1. Kucheka shinda

Kazhinji, inoreva machining shinda pane workpiece nekugadzira kana kugaya chishandiso, kunyanya kusanganisira kutenderedza, kugaya, kurova nekuisa shinda kukuya, kugaya, kucheka chamupupuri, nezvimwewo. mudziyo wemuchina unova nechokwadi chekuti chishandiso chekutenderedza, chigayo chekucheka, kana vhiri rekukuya chinofambisa mutobvu nemazvo uye zvakaenzana padivi peaxial nzira yeworkpiece yega yega. kutenderera kweworkpiece. Kana uchibaya kana shinda, chishandiso (pombi kana kufa) chinotenderera chinoenderana nechokushandisa, uye yekutanga yakaumbwa shinda groove inotungamira chishandiso (kana workpiece) kufamba axially.

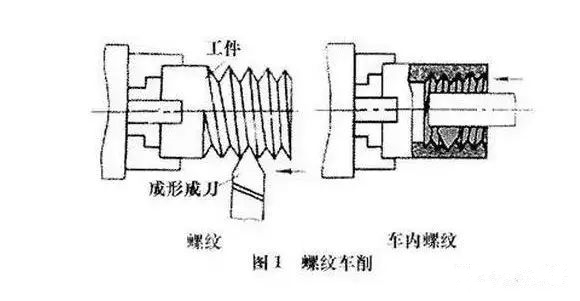

2. Kutenderedzwa kweshinda

Maturusi emakadhi anogona kushandiswa kutenderedza kana kupinza shinda pa lathe (ona shinda yekugadzirisa chishandiso). Kutenderedza shinda nekugadzira kushandura chishandiso inzira yakajairwa yechidimbu chimwe chete uye diki batch kugadzirwa kweshinda yekushanda nekuda kwechimiro chayo chiri nyore; kushandura shinda ine shinda yekumisikidza chishandiso ine yakakwirira kugadzirwa kwehunyanzvi, asi chimiro chayo chakaomarara, saka chakakodzera chete kushandura shinda pfupi workpiece ine mazino akanaka mukati uye yakakura batch kugadzirwa. Iyo yepitch yechokwadi yekutendeuka trapezoidal thread ine general lathe inogona kungosvika 8-9 mazinga (jb2886-81, zvakafanana pazasi); kugadzirwa kana kurongeka kunogona kuvandudzwa zvakanyanya kana uchigadzira shinda pane yakasarudzika tambo lathe.CNC machining chikamu

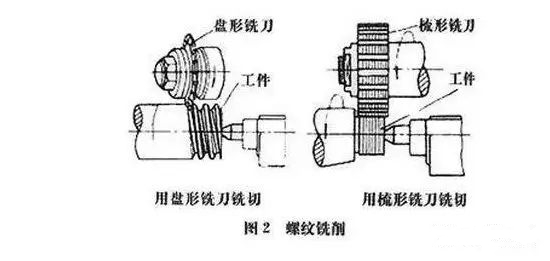

3. Kugaya shinda

Disc milling cutter kana comb milling cutter inoshandiswa pakugaya pamushini wekugaya shinda. Disc milling cutter inoshandiswa kunyanya pakugaya trapezoid shinda dzekunze dzescrew rods, makonye, uye mamwe maworkpieces. Nemhaka yokuti chikamu chayo chekushanda chakareba kudarika urefu hwetambo hunofanira kugadziriswa ne-multi-edge milling cutter, workpiece inogona kugadziriswa chete nekutenderera 1.25-1.5 revolutions, ine kugadzirwa kwepamusoro. Hurukuro hwekugaya shinda hunogona kusvika 8-9 mamakisi, uye kushata kwepamusoro kuri r5-0.63 μ M. Iyi nzira yakakodzera kugadzirwa kwehuwandu hwemachira eshinda chaiwo kana rough machining asati agaya.CNCc chikamu chekugaya

