Chii chinonzi slender ekisero yemota?

Esero yemota mutete imhando inoshandiswa mumotokari uye yakagadzirirwa kuve yakareruka. Slender axles anowanzo shandiswa mumotokari dzine tarisiro yemafuta ekufambisa zvakanaka uye agility. Vanoderedza huremu hwese hwemotokari pavanenge vachivandudza mabatirwo ayo. Aya maekisi anowanzo gadzirwa kubva kuhuremu, zvinhu zvakasimba sealuminium kana simbi yakasimba. Aya maekisi akavakwa kuti akwanise kubata masimba ekutyaira, senge torque inogadzirwa neinjini, uye achiri kuchengetedza compact, yakagadziridzwa dhizaini. Maekisero akatetepa akakosha pakufambiswa kwesimba kubva painjini kuenda kumavhiri.

Sei zviri nyore kukotama uye kukanganisa paunenge uchigadzira shaft yakatetepa yemotokari?

Zvingave zvakaoma kupeta kana kukanganisa shaft yakatetepa kudaro. Zvishandiso zvinoshandiswa kugadzira mashafu emotokari (zvinozivikanwawo semadhiraivha kana maekisi) zvinowanzosimba uye zvinogara, senge kabhoni fiber inoumba kana simbi. Zvinhu zvinoshandiswa zvinosarudzwa nokuda kwesimba ravo guru, rinodiwa kuti rirambe torque uye masimba anogadzirwa nekutumira uye injini yemotokari.

Panguva yekugadzira, shafts inopinda nenzira dzakasiyana-siyana, dzakadai sekugadzira uye kupisa kupisa, kuchengetedza kuoma uye simba. Zvinhu izvi, pamwe chete nemaitiro ekugadzira, zvinodzivirira shafts kubva pakukotama pasi pemamiriro ezvinhu. Nekudaro, masimba akanyanyisa akadai sekudhumhana uye tsaona anogona kukotama kana kukanganisa chero chikamu chemotokari, kusanganisira shafts. Izvo zvakakosha kugadzirisa kana kutsiva chero zvikamu zvakakuvadzwa kuti uve nechokwadi chekushanda kwakachengeteka uye kwakanaka kwemotokari yako.

Machining process:

Zvikamu zvakawanda zve shaft zvine chiyero che L / d> 25. Iyo yakatwasuka yakatetepa axis inokotama zviri nyore kana inogona kutorasikirwa nekugadzikana kwayo pasi pesimba regiravhiti, simba rekucheka uye mauto ekumusoro ekurovera. Dambudziko rekushushikana pane slender shaft rinofanira kuderedzwa kana uchishandura shaft.

Processing nzira:

Reverse-feed turning inoshandiswa, iine akati wandei matanho anoshanda, senge kusarudzwa kwechishandiso geometry paramita, kucheka huwandu, tensioning zvishandiso, uye bushing tool kuzorora.

