Chii chinonzi CNC chishandiso?

Iko kusanganiswa kwemidziyo yekugadzira yepamusoro uye yepamusoro-inoshanda CNC yekucheka maturusi anogona kupa kutamba kwakazara kune kwayo kwakakodzera kuita uye kuwana yakanaka mabhenefiti ehupfumi. Nekukurumidza kusimudzira kwekucheka maturusi emidziyo, akasiyana siyana ekucheka maturusi emidziyo akavandudza zvakanyanya iwo emuviri, michina zvivakwa uye kucheka mashandiro, uye yavo yekushandisa yakaramba ichiwedzera.

Iko kuumbwa kwezvishandiso zveCNC?

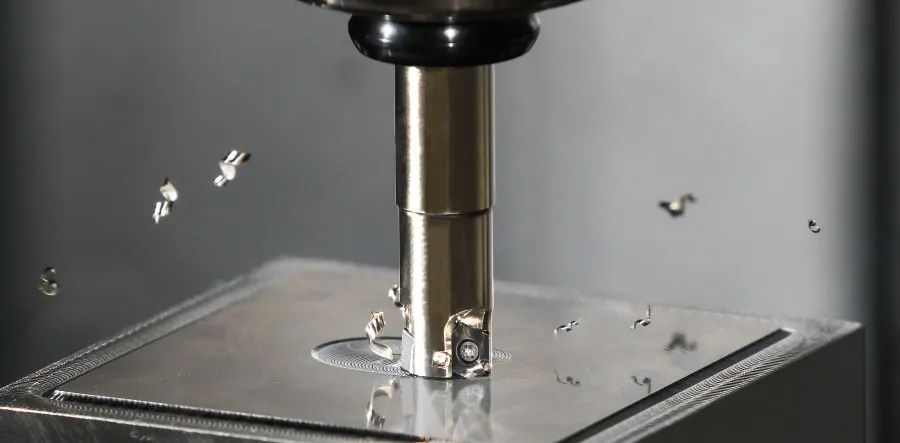

CNC (Computer Numerical Control) maturusi maturusi emuchina anoshandiswa nemirairo yakarongwa yakavharwa panzvimbo yekuchengetera, senge komputa. Zvishandiso izvi zvinoshandisa system inodzorwa nekombuta kuita mabasa emuchina chaiwo, sekucheka, kuchera, kugaya, uye kugadzira. Iwo maturusi anoshandiswa mukugadzira maitiro, kunyanya mumaindasitiri akadai seaerospace, mota, zvekurapa, uye simbi.

CNC zvishandiso zvinosanganisira huwandu hwemakina, sengeCNC kugayamichina, CNClathe process, CNC routers, CNC plasma cutters, uye CNC laser cutters. Zvishandiso izvi zvinoshanda nekufambisa chishandiso chekucheka kana workpiece mumatemo matatu kana anopfuura uchishandisa komputa nhamba yekudzora.

Zvishandiso zveCNC zvinozivikanwa nekurongeka, kurongeka, uye kudzokorora, izvo zvinoita kuti ive yakanakira kugadzira zvikamu zvakaoma uye zvikamu zvine kushivirira kwakasimba. Ivo zvakare vanokwanisa kugadzira zvigadzirwa zvemhando yepamusoro nekukurumidza kupfuura zvechinyakare zvemanyorero muchina, izvo zvinobatsira kuwedzera kubereka uye kugona mukugadzira.

Ndezvipi zvakakosha zvivakwa zvinofanirwa kuve neCNC zvishandiso?

1. Kuoma: CNC zvishandiso zvekushandisa zvinofanirwa kuve zvakaoma kuti zvirambe kupera uye kubvarura panguva yekugadzira machining.

2. Kuoma: CNC zvishandiso zvekushandisa zvinofanirwa kusimba zvakakwana kuti zvimirire kukanganiswa uye kuvhunduka mitoro.

3. Kupisa kupikisa: CNC zvishandiso zvekushandisa zvinofanirwa kutsungirira tembiricha yakakwira inogadzirwa panguva yekugadzira machining pasina kurasikirwa nesimba kana kusimba.

