1

Kupesvedzera pane tembiricha yekucheka: kukurumidza kucheka, chiyero chekudya, kumashure kucheka huwandu.

Kufurira pane simba rekucheka: kumashure kucheka huwandu, chiyero chekudya, kucheka kukurumidza.

Kupesvedzera pakusimba kwechishandiso: kukurumidza kucheka, chiyero chekudyisa, kumashure kucheka huwandu.

2

Kana huwandu hwekubatanidzwa kwemashure hunowedzera kaviri, simba rekucheka rinowedzera kaviri;

Kana chiyero chekudya chakapetwa kaviri, simba rekucheka rinowedzera ne70%;

Apo kukurumidza kucheka kunowedzera kaviri, simba rekucheka rinoderera zvishoma nezvishoma;

Mune mamwe mazwi, kana G99 ikashandiswa, kukurumidza kwekucheka kuchawedzera, asi simba rekucheka harizoshanduki zvakanyanya.

3

Zvinoenderana nekubuda kwesimbi filings, inogona kutongwa kana simba rekucheka uye tembiricha yekucheka iri mukati meyakajairika.

Kana iyo chaiyo kukosha X yakayerwa uye dhayamita Y yedhirowa yakakura kupfuura 0.8, chishandiso chekutenderedza chine chechipiri kutsauka angle ye 52 degrees (kureva, chinoshandiswa chinoshandiswa kushandura chipenga chine blade 35 madhigirii uye inotungamira yekutsauka angle ye. 93 madhigirii) Iyo R kunze kwemota inogona kupukuta banga panzvimbo yekutanga.

5

Iyo tembiricha inomiririrwa nemuvara wesimbi filings: chena isingasviki 200 degrees

Yero 220-240 madhigirii

Rima bhuruu 290 madhigirii

Bhuruu 320-350 madhigirii

Yepepuru dema yakakura kupfuura 500 madhigirii

Tsvuku yakakura kupfuura 800 degrees

6

FUNAC OI mtc kazhinji inosarudzika kuG command:

G69: handina chokwadi

G21: Metric saizi yekuisa

G25: Spindle speed fluctuation yekuona yakabviswa

G80: Canned kutenderera kukanzura

G54: default coordinate system

G18: ZX kusarudzwa kwendege

G96 (G97): nguva dzose mutsara kumhanya kudzora

G99: Feed per revolution

G40: Chishandiso mhino muripo kudzima (G41 G42)

G22: kuchengetedza sitiroko kuona ON

G67: Macro chirongwa modal call kudzima

G64: handina chokwadi

G13.1: Kudzimwa kwepolar coordinate interpolation mode

7

Iyo yekunze shinda kazhinji ndeye 1.3P, uye yemukati shinda ndeye 1.08P.

8

Thread kumhanya S1200/pitch* kuchengetedza chinhu (kazhinji 0.8).

9

Manual turusi mhino R muripo formula: kubva pasi kusvika kumusoro, chamfering: Z=R*(1-tan(a/2)) X=R(1-tan(a/2))*tan(a) kubva kumusoro kusvika kumusoro Buda pachamfer wochinja minus kuti uwedzere.

10

Pese apo chikafu chinowedzera ne 0.05, kukurumidza kunoderera ne50-80 revolutions. Izvi zvinodaro nekuti kudzikisa kumhanya kunoreva kuti kupfeka kwechombo kunoderera, uye iyocnc kuchekasimba rinowedzera zvishoma nezvishoma, kuitira kuti rigadzirise kuwedzera kwekudya kunoita kuti simba rekucheka riwedzere uye kutonhora kuwedzere. Impact.

11

Kupesvedzera kwekucheka kukurumidza uye kutema simba pachishandiso kwakakosha zvakanyanya, uye chikonzero chikuru chekuti chishandiso chipunzike nekuda kwesimba rakawandisa rekucheka. Ukama huri pakati pekucheka kukurumidza uye simba rekucheka: kana kukurumidza kwekucheka kunokurumidza, chikafu chinoramba chisingachinji, uye simba rekucheka rinoderera zvishoma nezvishoma. Iyo yakakwirira iyo, kana simba rekucheka uye kushushikana kwemukati kwakanyanyisa kuti kuiswa kutakure, kuchaita chip (hongu, kunewo zvikonzero zvakadai sekunetseka uye kuoma kudonha kunokonzerwa nekushanduka kwekushisa).

