1. Benchmark

Zvikamu zvinosanganisira nzvimbo dzakati wandei, imwe neimwe iine saizi chaiyo uye zvakafanana chinzvimbo zvinodiwa. Zvinodiwa zvechinzvimbo pakati pezvimiro zvezvikamu zvinosanganisira mativi maviri: kureba kwedimensional kurongeka pakati penzvimbo uye hukama hwechinzvimbo (senge coaxiality, parallelism, perpendicularity uye denderedzwa runout, nezvimwewo) zvinodiwa. Chidzidzo chehukama hwehukama pakati penzvimbo dzezvikamu hazviparadzaniswe kubva kune datum, uye nzvimbo yechikamu chepamusoro haigoni kutsanangurwa pasina datum yakajeka. Mupfungwa yayo yese, iyo datum ndiyo poindi, mutsetse, uye pamusoro pechikamu chinoshandiswa kuona nzvimbo yemamwe mapoinzi, mitsetse, uye nzvimbo. Zvinoenderana nemabasa avo akasiyana, mabhenji anogona kukamurwa kuita mapoka maviri: dhizaini mabhenji uye mabhenji mabhenji.

1. Dhizaini hwaro

Iyo datum inoshandiswa kuona mamwe mapoinzi, mitsetse uye nzvimbo pachikamu chekudhirowa inonzi dhizaini datum. Kune piston, iyo dhizaini datum inoreva pakati pepiston uye yepakati pegomba repini.

2. Maitiro ekuenzanisa

Iyo datum inoshandiswa nezvikamu mukuita machining uye kusangana inonzi process datum. Zvinoenderana nekushandiswa kwakasiyana, mabhenji ekugadzirisa akakamurwa kuita mabhenji ekumisikidza, kuyerwa mabhenji uye mabhenji egungano.

1) Positioning datum: Iyo datum inoshandiswa kuita kuti workpiece itore nzvimbo chaiyo muchina kana chigadziriso panguva yekugadziriswa inonzi iyo yekumisikidza datum. Zvinoenderana neakasiyana ekumisikidza zvikamu, anonyanya kushandiswa ndeaya anotevera mapoka maviri:

Otomatiki pakati uye chinzvimbo: senge matatu-shaya chuck chinzvimbo.

Positioning sleeve positioning: Nzvimbo yekumisikidza inogadzirwa kuita sleeve yekumisikidza, sekumisikidzwa kweplate yekumisa.

Zvimwe zvinosanganisira kumira mune V-yakaita furemu, kumira mune semicircular gomba, nezvimwe.

2) Measurement datum: Iyo datum inoshandiswa kuyera saizi uye chinzvimbo chemushini wakagadzirwa panguva yekuongorora chikamu inonzi kuyerwa datum.

3) Gwaro regungano: Datum rinoshandiswa kuona nzvimbo yechikamu muchikamu kana chigadzirwa panguva yegungano inonzi datum yegungano.

Chechipiri, nzira yekuisa ye workpiece

Kuti ugadzirise nzvimbo inosangana neyakatsanangurwa tekinoroji zvinodiwa pane chimwe chikamu chebasa rekushanda, iyo workpiece inofanirwa kutora nzvimbo chaiyo maererano nechishandiso chiri pamushini wemuchina usati wagadzira. Iyi nzira inowanzonzi "kumira" kweiyo workpiece. Mushure mokunge workpiece yaiswa, nekuda kwechiito chekucheka simba, giravhiti, nezvimwewo panguva yekugadzirisa, imwe nzira inofanira kushandiswa ku "clamp" workpiece kuitira kuti nzvimbo yakatemerwa irambe isina kuchinja. Maitiro ekuwana iyo workpiece munzvimbo chaiyo pamushini uye kusungirira iyo workpiece inonzi "setup".

