CNC machining sevhisi

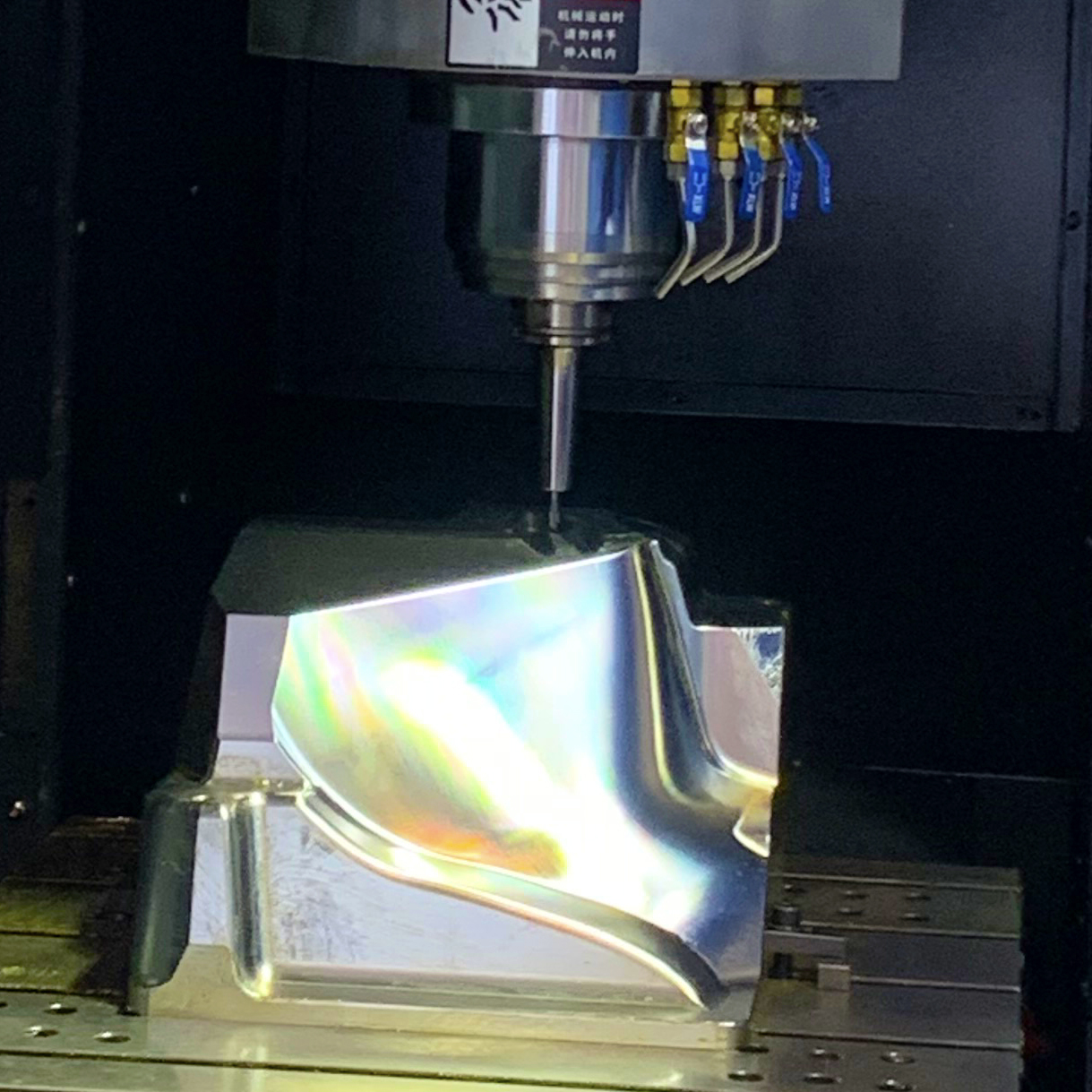

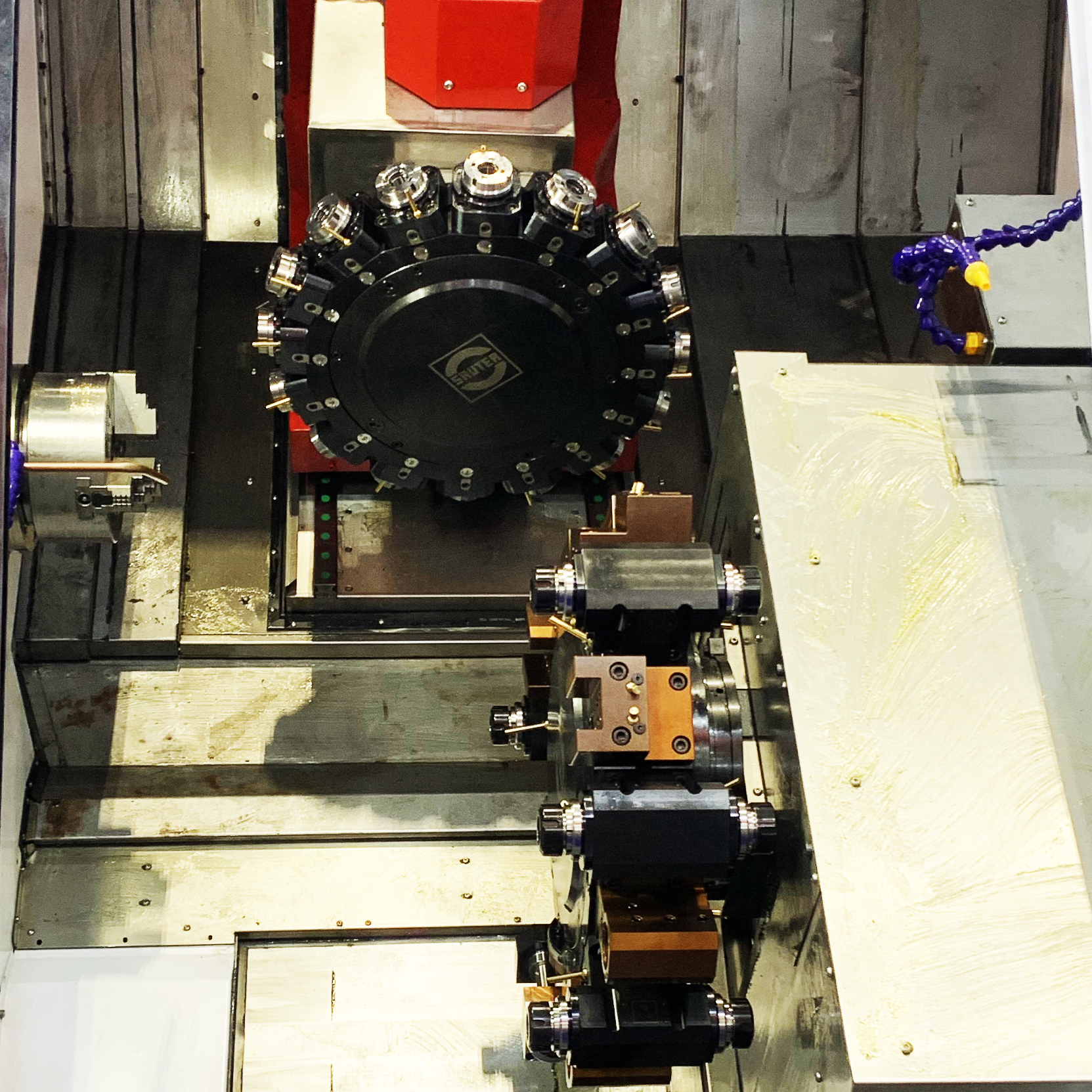

Anebon ine midziyo yepamusoro yekukupa huwandu hwakawanda hweCNC machining masevhisi, anosanganisira kugaya, kutendeuka, EDM, kucheka waya, kukuya pamusoro uye nezvimwe. Isu tinoshandisa kunze kwenyika 3, 4 uye 5-axis CNC machining nzvimbo kuti tikupe iwe kunyatsojeka, kuchinjika kunoshamisa, uye kuburitsa kwakanaka kwechero chero chirongwa chekugadzira. Isu hatina chete michina yakasiyana, asiwo chikwata chenyanzvi, avo vakazvipira kukupa iwe zvakanakisisa-mu-kirasi sevhisi muChina. Makanika edu ane hunyanzvi anogona kushandisa akasiyana epurasitiki nesimbi zvinhu kugadzira zvinotenderedza nekugaya zvikamu.

