Zvinodiwa zveCNC muchina maturusi pane zvishandiso zvekushandisa

High kuoma uye kupfeka kuramba

Kuoma kwechikamu chekucheka chechishandiso kunofanira kunge kwakakwirira kudarika kuoma kwezvinhu zvekushanda. Iyo yakakwirira kuoma kwezvinhu zvekushandisa, zviri nani kupfeka kwayo kuramba. Kuoma kwezvinhu zvekushandisa pakupisa kwekamuri kunofanira kunge kuri pamusoro peHRC62. Kuoma kwacho kunogona kuva kwakakwirira kudarika kwezvakajairwaCNC machining zvikamu.

Simba rakakwana uye kuoma

Chishandiso chinotakura kudzvanywa kwakanyanya mukuita kwekucheka zvakanyanya. Dzimwe nguva, inoshanda pasi pesimba uye vibration mamiriro. Kudzivirira chishandiso kubva pakutyoka nekutyoka, mudziyo unofanirwa kuve nesimba rakakwana uye kuoma. Kazhinji, simba rekukotama rinoshandiswa kumiririra kusimba kwechishandiso, uye kukosha kwemhedzisiro kunoshandiswa kutsanangura kuoma kwechishandiso.

yakakwirira kupisa kusagadzikana

Kudzivirira kupisa kunoreva kuita kwemidziyo yekuchengetedza kuoma, kusakara, simba, uye kuomarara pasi pekupisa kwakanyanya. Icho chiratidzo chinotungamira kuyera kucheka kwekuita kwezvinhu zvekushandisa. Kuita uku kunozivikanwa zvakare sekuomarara kwakatsvuka kwemidziyo yekushandisa.

Good thermal conductivity

Iyo yakanyanya kupisa conductivity yemidziyo yekushandisa, iyo yakanyanya kupisa inotamiswa kubva kune chishandiso, iyo inobatsira kudzikisa tembiricha yekucheka yechishandiso uye kuvandudza kusimba kwayo.

Good processability

Kuti ufambise maturusi ekugadzirisa uye kugadzira, zvishandiso zvematurusi zvinofanirwa kunge zvine zvinhu zvakanaka zvekugadzirisa, senge kuforoma, kukungurutsira, welding, kucheka uye grindability, zvivakwa zvekupisa kupisa, uye yakakwirira-tembiricha yepurasitiki deformation yemidziyo yemidziyo. Cemented carbide uye ceramic tool zvinhu zvinodawo zvakanaka sintering uye kumanikidza-kuumba zvivakwa.

Mhando yemidziyo yekushandisa

high-speed simbi

Yakakwira-kumhanya simbi ndeye alloy chishandiso simbi inoumbwa neW, Cr, Mo, uye zvimwe zvinhu zvealloy. Iine kugadzikana kwepamusoro kwekushisa, simba, kuoma, uye imwe dhigirii yekuoma uye kupfeka kusagadzikana, saka yakakodzera kugadzirisa zvisiri-ferrnonferrous uye zvakasiyana-siyana zvesimbi. Pamusoro pezvo, nekuda kwehunyanzvi hwekugadzira ruzha, yakanakira kugadzira maturusi ekugadzira maturusi, kunyanya poda metallurgy high-speed simbi, ine anisotropic mechanical properties uye inoderedza quenching deformation; yakanakira kugadzira chaiyo uye yakaoma kugadzira maturusi.

Hard alloy

Cemented carbide ine kuomarara kwakanyanya uye kupfeka kuramba. PakuchekaCNC inoshandura zvikamu, kushanda kwayo kuri nani pane simbi yakakwirira. Kusimba kwayo kwakati wandei kusvika kumakumi enguva iyo yesimbi inomhanya kwazvo, asi kusimba kwayo kwakashata. Nekuda kwekuita kwayo kwakanaka kwekucheka, inoshandiswa zvakanyanya sechinhu chekushandisa.

Kupatsanurwa uye kumaka kwemasimende carbides yekucheka maturusi

Coated blade

1) Iyo yekupfekedza zvinhu zveCVD nzira ndeyeTiC, iyo inowedzera kusimba kwesimende maturusi ecarbide ne1-3 nguva. Coating thickness: Iyo yekucheka mupendero haina kujeka uye inobatsira kuvandudza hupenyu hwekumhanya.

2) Zvinhu zvekuputira zvePVD zvemuviri mhute deposition nzira ndeye TiN, TiAlN, uye Ti (C, N), iyo inovandudza kusimba kweiyo simende carbide zvishandiso ne2-10 nguva. Thin coating; Mupendero wakapinza; Inobatsira pakuderedza simba rekucheka.