Ongororo yeZvinhu Zvinokonzera Kubhenda Deformation yeKutendeuka Slender Shaft

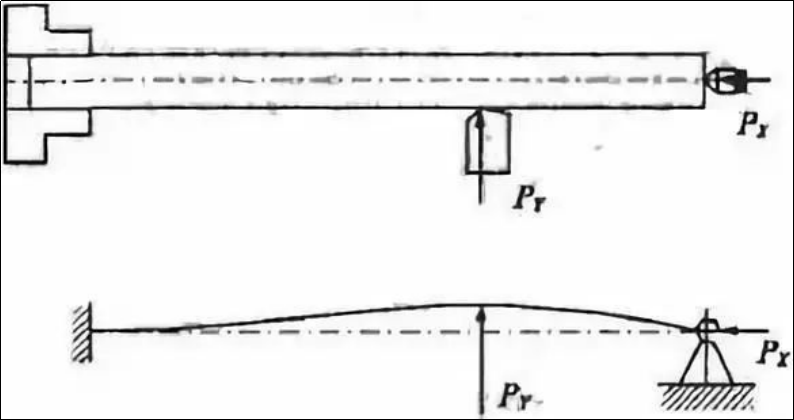

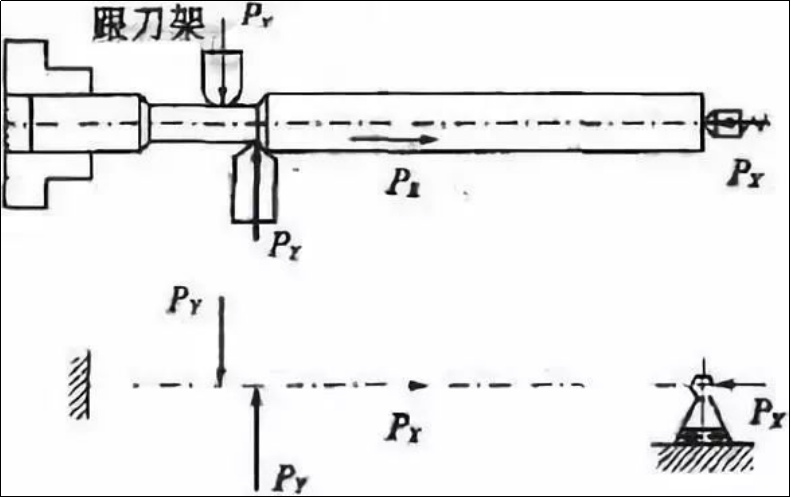

Maitiro maviri echinyakare ekurovera anoshandiswa kushandura matete shaft mumalathe. Imwe nzira inoshandisa imwe simbi ine imwe yepamusoro yekuisa, uye imwe yacho maviri epamusoro kumisikidzwa. Isu tichanyanya kutarisa pane clamping tekiniki yeimwe chete clamp uye kumusoro. Sezvakaratidzwa mumufananidzo 1.

Mufananidzo 1 Chimwe chisungiso uye imwe yepamusoro yekurovera nzira uye kuongorora simba

Zvikonzero zvikuru zvekubhenda deformation inokonzerwa nekutenderedza shaft yakatetepa ndeiyi:

(1) Kucheka simba kunokonzera deformation

Simba rekucheka rinogona kukamurwa kuita zvikamu zvitatu: axial force PX (axial force), radial force PY (radial force) uye tangential force PZ. Paunenge uchishandura shafts dzakatetepa, mauto akasiyana ekucheka anogona kuve nemhedzisiro yakasiyana pakukotama deformation.

1) Kufurira kweiyo radial yekucheka masimba PY

Iyo radial simba inocheka yakatwasuka nepakati peshaft axis. Iyo radial yekucheka simba inokotamisa shaft yakatetepa mundege yakachinjika nekuda kwekusasimba kwayo. Mufananidzo unoratidza mhedzisiro yesimba rekucheka pakukotama kweatete shaft. 1.

