Aluminium ndiyo inonyanya kushandiswa isiri-ferrous metal material, uye kushandiswa kwayo kuri kuramba kuchiwedzera. Anopfuura zviuru mazana manomwe emhando dzearuminiyamu zvigadzirwa zvinogadzirwa uchishandisa aruminiyamu zvinhu. Zvinoenderana nenhamba, kune anopfuura zviuru mazana manomwe emarudzi ezvigadzirwa zvealuminium, uye maindasitiri akasiyana, senge indasitiri yekuvaka nekushongedza, indasitiri yezvekufambisa, indasitiri yezvemuchadenga, nezvimwe, zvine zvido zvakasiyana. Nhasi, Xiaobian ichaunza tekinoroji yekugadzirisa zvigadzirwa zvealuminium uye maitiro ekudzivirira kugadzirisa deformation.CNC machining chikamu

Zvakanakira uye maitiro ealuminium ndeaya anotevera:

1. Low density. Density yealuminium inenge 2.7 g/cm3. Density yayo inongova 1/3 yesimbi kana mhangura.

2. High plasticity. Aluminium inochinjika uye inogona kugadzirwa kuita zvigadzirwa zvakasiyana nekumanikidza nzira dzekugadzirisa dzakadai seextrusion uye kutambanudza.

3. Corrosion resistance. Aluminium isimbi yakashata yakachajiswa, uye firimu rekudzivirira reoxide richaumbwa pamusoro pepasi pemamiriro echisikigo kana anodizing. Iine zviri nani corrosion resistance pane simbi.

4, nyore kusimbisa. Aluminium yakachena haina kusimba zvakanyanya, asi inogona kuwedzerwa neanodizing.

5. Easy pamusoro kurapwa. Kurapa kwepamusoro kunogona kuwedzera kana kushandura nzvimbo dzepamusoro dzealuminium. Iyo aluminium anodizing process yakanyatso kurongeka uye yakagadzikana uye yakashandiswa zvakanyanya kugadzira zvigadzirwa zvealuminium.

6. Good conductivity uye nyore kudzokorora.

Kugadzirisa tekinoroji yezvigadzirwa zvealuminium

Kurovera kwealuminium zvigadzirwa

1. Chibhakera chinotonhora

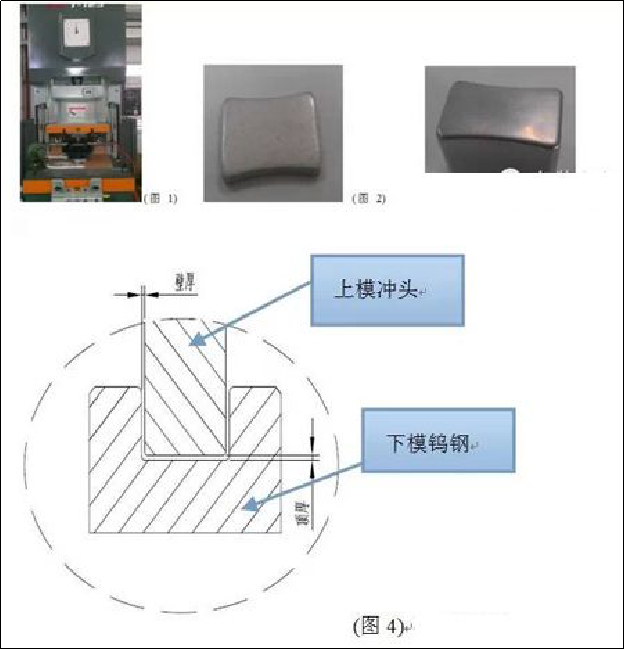

Shandisa zvinhu zvealuminium pellets. Iyo extrusion muchina uye inofa inoshandiswa kune imwe-nguva kuumba uye inokodzera zvigadzirwa zvecylindrical kana zvigadzirwa zvimiro zvinonetsa kuwana nekutambanudza maitiro, senge oval, square, uye rectangular zvigadzirwa.

