Zvakawanda sei iwe zvaunoziva nezve classification yeCNC muchina maturusi?

Kuiswa kweCNC muchina maturusi kunoenderana nebasa, chimiro uye mashandisiro.

Iye zvino tichatarisa kune zvakasiyana-siyana classifications:

Kubva paBasa

Turning machines:Michina iyi inoita kunyanya kushandura mashandiro pane cylindrical kana conical zvikamu.

Michina iyi inogona kushandiswa kukuya zvigayo zvakati sandara kana zvakaomarara.

Kubva paChimiro

Horizontal Machining Centers:Iyo spindle uye workpiece inoiswa yakatwasuka patafura.

Vertical Machining Centers:Iyo spindle uye workpiece inoiswa vertically patafura.

Multi-axis michina:Michina iyi yakashongedzerwa nematemo akawanda (3 kana kupfuura), ichivabvumira kuita mashandiro chaiwo uye akaomarara.

Kubva pane Application

Drilling Machines michina inoita mabasa ekuchera.

Michina yekukuya:Michina iyi inogona kushandiswa kukuya nekukwenenzvera simbi.

Laser Kucheka Machina:Laser tekinoroji inoshandiswa kucheka zvinhu zvakasiyana.

Electro-Discharge Machines (EDM):Michina iyi inoumba nekuboora zvinhu zvinobatisa magetsi.

Nzira dzekugadzirisa dzeCNC michina dzakasiyana. Kune marudzi akawanda uye zvakatemwa. Inogona kurongeka uchishandisa nzira dzekuisa pamusoro, pamwe nemisimboti mina yebasa uye chimiro.

1. Kurongwa kwezvishandiso zvemuchina zvinoenderana nekutonga kwavo trajectory

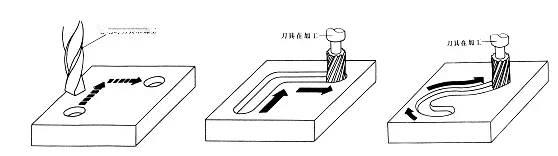

1) Point control CNC michina

Chinongodiwa chete chekudzora mapoinzi ndiko kunyatsomira kwezvikamu zvinofamba kubva kune imwe muchina chishandiso kuenda kune imwe. Zvinodiwa zvetrajectory pakati pezvibodzwa zvekufamba hazvina kuomesesa. Panguva yekufamba, hapana kugadzirisa kunoitwa. Hazvina kukosha kuti kufamba kunoitika sei pakati peiyo axis yekubatanidza. Kuti uwane chaiyo uye nekukurumidza chinzvimbo, zvakakosha kuti utange wafambisa chinhambwe pakati pemapoinzi maviri nekukurumidza, wozosvika zvishoma nezvishoma panzvimbo yenzvimbo kuti uve nechokwadi. The motion trajectory inoratidzwa pazasi.

CNC milling muchina uye CNC punching muchina mienzaniso yemuchina maturusi ane mapoinzi ekudzora masimba. CNC masisitimu anoshandiswa chete ekudzora mapoinzi ave mashoma nekuda kwekufambira mberi kweCNC tekinoroji.

(2) Linear kudzora CNC muchina maturusi

Parallel control CNC michina inonziwo linear control CNC michina. Iyo ine hunhu hwekuti haidzore chete nzvimbo chaiyo pakati pemapoinzi asiwo kumhanya kwekufamba uye nzira (trajectory), pakati pemapoinzi maviri. Mafambiro ayo ane hukama chete nemuchina wekushandisa anoronga matemo achifamba achienderana. Izvi zvinoreva kuti kurongeka kumwe chete kunodzorwa panguva. Chishandiso chinogona kushandiswa kucheka pachiyero chekudya chakatsanangurwa panguva yekuchinja. Kazhinji inogona kushandiswa chete kugadzira rectangular uye nhanho zvikamu.

CNC lathesine linear control inonyanya CNC milling machines uye CNC grinders. Uyu muchina weCNC system inozivikanwawo semutsara-kutonga CNC system. Nenzira imwecheteyo, CNC michina inoshandiswa chete yekudzora mutsara haiwanzo.

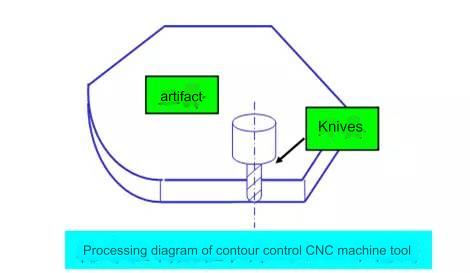

(3) 3D contour control CNC muchina maturusi

Kuenderera mberi kudzora CNC michina inozivikanwawo se contour control CNC michina. Iyo yekudzora chimiro chemuchina uyu kugona kudzora maviri kana anopfuura ekufambisa macoordesheni kamwechete.

