Nhanganyaya:

Muzvinyorwa zvakapfuura, timu yedu yeAnebon yakagovana newe ruzivo rwekugadzira michina yekugadzira. Nhasi tichaenderera mberi nekudzidza pfungwa dzakaoma mukugadzira michina.

Ndezvipi zvipingamupinyi zvikuru kumisimboti yekugadzira michina?

Kuoma kwekugadzira:

Mechanical dhizaini anowanzo kuoma, uye anoda mainjiniya kuti abatanidze akasiyana masisitimu, zvikamu uye mabasa.

Semuyenzaniso, kugadzira giya bhokisi rinofambisa simba zvakanaka pasina kukanganisa zvimwe zvinhu zvakaita sehukuru nehuremu pamwe neruzha idambudziko.

Kusarudzwa kwezvinhu:

Kusarudza chinhu chakakodzera dhizaini yako kwakakosha, nekuti ivo vanopesvedzera zvinhu zvakaita sekusimba, simba, uye mutengo.

Semuyenzaniso, kusarudza chinhu chakakodzera chikamu cheinjini yendege hakusi nyore nekuda kwekukosha kwekuyera huremu uchichengetedza kugona kutsungirira tembiricha yakanyanyisa.

Zvisungo:

Mainjiniya anofanirwa kushanda mukati mezvisingakwanisi senge nguva, bhajeti uye zviwanikwa zviripo. Izvi zvinogona kuderedza dhizaini uye zvinoda kushandiswa kwehungwaru tradeoffs.

Semuenzaniso, kugadzira inodziya inodziya system inodhura-inoshanda imba uye ichiri kuenderana nezvinodiwa zvesimba zvinogona kuunza nyaya.

Kuganhurirwa mukugadzira

Vagadziri vanofanirwa kufunga nezvavasingakwanisi mukugadzira nzira uye matekiniki pakugadzira madhizaini. Mukuenzanisa chinangwa chekugadzira nekugona kwemidziyo uye maitiro anogona kuve dambudziko.

Semuyenzaniso, kugadzira chinhu chakaoma-chiumbwa chinogona kugadzirwa chete nemuchina unodhura kana nzira dzekuwedzera dzekugadzira.

Zvinodiwa zvekushanda:

Kuzadzisa zvese zvinodiwa pakugadzira, kusanganisira kuchengetedza, kuita, kana kuvimbika kwechigadzirwa, kungave kwakaoma.

Semuenzaniso, kugadzira bhureki system inopa chaiyo yekumisa simba, ukuwo nekuona kuchengetedzwa kwevashandisi kunogona kuve dambudziko.

Dhizaini optimization:

Kutsvaga yakanakisa dhizaini mhinduro inoenzanisa zvinangwa zvakawanda zvakasiyana, kusanganisira huremu, mutengo, kana kugona, hazvisi nyore.

Semuyenzaniso, kugadzirisa dhizaini yemapapiro endege kuti ideredze kukweva nehuremu, pasina kukanganisa chimiro chechimiro, kunoda ongororo yakadzama uye nzira dzekugadzira dzinodzokororwa.

Kubatanidzwa muhurongwa:

Kubatanidza zvikamu zvakasiyana uye subsystems mune yakabatana dhizaini inogona kunge iri nyaya hombe.

Semuyenzaniso, kugadzira mota yekumisikidza sisitimu inodzora kufamba kwezvikamu zvakawanda, nepo kuyera zvinhu zvakaita sekunyaradza, kugadzikana uye kutsungirira kunogona kuunza matambudziko.

Dhizaini Iteration:

Magadzirirwo ekugadzira anowanzo sanganisira akawanda kudzokorora uye iterations kunatsiridza nekuvandudza pane yekutanga zano. Kuita dhizaini shanduko zvinobudirira uye zvinobudirira idambudziko zvese maererano nenguva inodiwa uye mari iripo.

Semuenzaniso, kugadzirisa dhizaini yechinhu chemutengi nekutevedzana kwekudzokororwa kunovandudza mushandisi ergonomics uye aesthetics.

Zvinotarisirwa maererano nemhoteredzo:

Kubatanidza kusimba mukugadzira uye kuderedza kukanganiswa kwezvakatipoteredza kwechivako kunowedzera kukosha. Huyero pakati pezvinhu zvinoshanda uye zvinhu zvakaita sekugona kudzokorodza, kugona kwesimba uye kuburitsa zvinogona kunetsa. Semuyenzaniso, kugadzira injini inoshanda iyo inoderedza mhepo inopisa gasi, asi kwete kukanganisa kushanda.