★ Ukobvu hwepamusoro hwekuputira ≤ 16um

CBN uye PCD

Cubic boron nitride (CBN) Kuomarara uye kupisa kwekuita kwe cubic boron nitride (CBN) yakaderera kune diamond, uye ine yakanyanya kupisa uye kugadzikana kwemakemikari. Naizvozvo, yakakodzera kugadzira simbi yakaoma, simbi yakaoma, superalloy, uye simende carbide.

Polycrystalline diamond (PCD) Kana PCD ichishandiswa semudziyo wekucheka, inosiiwa pane simende ye carbide substrate. Inogona kupedzisa kupfeka-kusagadzikana, kuomarara kwepamusoro, kusiri kwesimbi, uye nonferrononferrousaterials senge simende carbide, ceramics, uye yakakwira silicon aluminium alloy.

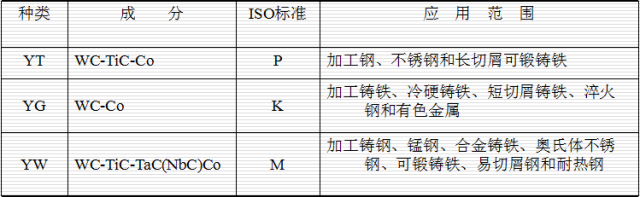

★ ISO machine clamp blade material classification ★

Zvikamu zvesimbi: P05 P25 P40

Simbi isina tsvina: M05 M25 M40

Kukandira simbi: K05 K25 K30

★ Iyo idiki nhamba yacho, iyo yakanyanya kuomarara blade, zviri nani kupfeka kupikisa kwechishandiso, uye zvakanyanya kuipa kupikisa.

★ Iyo yakakura nhamba yacho, iyo blade yakapfava, zviri nani kurwisa kwechishandiso uye kusapfeka kusakara.

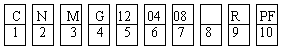

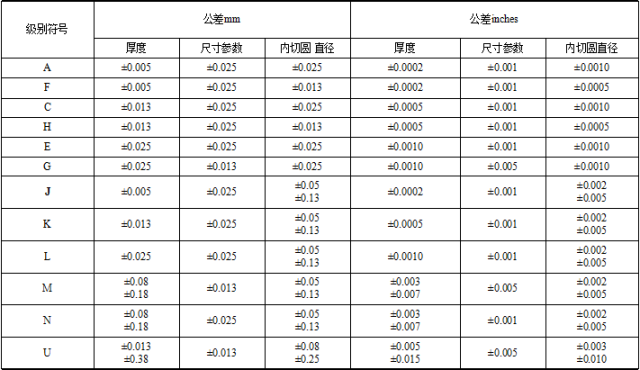

Inoshandurwa kuita blade modhi uye ISO inomiririra mitemo

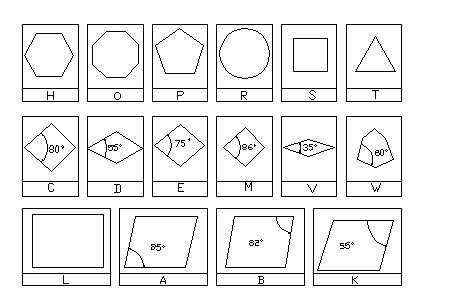

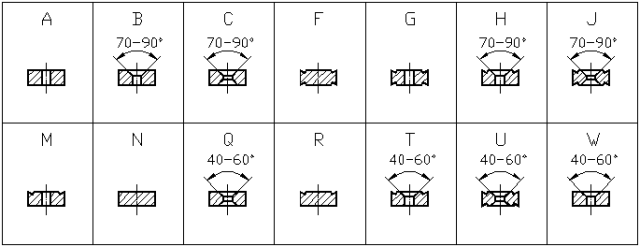

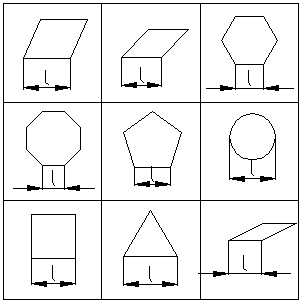

1. Kodhi inomiririra chimiro chebadza

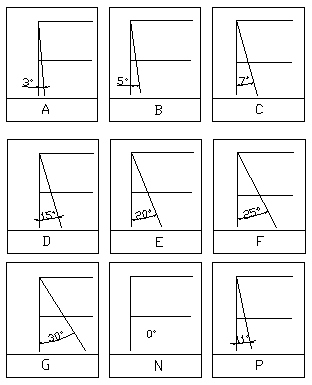

2. Kodhi inomiririra kumashure kwekona yekutungamira kwekucheka

3. Kodhi inomiririra kushivirira kwedimensional yeblade

4. Kodhi inomiririra kutsemuka kwechip uye kusungirira chimiro chebadza

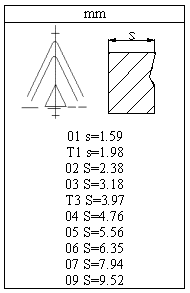

5. Inomiririrwa nehurefu hwekucheka

6. Kodhi inomiririra ukobvu hwebadza

7. Kodhi inomiririra kupenya kumucheto uye R angle

Zvinoreva mamwe manhamba

Rusere zvinoreva kodhi inoratidza zvinodiwa zvakakosha;