4. Pfeka kuramba: CNC zvishandiso zvekushandisa zvinofanirwa kupesana neabrasive kupfeka kunokonzerwa nekusangana neiyo workpiece.

5. Kugadzikana kwemakemikari: CNC zvishandiso zvekushandisa zvinofanira kunge zvakagadzikana nemakemikari kuti zvidzivise kuora uye mamwe maitiro ekukuvadza kwemakemikari.

6. Machinability: CNC zvishandiso zvekushandisa zvinofanirwa kunge zviri nyore kugadzira uye kuumba mune inodiwa fomu.

7. Mari-inoshanda: CNC zvishandiso zvekushandisa zvinofanirwa kuve zvisingadhuri uye zvisingadhuri, zvichifunga nezvekuita kwavo uye hupenyu hurefu.

Mhando, zvivakwa, maitiro uye mashandisirwo ekucheka maturusi emidziyo

Rudzi rwega rwega rwezvinhu rune zvimiro zvarwo, maitiro, uye mashandisiro. Heano mamwe akajairika ekucheka maturusi emidziyo, pamwe neayo zvivakwa uye mashandisirwo:

1. Simbi Inomhanya-mhanya (HSS):

HSS chinhu chinowanzo shandiswa chekucheka chishandiso, chakagadzirwa kubva musanganiswa wesimbi, tungsten, molybdenum, uye zvimwe zvinhu. Iyo inozivikanwa nekuoma kwayo kwepamusoro, kusapfeka, uye kuomarara, zvichiita kuti ive yakakodzera kugadzira zvinhu zvakasiyana siyana, zvinosanganisira simbi, aruminiyamu alloys, uye mapurasitiki.

2. Carbide:

Carbide chinhu chakaumbwa chakagadzirwa kubva musanganiswa we tungsten carbide zvimedu uye simbi inosungira, senge cobalt. Iyo inozivikanwa nekuomarara kwayo kwakasarudzika, kusapfeka, uye kupisa kupisa, zvichiita kuti ive yakakodzera kugadzira zvinhu zvakaomarara, sesimbi isina tsvina, simbi yakakandwa, uye alloys anopisa.

3. Ceramic:

Ceramic yekucheka maturusi anogadzirwa kubva kune akasiyana eceramic zvinhu, senge aluminium oxide, silicon nitride, uye zirconia. Ivo vanozivikanwa nekuomarara kwazvo, kusapfeka, uye kugadzikana kwemakemikari, zvichiita kuti vakwanise kugadzira zvinhu zvakaoma uye zvinokwesha, senge ceramics, composites, uye superalloys.

4. Cubic Boron Nitride (CBN):

CBN chinhu chekugadzira chakagadzirwa kubva kucubic boron nitride makristasi. Iyo inozivikanwa nekuoma kwayo kunoshamisa, kusapfeka, uye kupisa kupisa, zvichiita kuti ive yakakodzera kugadzira simbi dzakaomeswa nezvimwe zvinhu zvakaoma kugadzira uchishandisa zvimwe zvekucheka maturusi.

5. Dhaimondi:

Maturusi ekucheka madhaimani anogadzirwa kubva kumadhaimondi echisikigo kana ekugadzira. Ivo vanozivikanwa nekuomarara kwavo kunoshamisa, kusapfeka, uye kupisa kupisa, zvichiita kuti vakwanise kugadzira simbi dzisina-ferrous, macomposites, uye zvimwe zvinhu zvakaoma uye zvinopwanya.

Kune zvakare rudzi rwakakosha rwechishandiso chinonzi coated tool.

Kazhinji, zvinhu zviri pamusoro zvinoshandiswa semachira, uye zvinonyanya kushandiswa muCNC muchina maturusi.

Chishandiso chakavharidzirwa chishandiso chine dhata rakatetepa rezvinhu zvakaiswa pamusoro payo kuvandudza kushanda kwayo uye kuwedzera hupenyu hwayo. Iyo yekupfekedza zvinhu inosarudzwa zvichibva pane yaitarisirwa kushandiswa, uye zvakajairika coating zvinhu zvinosanganisira titanium nitride (TiN), titanium carboni (TiCN), uye diamond-senge kabhoni (DLC).