Hunhu hwekuisa workpiece inyaya yakakosha mukugadzira. Izvo hazvisi izvo zvinongokanganisa zvakananga machining accuracy, kukurumidza uye kugadzikana kwekugadzirisa workpiece, asiwo kunokanganisa chiyero chekubudirira. Kuti ive nechokwadi chekumisikidzwa kwechinzvimbo pakati penzvimbo yakashongedzwa uye dhizaini yedhizaini, iyo workpiece inofanirwa kuisirwa kuitira kuti dhizaini yedhizaini yenzvimbo yakashongedzwa itore nzvimbo chaiyo inoenderana nemuchina chishandiso. Semuenzaniso, mukupedzisa kupedzisa grooves yemhete, kuitira kuti ive nechokwadi chezvinodiwa zvedenderedzwa runout yezasi dhayamita yemhete groove uye axis yejasi, iyo workpiece inofanirwa kuiswa kuitira kuti dhizaini yayo ienderane neaxis. yemuchina wekushandisa spindle.

Paunenge uchigadzira zvikamu pamhando dzakasiyana dzematurusi emuchina, kune nzira dzakasiyana dzekuisa. Iyo nzira dzekuisa dzinogona kuiswa mumhando nhatu: yakananga kurongeka nzira, vanyori alignment nzira uye fixture yekuisa nzira.

1) Yakananga kurongeka nzira Paunenge uchishandisa iyi nzira, iyo chaiyo nzvimbo iyo workpiece inofanira kugara pamushini wemuchina inowanikwa kuburikidza neyakatevedzana yekuedza. Iyo chaiyo nzira ndeye kushandisa dial chiratidzo kana tsono yekunyora pane scribing ndiro kugadzirisa iyo chaiyo nzvimbo yeworkpiece nekutarisa kwekuona mushure mekunge workpiece yaiswa zvakananga pamushini wemuchina, kusvika yazadzisa zvinodiwa.

Kurongeka kwekugadzirisa uye kukurumidza kweiyo nzira yekuenzanisa yakananga kunoenderana nekurongeka kwechokwadi, nzira yekuenzanisa, maturusi ekugadzirisa uye tekinoroji yevashandi. Kukanganisa kwayo ndeyekuti inotora nguva yakawanda, kugadzirwa kwakaderera, uye inoda kushandiswa neruzivo, uye inoda hunyanzvi hwepamusoro kune vashandi, saka inongoshandiswa mune imwechete-chidimbu uye diki-batch kugadzirwa. Semuenzaniso, kuvimba nekutevedzera kurongeka kwemuviri inzira yekurongedza yakananga.

2) Kunyorera kurongedza nzira Iyi nzira ndeyekushandisa scribing tsono pamushini wemuchina kurongedza workpiece zvinoenderana nemutsara wakadhirowewa pane isina chinhu kana semi-yakapera chigadzirwa, kuti iwane iyo chaiyo chinzvimbo. Zviripachena, iyi nzira inoda imwe nzira yekunyora. Mutsetse wakadhirowewa pachawo une hupamhi hwakati, uye pane chikanganiso chekunyora paunenge uchinyora, uye pane chikanganiso chekutarisa paunenge uchigadzirisa chinzvimbo chebasa. Naizvozvo, iyi nzira inonyanya kushandiswa kune madiki ekugadzira mabhechi, yakaderera isina kurongeka, uye mahombe workpiece. Izvo hazvina kukodzera kushandisa zvigadziriso. mukugadzira kwakashata. Semuenzaniso, nzvimbo yepini yepini yechigadzirwa che-two-stroke inotsanangurwa nekushandisa nzira yekumaka yemusoro we indexing.

