwa (uye rozoburitswa) mumuenzaniso panguva kukanganisa (kuburikidza nekudzoka kwesando diki) svetuka urefu hwechiyero) kuona kuoma kwechinhu.

Iyo yakajairika Brinell kuomarara, Rockwell kuomarara uye Vickers kuomarara kwesimbi zvinhu ndezvekuomarara kwemukati. Iko kuomarara kukosha kunoratidza kugona kwechinhu chepamusoro kurwisa deformation yepurasitiki inokonzerwa nechimwe chinhu chiri kudzvanywa mukati; C) kuyera kuomarara, uye kukosha kwekuomarara kunomiririra saizi yeiyo elastic deformation basa resimbi.

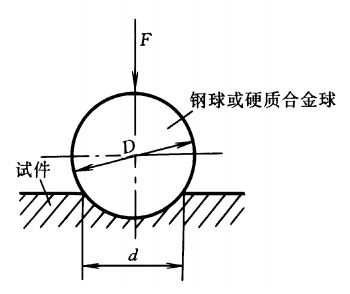

Brinell Hardness

Shandisa bhora resimbi rakadzimwa kana bhora rakaomarara rine dhayamita yeD se indenter, dzvanya mukati mechikamu chebvunzo neiyo inowirirana test force F, uye mushure menguva yakatarwa yekubata, bvisa simba rekuyedza kuti uwane indentation ne. dhayamita yed. Gurai simba rekuedza nepamusoro penzvimbo ye indentation, uye kukosha kunoguma ndiko kukosha kwekuoma kweBrinell, uye chiratidzo chinomiririrwa neHBS kana HBW.

Musiyano uripo pakati peHBS neHBW ndiwo mutsauko mune indenter. HBS inoreva kuti indenter ibhora resimbi rakaomarara, rinoshandiswa kuyera zvinhu zvine Brinell kuomarara ukoshi pasi pe450, sesimbi yakapfava, grey cast iron uye non-ferrous metals. HBW zvinoreva kuti indenter is cemented carbide, iyo inoshandiswa kuyera zvinhu neBrinell hardness value iri pasi pe650.

Kune imwechete test block, kana mamwe mamiriro ebvunzo akanyatsofanana, mhedzisiro yebvunzo mbiri dzakasiyana, uye kukosha kweHBW kunowanzo hukuru kupfuura kukosha kweHBS, uye hapana mutemo wehuwandu wekutevera.

Mushure megore ra2003, nyika yangu yakatora zvakangofanana zviyero zvepasi rose, yakadzima simbi bhora indenters, uye ese akashandiswa carbide bhora misoro. Naizvozvo, HBS inomiswa, uye HBW inoshandiswa kumiririra chiratidzo chekuoma kweBrinell. Kazhinji, kuomarara kweBrinell kunongoratidzwa muHB, zvichireva HBW. Nekudaro, HBS ichiri kuonekwa nguva nenguva mumapepa emabhuku.

Iyo Brinell kuomarara nzira yekuyera yakanakira simbi yakakandwa, isina-ferrous alloys, akasiyana annealed uye kudzimwa uye kudziya simbi, uye haina kukodzera kuyedza samples kana.cnc kushandura zvikamuidzo dzakaomarara, diki, dzakatetepa, kana dzisingatenderi mapindiro makuru pamusoro.

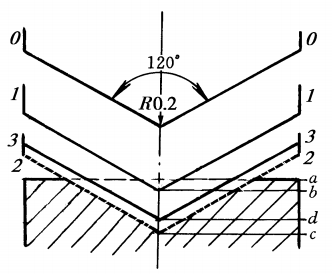

Rockwell Hardness

Shandisa koni yedhaimondi ine koni ye120 ° kana Ø1.588mm uye Ø3.176mm yakadzima mabhora esimbi se indenter uye mutoro kushandira pamwe nayo. Mutoro wekutanga ndeye 10kgf uye mutoro wose i60, 100 kana 150kgf (kureva, mutoro wekutanga pamwe nemutoro mukuru). Kuomarara kunoratidzwa nemusiyano pakati pekudzika kwemukati kana mutoro mukuru uchibviswa uye kudzika kwemukati kana mutoro mukuru uchichengetwa uye kudzika kwemukati pasi pemutoro wekutanga mushure mekunge mutoro wese waiswa.

Iyo Rockwell kuomarara bvunzo inoshandisa matatu bvunzo masimba uye matatu indenters. Kune 9 musanganiswa wavo, unoenderana ne9 zviyero zveRockwell kuoma. Kushandiswa kweaya vatongi 9 kunovhara zvinenge zvese zvinowanzo shandiswa simbi zvinhu. Kune matatu anowanzo shandiswa HRA, HRB uye HRC, pakati peiyo HRC ndiyo inonyanya kushandiswa.