Mabatiro anogona kuvandudza kushanda kwechishandiso nenzira dzakasiyana, sekudzikisa kukweshera uye kupfeka, kuwedzera kuomarara uye kuoma, uye kuvandudza kurambana nekuora uye kukuvara kwemakemikari. Semuenzaniso, TiN-coated drill bit inogona kugara kusvika katatu kureba kupfuura isina kuvharwa, uye TiCN-yakavharidzirwa kupera kweguyo inogona kucheka nezvinhu zvakaoma nekupfeka kushoma.

Maturusi akavharidzirwa anowanzo shandiswa mumaindasitiri akadai sekugadzira, aerospace, mota, uye kugadzira michina yekurapa. Anogona kushandiswa kucheka, kuchera, kugaya, kugaya, uye mamwe machining mashandiro.

Kusarudzwa kwemisimboti yeCNC chishandiso zvinhu

Kusarudzwa kweCNC zvishandiso zvekushandisa chinhu chakakosha chekutarisa paunenge uchigadzira uye kugadzira chaikokushandura zvikamu. Kusarudzwa kwechigadzirwa chemidziyo kunoenderana nezvakati wandei, zvinosanganisira mhando yezvinhu zviri kugadzirwa, mashandiro emuchina, uye kupera kwaunoda.

Heano mamwe emisimboti yesarudzo yeCNC zvishandiso zvekushandisa:

1. Kuoma:Chishandiso chemidziyo chinofanira kunge chakaoma zvakakwana kuti chimirire masimba uye tembiricha inogadzirwa panguva yekugadzira. Hurema hunowanzoyerwa pachiyero cheRockwell C kana chiyero cheVickers.

2. Kuoma:Chishandiso chacho chinofanirawo kuva chakasimba zvakakwana kuti chirambe kutsemuka uye kutsemuka. Kuoma kunowanzoyerwa nekusimba kwesimba kana kuomarara kwekutsemuka.

3. Kuramba kupfeka:Iyo yemidziyo yemidziyo inofanirwa kuve neyakanaka kupfeka kuramba kuchengetedza kwayo yekucheka uye kudzivirira kutadza kwechishandiso. Kupfeka kupikisa kwechinhu kunowanzoyerwa nehuwandu hwezvinhu zvinobviswa kubva pachishandiso panguva yeimwe chiyero chekugadzira.

4. Thermal conductivity: Chishandiso chekushandisa chinofanira kunge chine yakanaka yekupisa conductivity yekubvisa kupisa kunogadzirwa panguva yekugadzira. Izvi zvinobatsira kudzivirira kutadza kwechishandiso uye kuchengetedza dimensional kurongeka.

5. Kugadzikana kwemakemikari:Iyo midziyo yemidziyo inofanirwa kuve yakagadzikana nemakemikari kudzivirira kuita kwemakemikari neiyo workpiece zvinhu.

6. Mutengo:Mutengo wemidziyo yekushandisa zvakare yakakosha kutariswa, kunyanya kune yakakwira-vhoriyamu yekugadzira inomhanya.

Zvishandiso zvakajairika zvinoshandiswa CNC zvishandiso zvinosanganisira carbide, high-speed simbi, ceramic, uye diamond. Kusarudzwa kwechishandiso chekushandisa kunoenderana nechaiyo machining mashandiro uye inodiwa kupera, pamwe nemidziyo iri kugadzirwa uye midziyo iripo.

1)Chishandiso chekucheka chinoenderana nemakanika echinhu chakagadzirwa

Kufananidza iyo yekucheka maturusi zvinhu kune mechaniki zvivakwa zvechigadzirwa chinhu chakakosha kufunga muCNC machining. Mamichina echinhu chakagadzirwa anosanganisira kuoma kwayo, kuoma, uye ductility, pakati pezvimwe. Kusarudza chishandiso chekucheka chinoenderana kana chinozadzisa ma mechanika echinhu chakagadzirwa kunogona kuvandudza machining mashandiro uye kugona, kuderedza kupfeka kwezvishandiso, uye kugadzirisa kunaka kwechikamu chakapedzwa.