Manufacturability dhizaini uye kusangana

Iko kugona kuve nechokwadi chekuti dhizaini ichagadzirwa uye kuunganidzwa mukati menguva uye zvipingamupinyi zvemutengo zvinogona kuve dambudziko.

Semuyenzaniso, kurerutsa kuungana kwechigadzirwa chakaomesesa kunoderedza mutengo wevashandi nekugadzira, uku uchisimbisa zviyero zvemhando.

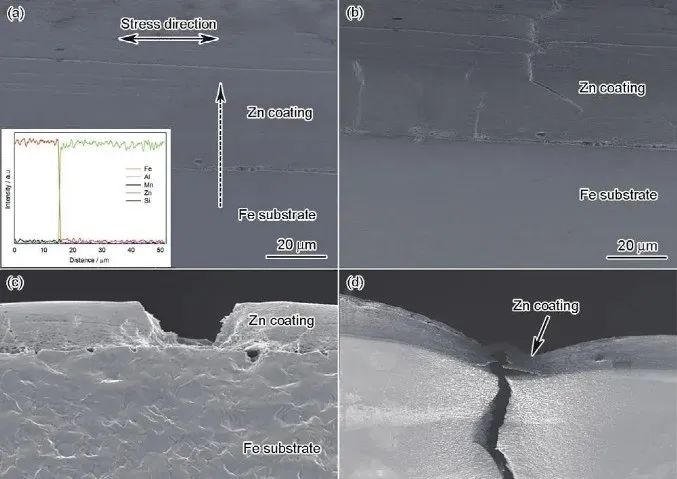

1. Kukundikana kunokonzerwa nemagetsi emagetsi anowanzo kuputsika, zvakanyanya kusara deformation, kukuvadzwa kwepamusoro pezvikamu (kupfeka kwekuora, kubata kuneta uye kupfeka) Kukundikana nekuda kwekupfeka uye kubvarura kune yakajairika nzvimbo yekushanda.

2. Zvikamu zvekugadzira zvinofanira kusangana zvinosanganisira zvinodiwa kuti zvive nechokwadi kuti hazvikundikani mukati menguva-yenguva yehupenyu hwavo hwakafanotemerwa (simba kana kuoma, hupenyu hurefu) uye maitiro ekugadzirisa zvinodiwa zvehupfumi, huremu hunodiwa, uye kuvimbika zvinodiwa.

3. Dhizaini yemaitiro ezvikamu zvinosanganisira kusimba uye kuomarara maitiro, zvinodikanwa zvehupenyu pamwe nekudengenyeka kwekugadzikana kwemaitiro uye maitiro ekuvimbika.

4. Zvikamu zvekugadzira nzira: theoretical dhizaini, empirical dhizaini uye muenzaniso bvunzo dhizaini.

5. Inowanzo shandiswa pakugadzira zvinhu zveMetal, ceramic materials, polymer material pamwe necomposite material.

6. Simba rezvikamu zvinogona kugoverwa kuva static stress simba pamwe nekushanduka kwesimba kusimba.

7. Ratio yekushungurudzika: = -1 inofananidzira kushungurudzika mu cyclic fomu; iyo r = 0 kukosha ndiyo cyclic stress iri kuputika.

8. Zvinotendwa kuti BC nhanho inonzi strain fatigue (low cycle fatigue) CD inoreva kusingaperi kuneta danho. Chikamu chemutsara chinotevera poindi D ndiyo isingaperi hupenyu-kutadza mwero wemuenzaniso. Point D ndiyo muganhu wekuneta zvachose.

9. Matanho ekuvandudza kusimba kwezvikamu zvakaneta kuderedza mhedzisiro yekushushikana pazvinhu (mutoro wekununura grooves yakavhurika zvindori) Sarudza zvinhu zvine simba rakawanda rekuneta uye wozotsanangura nzira dzekupisa kupisa uye nzira dzekusimbisa dzinowedzera simba re akaneta zvinhu.

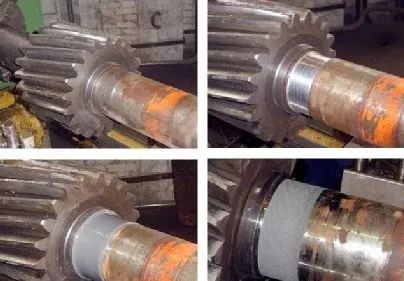

10. Slide friction: Dry friction boundary frictions, fluid friction, uye kusanganiswa kwakasanganiswa.

11. Kusakara nekubvaruka kwezvikamu zvinosanganisira kumhanya-mudanho, nhanho yekupfeka yakagadzikana uye nhanho yekupfeka kwakanyanya Tinofanira kuedza kuderedza nguva yekumhanya-mukati pamwe nekuwedzera nguva yekupfeka kwakagadzikana uye kumisa kutaridzika kwekupfeka. izvo zvakaoma.