Inowanzo shandiswa Rockwell kuomarara bvunzo yakatarwa tafura:

| Kuoma | | | Kuoma | |

| | | | | Carbide, carbide, |

| | | | | Annealed, normalized simbi, aluminium alloy |

| | | | | simbi yakaoma, yakadzimwa uye yakanyoroveswa, yakadzika |

Kuwanda kwekushandiswa kwechiyero cheHRC ndeye 20 ~ 70HRC. Kana kukosha kwekuoma kuri pasi pe20HRC, nekuti iyo conicalaluminium cnc machining chikamuyeindenter inodzvanywa zvakanyanya, kunzwa kunodzikira, uye chiyero cheHRB chinofanira kushandiswa pachinzvimbo; apo kuoma kwemuenzaniso kwakakura kudarika 67HRC, kumanikidzwa pamuromo we indenter yakakura zvikuru, uye dhaimondi rinokuvara nyore. Hupenyu hweindenter huchapfupikiswa zvakanyanya, saka chiyero cheHRA chinofanirwa kushandiswa pachinzvimbo.

Iyo Rockwell kuomarara bvunzo iri nyore, inokurumidza, uye diki indentation, uye inogona kuyedza pamusoro pezvigadzirwa zvakapedzwa uye dzakaoma uye dzakatetepa workpieces. Nekuda kwediki indentation, kune zvigadzirwa zvine chimiro chisina kuenzana uye kuoma, kukosha kwekuoma kunochinja zvakanyanya, uye iko kurongeka hakuna kukwirira seBrinell kuomarara. Rockwell kuomarara kunoshandiswa kuona kuoma kwesimbi, asiri-ferrous simbi, hard alloys, nezvimwe.

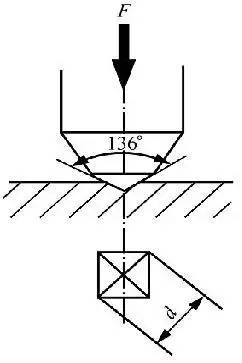

Vickers Hardness Vickers Hardness

Nheyo yeVickers kuomarara kuyerwa kwakafanana neiyo yeBrinell kuomarara. Shandisa dhaimondi sikweya piramidhi indenter ine kona inosanganisirwa ye136 ° kudzvanya pamusoro pechinhu neyakatsanangurwa bvunzo simba F, uye bvisa simba rekuyedza mushure mekuchengetedza nguva yakatarwa. Kuomarara kunoratidzwa neavhareji yekumanikidza pane yeyuniti nzvimbo yeskweya piramidi indentation. Kukosha, chiratidzo chechiratidzo iHV.

Iyo Vickers kuomarara kuyerwa kwakakura, uye inogona kuyera zvinhu nekuomarara kubva pa10 kusvika 1000HV. Iyo indentation idiki, uye inowanzo shandiswa kuyera zvinhu zvakatetepa uye pamusoro akaomeswa akaturikidzana senge carburizing uye nitriding.

Leeb Kuoma Leeb Kuoma

Shandisa muviri unokanganisa uine humwe huremu hwetungsten carbide bhora musoro kubata pamusoro peyeyedzo chidimbu pasi pechiito cheimwe simba, wobva wadzokorodza. Nekuda kwekuoma kwakasiyana kwezvinhu, iyo rebound kumhanya mushure mekuita kwakasiyanawo. Magineti echigarire akaiswa pane inokanganisa mudziyo. Kana iyo inokanganisa muviri inofamba ichikwira nekudzika, peripheral coil inopinza chiratidzo chemagetsi chinoenderana nekumhanya, uye wochishandura kuita kukosha kweLeeb kuburikidza nemagetsi edunhu. Chiratidzo chakanyorwa kuti HL.

Leeb hardness tester haidi worktable, uye kuoma kwayo sensor iduku sepeni, iyo inogona kushandiswa zvakananga nemaoko, uye inogona kuonekwa nyore nyore kana yakakura, inorema workpiece kana workpiece ine yakaoma geometric dimensions.

Imwe bhenefiti yeLeeb kuomarara ndeyokuti ine zvishoma kukuvadza pamusoro pechigadzirwa, uye dzimwe nguva inogona kushandiswa seyedzo isingaparadzi; yakasarudzika mukuomarara bvunzo munzvimbo dzese, nzvimbo dzakamanikana uye dzakakoshazvikamu zvealuminium.

Anebon inoomerera pane dzidziso "Kutendeseka, kubishaira, kushambadza, kuvandudza" kuwana mhinduro nyowani nguva dzose. Anebon inotarisa tarisiro, kubudirira sekubudirira kwayo pachako. Rega Anebon ivake rakabudirira remangwana ruoko muruoko rwemhangura dzakagadzirwa zvikamu uye Complex titanium cnc zvikamu / stamping accessories. Anebon ikozvino ine huwandu hwezvinhu zvekutengesa pamwe nekutengesa mutengo ndiyo mukana wedu. Kugamuchirwa kubvunza nezve zvigadzirwa zveAnebon.

Trending Products China CNC Machinging Chikamu uye Precision Chikamu, chaizvo kana chimwe chezvinhu izvi chingave chekufarira kwauri, ndapota tizivise. Anebon ichafara kukupa kotesheni pawatambira zvinotsanangurwa zvemunhu. Anebon ine yedu pachedu nyanzvi yeR&D mainjiniya kuti asangane nechero zvinodikanwa. Anebon inotarisira kugamuchira kubvunza kwako munguva pfupi uye ndinovimba kuve nemukana wekushanda newe mukati mune ramangwana. Kugamuchirwa kuti utarise sangano reAnebon.

Nguva yekutumira: May-18-2023