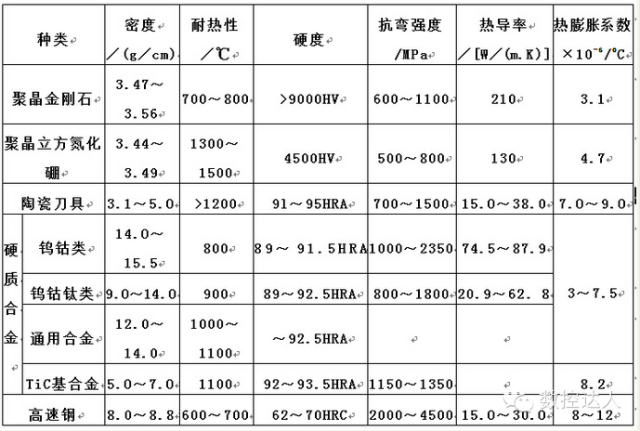

① Kurongeka kwechishandiso chekuoma kwezvinhu ndeichi: dhaimondi chishandiso> cubic boron nitride chishandiso>ceramic chishandiso> tungsten carbide> yakakwirira-kumhanya simbi.

② Kurongeka kwekukombama kwesimba rezvishandiso ndeiyi: simbi inomhanya-mhanya> simende carbide> ceramic zvishandiso> diamond uye cubic boron nitride zvishandiso.

③ Kurongeka kwekuoma kwezvinhu zvekushandisa ndeichi: simbi inomhanya-mhanya> simende carbide> cubic boron nitride, diamondi uye ceramic maturusi.

Semuenzaniso, kana chinhu chakagadzirwa chakagadzirwa nechinhu chakaoma uye chine brittle sesimbi yakaomeswa kana simbi yakakandwa, mudziyo wekucheka wakagadzirwa nechinhu chakaoma uye chisingachinjiki senge carbide kana ceramic ingave sarudzo yakanaka. Izvi zvinhu zvinokwanisa kumirisana nepamusoro pekucheka masimba uye tembiricha inogadzirwa panguva yekugadzira uye kuchengetedza yavo yakapinza mipendero yekucheka kwenguva yakareba.

Kune rumwe rutivi, kana chinhu chakagadzirwa chakagadzirwa nechinhu chakapfava uye chinowedzera ductile sealuminium kana mhangura, chigadziro chekucheka chakagadzirwa nechinhu chakasimba sesimbi yepamusoro-soro chinogona kunge chakakodzera. Simbi yepamusoro-soro inogona kutora zvirinani kuvhunduka uye kuzununguka panguva yekugadzira, kuderedza njodzi yekuputsika kwechishandiso uye kugadzirisa hupenyu hwematurusi.

2)Kufananidza yekucheka chishandiso zvinhu kune zvemuviri zvimiro zvechinhu chakagadzirwa

Kufananidza iyo yekucheka chishandiso zvinhu kune yemuviri zvimiro zvemuchina chinhu zvakare chakakosha kufunga muCNC machining. Hunhu hwemuviri hwechinhu chakagadzirwa zvinosanganisira kupisa kwayo, coefficient yekuwedzera kwemafuta, uye pamusoro pekupedzisira zvinodiwa, pakati pezvimwe. Kusarudza chishandiso chekucheka chinoenderana kana chinozadzisa chimiro chechinhu chakagadzirwa chinogona kuvandudza machining mashandiro, kuderedza kupfeka kwechishandiso, uye kugadzirisa kunaka kwechikamu chakapedzwa.

① Tembiricha inodzivirira kupisa kwezvinhu zvakasiyana-siyana zvekushandisa: 700-8000C yemidziyo yedhaimondi, 13000-15000C yePCBN maturusi, 1100-12000C yemidziyo yeceramic, 900-11000C yeTiC(N)-based cemented carbide, uye 1000C-WC1000C. -yakavakirwa ultrafine zviyo Cemented carbide i800~9000C, HSS i600~7000C.