Isu tinokuvimbisai kuti zvisinei nekukura kwebasa racho, nyanzvi dzedu dzinoritora sekunge nderavo. Isu tinogona zvakare kupa prototype CNC machining masevhisi ayo angakubatsira iwe kuwana yakajeka mufananidzo wechigadzirwa chekupedzisira.

Sei kusarudza isu?

Anebon anga ari mutungamiri mukugadzira zvigadzirwa zvitsva. Specialty Integrated Services yakakudza hunyanzvi hwayo uye maitiro. Iyo Kambani inogadzira zvinenge zvese zvepasi rose zvesimbi zvikamu. Mainjiniya edu achashanda newe kuti ave nechokwadi chepamusoro dhizaini yemhando yekugadzira uye kusangana. Yakanakisa sevhisi yevatengi uye kugutsikana zviratidzo zvekambani yedu uye hwaro hwekubudirira kwebhizinesi redu.

Nenguva Yakafanira - Tinonzwisisa kuti zvimwe zvikamu zvebasa redu zvine nguva yekukasika, uye tine hunyanzvi nemaitiro ekuona kuti tinouyisa nenguva pasina kukanganisa kunaka kwebasa ratinoita.

Ane ruzivo - Tave tichipa CNC milling masevhisi kweanopfuura makore gumi. Isu takaunganidza huwandu hwakasiyana hwemakina ekugaya emhando dzakasiyana siyana uye tine timu ine ruzivo rwemainjiniya nevashandisi kuti vape zvigadzirwa zvemhando yepamusoro kune vese vatengi vedu.

Kugona - Nekusiyana kwemakina edu, isu tinokwanisa kuvimbisa huchokwadi hwezvinhu zvese muhukuru hwese.

Chii chinonzi CNC Machining?

CNC machining inzira inobvisa yekugadzira iyo inocheka zvigadzirwa kuburikidza nemhando dzakasiyana dzekucheka maturusi. Yepamberi software inoshandiswa kudzora mudziyo zvinoenderana neiyo 3D dhizaini. Chikwata chedu chemainjiniya uye makanika chinoronga midziyo yekugonesa nguva yekucheka, kupera kwepamusoro uye kushivirira kwekupedzisira kuzadzisa zvaunoda. Isu tinoshandisa CNC machining kwete chete kugadzira zvikamu uye prototypes, asiwo kugadzira mold maturusi.

Design Principles:

(1) Iyo yakagadzirirwa maitiro ekutemerwa ichave nechokwadi chekugadzirisa mhando yezvikamu zvemuchina (kana mhando yemusangano wemuchina) uye inosangana nezvinodiwa zvehunyanzvi zvinotsanangurwa padhizaini yedhizaini.

(2) Maitiro acho anofanira kunge aine chibereko chepamusoro uye chigadzirwa chinofanira kuiswa pamusika nekukurumidza sezvinobvira.

(3) Edza kuderedza mari yekugadzira

(4) Chenjerera kudzikisa kuwanda kwevashandi uye kuve nechokwadi chekuchengetedzwa kwekugadzirwa.

Low-Volume Manufacturing

Kugadzira mumavhoriyamu akaderera ndiyo mhinduro yakanaka yekugadzirisa yako hesiti uye kuyedza musika usati wagadzira huwandu hukuru. kusarudza Low-Volume Manufacturing ndiyo sarudzo yako yakanakisisa.

Anebon ichasarudza yakanyanya kunaka yekugadzirisa tekinoroji zvinoenderana nechinhu, kurapwa kwepamusoro uye huwandu, asi zvakare inopa kurongedza uye imwe yekumira sevhisi.