12. Mutsara wekupfeka ndeye Adhesive wear, abrasive wear uye kuneta corrosion wear, erosion wear, uye fretting wear.

13. Mafuta ekuzora anogona kuiswa muzvikamu zvina zvinoti mvura, gasi semi-solid, yakasimba uye magirosi emvura anoiswa muCalcium-based greases, Nano-based Grease aluminium-based grease, uye lithium-based grease.

14. Normal tambo dzekubatanidza dzine equilateral triangle fomu uye yakanakisa yekuzvivharira zvivakwa. rectangular transmission threads inopa kushanda kwepamusoro mukutapurirana kupfuura dzimwe shinda. Trapezoidal transmission tambo dziri pakati peanonyanya kufarirwa tambo dzekutumira.

15. Kubatanidza tambo dzinowanzo shandiswa dzinoda kuzvivharira, saka shinda imwechete ndiyo inowanzo shandiswa. Tambo dzekutumira dzinoda kushanda zvakanaka kwekufambisa uye nekudaro tambo-katatu kana mbiri-tambo dzinowanzo shandiswa.

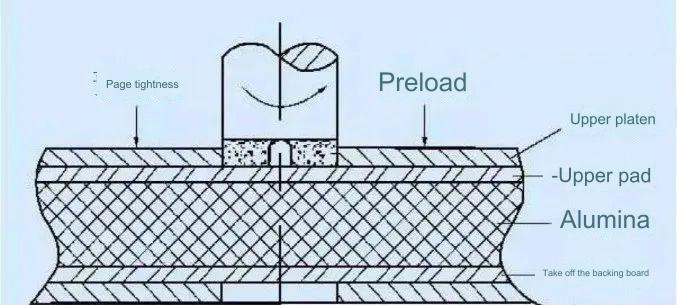

16. Kubatanidzwa kwebhoti nguva dzose (zvikamu zvakabatana zvinosanganisira maburi kuburikidza kana kuti zvakadzokororwa) Zvisungo zvekubatanidza zvigadziriswe zviviri zvine musoro, zvisungo zvekubatanidza, pamwe chete nemakumbo ane zvibatanidza zvakagadzirirwa.

17. Chinangwa chekubatanidzwa kwe threaded pre-tightening ndechekuvandudza kusimba uye simba rekubatanidza, uye kumisa mapeji kana kutsvedza pakati pezvikamu zviviri kana zvakatakurwa. Nyaya huru ine tensioning yekubatanidza iyo yakasununguka ndeyekumisa spiral pair kubva kutendeuka neruremekedzo kune imwe neimwe ichiremerwa. (Frictional anti-loosening uye mechanical kuti irege kusunungura, kubvisa chinongedzo pakati pekufamba uye kufamba kwevaviri vanotenderera)

18. Kuwedzera kusimba kwezvibatanidza zvakasungirirwa kuderedza kushungurudza amplitude kunokonzera simba rekuneta mabhoti (kuderedza kuoma kwebhoti, kana kuwedzera kuoma kwekubatanidza.tsika cnc zvikamu) uye kuvandudza kusaenzana kwekugoverwa kwemutoro pamusoro peshinda. kuderedza mhedzisiro kubva mukushushikana kuunganidza, pamwe nekuita iyo inonyanya kushanda nzira yekugadzira.

19. Mhando dzekubatanidza dzakakosha: flat connection (mativi ose maviri anoshanda sepamusoro) semicircular key connection wedge key connection key connection with tangential angle.

20. Bhandi motokari inogona kugoverwa mumhando mbiri: meshing type uye friction type.

21. Nguva yekunyanya kunetseka kwebhanhire apo chikamu chakamanikana chayo chinotanga pa pulley. Makakatanwa anochinja kanokwana kana panguva imwe kumukirana pabhandi.

22. Tensioning yeV-belt drive: Nguva dzose tensioning mechanism, auto tensioning device, uye tensioning device inoshandisa vhiri rekukwenya.

23. Zvisungo muketani ye roller zvinowanzoita nhamba isinganzwisisike (huwandu hwezino mu sprocket haigoni kuva nhamba yenguva dzose). Kana iyo roller chain ine nhamba dzisiri dzechisikigo, saka ma link akawandisa anoshandiswa.

24. Chinangwa chekumanikidza cheni drive ndechekudzivirira matambudziko emeshing uye kudengenyeka kwecheni kana mipendero yakasununguka yecheni yanyanya, uye kuwedzera kona ye meshing pakati pe sprocket neketani.