9 inomiririra kodhi yekutungamira kwekudya; semuenzaniso, kodhi R inomiririra chikafu chekurudyi, kodhi L inomiririra chikafu chekuruboshwe, uye kodhi N inomiririra chikafu chepakati;

10 inomiririra kodhi ye chip breaking groove type;

11 inomiririra kodhi yezvinhu zvekambani yekushandisa;

kasi yekucheka

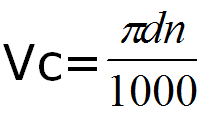

Calculation formula yekucheka kumhanya Vc:

Mune formula:

D - rotary dhayamita yeworkpiece kana tooltip, unit: mm

N - inotenderera yekumhanya yeworkpiece kana chishandiso, unit: r/min

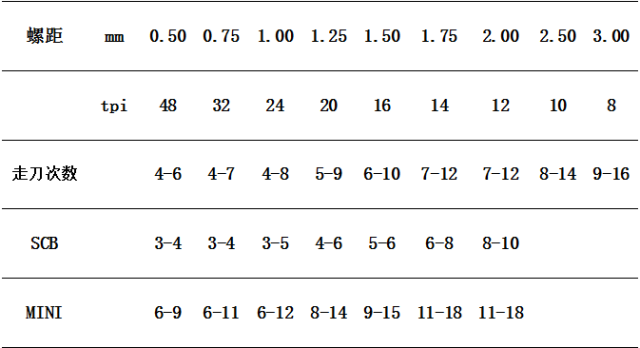

Iyo Speed yeMachining Thread ine Ordinary Lathe

Spindle speed n yekutenderedza shinda. Pakucheka shinda, kumhanya kwechirukwa chelathe kunokanganiswa nezvinhu zvakawanda, senge saizi yeshinda yeshinda (kana lead) yebasa rekushanda, kusimudza nekudzikisa hunhu hwemotokari yedhiraivha, uye kukurumidza kwekududzirwa kweshinda. Naizvozvo, misiyano chaiyo iripo mukumhanya kwekutenderera kwetambo yekutenderera kune akasiyana CNC masisitimu. Iyi inotevera ndiyo fomula yekuverenga iyo spindle kumhanya kana uchitenderedza tambo pane general CNC lathes:

Mune formula:

P - thread pitch kana mutungamiri we workpiece thread, unit: mm.

K - inishuwarenzi coefficient, kazhinji 80.

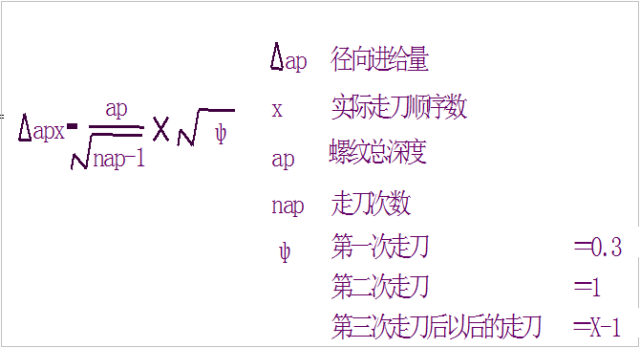

Kuverengera kudzika kwega kwega kwekudya kwekugadzira shinda

Huwandu hwematurusi ekushandisa nzira

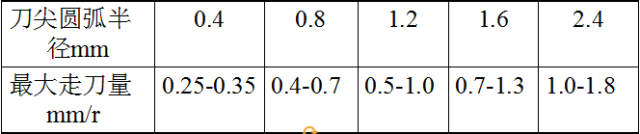

1) Kugadzira kwakashata

Empirical calculation formula ye rough machining feed: f rough=0.5 R

Kupi: R ------ chishandiso tip arc radius mm

F ------ rough machining tool feed mm

2) Kupedza

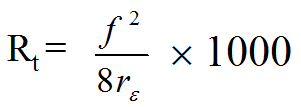

Mune fomula: Rt ------ kudzika kwecontour µ m

F ------ Chiyero chekudya mm/r

r ε ------ Radius ye tooltip arc mm

Siyanisa hutsinye uye pedzisa kutendeuka zvinoenderana nechiyero chekudya uye chip-breaking groove

F ≥ 0.36 rough machining

0.36 > f ≥ 0.17 semi-finishing

F < 0.17 kupedza kugadzira

Haisi zvinhu zveblade asi chip-breaking groove inokanganisa kushata uye kupedzwa kugadzira kweblade. Kucheka kunopinza kana chamfer iri pasi pe40um.

Nguva yekutumira: Nov-29-2022