Iyo tonnage yemuchina unoshandiswa ine hukama neyakachinjika-chikamu nharaunda yechigadzirwa. Chigadzirwa kukora kwemadziro ndiwo mukaha uripo pakati peyepamusoro die punch uye yakaderera die tungsten simbi. Kana iyo yekumusoro die punch uye yepasi die tungsten simbi zvakatsikirirwa pamwe chete, iro rakamira rakamira kuzasi rakafa pakati nderokukora kwepamusoro kwechigadzirwa.chikamu chealuminium

Zvakanakira: Iyo mold yekuvhura kutenderera ipfupi, uye mutengo wekuvandudza wakaderera pane iwo wekudhirowa mold.

Zvakaipa: Maitiro ekugadzira akareba, saizi yechigadzirwa inochinja zvakanyanya, uye mutengo wevashandi wakakwira.

2. Kutambanudza

Shandisa zvinhu zvealuminium ganda. Yakakodzera kutsveyamisa isiri-cylindrical miviri (aruminiyamu zvigadzirwa zvine curved zvigadzirwa), kazhinji uchishandisa inoenderera inofa michina uye molds kusangana nezvinodiwa zvechimiro.

Zvakanakira: zvakanyanya kuomarara uye akawanda deformation zvigadzirwa zvine yakagadzikana dimensional kudzora mukugadzira maitiro, uye chigadzirwa chepamusoro chiri nyore.

Zvakaipa: mutengo wakakwira mold, kutenderera kwakareba kwekusimudzira, uye kusarudzwa kwemuchina wepamusoro uye zvinodiwa nemazvo.

Kurapa kwepamusoro kwezvigadzirwa zvealuminium

1. Sandblasting (pfuti peening)

Iyo nzira yekuchenesa uye roughening simbi nzvimbo uchishandisa kukanganisa kwepamusoro-kumhanya jecha kuyerera.

Iko kurapwa kwepamusoro kwezvikamu zvealuminium mune iyi nzira inogona kuwana imwe dhigirii yehutsanana uye hutsinye hwakasiyana pamusoro peiyo workpiece kuitira kuti mashandiro emagetsi epamusoro peiyo workpiece avandudzwe, nekudaro kuvandudza kusimba kwekuneta kweiyo workpiece uye kuwedzera iyo mukaha pakati payo nejasi. Iko kusungirirwa kwekuputira kunowedzera kusimba kweiyo firimu yekuvhara uye kunobatsirawo kuenzana nekushongedza kwejira. Isu tinoona mukuita uku kuti zvigadzirwa zveApple ndezve o2. Kukwenenzvera

Ivo vanoshandisa mechanika, kemikari, kana electrochemical chiito kudzikisa kushata kwepamusoro kwechishandiso uye kuwana inopenya, yakatsetseka pamusoro pekugadzirisa nzira. Iyo polishing process yakakamurwa kuita mechanic, makemikari, uye electrolytic polishing. Mushure memechani yekupenya + electrolytic polishing, zvikamu zvealuminium zvinogona kuva padyo negirazi mhedzisiro yesimbi isina tsvina. Iyi nzira inopa vanhu pfungwa yekureruka kwepamusoro uye ramangwana rine fashoni.

3. Kudhirowa

Metal waya kudhirowa ndiyo nzira yekugadzira yekudzokorora kukwesha pepa realuminium kunze kwemitsara nesandpaper. Kudhirowa kunogona kupatsanurwa kuita kwakatwasuka, kusina, kutenderera, uye shinda. Iyo simbi waya yekudhirowa maitiro inogona kunyatsoratidza diki diki mamaki, saka rakanatswa bvudzi rinopenya rinoonekwa mune simbi matte, uye chigadzirwa chine pfungwa yefashoni uye tekinoroji.