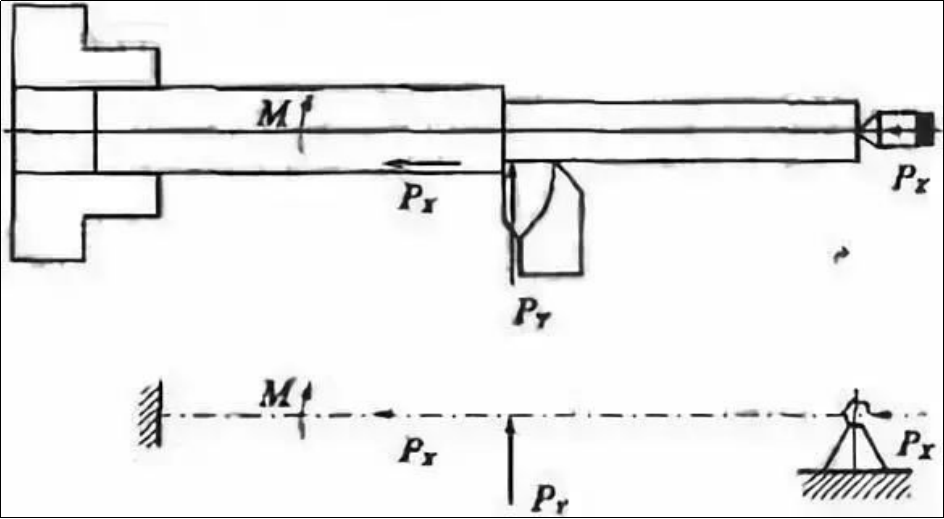

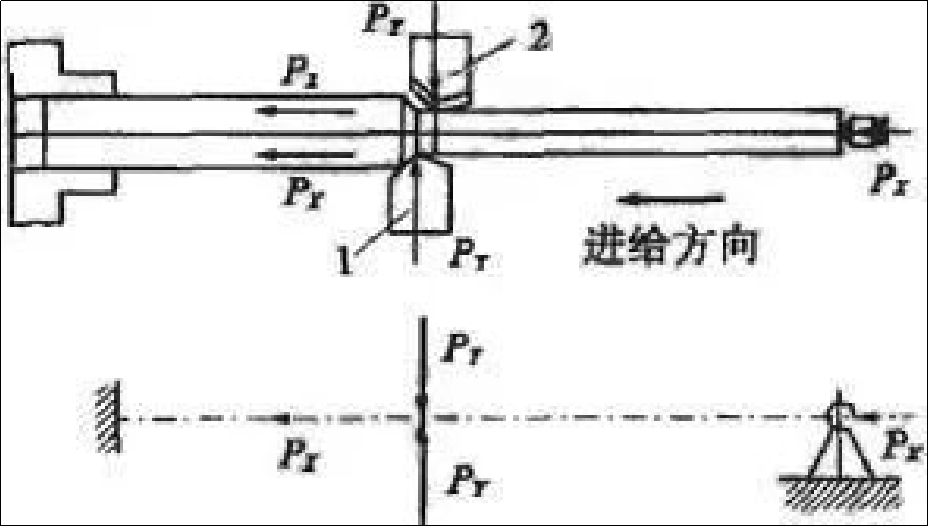

2) Mhedzisiro yeaxial yekucheka simba (PX)

Iyo axial simba inofanana neaxis pane yakaonda shaft uye inoumba nguva yekukotama muworkpiece. Iyo axial simba haina kukosha kune general kutendeuka uye inogona kufuratirwa. Nekuda kwekusasimba kwayo, shaft haina kugadzikana nekuda kwekusagadzikana kwayo. Iyo shaft yakatetepa inokotama kana simba reaxial rakakura kupfuura huwandu hwakati. Sezvakaratidzwa mumufananidzo 2.

Mufananidzo 2: Mhedzisiro yekucheka simba pane axial simba

(2) Kucheka kupisa

Thermal deformation ye workpiece ichaitika nekuda kwekucheka kupisa kunogadzirwa nekugadzirisa. Nharaunda pakati pechuck, pamusoro peiyo rearstock uye workpiece yakagadziriswa nekuti chuck yakagadziriswa. Izvi zvinogadzirisa kuwedzera kweaxial ye shaft, iyo inoguma mukukotama kweshaft nekuda kweaxial extrusion.

Zviri pachena kuti kuvandudza kurongeka kwekugadzira shaft yakaonda idambudziko rekudzora kushushikana uye deformation yekupisa muhurongwa hwekuita.

Matanho eKuvandudza Machining Kurongeka kweSlender Shaft

Kuvandudza iko kurongeka kwekugadzira shaft yakatetepa, zvinodikanwa kutora matanho akasiyana zvichienderana nemamiriro ekugadzira.

(1) Sarudza nzira chaiyo yekusunga

Kaviri-pakati clamping, imwe yenzira mbiri dzekusunga dzagara dzichishandiswa kutenderedza shafts dzakatetepa, inogona kushandiswa kunyatso misa iyo workpiece uku uchisimbisa coaxiality. Iyi nzira yekusungirira sleeve yakatetepa haina kusimba, yakakura kubhenda deformation, uye inobatwa nekudedera. Saka inokodzera chete kumisikidzwa ine hurefu hudiki kusvika dhayamita reshiyo, diki machining mvumo uye yakakwirira zvinodiwa zve coaxiality. Tallprecision machining zvikamu.

Muzviitiko zvakawanda, kugadzirwa kweshafts dzakatetepa kunoitwa uchishandisa clamping system inosanganisira imwe yepamusoro uye imwe clamp. Mune iyi clamping tekinoroji, zvisinei, kana iwe uine muromo wakanyanya kusimba haingopedzisire shaft asi zvakare kudzivirira kuti isarebe kana shaft yatenderedzwa. Izvi zvinogona kuita kuti shaft idzvinyirwe axially uye kukotama kunze-kwechimiro. Iyo clamping surface inogona kusaenderana negomba remuromo, izvo zvinogona kuita kuti shaft ikotame mushure mekunge yasungwa.