Yedu CNC Machining, yekukurumidza prototype uye Yakaderera-Volume Kugadzira yakakodzera kune akawanda indasitiri seMota, Midhudhudhu, Machina, Ndege, bullet chitima, Mabhasikoro, Mvura, Yemagetsi, Sainzi zvishandiso, Laser theatre, Robhoti, Mafuta & Gasi Kudzora Systems, Zvishandiso zvekurapa. , midziyo yekugamuchira chiratidzo, Optical devices, Kamera & Mufananidzo, Sporting equipment Runako neMheni, Furniture.

Zvakanakira CNC machining

CNC machining yakanakira yako huwandu hwezvigadzirwa zvekuvandudza zvinodiwa. Heano mamwe emabhenefiti eiyo precision machining:

• Mechanical processing yetitanium alloys, superalloys, non-metals, nezvimwewo, mold design nekugadzira

• Non-standard midziyo kugadzira uye kugadzira

• Machining maitiro: kuchera, kugaya shinda, broaching, kubaya, spline, reaming, kucheka, Profile, kupedza, kutenderedza, shinda, kuumba mukati, dimples, knurling, countersunk, boring, reverse drilling, hobbing.

• Kurumidza kubvisa zvinhu zvakawanda zvesimbi

• Inokodzera mhando dzakawanda dzakasiyana dze substrates

• Kudyara kwakaderera mu mold uye mari yekugadzirira

• Yakarurama uye inodzokororwa

• Mold kugadzira uye kugadzira

• Kushivirira: ± 0.002mm

• Upfumi

R&D

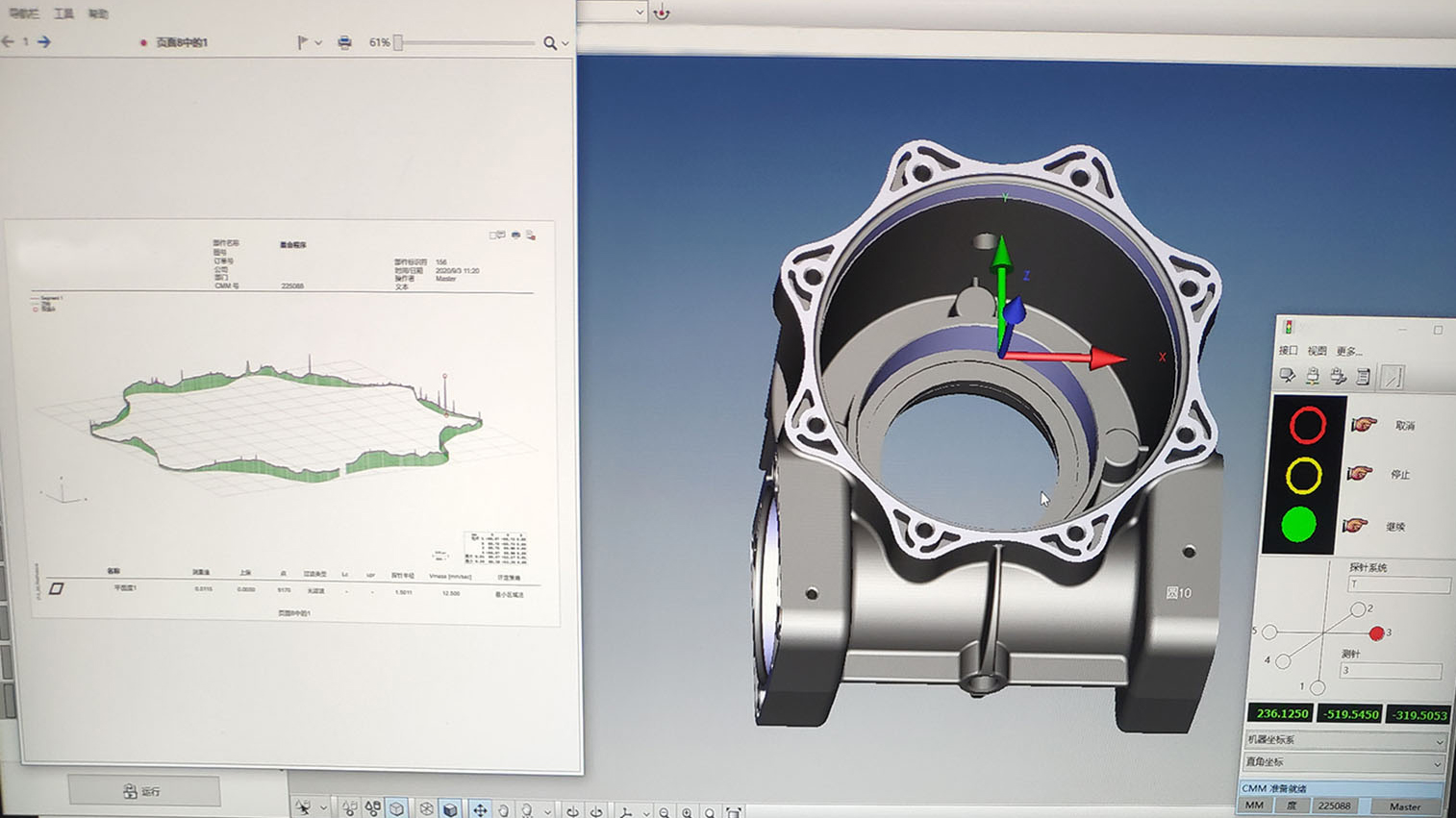

Tine anopfuura makore gumi ehunyanzvi mukugadzira 3D. Chikwata chedu chinoshanda nevatengi kugadzira madhizaini / zvikamu zvinosangana nezvavanoda, tichifunga nezve mutengo, uremu uye maitiro ekugadzira.Mushure mekunge dhizaini yapera, isu tinomisa iyo yese engineering uye kugadzirwa kwechishandiso. Uye isu tinogona kutanga bvunzo inotevera chete mushure mekunge dhipatimendi remhando rabvumidza chishandiso.

Isu tinotarisa pane aya makuru maitiro muR&D maitiro:

Component design

Chishandiso DFM

Tool / mold design