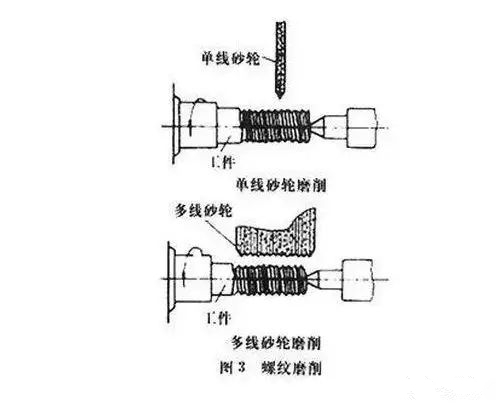

4. Kukuya shinda

Iyo inonyanya kushandiswa kugadzira tambo chaiyo yeyakaomeswa workpiece pane shinda grinder. Zvinoenderana neakasiyana-siyana-chikamu maumbirwo evhiri rekukuya, rinogona kukamurwa kuita marudzi maviri: mutsara-mutsetse wekukuya vhiri uye akawanda-mutsara vhiri rekukuya. Kurongeka kweiyo mutsara-mutsetse wekukuya ndeye 5-6 mamakisi, uye kushata kwepamusoro kuri r1.25-0.08 μ m, saka zviri nyore kupedzisa vhiri rekukuya. Iyi nzira yakanakira kukuya masiruuru, shinda dzegeji, makonye, mabhechi madiki eshinda, uye chaiyo hobMarudzi maviri ekukuya aivapo: kureba nekukuya uye kucheka-kukuya. Upamhi hwegumbo rekukuya nenzira yelongitudinal ishoma pane kureba kweshinda ichagayiwa, uye shinda inogona kukuyiwa kusvika pakukura kwekupedzisira mushure mekunge vhiri rekukuya rafamba kureba kamwe kana kakawanda. Upamhi hwegumbo rekukuya-mu-mu-kugaya nzira yakakura kudarika urefu hweshinda ichagayiwa. Gumbo rekukuya rinocheka mukati meiyo workpiece radially, uye workpiece inogona kuvhurika mushure mekutendeuka anenge 1.25 revolutions. Kugadzirwa kwacho kwakakwira, asi kurongeka kwakadzikira zvishoma, uye kupfeka kwegumbo rekukuya kunowedzera kuoma. Nzira yekucheka-mukati yakanakira kufoshorora mapombi akawanda uye kukuya dzimwe shinda dzekusunga.chikamu chepurasitiki

5. Kukuya shinda

Iyo nut-type kana screw-type thread-lapping tool inogadzirwa nezvinhu zvakapfava sesimbi yakakandwa. Zvikamu zveshinda yakagadziridzwa pane workpiece ine pitch error inogadzikwa nemberi uye neshure kutenderera kuti kunatsiridza nzwimbo. Iyo yakaomeswa shinda yemukati inowanzobviswa nekukuya kuvandudza kurongeka.

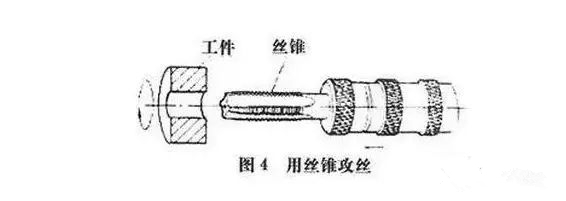

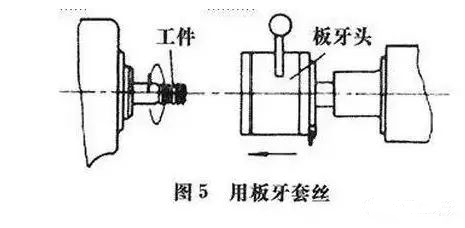

6. Kubata uye kupinza

Kubaya ndiko kushandisa torque chaiyo kukwenya pombi mugomba repazasi rakaboorwa pane workpiece kugadzirisa shinda yemukati.

Kurukwa ndiko kucheka shinda yekunze pabhara (kana chubhu) workpiece ine difa. Kurongeka kwemachina ekutepa kana kupinza kunoenderana nekurongeka kwepombi kana kufa. Kunyangwe paine nzira dzakawanda dzekugadzirisa tambo dzemukati nekunze, diki-dhayamita dzemukati tambo dzinogona kungogadziriswa nemapombi. Kutepa nekukaruka kunogona kuitwa nemaoko kana nelathe, muchina wekuchera, muchina wekutepa, nemuchina weshinda.