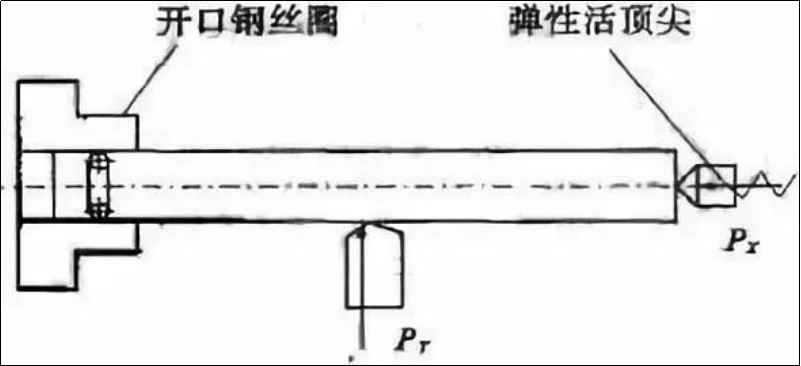

Paunenge uchishandisa iyo clamping nzira yeimwe clamp ine imwe yepamusoro, iyo yepamusoro inofanirwa kushandisa elastic yekugara nzvimbo. Mushure mekupisa sleeve yakatetepa, inogona kurebedzwa zvakasununguka kuti ideredze kukanganisa kwayo. Panguva imwecheteyo mufambi wesimbi akavhurika anopinzwa pakati peshaya kusvika kune slee sleeve kuti aderedze axial contact pakati peshaya kusvika kune slee sleeve uye kubvisa over-position. Mufananidzo 3 unoratidza kuiswa.

Mufananidzo 3: Nzira yekuvandudza uchishandisa chisungiso chimwe chete nechepamusoro

Deredza simba rekugadzirisa nekuderedza kureba kweshaft.

1) Shandisa heelrest uye centre frame

Chimwe chinosungirirwa nechepamusoro chinoshandiswa kushandura shaft yakatetepa. Kudzikisa kukanganiswa kweiyo radial simba pane deformation inokonzerwa neatete shaft, iyo yechinyakare toolrest uye yepakati furemu inoshandiswa. Izvi zvakaenzana nekuwedzera rutsigiro. Izvi zvinowedzera kuoma uye zvinogona kuderedza kukanganiswa kweiyo radial simba pane shaft.

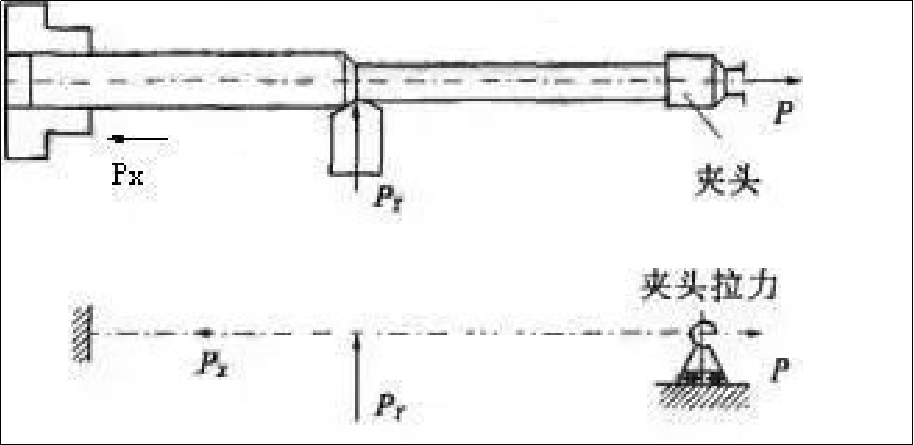

2) Sleeve yakatetepa inotenderedzwa neaxial clamping technique

Izvo zvinokwanisika kuwedzera kuomarara uye kubvisa mhedzisiro yeiyo radial simba pane workpiece nekushandisa zororo rekushandisa kana yepakati furemu. Izvo hazvigone kugadzirisa dambudziko reiyo axial simba inokotama iyo workpiece. Izvi ndezvechokwadi kunyanya kune shaft yakatetepa ine dhayamita yakati rebei. Iyo shaft yakatetepa saka inokwanisa kushandurwa uchishandisa axial clamping maitiro. Axial clamping zvinoreva kuti, kuitira kushandura shaft yakatetepa, imwe magumo eshaft inosungirirwa ne chuck uye imwe magumo neyakagadzirirwa-yakagadzirirwa clamping musoro. Musoro unosunga unoshandisa axial force kune shaft. Mufananidzo 4 unoratidza musoro unosunga.