3) Kushandisa iyo yekuisa yekumisikidza nzira: magadzirirwo emidziyo inoshandiswa kusungirira iyo workpiece uye kuita kuti igare panzvimbo chaiyo inonzi muchina chishandiso chekugadzirisa. Iyo gadziriso ndeyekuwedzera mudziyo wemuchina chishandiso. Chinzvimbo chayo chinoenderana nechishandiso chiri pamushini wemuchina chakagadziridzwa pachine nguva isati yaiswa workpiece, saka hazvifanirwe kurongedza chinzvimbo chimwe nechimwe kana uchigadzira batch yeworkpieces, iyo inogona kuve nechokwadi chehunyanzvi zvinodiwa pakugadzirisa. Iyo inzira inoshanda yekumisikidza inochengetedza basa nedambudziko, uye inoshandiswa zvakanyanya mubatch uye kugadzirwa kwakawanda. Yedu yazvino piston kugadzirisa ndiyo nzira yekumisikidza inoshandiswa.

①. Mushure mekunge workpiece yaiswa, kushanda kwekuchengetedza nzvimbo yekuisa isina kuchinjwa panguva yekugadzira machining inonzi clamping. Chishandiso chiri muchigadziriso chinochengeta workpiece chiri munzvimbo imwechete panguva yekugadziriswa inonzi clamping mudziyo.

②. Iyo clamping mudziyo unofanirwa kuzadzisa zvinotevera zvinodiwa: kana clamping, iyo yekumisikidzwa kweiyo workpiece haifanirwe kukuvadzwa; mushure mekuvhara, nzvimbo ye workpiece panguva yekugadzirisa haifaniri kuchinja, uye iyo clamping inofanira kuva yakarurama, yakachengeteka uye yakavimbika; clamping Chiito chacho chinokurumidza, kushanda kuri nyore uye kuchengetedza basa; chimiro chiri nyore uye kugadzirwa kuri nyore.

③. Chengetedzo kana uchirovera: iyo clamping simba inofanirwa kuve yakakodzera. Kana yakakura kwazvo, workpiece ichave yakaremara. Kana ikanyanya kudiki, iyo workpiece ichabviswa panguva yekugadziriswa uye ichakuvadza kumira kweiyo workpiece.

3. Ruzivo rwekutanga rwekucheka simbi

1. Kushandura kufamba uye kuumbwa kwepamusoro

Kutendeuka kwekufamba: Muchigadziro chekucheka, kuitira kuti ubvise simbi yakawandisa, zvakakosha kuita kuti workpiece uye chigadziro chiite hukama hwekucheka. Iko kufamba kwekubvisa simbi yakawandisa pane yekushanda nechishandiso chekutenderedza palathe inonzi kutendeuka motion, iyo inogona kukamurwa kuita main motion uye feed motion. ipai maekisesaizi.

Main movement: Iyo yekucheka layer pane workpiece inogurwa zvakananga kuti ishanduke kuita machipisi, nekudaro ichigadzira kufamba kwenzvimbo nyowani yeworkpiece, iyo inonzi main movement. Paunenge uchicheka, kutenderera kutenderera kweworkpiece ndiko kufamba kukuru. Kazhinji, kukurumidza kwekufambisa kukuru kwakakwirira, uye simba rekucheka rinopedzwa rakakwirira.

Kudya kwekudya: kufamba kwekugadzira mutsva wekucheka unoramba uchiiswa mukucheka, kufamba kwekudya ndiko kufamba pamwe chete nechepamusoro pe workpiece kuti iumbwe, iyo inogona kuenderera mberi kana kufamba kwepakati. Semuyenzaniso, kufamba kwechishandiso chekushandura pane yakatwasuka lathe kunoenderera, uye kufamba kwechikafu kwechishandiso papurani ndiko kufamba kunopindirana.

Zviso zvakaumbwa pane workpiece: Panguva yekucheka, nzvimbo dzakagadzirwa nemichina, nzvimbo dzakagadzirwa nemichina, uye nzvimbo dzinofanirwa kugadzirwa dzinoumbwa pane workpiece. Finished surface (finished surface) zvinoreva nzvimbo itsva yakabviswa pasimbi yakawandisa. Musoro unogadzirwa (face to be machined) zvinoreva nzvimbo panochekwa simbi. Mushonga wakagadzirwa (machined surface) unoreva nzvimbo iri kutenderedzwa nechikamu chekucheka.