Kuti ive nechokwadi chekuti kufambisa kwechishandiso pane iyo workpiece contour inoenderana neiyo machining contour yebasa rekushanda, zvinodikanwa kunyatso kurongedza kutama uye nekumhanyisa kwega kwega kurongeka kwekufamba zvinoenderana nehukama hwakaenzana hwakatemwa.

Kuti ushandise iyi nzira yekudzora, mudziyo weCNC unofanirwa kuve nebasa rekududzira. Interpolation inotsanangura chimiro chemutsara wakatwasuka kana arc nekugadziriswa kwemasvomhu kunoitwa nevashandisi veinterpolation muCNC system. Izvi zvinobva padhata rekutanga rakaiswa nechirongwa, senge zvinorongedzerwa zvemagumo emutsara wakatwasuka, zvinorongedzerwa pamagumo earc, kana radius kana pakati coordinate. Paunenge uchiverenga, govera pulses kune yega yega controller yecoordination axis zvinoenderana nemhedzisiro. Izvi zvinotonga kutamiswa kwekubatanidza kune imwe neimwe konidhi kuti ienderane neinodiwa contour. Panguva yekufamba, chishandiso chinocheka chinoramba chiri pamusoro pechishandiso, icho chinobvumira kugadziridzwa kwakasiyana semitsetse yakatwasuka, macurves, uye arcs. Contour-inodzorwa machining trajectory.

Zvishandiso zvemuchina izvi zvinosanganisira CNC lathes uye milling machines pamwe neCNC wire-cut machines, machining centers, etc. Michina yeCNC inoenderana navo inonzi contour control systems. Inogona kuiswa mumhando nhatu zvichienderana nehuwandu hwematemo ainotonga: fomu

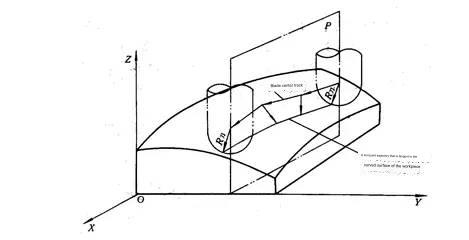

1 maviri-axis links:inonyanya kushandiswa kuCNC lathes iyo inotenderera inotenderera, kana CNC milling muchina iyo inogadzirisa cylindrical nzvimbo yakakomberedzwa.

2 Semi-linkage 2 matemo:Izvi zvinonyanya kushandiswa kudzora maturusi emuchina ane anopfuura matatu mbezo. Mademo maviri anogona kubatanidzwa uye akisi yechitatu inogona kuita nguva nenguva kudya.

3 Matatu-axis Kubatana:Ichi chinongedzo chinosanganisira matatu mitsara yekubatanidza matemo, kazhinji X/Y/Z, uye inoshandiswa ne CNC milling machines, machine centers, etc. Rudzi rwechipiri runokutendera kuti udzore mitsetse miviri yakabatana panguva imwe chete mu X/Y/Z, se pamwe chete neakisi inotenderera inotenderera inotenderedza mutsara wematekisi.

Munzvimbo yemuchina wekutenderedza, semuenzaniso, chinongedzo chiri pakati pematemo maviri emutsetse (X-axis uye Z-axis munzira refu) inofanirwa kudzorwa panguva imwe chete nekubatanidza kune spindle's (C-axis), iyo inotenderera yakatenderedza Z axis. .

4 Four-axis Linkage:Dzora matatu mitsara anoronga X, Y uye Z panguva imwe chete kuti abatanidzwe neakisi imwe inotenderera yekubatanidza.

5 Kubatana kweshanu-axis:Izvi zvinokutendera kuti udzore kubatanidza kweakisi matatu ekubatanidza kamwechete, X/Y/Z. Chishandiso ichi zvakare chinodzora panguva imwe chete maviri eAB uye C anoronga matemo anotenderera achitenderedza aya mademo. Izvi zvinopa huwandu hwematemo mashanu. Chishandiso chave kugona kuiswa chero munzvimbo.

Chishandiso chinogona kudzorwa kuti chitenderere kumativi ese ari maviri x uye y axes panguva imwe chete, saka chinogara chichicheka munzira imwechete seye contour surface. Izvi zvinovimbisa kutsetseka uye kurongeka kwepamusoro. Iyo yakagadzirwa nemichina yakatsetseka, inowedzera kushanda zvakanaka.

