Die Casting Service

Die casting yanga iri hunyanzvi hweAnebon kweanopfuura makore gumi. Masevhisi edu ekukanda aruminiyamu anga achibatsira mainjiniya, vagadziri vezvigadzirwa uye vagadziri vezvivakwa kuunza dhizaini yavo kuhupenyu nemamiriro ehunyanzvi chikamu magadzirirwo uye yakavimbika mhando. Tichifunga nezve ruzivo rwedu muindastiri, pamwe chete nemidziyo yedu yemazuva ano, nyanzvi yedu yekugadzira uye mainjiniya emhando, uye vashandi vekugadzira, unovimbiswa kugadzirwa kwemhando yezvikamu zvako uye zvigadzirwa pamwero wehupfumi neAnebon.Isu tiri ISO 9001: 2015 yakasimbiswa kufa yekukandira mugadziri anonyanya kuita mabasa ekukanda kufa kumaindasitiri nemakambani anotungamira pasirese. Midziyo yedu inovhara dzinenge dzese kufa kukanda engineering, dhizaini nekusimudzira zvinodiwa nekambani yako.

Midziyo yekukanda uye mold zvinodhura, saka nzira yekukanda kufa inowanzo shandiswa kuburitsa huwandu hukuru hwezvigadzirwa. Zviri nyore kugadzira zvikamu zve-die-cast, izvo zvinowanzoda matanho mana makuru chete, nekuwedzera kwemutengo kuri kuderera. Die casting inonyanya kukodzera kugadzirwa kwenhamba huru yediki uye yepakati-saizi castings, saka kufa casting ndiko kunonyanya kushandiswa kweakasiyana maitiro ekukanda. Kana ichienzaniswa nemamwe matekiniki ekukanda, iyo die-cast surface ine flatter uye ine yakakwira dimensional kuenderana.

Chii chinonzi Die Casting?

Die casting inzira yekukanda simbi inoratidzirwa nekushandiswa kwegomba rekuumba kuisa high pressure kusimbi yakanyungudutswa. Molds anowanzo kugadzirwa kubva kune alloys esimba repamusoro, mamwe acho akafanana nekuumba jekiseni. Mazhinji anofa castings haana iron-isina, senge zingi, mhangura, aluminium, magnesium, lead, tin, uye lead-tin alloys nemamwe maalloys. Zvichienderana nerudzi rwekukanda kufa, muchina unotonhora wekamuri yekukanda kana muchina unopisa wekamuri yekukanda unodiwa.

Hunhu

Die casting inzira yekukanda iyo yakanyungudutswa alloy fluid inodururwa mukamuri yekumanikidza, mhango yesimbi mold inozadzwa nekumhanya kukuru, uye alloy fluid inosimbiswa pasi pekumanikidzwa kuita kukanda. Iwo makuru maficha ekukanda kufa ayo anoisiyanisa kubva kune dzimwe nzira dzekukanda ndeyekumanikidza kwakanyanya uye kumhanya kwakanyanya.

1. Simbi yakanyungudutswa inozadza mhango pasi pekumanikidzwa uye inopenya pamhepo yakakwirira. Kudzvinyirira kwakajairika ndeye 15-100 MPa.

2 . Metal liquid inozadza gomba nekumhanya kwakanyanya, kazhinji pa10-50 m / s, uye mamwe anogona zvakare kudarika 80 m / s, (kumhanya kwemutsara kuburikidza neunga mugomba - ingate kumhanya), saka nguva yekuzadza simbi yakanyungudutswa yakanyanyisa. pfupi, uye mhango inogona kuzadzwa muinenge 0.01-0.2 masekondi (zvichienderana nehukuru hwekukanda).

Die-casting inzira chaiyo yekukanda. Die-casting parts akakandwa ne-die-casting, ane diki diki diki kushivirira uye yakakwirira yepamusoro kunyatsoita. Muzviitiko zvakawanda, zvikamu zvinofa zvinogona kuunganidzwa pasina kutendeuka. Zvikamu zvinogonawo kukandwa zvakananga.

Ndezvipi zvakanakira die casting services?

Yedu shanduko yekufa yekukanda maitiro inopa akawanda akakosha mabhenefiti, anosanganisira:

l Kugadziridza: Inobatsira kuwana madhizaini akaomarara uye mafomu anoita kuti zvive nyore kugadzirisa castings kune chaiwo maitiro ekugadzira.

ll Mutengo wakaderera

lll High effiency

llll Multi-inoshanda uye inodzivirira kuora

Semugadziri wekufa-casting, Anebon Die Casting inopa yakakwana, yakazara kusangana uye kuyedzwa kwese kufa-cast zvikamu uye zvigadzirwa. Kunyangwe iwe uchifarira zvinhu zvakakosha senge aluminium die casting kana vacuum die casting, kana kungoda kuve prototype yechikamu chitsva, unogona kuwana yakazara sevhisi ruzivo mufekitori yedu.