②Kurongeka kwekupisa kwekupisa kwezvinhu zvakasiyana-siyana zvekushandisa: PCD>PCBN>WC-based cemented carbide>TiC(N)-based cemented carbide>HSS>Si3N4-based ceramics>A1203-based ceramics.

③ Kurongeka kwemafuta ekuwedzera kwemafuta emhando dzakasiyana-siyana dzematurusi ndeichi: HSS>WC-based cemented carbide>TiC(N)>A1203-based ceramics>PCBN>Si3N4-based ceramics>PCD.

④Kurongeka kwekupikiswa kwekupisa kwemhando yemidziyo yakasiyana-siyana ndeye: HSS>WC-based cemented carbide>Si3N4-based ceramics>PCBN>PCD>TiC(N)-based cemented carbide>A1203-based ceramics.

Semuenzaniso, kana chinhu chakagadzirwa chine high thermal conductivity, semhangura kana aluminium, chigadziro chekucheka chine high thermal conductivity uye yakaderera coefficient yekuwedzera kwekushisa inogona kuva sarudzo yakanakisisa. Izvi zvinobvumira chishandiso kuti chibvise kupisa zvakanaka panguva yekugadzira uye kuderedza njodzi yekukuvadza kwekupisa kune zvese chishandiso uye chinhu chakagadzirwa.

Saizvozvo, kana chinhu chakagadzirwa chine kuomarara kwepamusoro pekupedzisira zvinodiwa, chishandiso chekucheka chine yakakwirira kupfeka kuramba uye yakaderera coefficient yekukwesha inogona kunge iri sarudzo yakanyanya kunaka. Izvi zvinogona kubatsira kuzadzisa yaunoda pamusoro pekupedzisira pasina yakawandisa maturusi kupfeka kana kukuvadzwa kwechinhu chakagadzirwa.

3)Kufananidza midziyo yekucheka nemakemikari echinhu chakagadzirwa

Kufananidza iyo yekucheka chishandiso zvinhu kune kemikari yechinhu chakagadzirwa chinhu zvakare chakakosha kufunga muCNC machining. Iyo kemikari yechinhu chakagadzirwa inosanganisira reactivity, corrosion resistance, uye kuumbwa kwemakemikari, pakati pezvimwe. Kusarudza chishandiso chekucheka chinoenderana kana chinozadzisa chimiro chemakemikari echinhu chakagadzirwa chinogona kuvandudza machining mashandiro, kuderedza kupfeka kwechishandiso, uye kugadzirisa kunaka kwechikamu chakapedzwa.

Semuyenzaniso, kana chinhu chakagadzirwa chakagadzirwa nechinhu chinobatika kana chinopisa senge titanium kana simbi isina tsvina, mudziyo wekucheka wakagadzirwa nechinhu chisingaite ngura sedhaimondi kana PCD (polycrystalline diamond) inogona kunge iri sarudzo yakanaka. Zvishandiso izvi zvinokwanisa kumirisana nenzvimbo inoora kana kuti inoshanda uye kuchengetedza mipendero yazvo yakapinza kwenguva yakareba.

Saizvozvo, kana chinhu chakagadzirwa chine chimiro chakaoma chemakemikari, chishandiso chekucheka chakagadzirwa nechinhu chakagadzika chemakemikari uye inert, sedhaimondi kana cubic boron nitride (CBN), inogona kunge iri sarudzo yakanaka. Zvinhu izvi zvinogona kudzivirira kuita kwemakemikari neiyo workpiece zvinhu uye kuchengetedza yavo yekucheka mashandiro nekufamba kwenguva.

① Iyo inodzivirira-kusunga tembiricha yezvinhu zvakasiyana-siyana zvekushandisa (nesimbi) ndeiyi: PCBN>ceramic>hard alloy>HSS.

② The oxidation kuramba tembiricha yezvakasiyana maturusi emidziyo yakaita seiyi: ceramic> PCBN> tungsten carbide> diamondi> HSS.