4. High gloss kucheka

Uchishandisa muchina wekutemera, banga redhaimani rinosimbiswa pane shaft huru yemuchina wekutemera, ichitenderera nekumhanya kwazvo (kazhinji 20,000 rpm) kucheka zvikamu, uye nzvimbo yenzvimbo inoyevedza inogadzirwa pamusoro pechigadzirwa. Kupenya kwezvibodzwa zvekucheka kunokanganiswa nekumhanya kwechigayo. Iyo inokurumidza kukurumidza kudhiraivha, kupenya kwekucheka kwakakwirira, uye zvinopesana, kusviba uye kunowanikwa zvakanyanya kugadzira mitsara yekucheka. High-gloss uye yakakwirira-gloss yekucheka inonyanya kushandiswa mumafoni efoni sePhones. Mamwe epamusoro-ekupedzisira TV simbi mafuremu achangobva kutora yakakwira-gloss milling process. Pamusoro pezvo, anodizing uye waya yekudhirowa maitiro anoita kuti TV seti izere nefashoni uye tekinoroji.

5. Anodizing

Anodic oxidation inoreva electrochemical oxidation yesimbi kana alloys. Pasi pema electrolyte anoenderana uye chaiwo maitirwo ezvinhu, aruminiyamu uye alloys ayo anoumba oxide firimu pane aruminiyamu chigadzirwa (anode) nekuda kwekuita kweiyo yakaiswa ikozvino. Anodizing haingogadzirise chete kukanganisa kwealuminium kuomarara kwepamusoro uye kupfeka kuramba asi zvakare kurebesa hupenyu hwesevhisi yealuminium uye kuwedzera aesthetics. Yakave chikamu chakakosha chealuminium pamusoro kurapwa uye parizvino ndiyo inonyanya kushandiswa uye yakabudirira kwazvo. craft

6. Anode-mavara maviri

Mbiri-mavara anodizing inoreva anodizing pane chimwe chigadzirwa uye kupa mavara akasiyana kune dzakati nzvimbo. Iwo maviri-mavara anodizing maitiro haawanzo shandiswa muindasitiri yeTV nekuti maitiro acho akaoma uye anodhura zvakanyanya. Kunyange zvakadaro, kusiyana pakati pemavara maviri kunogona

zviri nani kuratidza chimiro chepamusoro uye chakasiyana chechigadzirwa.

Maitiro matanho uye hunyanzvi hwekushanda kuderedza deformation yealuminium kugadzirisa

Pane zvikonzero zvakawanda zvekugadziriswa kwealuminium zvikamu, zvine hukama nechinhu, chimiro chechikamu, uye mamiriro ekugadzira. Pane zvinonyanya zvinotevera zvinhu: deformation inokonzerwa nekushushikana kwemukati kwe blank, deformation inokonzerwa nekucheka simba uye kucheka kupisa, uye deformation inokonzerwa ne clamping simba.

Maitiro matanho ekudzikisa kugadzirisa deformation

1. Deredza kushushikana kwemukati kwetsika yebvudzi

Kuchembera kwechisikigo kana kwekugadzira uye kurapwa kwekudengenyeka kunogona kubvisa zvishoma kushushikana kwemukati kwechinhu chisina chinhu. Pre-processing zvakare inzira inoshanda nzira. Nekuda kwemvumo yakakura, iyo deformation mushure mekugadzirisa yakakoshawo kune isina chinhu ine mafuta musoro uye nzeve hombe. Ngatiti iyo yakawandisa chikamu chisina chinhu chakafanogadziriswa, uye kubvumirwa kwechikamu chimwe nechimwe kunoderedzwa. Muchiitiko ichocho, inogona kuderedza kushandiswa kwekugadzirisa kwemaitiro anotevera uye kusunungura kumwe kushushikana kwemukati mushure mekugadzirisa kwekugadzirisa kwenguva yakati.

2. Kuvandudza kugona kwekucheka kwechombo

Zvinhu uye geometric parameters yechishandiso zvine simba rinokosha pakucheka simba uye kupisa kupisa. Kusarudzwa kwakakodzera kwechishandiso kunofanirwa kuderedza machining deformation yechikamu.

1) Kusarudzwa kunonzwisisika kwechishandiso geometric parameter.

①Rake angle: Pasi pemamiriro ekuchengetedza simba reblade, iyo angle angle inosarudzwa zvakakodzera kuti ive yakakura; kune rumwe rutivi, inogona kukuya muromo wakapinza, uye kune rumwe rutivi, inogona kuderedza kucheka deformation, kuita kuti chip chibviswe chinyoro, uye zvino kuderedza simba rekucheka uye kupisa kwekucheka. Usamboshandisa zvishandiso zvine negative rake angle.