Mold Flow - Simulation

Kudhirowa

CAM

Rudzi rwechishandiso chekugadzirisa

Kune akawanda marudzi ekugadzirisa maturusi anogona kushandiswa ari ega kana musanganiswa nemamwe maturusi mumatanho akasiyana-siyana ekugadzira maitiro kuti uwane inodiwa chikamu geometry. Iwo makuru ekugadzirisa maturusi mapoka:

• Zvishandiso Zvinobhowa: Zvishandiso izvi zvinowanzoshandiswa semidziyo yekupedzisa kuwedzera maburi akambochekwa mumidziyo.

• Maturusi ekuchekeresa: Midziyo yakaita semasaha nechigero midziyo inomiririra yekucheka maturusi. Anowanzo shandiswa kucheka chinhu chine saizi yakafanotemerwa, senge simbi, kuita chimiro chinodiwa.

• Chishandiso chekucheresa: Ichi chikamu chinosanganisira kaviri-kunotenderera kutenderera kunoita denderedzwa gomba rakaenderana neakisi yekutenderera.

• Zvishandiso zvekukuya: Zvishandiso izvi zvinoshandisa vhiri rinotenderera pakugadzira machini akanaka kana kuti kucheka kudiki pane workpiece.

• Zvishandiso zvekugaya: Zvishandiso zvekugaya zvinoshandisa nzvimbo yekucheka inotenderera nekuisa kwakawanda kugadzira gomba risina denderedzwa kana kucheka dhizaini yakasiyana kubva kune iyo.

• Zvishandiso zvinotenderedza: Zvishandiso izvi zvinotenderedza shandiso pashaft apo mudziyo wekucheka uchiuumba.

Material

| Simbi | Carbon Steel, 4140,20 #, 45#, 4340, Q235, Q345B, nezvimwe. |

| Simbi isina ngura | SS303, SS304, SS316, SS416 nezvimwe. |

| Aluminium | Al6063, AL6082, AL7075, AL6061, AL5052, A380 etc. |

| Iron | 12L14, 1215, 45#, A36, 1213, nezvimwewo. |

| Brass | HSn62-1, HSn60-1, HMn58-2, H68, HNi65-5, H90, H80 , H68, H59 zvichingodaro. |

| Mhangura | C11000, C12000, C12000, C26000, C51000 nezvimwe. |

| Plastiki | Delrin, Nylon, Teflon, PP, PEI, ABS, PC, PE, POM, Peek.Carbon Fiber |