2. Kurongwa kwe servo-controlled systems

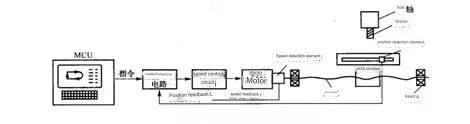

1) Vhura-loop CNC muchina maturusi

Iyi mhando yemuchina wekushandisa ine yakavhurika-loop feed servo, zvinoreva kuti hapana mhinduro yekuona mudziyo. Motokari yayo yekutyaira inowanzova stepper. Chinhu chikuru cheiyo stepper mota ndechekuti inotenderera nhanho izere pese pese apo iyo control system inoshandura pulse chiratidzo. Iyo mota ine yekuzvivharira ficha uye inogona kushandiswa kugadzirisa kureba kona.

Iyo pulse distributor inodzora dhiraivha nekushandisa iyo feed yekuraira chiratidzo kubva kuCNC system. Huwandu hwema pulses uye pulse frequency inogona kuchinjika kudzora kurongeka kwekutamisa, kumhanya kwekufambisa, kana kutamiswa. direction.

Chinhu chikuru cheiyi nzira ndeye nyore, nyore kushandisa, uye mutengo wakaderera. Hapana dambudziko rekusagadzikana nehurongwa hwekutonga nekuti iyo CNC system inongotumira masaini enzira imwe chete. Iko kurongeka kwekutamisa kwakaderera, zvisinei, nekuti iyo mechanical transmission error haina kugadziriswa kuburikidza nemhinduro.

Iyi nzira yekudzora yakashandiswa nemichina yese yekutanga CNC, asi yaive nehuwandu hwekutadza. Pasinei nekuvandudzwa kwemasekete ekutyaira, iyi nzira yekudzora ichiri kushandiswa zvakanyanya nhasi. Iyi nzira yekudzora, kunyanya munyika yedu inoshandiswa kune general CNC masisitimu ane hupfumi uye kushandura midziyo yekare uchishandisa CNC. Iyi nzira yekudzora inobvumirawo imwechete chip komputa kana imwechete bhodhi komputa kuti igadziriswe se CNC muchina, izvo zvinoderedza mutengo weiyo system.

Zvishandiso zvemuchina zvine yakavharwa-loop control

Iyi mhando yeCNC muchina chishandiso inoshandisa yakavharwa-loop control. Iyo mota dhiraivha inogona kunge iri DC kana AC uye inofanirwa kunge iine zvese chinzvimbo mhinduro uye velocity mhinduro yakagadziridzwa kuona chero kufamba chaiko kwechikamu chinofamba chero nguva panguva yekugadziriswa. Iyo CNC system inodyisa iyo mari kumashure munguva chaiyo kune muenzanisi. Chiratidzo chekuraira chinowanikwa kuburikidza nekududzira uye kuenzaniswa nehuwandu. Musiyano unobva washandiswa kudzora servodrive, iyo inotyaira chikamu chekubvisa kuitira kubvisa chikanganiso.

Zvichienderana nenzvimbo uye dhizaini yemhinduro yenzvimbo yemhinduro detector, pane nzira mbiri: yakavharwa loop (yakazara) uye semi-yakavharwa loop (semi-yakavharwa loop).

1 Yakavharwa loop control

Mudziyo wemhinduro yenzvimbo, sezviri kuratidzwa pamufananidzo inoshandisa mutsara wekuona chinhambwe. (Parizvino, mutemo wekugezera unoshandiswa zvakanyanya) Izvi zvakaiswa pachisaro chemuchina. Iyo inoona yakananga mutsara wekutamisa mumichina yekushandisa inoronga. Chiratidzo kubva kumota chinogona kubviswa kuburikidza nemhinduro. Kukanganisa kwekutapurirana kunoderedzwa mucheni yekutapurirana, izvo zvinokonzeresa kurongeka kwepamusoro kwekumisikidzwa kwemuchina.

Mhedzisiro yemagetsi ye mechanical transmission chain yose yakareba zvikuru kupfuura mhinduro yemagetsi. Iyo yese yakavharwa-loop control system yakaoma kwazvo kudzikamisa, uye magadzirirwo ayo uye zvigadziriso zvakaoma. Iyi yakavharwa-loop nzira yekudzora inoshandiswa zvakanyanya kune CNC coordinate michina, CNC chaiyo yekukuya michina, nezvimwe. Izvo zvinoda kurongeka kwepamusoro.