②Kuyamura kona: Saizi yekona yekuyamura inobata zvakananga kupfeka kweflank uye mhando yemuchina. Ukobvu hwekucheka chinhu chakakosha pakusarudza angle yekubvisa. Chishandiso chinoda kupisa kwakanaka kwekupisa panguva yekugaya kwakashata nekuda kweiyo yakakosha chiyero chekudya, inorema yekucheka mutoro, uye yakakura kupisa chizvarwa. Nokudaro, kona yekuchenesa inofanira kusarudzwa kuti ive duku. Kana kugaya kwakanaka, mupendero wekucheka unofanirwa kuve wakapinza, kupokana pakati pechiso cheflank uye nzvimbo yakashongedzwa inoderedzwa, uye elastic deformation inoderedzwa. Nokudaro, kona yekuchenesa inofanira kuva yakakosha.

③ Helix angle: Iyo helix angle inofanirwa kunge yakakura sezvinobvira kutsvedzerera uye kuderedza simba rekugaya.

④Main declination angle: Kunyatso kudzikisa iyo yepakati declination angle inogona kuvandudza kupisa kwekupisa mamiriro uye kuderedza avhareji tembiricha yenzvimbo yekugadzirisa.

2) Kuvandudza chigadziro chekushandisa.

① Deredza huwandu hwemazino ekucheka kwekucheka uye kuwedzera chip nzvimbo. Nekuda kwehukuru hwepurasitiki yearuminiyamu zvinhu uye yakakura yekucheka deformation panguva yekugadziriswa, yakakwana chip nzvimbo inodiwa, saka radius yepasi ye chip groove inofanirwa kuve yakakosha, uye huwandu hwemazino ekugaya ekucheka hunofanira kunge hudiki.

② Kugeda mazino zvakanaka. Iko roughness kukosha kwekucheka kwekucheka kwemazino ekucheka kunofanira kuva pasi peRa = 0.4um. Usati washandisa banga idzva, unofanira kushandisa dombo rakanaka remafuta kurodza zvishoma kumberi nekuseri kwemazino ebanga kuti ubvise maburrs uye kutsemuka kudiki kwasara pakurodza mazino. Nenzira iyi, kupisa kwekucheka kunogona kuderedzwa, uye deformation yekucheka ishoma.

③ Nyatsodzora chiyero chekupfeka chechishandiso. Mushure mekunge chishandiso chapfekwa, kukosha kwepamusoro kweiyo workpiece kunowedzera, tembiricha yekucheka inokwira, uye iyo workpiece deformation inowedzera. Naizvozvo, mukuwedzera pakusarudza maturusi emidziyo ane yakanaka kupfeka kuramba, chiyero chekupfeka hachifanirwe kuve chakanyanya kunaka kupfuura 0.2mm. Zvikasadaro, zviri nyore kugadzira mupendero wakavakwa. Kana uchicheka, tembiricha yeworkpiece haifanire kudarika 100 ℃ kudzivirira deformation.

3. Kuvandudza clamping nzira ye workpiece

Kune matete-walled aruminiyamu workpieces asina kusimba kusimba, dzinotevera nzira dzekusunga dzinogona kushandiswa kuderedza deformation:

①Kune zvikamu zvakatetepa-zvakakomberedzwa nemadziro, kana iyo-shayi-yega-yega-yepakati chuck kana chitubu chuck ichishandiswa kune radial clamping, iyo workpiece inozokanganisa kana ichinge yaburitswa mushure mekugadziriswa. Iyo nzira yekutsikirira iyo axial yekupedzisira kumeso nekuomarara kuri nani inofanira kushandiswa. Isa buri remukati mechikamu, gadzira mandrel ane thread, woipinza mukati megomba remukati, dzvanya kumagumo kumeso nendiro yekuvhara pairi, wobva waisimbisa nenzungu. Clamping deformation inogona kudzivirirwa kana uchigadzira denderedzwa rekunze kuti uwane chokwadi chinogutsa.