③Kusimba kwekupararira kwemidziyo (yesimbi) ndeiyi: diamond>Si3N4-based ceramics>PCBN>A1203-based ceramics. Diffusion intensity (yetitanium) ndeye: A1203-based ceramics>PCBN>SiC>Si3N4>diamond.

4) Kusarudzwa kunonzwisisika kweCNC yekucheka maturusi emidziyo

Kusarudzwa kweCNC yekucheka maturusi emidziyo kunoenderana nezvinhu zvakasiyana senge workpiece zvinhu, machining mashandiro, uye chishandiso geometry. Nekudaro, mamwe mazano akajairwa ekusarudza ekucheka maturusi emidziyo yeCNC machining anosanganisira:

1. Material properties of the workpiece: Funga nezve mechanical, physical, and chemical properties of the workpiece material kana uchisarudza kucheka chombo. Batanidza iyo yekucheka chishandiso zvinhu kune workpiece zvinhu kuti uwane inoshanda uye yemhando yepamusoro machining.

2. Machining oparesheni: Funga nezverudzi rwemachining oparesheni ari kuitwa, sekutenderedza, kugaya, kuchera, kana kukuya. Akasiyana machining mashandiro anoda akasiyana ekucheka maturusi geometri uye zvinhu.

3. Tool geometry: Funga nezvekucheka chishandiso geometry paunenge uchisarudza chishandiso. Sarudza chinhu chinogona kuchengetedza chakapinza chekucheka uye kutsungirira masimba ekucheka anogadzirwa panguva yekugadzira machining.

4. Kupfeka kwechishandiso: Funga nezveyero yekupfeka kwechombo paunenge uchisarudza chinhu chekucheka. Sarudza chinhu chinogona kumirisana nemasimba ekucheka uye chengetedza yakapinza yekucheka mupendero kwenguva yakareba sezvinobvira kuderedza shanduko yekushandisa uye kugadzirisa machining kunyatsoita.

5. Mutengo: Funga nezvekudhura kwezvinhu zvekucheka pakusarudza chigadzirwa. Sarudza chinhu chinopa yakanakisa chiyero chekucheka kuita uye mutengo.

Zvimwe zvakajairika zvekucheka zvishandiso zvinoshandiswa mukatiCNC machininginosanganisira yakakwirira-kumhanya simbi, carbide, ceramic, diamond, uye CBN. Chinhu chimwe nechimwe chine zvakanakira uye nekuipa kwacho, uye kusarudzwa kwechishandiso chekushandisa kunofanirwa kuve kwakavakirwa pakunyatsonzwisisa kweiyo machining mashandiro uye workpiece zvinhu.

Zvitsva zveAnebon zvekusingaperi ndiwo maitiro e "kutarisira musika, tarisa tsika, tarisa sainzi" uye dzidziso ye "mhando yekutanga, vimba yekutanga uye manejimendi epamberi" yeHot sale Factory OEM Service High Precision CNC Machining zvikamu zve otomatiki. indasitiri, Anebon quote yekubvunza kwako. Kuti uwane rumwe ruzivo, ndapota taura nesu, Anebon ichakupindura ASAP!

Kupisa kutengesa Factory China 5 axis cnc machining zvikamu, CNC yakashandura zvikamu uye kugaya mhangura chikamu. Tikugashirei kushanyira kambani yedu, fekitori uye yedu showroom inoratidzira zvakasiyana siyana zvekutengesa bvudzi zvinosangana nezvaunotarisira. Zvichakadaro, zviri nyore kushanyira webhusaiti yeAnebon, uye vashandi vekutengesa kweAnebon vanoedza nepavanogona napo kuti vakupe sevhisi yakanakisa. Ndokumbira utaure neAnebon kana iwe uine rumwe ruzivo. Chinangwa cheAnebon ndechekubatsira vatengi kuona zvinangwa zvavo. Anebon yanga ichiita nhamburiko huru kuti iwane iyi win-win mamiriro.

Nguva yekutumira: Mar-08-2023