2. Zvinhu zvitatu zvekucheka huwandu zvinoreva kucheka kudzika, chiyero chekudya uye kukurumidza kucheka.

1) Kucheka kudzika: ap = (dw-dm) / 2 (mm) dw = dhayamita yeunmachined workpiece dm = dhayamita yemashini yakagadzirwa workpiece, kudzika kwekucheka ndiko kwatinowanzo kudana kuwanda kwekucheka.

Sarudzo yekucheka kudzika: Iyo yekucheka kudzika αp inofanirwa kutemerwa zvinoenderana neiyo machining mvumo. Kana uchimonera, kuwedzera pakusiya mvumo yekupedzesa, iyo yese yekubvumidza yekubvumidza inofanira kubviswa mune imwe ipfuure kusvika sezvinobvira. Izvi hazvigone kungoita chigadzirwa chekucheka kudzika, chiyero chekudya ƒ uye kucheka kukurumidza V yakakura pasi pechigadziro chekuvimbisa imwe nhanho yekusimba, asi zvakare kuderedza nhamba yekupfuura. Kana iyo machining allowance yakakura kana kuti kuomarara kwegadziriro yegadziriro hakuna kukwana kana kuti simba reblade harina kukwana, rinofanira kukamurwa kuita zvinopfuura zviviri. Panguva ino, kudzika kwekucheka kwekupfuura kwekutanga kunofanira kunge kwakakura, iyo inogona kuverenga 2/3 kusvika 3/4 yemubhadharo wose; uye kudzika kwekucheka kwechipiri chekupfuura kunofanira kuva kuduku, kuitira kuti nzira yekupedzisa inogona kuwanikwa. Diki pamusoro roughness parameter ukoshi uye yakakwirira machining kururama.

Kana pamusoro pezvikamu zvekucheka zvikaita ganda rakaoma-ganda castings, forgings kana simbi isina tsvina uye zvimwe zvakanyanya kutonhora zvinhu, kudzika kwekucheka kunofanira kudarika kuoma kana kuti chilled layer kuti urege kucheka mipendero kubva pakucheka pamucheka wakaoma kana wakatonhora.

2) Kusarudzwa kwehuwandu hwekudya: iyo hama yekuchinjisa yeworkpiece uye chishandiso munzira yekufambisa kwekudya pese pese kana workpiece kana chishandiso chinotenderera kana kudzorera kamwe chete, iyo unit ndeye mm. Mushure mekucheka kudzika kwakasarudzwa, chikafu chikuru chinofanira kusarudzwa kusvika pazvinobvira. Kusarudzwa kwekukosha kunonzwisisika kwechikafu kunofanirwa kuve nechokwadi chekuti chishandiso chemuchina uye chishandiso hachizokuvadzwa nekuda kwesimba rakawanda rekucheka, kutsauka kweiyo workpiece inokonzerwa neiyo yekucheka simba haipfuure kukosha kunobvumidzwa kweiyo workpiece kurongeka, uye iyo yepamusoro roughness parameter kukosha haizove yakakurisa. Kana roughing, muganho mukuru wekudyisa kucheka simba, uye muhafu-yekupedzisa nekupedzisa, muganho mukuru wekudyisa ndeyekushata kwepamusoro.