Mufananidzo 4 Axial clamping uye mamiriro ekushushikana

Iyo sleeve yakatetepa inoiswa pasi pekugara axial tension panguva yekutendeuka. Izvi zvinobvisa dambudziko reiyo axial yekucheka simba inokotama shaft. Iyo axial simba inoderedza kukotama deformation inokonzerwa neiyo radial yekucheka masimba. Inobhadharawo axial kureba nekuda kwekupisa kwekucheka. nemazvo.

3) Reverse kucheka shaft kuti itendeuke

Sezvinoratidzwa muFigure 5, iyo reverse yekucheka nzira ndeye apo chishandiso chinodyiswa kuburikidza ne spindle kune tailstock panguva yekushandura shaft yakatetepa.

Mufananidzo 5 Kuongororwa kweMachining Forces uye Machining neReverse Cutting Method

Iyo axial simba inogadzirwa panguva yekugadziriswa inomanikidza shaft, kudzivirira kubhenda deformation. Iyo elastic tailstock inogona zvakare kutsiva iyo yekushisa elongation uye compression deformation inokonzerwa neworkpiece sezvainofamba kubva pachishandiso ichienda kune tailstock. Izvi zvinodzivirira deformation.

Sezvinoratidzwa muMufananidzo 6, ndiro yepakati inotsvedza inogadziridzwa nekuwedzera chibatiso chekumashure uye kutenderedza ese maturusi ekumberi nekumashure panguva imwe chete.

Mufananidzo 6 Simba rekuongorora uye maviri-banga machining

Chishandiso chekumberi chinoiswa chakatwasuka, uku chimbo chekumashure chakaiswa kumashure. Masimba ekucheka anogadzirwa nemidziyo miviri inodzima imwe neimwe panguva yekutendeuka. Iyo workpiece haina kuremara kana kuzunguzwa, uye kugadzirisa chaiko kwakakwira zvakanyanya. Izvi zvakanakira kugadzirwa kwehuwandu.

4) Magnetic yekucheka nzira yekushandura shaft yakaonda

Nheyo yekuseri kwemagineti yekucheka yakafanana nekucheka reverse. Iyo magnetic force inoshandiswa kutambanudza shaft, kuderedza deformation panguva yekugadzirisa.

(3) Deredza kuwanda kwekucheka

Kuwanda kwekupisa kunokonzerwa nekucheka kunogadzirisa kufanirwa kwehuwandu hwekucheka. Iyo deformation inokonzerwa nekutenderera shaft yakaonda ichave yakasiyana.

1) Kudzika Kwekucheka (t)

Maererano nekufungidzira kuti kuoma kunotarirwa nehurongwa hwekugadzirisa, sezvo kudzika kwekucheka kunowedzera, ndizvo zvinoita simba rekucheka, uye kupisa kunogadzirwa kana kutendeuka. Izvi zvinokonzeresa kushushikana uye kukanganiswa kwekupisa kweiyo shaft yakaonda kuwedzera. Paunenge uchishandura shafts dzakaonda, zvakakosha kuderedza kudzika kwekucheka.

2) Nhamba yekudya (f).

Kuwedzera kwekudya kunowedzera simba rekucheka uye ukobvu. Simba rekucheka rinowedzera, asi kwete zvakaenzana. Nekuda kweizvozvo, iyo simba deformation coefficient kune yakaonda shaft yakaderedzwa. Panyaya yekuwedzera kwekucheka kwekucheka, zviri nani kuwedzera chiyero chekudya pane kuwedzera kudzika kwekucheka.

3) Kucheka kumhanya (v).