② Paunenge uchigadzira matete-akakomberedzwa uye akatetepa-plate workpieces, zviri nani kushandisa vacuum suction cups kuti uwane yakaenzana yakagovaniswa clamping simba uye wozogadzira nekadiki kekucheka, izvo zvinogona kudzivirira workpiece deformation.

Mukuwedzera, nzira yekutakura inogonawo kushandiswa. Kuti uwedzere kuomarara kweatete-walled workpieces, svikiro rinogona kuzadzwa mukati meiyo workpiece kuderedza deformation ye workpiece panguva ye clamping nekucheka. Semuenzaniso, urea melt ine 3% kusvika 6% potassium nitrate inodururwa muworkpiece. Mushure mekugadzirisa, iyo workpiece inogona kunyudzwa mumvura kana doro, uye iyo filler inogona kunyungudutswa uye kudururwa.

4. Kurongeka kunonzwisisika kwemaitiro

Munguva yekucheka kwepamusoro-soro, nekuda kwemvumo yakakura yekugadzira uye kukanganiswa kwekucheka, maitiro ekugaya anowanzo gadzira vibration, iyo inokanganisa machining iko uye kushata kwepamusoro. Naizvozvo, iyo CNC yakakwira-kumhanya yekucheka maitiro anogona kazhinji kukamurwa kuita roughing-semi-kupedza-kona-kuchenesa-kupedza uye dzimwe nzira. Dzimwe nguva zvinodikanwa kuti zvikamu zvine yakanyanya kurongeka zvinodiwa kuita yechipiri semi-kupedzisa uye kupedza. Mushure mekugadzirwa kwakashata, zvikamu zvinogona kutonhodzwa zvakasununguka, kubvisa kushushikana kwemukati kunokonzerwa nekukasira machining uye kuderedza deformation. Mvumo inosiiwa mushure mekugadzirwa kwakashata inofanira kunge yakakura kudarika deformation, kazhinji 1 kusvika 2 mm. Munguva yekupedzisa, iyo yekupedzisa nzvimbo yezvikamu inofanira kuchengetedza yunifomu machining mvumo, kazhinji 0.2 ~ 0.5mm, kuitira kuti chishandiso chigadzikane panguva yekugadzira machining, iyo inogona kuderedza zvakanyanya kutema deformation, kuwana yakanaka machining mhando uye kuve nechokwadi cheChigadzirwa chakarurama.

Unyanzvi hwekushanda kuderedza machining kukanganisa

Pamusoro pezvikonzero zviri pamusoro apa, zvikamu zvealuminium zvikamu zvakaremara panguva yekugadziriswa. Nzira yekushanda inokoshawo mukushanda chaiko.

1. Kune zvikamu zvine mvumo yakakura yekugadzira machining, kuvapa mamiriro ari nani ekupisa kupisa panguva yekugadzira uye kudzivirira kupisa kwekupisa, symmetrical machining inofanira kugamuchirwa panguva yekugadzira. Kana 90mm gobvu shizha rinoda kugadziriswa kusvika 60mm kana rumwe rutivi rwakagayiwa uye rumwe rutivi ruchigaiwa pakarepo, uye saizi yekupedzisira inogadziriswa panguva imwe chete, iyo flatness ichasvika 5mm; kana ikagadziriswa symmetrically nekudzokororwa kudyisa, divi rega rega rinogadziriswa kaviri kusvika Iyo yekupedzisira dimension inogona kuvimbisa flatness ye0.3mm.stamping chikamu

2. Kana pane zvivharo zvakawanda pazvikamu zveplate, hazvina kukodzera kushandisa sequential processing method yeimwe cavity uye imwe mhango panguva yekugadzirisa, iyo inokurumidza kuita kuti zvikamu zvigadziriswe nekuda kwekusagadzikana kusagadzikana. Multi-layer processing inogamuchirwa, uye yega yega inogadziriswa kune ese cavities panguva imwe chete, uye ipapo iyo inotevera dhizaini inogadziriswa kuita kuti zvikamu zvisimbiswe zvakaenzana uye kuderedza deformation.