3) Kusarudzwa kwekucheka kukurumidza: Panguva yekucheka, kukurumidza kwekukurumidza kweimwe nzvimbo pamucheto wekucheka kwechigadziro chinoenderana nechepamusoro kuti chigadzirwe mumutambo mukuru wekufamba, chikwata chiri m / min. Kana iyo yakadzika yeakachekwa αp uye chiyero chekudya ƒ inosarudzwa, iyo yakanyanya kucheka kumhanya inosarudzwa pane izvi hwaro, uye kutungamira kwekutungamira kwekucheka kwekucheka kwakanyanya-kumhanya kucheka.stamping chikamu

Chechina, iyo mechanical pfungwa yekukasharara

Mumakanika, kukwasha kunoreva zvimiro zve geometrical zvidiki zvine nzvimbo diki nenhongonya uye mipata panzvimbo yakagadzirwa nemichina. Ndiyo imwe yematambudziko ekutsvaga kwekushandurwa. Kushata kwepamusoro kunowanzo kuumbwa nemaitiro ekugadzirisa anoshandiswa uye zvimwe zvinhu, senge kupokana pakati pechishandiso nepamusoro pechikamu panguva yekugadziriswa, kugadzirwa kwepurasitiki kwesimbi yepamusoro kana machipisi apatsanurwa, uye yakanyanya-frequency vibration mukati. iyo process system. Nekuda kwemaitiro akasiyana ekugadzirisa uye workpiece zvinhu, kudzika, density, chimiro uye manyorerwo emamaki akasiiwa pachigadzirwa chakagadzirwa zvakasiyana. Kushata kwepamusoro kune hukama nehukama hwezvivakwa, kupfeka kuramba, simba rekuneta, kuomarara kwekubata, kuzunguzika uye ruzha rwezvikamu zvemakina, uye zvine chekuita kwakakosha pahupenyu hwesevhisi uye kuvimbika kwezvigadzirwa zvemakanika.aluminium yekukanda chikamu

Hushasha hunomiririra

Mushure mokunge chikamu chechikamu chacho chagadziriswa, chinotaridzika chakatsetseka, asi chisina kuenzana mushure mekukura. Surface roughness inoreva ma micro-geometric maficha anoumbwa netunhambwe uye madiki enhongonya uye mipata pamusoro pechikamu chakagadziriswa, icho chinowanzo umbwa nenzira yekugadzirisa uye (kana) zvimwe zvinhu. Basa repamusoro pechikamu rakasiyana, uye iyo inodiwa yepamusoro roughness parameter kukosha yakasiyanawo. Iyo yekumusoro roughness kodhi (chiratidzo) inofanirwa kumakwa pachikamu chekudhirowa kutsanangura maitiro epamusoro anofanirwa kuwanikwa mushure mekupedzwa kwepamusoro. Kune mhando nhatu dzehurebu hwepamusoro paramita:

1. Contour arithmetic zvinoreva kutsauka Ra

Masvomhu anoreva kukosha kwechinhambwe chiri pakati pemapoinzi pamutsara wecontour munzira yekuyera (Y direction) uye mutsara wereferenzi mukati meurefu hwesampling.

2. Gumi-point urefu Rz ye microscopic kusaenzana

Zvinoreva huwandu hweavhareji ye5 hombe mbiri yepamusoro peak uye 5 yakakura mbiri mupata wakadzika mukati meurefu hwesampling.

3. Kureba kwepamusoro kwe contour Ry

Nhambwe iri pakati pemutsara wepamusoro-soro uye mutsetse wemupata wakaderera weprofile mukati meurefu hwesampling.

Panguva ino, Ra. inonyanya kushandiswa muindasitiri yekugadzira michina.