. ).

26. Magiya ane kuoma kwechiso kunopfuura 350HBS, kana 38HRS anozivikanwa semagiya akaomarara kana akaomarara kana, kana asina, magiya akapfava.

27. Kunatsiridza kugadzira chaiko, kuderedza dhayamita yegiya kuti kuderedze kumhanya kwekutenderera, kunogona kuderedza simba remutoro. Kuti uderedze mutoro wesimba, giya rinogona kutemwa. Chinangwa chekushandura mazino egiya kuita chigubhu ndechekuwedzera kusimba kwechimiro chemuromo wezino. kutungamira mutoro kugovera.

.

29. Giya rehonye rinofanira kutamiswa. Mushure mekutamiswa denderedzwa reindex pamwe chete nehonye yepitch denderedzwa match zvisinei zviri pachena kuti mutsetse uri pakati pemakonye maviri wachinja, uye hauenderane nedenderedzwa regiya rehonye.

30. Nzira dzekutadza kutapurira honye dzakadai segomba midzi yezino inopwanya kunama pamusoro pemazino uye kusakara zvakanyanya; izvi zvinowanzoitika pamagiya ehonye.

.cnc milling componentsunodirwa mudziva ramafuta unokusa mafuta.

32. Iyo worm drive inofanirwa kuita thermal balance calculations zvichibva pakufungidzira kuti simba rinogadzirwa pane imwe unit yenguva rakafanana nekupisa kupisa munguva imwechete yenguva. Matanho ekutora: Isa masingi ekupisa, uye wedzera nzvimbo yekubvisa kupisa uye isa mafeni pamagumo eshaft kuitira kuwedzera kuyerera kwemhepo, uye pakupedzisira, isa circulator inotonhorera mapaipi mukati mebhokisi.

. mafuta ekuzora kuti afambe nepaburi hombe achipinda mudiki uye kuzora kunofanira kunge kuri kweimwe viscosity, uye huwandu hwemafuta huripo hunofanirwa kunge hwakakwana.

.

35. 3 roller bearings tapered five thrust bearings matanhatu akadzika groove bhora mabearings manomwe angular contact bearings N cylindrical roller bearings 01, 02and 03 zvakateerana. D=10mm, 12mm 15mm, 17,mm zvinoreva 20mm iri d=20mm, 12 inoreva 60mm.

36. Hupenyu hwekutanga chiyero huwandu hwemaawa ekushanda umo 10% yemabheya ari mukati meseti yemabheri anobatwa nekuora kwegomba, asi 90percent yavo havatambure nekukuvadzwa kwegomba kunoonekwa sehupenyu hurefu hwehumwe. kubereka.

37. Chiyero chakakosha chemutoro wemutoro: huwandu hunokwanisa kutakura kana hupenyu hunokosha hwechikwata hunonyatso 106 revolutions.

38. Nzira yekutakura gadziriro: Imwe neimwe yemafurumu maviri akaiswa mune imwe nzira. kune nzvimbo yakatemwa mumativi ese, nepo imwe fulcrum inoperera isina kufamba. Mativi ese ari maviri anobatsirwa nekufamba kwakasununguka.

39. Bearings inorongwa maererano nemutoro unoshandiswa kune shaft inotenderera (kukotama nguva uye torque) uye spindle (nguva yekukotama) uye shaft yekutumira (torque).

Anebon inonamira mune yakakosha musimboti we "Hunhu zvirokwazvo ndihwo hupenyu hwebhizinesi, uye chimiro chinogona kunge chiri mweya waro" kune yakakura kuderedzwa tsika chaiyo 5 Axis CNC Lathe.CNC Machined Chikamu, Anebon ine chivimbo chekuti tinogona kupa zvigadzirwa zvemhando yepamusoro uye zvigadziriso pamutengo unogoneka, rutsigiro rwepamusoro mushure mekutengesa muvatengi. Uye Anebon ichavaka inoyevedza refu refu.

Chinese ProfessionalChikamu cheChina CNCuye Metal Machining Zvikamu, Anebon inotsamira pazvinhu zvemhando yepamusoro, dhizaini yakakwana, yakanakisa sevhisi yevatengi uye mutengo wemakwikwi kuhwina kuvimba kwevatengi vazhinji kumba nekune dzimwe nyika. Zvigadzirwa zvinosvika 95% zvinotengeswa kunze kwenyika kumisika yemhiri kwemakungwa.

Kana uchida kuziva zvakawanda kana kubvunza nezvemitengo, ndapota taurainfo@anebon.com

Nguva yekutumira: Nov-24-2023