12

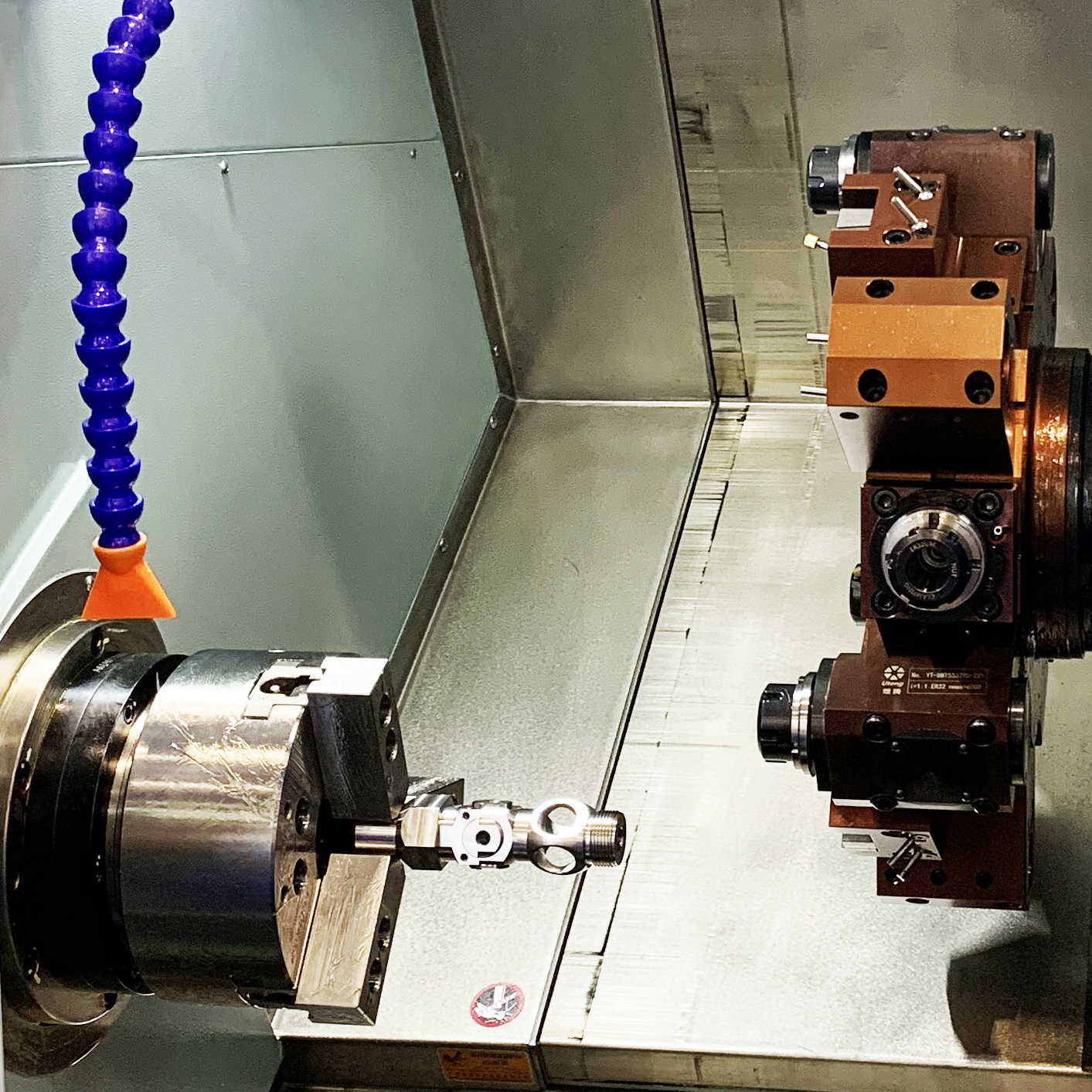

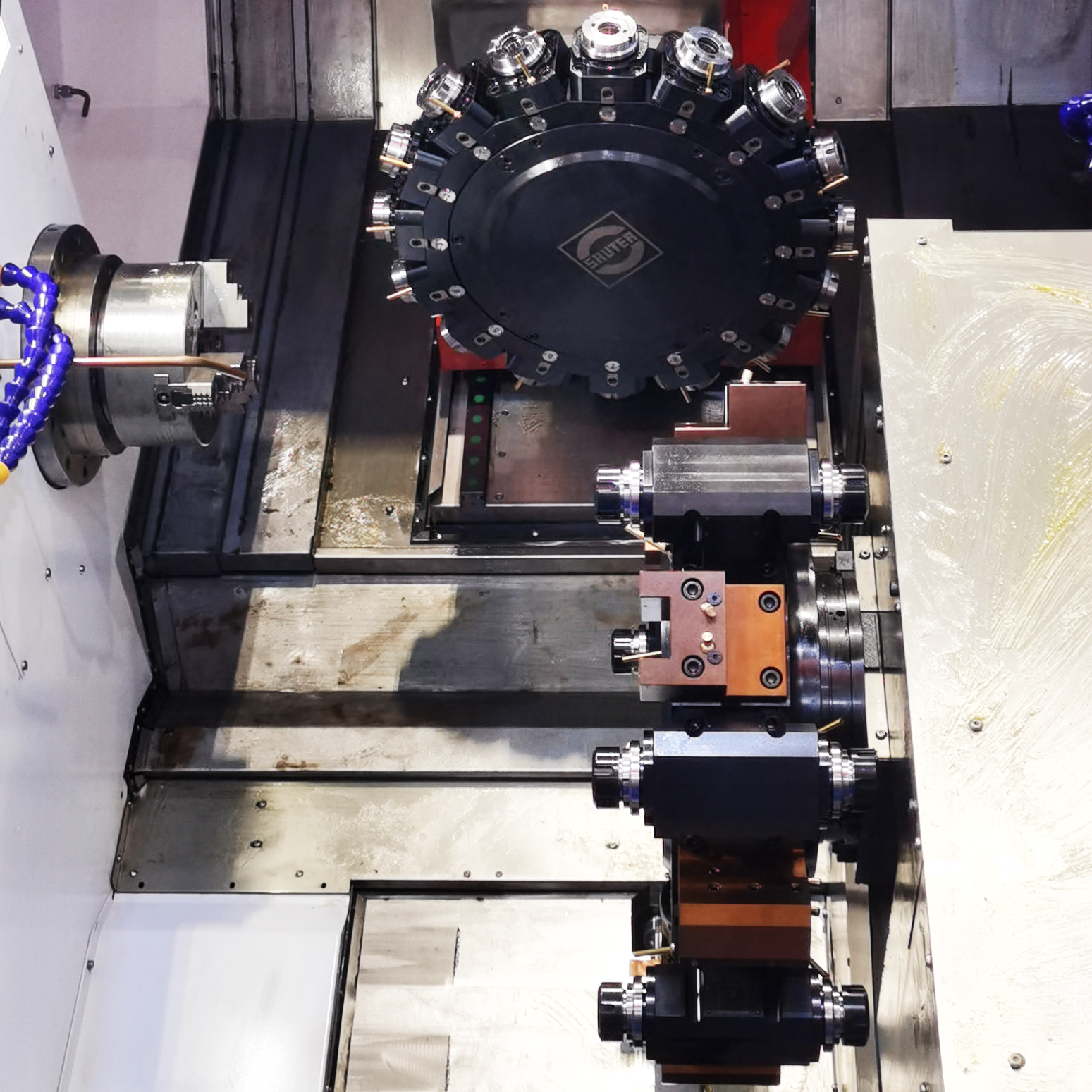

Riniprecision machiningCNC lathes, anotevera mapoinzi anofanirwa kutariswa zvakanyanya kune:

(1) Kune yazvino yehupfumi CNC lathes munyika yangu, akajairwa matatu-chikamu asynchronous mota anowanzo shandiswa kuona isina nhanho yekumhanya shanduko kuburikidza ne frequency converters. Kana pasina mechanical deceleration, torque inobuda yespindle inowanzo shaya kukwana pakumhanya kwakaderera. Kana mutoro wekucheka wakakurisa, zviri nyore kufinhwa Mota, asi mamwe maturusi emuchina ane magiya ekugadzirisa dambudziko iri zvakanyanya.

(2) Nepazvinobvira, chishandiso chinogona kupedzisa kugadziridzwa kwechikamu chimwe kana imwe shift yebasa. Mukupedzisa kwezvikamu zvakakura, kutarisisa kwakakosha kunofanirwa kubhadharwa kudzivirira kushandura chishandiso pakati kuti uve nechokwadi chekuti chishandiso chinogona kugadziriswa panguva imwe chete.

(3) Rinikutendeukashinda ine CNC lathe, shandisa kumhanya kwepamusoro zvakanyanya sezvinobvira kuti uwane kugadzirwa kwepamusoro uye kwakanaka.

(4) Shandisa G96 zvakanyanya sezvinobvira.