Surface Treatment

| Mechanical Surface Treatment | Kuputika kwejecha, Kupfurwa Kwepfuti, Kukuya, Kukungurutsa, Kupukuta, Kukwesha, Kupfapfaidza, Kupenda, Kupenda Oiri nezvimwe. |

| Chemical Surface Treatment | Bluing uye Blackening, Phosphating, Pickling, Electroless Plating yeMasimbi Akasiyana-siyana uye Alloys nezvimwe. |

| Electrochemical Surface Treatment | Anodic Oxidation, Electrochemical Polishing, Electroplating etc. |

| Mazuvano Surface Treatment | CVD, PVD, Ion implantation, Ion Plating, Laser Surface Treatment ect. |

| Kuputika kwejecha | Dry Sand Blasting, Wet Sand Blasting, Atomized Sand Blasting etc. |

| Kupfapfaidza | Kupfapfaidza Electrostatic, Kupfapfaidza Mbiri, Kupfapfaidza Hupfu, Kupfapfaidza Purasitiki, Kupfapfaidza Plasma |

| Electroplating | Copper Plating, Chromium Plating, Zinc Plating, Nickel Plating |

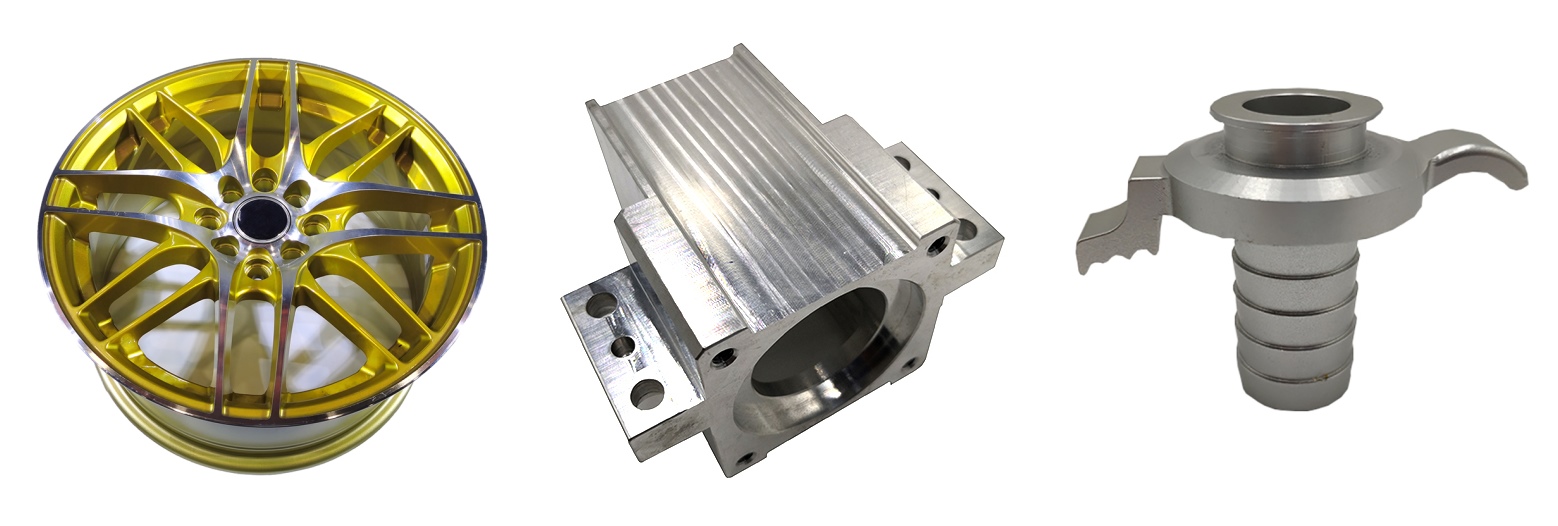

Product

CNC Precision Wheels

CNC Aluminium Milling

CNC Machining Prototyping

5 Axies CNC Machining

Tsika CNC Machining Gear

CNC Turning Machining