7. Thread rolling

Iyo nzira yekugadzirisa yekugadzira uye kukungurutsa dhi kuti ibudise epurasitiki deformation yeworkpiece kuti uwane tambo yekutenderedza inowanzoitwa pamushini wekutenderedza shinda kana otomatiki lathe yakasungirirwa ine otomatiki kuvhura uye kuvhara tambo inotenderedza musoro, iyo yakakodzera kugadzirwa kwakawanda. yekunze kweshinda pateni yezvisungo zvemhando uye mamwe majoini akarukwa. Kazhinji, dhayamita yekunze yetambo inoputika haisi kupfuura 25 mm, kureba hakusi kupfuura 100 mm, uye tambo yakarurama inogona kusvika pazinga 2 (gb197-63). Uyo dhayamita rechinhu chisina chinhu chakashandiswa chinoda kuenzana nedhayamita yehupamhi hweshinda ichagadziriswa. Kazhinji, shinda yemukati haigoni kugadziriswa nekukunguruka. Zvakadaro, kune iyo yakapfava workpiece, inotonhora extrusion yemukati shinda inogona kushandiswa isina slot extrusion tap (yakanyanya dhayamita inogona kusvika anenge 30mm), uye iyo inoshanda musimboti yakafanana nekutapa. Iyo torque inodiwa pakutonhora kuwedzeredza kweshinda yemukati yakakura zvakapetwa ka1 pane iyo yekutepa, uye iyo machining chaiyo uye yemhando yepamusoro yakakwira zvishoma pane iyo yekubaya.

Zvakanakira kutenderedza thread ndeizvi:

① kushata kwepamusoro kushoma pane kutendeuka, kukuya, nekukuya;

② pamusoro peshinda mushure mekukunguruka kunogona kuvandudza simba uye kuoma nekuda kwekutonhora kwebasa kuoma;

③ mwero wekushandiswa kwezvinhu wakakwira;

④ kugadzirwa kwakapetwa kaviri zvichienzaniswa nekucheka maitiro, uye zviri nyore kuziva otomatiki;

⑤ Hupenyu hwesevhisi hwekukunguruka kufa hurefu kwazvo. Zvisinei, kuoma kwezvinhu zvekushanda hakusi kudarika hrc40, kururamisa kwehukuru husina chinhu kunodiwa kuti huve hwakakwirira, uye kururamisa uye kuoma kwekufa kunoputika zvakare, saka zvakaoma kugadzira kufa. Haikodzere tambo dzine asymmetric rolling profile.

Zvinoenderana neyakasiyana-siyana yekukunguruka inofa, tambo yekukungurusa inogona kupatsanurwa mumhando mbiri: shinda yekukungurusa uye shinda.

Thread rolling: mahwendefa maviri eshinda ane tambo profiles anodzika uye akarongwa ne1/2 pitch. Iyo static plate inogadziriswa, uye ndiro inofamba inofamba mumutsara unodzokorora wakatwasuka wakafanana neplate yakamira. Kana iyo workpiece inotumirwa pakati pemahwendefa maviri, ndiro inofamba inofamba inoenda mberi kukwesha uye kudzvanya iyo workpiece, ichiita iyo pamusoro pepurasitiki deformation uye kugadzira shinda. Mo Mo Q boka 373600976

Kune marudzi matatu ekukunguruka: radial, tangential, g, uye musoro kukunguruka.

① Radial tambo inotenderedzwa: maviri (kana matatu) shinda-yakaita shinda inomonereka mavhiri akaiswa paakaenzana mashaft, workpiece inoiswa parutsigiro pakati pemavhiri maviri, uye mavhiri maviri anotenderera nekumhanya kwakafanana munzira imwe chete. iyo inoitawo radial feed motion. Gumbo rinotenderedza rinofambisa workpiece kuti ritenderere, uye nzvimbo yacho inowedzerwa radially kuita shinda. Iyo yakafanana yekukungurusa nzira inogona zvakare kushandiswa kune mamwe screws ane yakaderera chaiyo zvinodiwa.

②tangential tambo inokunguruka: inozivikanwawo seyepuraneti shinda inokunguruka. Chishandiso chekumoneredza chinosanganisira vhiri repakati rinotendereka uye matatu akagadzika-arc-shapa mahwendefa. Iyo workpiece inogona kudyiswa nguva dzose panguva yekukunguruka, saka chibereko chakakwira kupfuura icho chekukwesha shinda uye radial rolling.

③ Kutenderedzwa kweshinda yeshinda inotenderedza musoro: inoitwa pane otomatiki lathe uye inowanzo shandiswa kugadzira shinda pfupi pane workpiece. Kune 3-4 rolling rollers yakagoverwa zvakafanana kutenderedza workpiece. Kana uchikunguruka, workpiece inotenderera, uye musoro unotenderera unodyisa axially kuti ubvise workpiece kunze kweshinda.

Anebon Metal Products Limited inogona kupa CNC machining, kufa casting, sheet simbi machining masevhisi, ndapota inzwa wakasununguka kutibata nesu.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Nguva yekutumira: Oct-04-2019