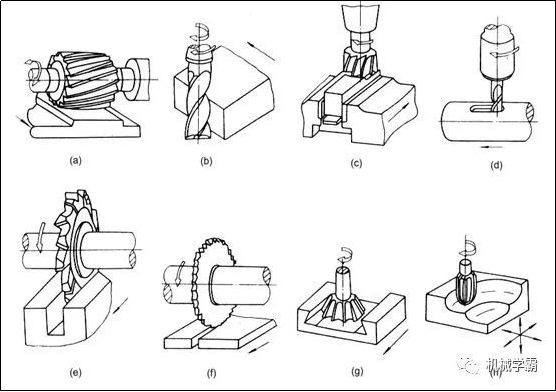

mufananidzo

4. Roughness Representation Method

5. Mhedzisiro yekukasharara pakuita kwezvikamu

Hunhu hwepamusoro hweiyo workpiece mushure mekugadzirisa hunobata zvakanangana nemuviri wayo, kemikari, uye michina zvinhu. Kushanda kwekushanda, kuvimbika uye hupenyu hwechigadzirwa hunoenderana nehupamhi hwepamusoro hwepamusoro pezvikamu zvikuru. Kazhinji, zvinodikanwa zvemhando yepamusoro zvezvikamu zvakakosha kana zvakakosha zvakakwirira kupfuura zvikamu zvakajairwa nekuti zvikamu zvine kunaka kwepamusoro zvinovandudza zvakanyanya kusagadzika kwavo kupfeka, kuramba kwecorrosion, uye kusagadzikana kwekukuvara kwekuneta.CNC machining aluminium chikamu

6. Kucheka mvura

1) Basa rekucheka mvura

Kutonhodza maitiro: Kupisa kwekucheka kunogona kubvisa huwandu hukuru hwekucheka kupisa, kunatsiridza mamiriro ekupisa kupisa, kuderedza tembiricha yechishandiso uye workpiece, nekudaro kuwedzera hupenyu hwesevhisi yechishandiso uye kudzivirira kukanganisa kwedimensional yeworkpiece inokonzerwa ne. thermal deformation.

Lubrication: Mvura yekucheka inogona kupinda pakati pechishandiso nechishandiso, kuitira kuti mutsetse wakatetepa we adsorption firimu uumbwe mudiki diki pakati pechipi nechishandiso, izvo zvinoderedza friction coefficient, saka inogona kuderedza kupokana pakati pechishandiso. chip uye workpiece , kuderedza simba rekucheka uye kupisa kupisa, kuderedza kupera kwechishandiso uye kuvandudza hutano hwepamusoro hwebasa rekushanda. Pakupedzisa, lubrication inonyanya kukosha.

Kuchenesa maitiro: Iwo machipisi madiki anogadzirwa panguva yekuchenesa ari nyore kuomerera kune workpiece uye chishandiso, kunyanya kana kudhirowa makomba akadzika uye maburi ekudzoreredza, machipisi anovharika zviri nyore muchip flute, ayo anokanganisa kushata kweiyo workpiece uye. hupenyu hwesevhisi yechishandiso. . Kushandiswa kwekucheka kwemvura kunogona kukurumidza kushambidza machipisi, kuitira kuti kucheka kuitwe zvakanaka.

2) Type: Kune marudzi maviri ezvinwiwa zvekucheka zvinowanzoshandiswa

Emulsion: Inonyanya kuita basa rekutonhora. Iyo emulsion inogadzirwa nekudzikisa mafuta emulsified ne 15 ~ 20 nguva dzemvura. Iri rudzi rwekucheka mvura ine hombe chaiyo kupisa, yakaderera viscosity uye yakanaka fluidity, uye inogona kutora kwakawanda kupisa. Kucheka fluid kunonyanya kushandiswa kutonhora chishandiso uye workpiece, kunatsiridza hupenyu hwematurusi uye kuderedza kupisa kwemafuta. Iyo emulsion ine yakawanda mvura, uye iyo lubrication uye ngura yekudzivirira mabasa haina kunaka.

Kucheka mafuta: Chinhu chikuru chekucheka mafuta imineral oil. Mhando iyi yekucheka mvura ine diki chaiyo kupisa, yakakwira viscosity uye isina kuyerera mvura. Inonyanya kuita basa rekuzora. Mamineral oiri ane low viscosity anowanzo shandiswa, senge mota mafuta, light diesel mafuta, Kerosene nezvimwe.

Anebon Metal Products Limited inogona kupa CNC Machining, Die Casting, Sheet Metal Fabrication service, ndapota inzwa wakasununguka kutibata nesu.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Nguva yekutumira: Jun-24-2022