(5) Mhedziso yekutanga yekumhanyisa machining ndeyekuita kuti chikafu chipfuure kukurumidza kupisa, kuitira kuti kupisa kwekucheka kunoburitswa nemafirita esimbi kuparadzanisa kupisa kwekucheka kubva kune workpiece, kuitira kuti ive nechokwadi chekuti workpiece inoita. kwete kupisa kana kupisa zvishoma. Naizvozvo, high-speed machining isarudzo yakakwirira kwazvo. Iko kukurumidza kucheka kunofananidzwa nehuwandu hwekudya kwekudya paunenge uchisarudza chidimbu chiduku chekudzokera shure.

(6) Teerera kune muripo wechishandiso mhino R.

13

Workpiece Material Machinability Grading Tafura (Minor P79)

Inowanzo shandiswa shinda yekucheka nguva uye kumashure kubatanidzwa chiyero (hombe P587)

Kuverengera mafomula eanowanzo shandiswa geometric manhamba (hombe P42)

Inches kusvika Mamirimita Shanduko Chati (Hombe P27)

14

Kudengenyeka uye kuputsika kwechishandiso kunowanzoitika panguva yekuchera. Chikonzero chezvose izvi ndechekuti simba rekucheka rinova rakakura uye kusimba kwechishandiso hakuna kukwana. Iyo ipfupi yehurefu hwechishandiso chekuwedzera, idiki iyo kona yekuyamura, uye yakakura nzvimbo yeblade, zviri nani kuomarara. Nesimba guru rekucheka, asi hukuru hwehupamhi hwekucheka groove, simba rekucheka rinogona kumira richawedzera maererano, asi simba rayo rekucheka richawedzerawo. Pane zvinopesana, iyo diki iyo groove cutter, idiki iyo simba inogona kumira, asi yayo Simba rekucheka zvakare diki.

15

Zvikonzero zvekuzununguka panguva yekucheka:

(1) Kureba kwechishandiso kwakarebesa, zvichikonzera kudzikira kwekuoma.

(2) Chiyero chekudya chinononoka, izvo zvichaita kuti chikwata chekucheka chikwata chiwedzere uye chinokonzera kuzununguka kukuru. Iyo fomula ndeiyi: P = F / kumashure yekucheka huwandu * f P ndiyo unit yekucheka simba F isimba rekucheka, uye iyo yekumhanyisa inokurumidza Inozunzawo banga.

(3) Kuomarara kwechishandiso chemuchina hakuna kukwana, kureva kuti, mudziyo unogona kutakura simba rekucheka, asi mudziyo wemuchina haugone kuutakura. Kuti uzviise pachena, mudziyo wemashini haufambi. Kazhinji, mibhedha mitsva haina dambudziko rerudzi urwu. Mubhedha une dambudziko rerudzi urwu ungave wasakara kana wasakara. Zvimwe iwe unowanzosangana nemhondi dzemuchina.

16

Pandakanga ndichityaira zvinhu, ndakaona kuti ukuru hwakanga hwakanaka pakutanga, asi pashure pemaawa mashomanana ebasa, ndakaona kuti ukuru hwachinja uye ukuru hwakanga husina kugadzikana. Chikonzero chinogona kunge chiri chekuti simba rekucheka rakanga risina kunyanya kusimba nekuti mapanga aive matsva pakutanga. Yakakura, asi mushure menguva, chimbo chacho chinopera uye simba rekucheka rinova rakakura, zvichiita kuti workpiece ishanduke pane chuck, saka ukuru hwakwegura uye husina kugadzikana.

Anebon ine zvigadzirwa zvemhando yepamusoro zvekugadzira, mainjiniya ane ruzivo uye ane hunyanzvi nevashandi, anozivikanwa ekudzora emhando masisitimu uye ine hushamwari nyanzvi yekutengesa timu yekutanga / mushure-yekutengesa tsigiro yeChina yakazara OEM Plastic ABS/PA/POM CNC Lathe CNC Milling 4 Axis/5 Axis. CNC machining zvikamu, CNC inoshandura zvikamu. Parizvino, Anebon iri kutsvaga kumberi kwekushandira pamwe kwakakura nevatengi vekunze maererano nezvakawaniswa. Ndokumbirawo uwane mahara kuti ubatane nesu kuti uwane mamwe mashoko.

2022 Yemhando yepamusoro China CNC uye Machining, Nechikwata chevashandi vane ruzivo uye vane ruzivo, musika weAnebon unofukidza South America, USA, Mid East, uye North Africa. Vatengi vazhinji vava shamwari dzeAnebon mushure mekubatana kwakanaka neAnebon. Kana iwe uine zvinodiwa kune chero zvigadzirwa zvedu, rangarira kutibata nesu izvozvi. Anebon anotarisira kunzwa kubva kwauri munguva pfupi.

Nguva yekutumira: Feb-09-2023