Izvo zvinobatsira kuwedzera kasi yekucheka kuitira kuderedza simba. Sezvo kumhanya kwekucheka kunowedzera tembiricha yechishandiso chekucheka, kukakavara pakati pechishandiso, workpiece, uye shaft inoderera. Kana kumhanya kwekucheka kwakanyanyisa, ipapo shaft inogona kukotama nyore nyore nekuda kwemasimba e centrifugal. Izvi zvinokanganisa kugadzikana kwemaitiro. Iyo yekucheka kumhanya kweworkpieces iyo yakakura kureba uye dhayamita inofanira kuderedzwa.

(4) Sarudza kona inonzwisisika yechishandiso

Kuti uderedze kubhenda deformation iyo inokonzerwa nekushandura shaft yakaonda, simba rekucheka panguva yekutendeuka rinofanira kunge rakaderera sezvinobvira. Iyo rake, inotungamira uye kumucheto inclination angles ine yakanyanya pesvedzero pakucheka simba pakati pemakona ejometri ezvishandiso.

1) kona yekumberi (g)

Saizi yerake (g) kona inobata zvakananga simba rekucheka, tembiricha uye simba. Simba rekucheka rinogona kuderedzwa zvakanyanya nekuwedzera rake angles. Izvi zvinoderedza deformation yepurasitiki uye zvinogona zvakare kuderedza huwandu hwesimbi iri kuchekwa. Kuti uderedze mauto ekucheka, kuwedzera kwerake angles kunogona kuitwa. Makona erake anowanzo ari pakati pe13deg ne17deg.

2) Lead angle (kr)

The main deflection (kr), inova kona hombe, inokanganisa kuenzana uye saizi yezvikamu zvitatu zvekucheka simba. Iyo radial simba inoderedzwa sezvo kona yekupinda inowedzera, nepo tangential simba rinowedzera pakati pe60deg ne90deg. Hukama hwakaenzana pakati pezvikamu zvitatu zvekucheka simba zviri nani muhuwandu 60deg75deg. Iyo inotungamira kona yakakura 60deg inowanzo shandiswa pakutendeuka matete shafts.

3) Blade kurerekera

Kurerekera kweblade (ls), kunokanganisa kuyerera kwemachipisi uye kusimba kwechishandiso tipi, pamwe nehukama hwakaenzana pakati pevatatu.akashandura zvikamuyekucheka panguva yekutendeuka. Iyo radial simba rekucheka inodzikira sezvo kurerekera kunowedzera. Nekudaro, iyo axial uye tangential masimba anowedzera. Hukama hwakaenzana pakati pezvikamu zvitatu zvekucheka simba zvinonzwisisika kana blade inclination iri mukati me -10deg + 10deg. Kuti uite kuti machipisi ayerere akananga kumusoro kweshaft kana uchitenderedza shaft yakatetepa, zvakajairika kushandisa yakanaka edge angle pakati pe0deg uye +10deg.

Izvo zvakaoma kuzadzisa zviyero zvemhando ye slender shaft nekuda kwekusasimba kwayo. Hunhu hwekugadzirisa hweiyo shaft yakatetepa hunogona kuvimbiswa nekutora nzira dzepamusoro dzekugadzirisa uye nzira dzekunamatira, pamwe nekusarudza maekiseni echishandiso akakodzera uye paramita.

Chinangwa cheAnebon ndechekuziva kusakwana kwekugadzira kwakanaka uye kupa sevhisi yakanakisa kune vatengi vedu vekumba nekumhiri kwemakungwa zvizere 2022 Yepamusoro mhando Stainless Aluminium Yakakwira Precision CNC Kushandura Milling Machine Chikamu chikamu cheAerospace kuitira kuti tiwedzere musika wedu pasi rose, Anebon inonyanya kupa vatengi vedu vekunze. nemichina yemhando yepamusoro, milled zvidimbu uyeCNC kushandura masevhisi.

China wholesale China Machinery Parts uye CNC Machining Service, Anebon inochengeta mweya we "innovation uye kubatana, kushanda pamwe, kugovana, nzira, kufambira mberi kunoshanda". Kana iwe ukatipa mukana, isu ticharatidza kugona kwedu. Nerutsigiro rwako, Anebon tenda kuti tichakwanisa kuvaka ramangwana rakajeka iwe nemhuri yako.

Nguva yekutumira: Aug-28-2023