Material

Simbi yataishandisa pakukanda kufa inosanganisira zingi, mhangura, aluminum, magnesium, lead, tin, uye lead-tin alloys, nezvimwewo. Kunyange zvazvo simbi yakakandwa isingawanzoitiki, inogonawo kuitika. Hunhu hwemasimbi akasiyana panguva yekukanda kufa ndeaya anotevera:

•Zinc: Iyo inonyanya kufa-yakandwa simbi, inodhura kana ichigadzira zvidimbu zvidiki, zviri nyore kupfeka, yakakwirira yekumanikidza simba, yakakwira plastiki, uye hupenyu hurefu hwekukanda.

•Aluminium: Hunhu hwepamusoro, kugadzirwa kwakaoma uye dzakatetepa-madziro castings ane yakakwirira dimensional kugadzikana, yakakwira corrosion resistance, yakanaka mechanical properties, high thermal conductivity uye magetsi conductivity, uye simba rakakwirira pakupisa kwepamusoro.

•Magnesium: Nyore kumichina, yakakwirira simba kune huremu reshiyo, iyo yakareruka pane inowanzo shandiswa die-cast simbi.

•Mhangura: Kuoma kwepamusoro uye kusimba kwakasimba kwegora. Iyo inonyanya kushandiswa die-cast simbi ine yakanakisa mechanical zvivakwa, anti-kupfeka uye simba padyo nesimbi.

•Mutobvu nemarata: Yakakwira density uye yakakwirira dimensional kurongeka kune yakakosha corrosion kudzivirira zvikamu. Nezvikonzero zvehutano hweveruzhinji, iyi alloy haigone kushandiswa sechikafu chekugadzira uye nzvimbo yekuchengetedza. Lead-tin-bismuth alloys (dzimwe nguva iinewo mhangura shoma) inogona kushandiswa kugadzira mabhii anopera nemaoko uye kupisa stamping mukutsikirirwa kweletterpress.

Aluminium Casting

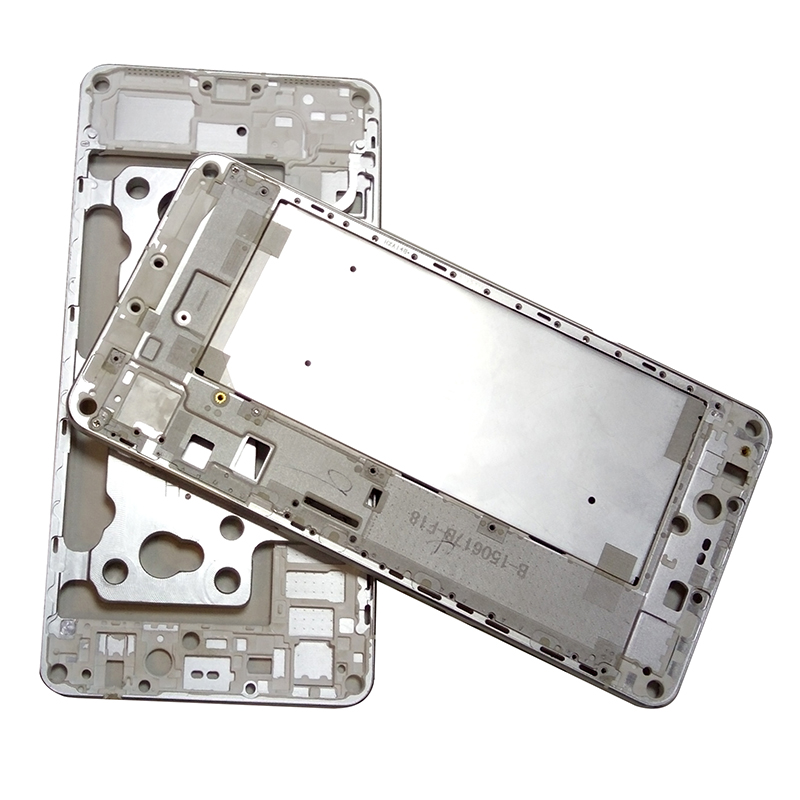

Kukanda Mobile Phone Accessories

Aluminium Die Cast