2 Semi-yakavharwa loop control

Mhinduro yenzvimbo yakavakirwa pamakona ekuona zvikamu, izvo parizvino zvakanyanya encoder. Iyo servo motors kana screws yakaiswa nekona yekuona zvikamu (ikozvino kunyanya encoder). Maitiro ekutonga eiyo sisitimu akanyanya kugadzikana nekuti mazhinji emakanika ekutapurirana zvinongedzo haasi muakavharika-loop. Software yakamisikidzwa kukosha muripo inogona kunatsiridza huchokwadi hwema mechanical transmission zvikanganiso, senge screw error. Michina yakawanda yeCNC inoshandisa semi-yakavharwa loop mode.

3 Dimensional hybrid kudzora CNC michina

Kugadzira hybrid control system, maitiro ega ega nzira yekudzora anogona kutariswa zvakasarudzwa. Kuti zvizadzise zvinodiwa zvemamwe maturusi emuchina uye kubhadhara mutsauko uripo pakati penzira mbiri idzi, zvinokurudzirwa kuti chirongwa chekutonga chehybrid chishandiswe. Nzira mbiri dzakajairika imhando yakavhurika-loop inobhadhara uye semi-yakavharwa loop inobhadhara mhando.

3. CNC Systems yakarongedzerwa zvichienderana nebasa ravo rekuita

Iwo CNC masisitimu akaiswa mumapoka matatu zvichienderana neayo nhanho yekushanda: yakaderera, yepakati, uye yakakwirira. Iyi nzira yekupatsanura inoshandiswa zvakanyanya munyika yedu. Zviyero zvezvikamu zvakasiyana kubva kune imwe nguva kuenda kune inotevera. Zvinoenderana nedanho razvino rekusimudzira, marudzi akasiyana eCNC masisitimu akakamurwa kuita mapoka matatu zvichienderana nemamwe mabasa uye zviratidzo. Epakati uye yepamusoro-yekupedzisira CNC masisitimu anowanzo kunzi akazara-basa kana akajairwa CNC.

(1) Kucheka Simbi

Inoreva CNC michina inoita akasiyana siyana ekucheka maoparesheni akadaicnc kutendeuka & kugaya. Izvi zvinogona kukamurwa kuva mapoka makuru maviri.

CNC michina senge lathes uye milling muchina.

Chinhu chikuru chenzvimbo yekugadzira machining iraibhurari yayo yezvishandiso, iyo ine otomatiki-inoshandura michina. Inongopfuura workpiece kuburikidza nemushini kamwe chete. Mushure mekuvhara iyo workpiece, maturusi ekucheka anotsiviwa otomatiki. Nzira dzakasiyana-siyana, kusanganisira kugaya (kutendeuka), makiyi, reming (kuchera), uye tambo taping inoitwa nguva dzose pane imwe neimwe yechidimbu pamushini mumwe chete, semuenzaniso, (kuvaka / kugaya). Center, turning centre, nzvimbo yekuchera, nezvimwe.

(2) Metal Forming

Zvinoreva CNC michina inoshandiswa extrusion, punching uye kudzvanya, pamwe nokudhirowa, uye mamwe kuumba mashandiro. Mimwe yeanonyanya kushandiswa CNC michina inosanganisira CNC mashina uye CNC pombi benders.

(3) Special Processing Category

CNC waya EDM michina ndiyo yakawanda, inoteverwa necnc simbi yekuchekamichina uye CNC laser kugadzirisa michina.

(4) Kuyera nekudhirowa

Inosanganisirwa muchikamu ichi inonyanya kurongeka matatu-dimensional yekuyeresa zviridzwa, CNC maturusi setter, CNC plotters, nezvimwe.

Chinangwa chikuru cheAnebon chichava chekupa iwe vatengi vedu hukama hwakakomba uye hune mutoro webhizinesi, uchipa tarisiro yemunhu kune vese kune New Fashion Design yeOEM Shenzhen Precision Hardware Factory Custom Fabrication.CNC kugayaprocess, precision casting, prototyping service. Unogona kuburitsa mutengo wakaderera pano. Zvakare iwe uchawana yakanaka mhando zvigadzirwa uye mhinduro uye inonakidza sevhisi pano! Haufanire kuzeza kubata Anebon!

New Fashoni Dhizaini yeChina CNC Machining Service uye Tsika CNC Machining Service, Anebon ine nhamba dzekunze dzekutengeserana mapuratifomu, ayo ari Alibaba, Globalsources, Global Market, Made-in-china. "XinGuangYang" HID mhando zvigadzirwa nemhinduro zvinotengeswa zvakanyanya muEurope, America, Middle East nemamwe matunhu anopfuura makumi matatu nyika.

Nguva yekutumira: Oct-06-2023