3. Deredza simba rekucheka nekucheka kupisa nekushandura chiyero chekucheka. Pakati pezvinhu zvitatu zvekucheka chiyero, chiyero chekudzokera shure chinokanganisa zvikuru simba rekucheka. Kana machining allowance akakurisa, simba rekucheka reimwe pass rakakurisa, izvo zvisingazongokanganisa zvikamu chete asiwo zvinokanganisa kusimba kwechirukwa chemuchina uye kuderedza kusasimba kwechishandiso—nhamba yemapanga anofanira kudyiwa. Kana musana wakaderedzwa, kushanda kwekugadzira kuchaderedzwa zvakanyanya. Nekudaro, kumhanyisa-kumhanya kunoshandiswa muCNC machining, iyo inogona kukunda dambudziko iri. Paunenge uchideredza huwandu hwekucheka-shure, chero bedzi chikafu chichiwedzerwa maererano uye kukurumidza kwechigadzirwa chechina kuchiwedzerwa, simba rekucheka rinogona kuderedzwa, uye kushanda kwekugadzirisa kunogona kuvimbiswa panguva imwe chete.

4. Kurongeka kwekufamba kwebanga kunofanirawo kutariswa. Hutsinye machining inosimbisa kuvandudza kushanda zvakanaka uye kutevera chiyero chekubvisa pachikamu chenguva. Kazhinji, up-cut milling inogona kushandiswa. Ndiko kuti, iyo yakawandisa zvinhu pamusoro peiyo isina chinhu inobviswa nekukurumidza nekukurumidza uye nguva pfupi, uye geometric contour inodiwa pakupedzisa inoumbwa. Kunyange kupedzisa kunosimbisa kurongeka kwepamusoro uye mhando yepamusoro, zvinokurudzirwa kushandisa pasi milling. Nemhaka yokuti kucheka kwekucheka kwemazino ekucheka zvishoma nezvishoma kunoderera kubva pahupamhi kusvika kune zero panguva yekugaya pasi, dhigirii rekuoma kwebasa rinonyanya kuderedzwa, uye dhigirii ye deformation yechikamu inoderedzwawo.

5. Matete-walled workpiece akaremara nekuda kwekusungirira panguva yekugadziriswa; kunyange kupedza hakunzvengeki. Kuti uderedze deformation yeworkpiece kusvika padiki, unogona kusunungura chidimbu chekudzvanya usati wapedza saizi yekupedzisira kuitira kuti workpiece idzokere zvakasununguka kune yayo yekutanga uye wozoidzvanya zvishoma, chero bedzi workpiece inogona kusungirirwa (zvese) . Zvinoenderana nekunzwa kweruoko), iyo yakanakira kugadzirisa mhedzisiro inogona kuwanikwa nenzira iyi. Mune mamwe mazwi, nzvimbo yekuita yesimba rekurovera iri nani pane inotsigira nzvimbo, uye iyo clamping simba rinofanirwa kuiswa munzira yeyakanaka workpiece rigidity. Kuve nechokwadi chekuti workpiece haina kusununguka, iyo idiki iyo clamping simba, zviri nani.

6. Paunenge uchigadzira zvidimbu zvine mhango, edza kusarega mucheki weguyo achinyura zvakananga muchikamu sechibooreso paunenge uchigadzira mhango, zvichikonzera kusakwana kwenzvimbo yekuti mucheki weguyo agare machipisi uye kusabvisa chip, zvichikonzera kupisa, kuwedzera. , uye kuputsika kwezvikamu-mapanga, kuputsika, uye zvimwe zviitiko zvisingafadzi. Chekutanga, chera gomba nedhiraivha saizi yakafanana neyeguyo kana imwe saizi yakakosha, wobva waigaya nechigayo. Neimwe nzira, CAM software inogona kushandiswa kugadzira spiral rundown zvirongwa.

Anebon Metal Products Limited inogona kupa CNC Machining, Die Casting, Sheet Metal Fabrication service, ndapota inzwa wakasununguka kutibata nesu.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Nguva yekutumira: Jun-16-2022