Brass Inoshandura Zvikamu

Product Detail:

| Kurongeka kweworkpiece: | +/-0.005~+/-0.002mm | ||

| Kuoma kweworkpiece: | Ra≤0.1 | ||

| Quality mwero: | DIN, ASTM, GOST, GB, JIS, ANSI, BS; | ||

| Mafomati ekudhirowa: | JPEG, PDF, AI, PSD, DWG, DXF, IGS, STEP.CAD | ||

| Product certification: | ISO9001:2015, CE, RoHS, SGS; | ||

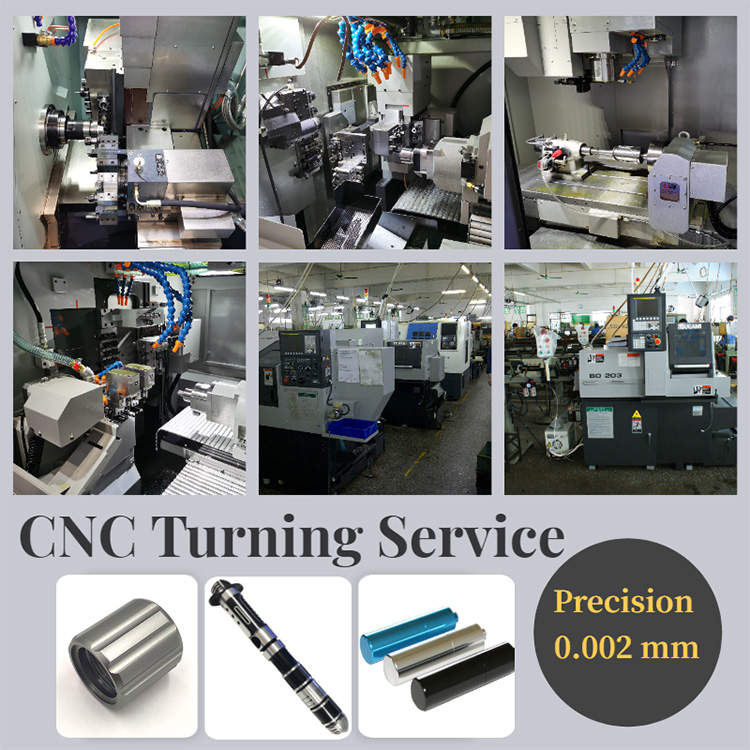

| Processing equipments: | DMG shanu-axis machining centre/DMG yakasanganiswa processing centre/processing centre/CNC verticle lathe/CNC lathe/CNC milling machine/CNC grinding machine/turning-lathe/laser cutting/waya-electrode cutting/CNC sharing machine | ||

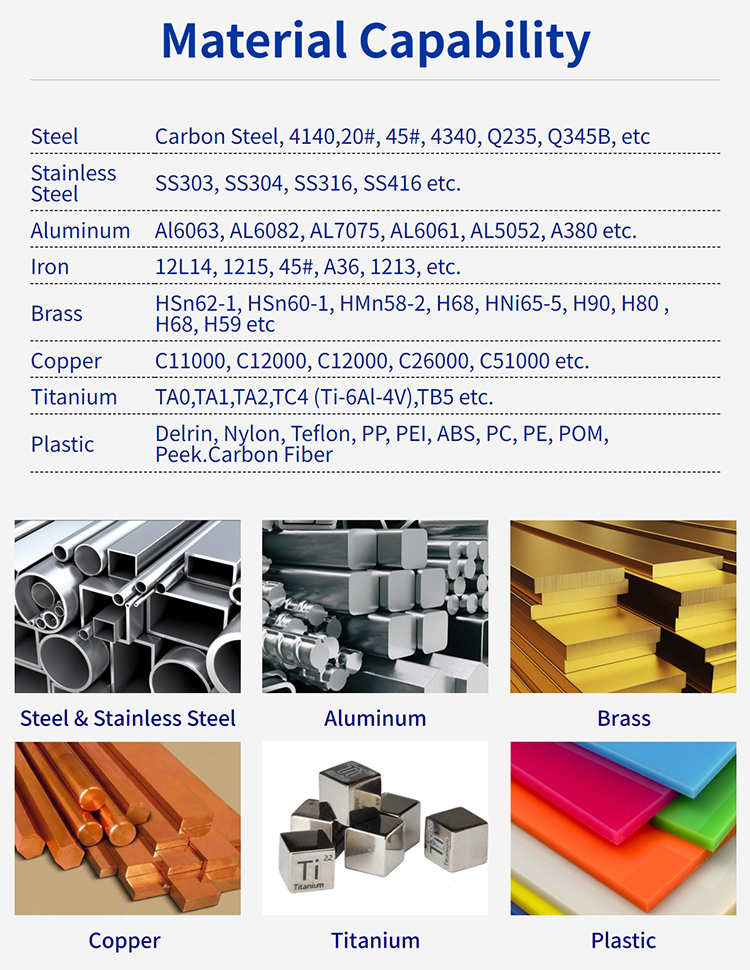

| Optional zvinhu | Simbi: simbi, kabhoni simbi, M3,4340,20#,45#,40Cr,20Cr, nezvimwewo. | ||

| Aluminium: AL6061, AL6063, AL6082, AL7075, AL5052 nezvimwe. | |||

| Simbi isina tsvina: 201SS, 301SS, 304SS, 316SS nezvimwe. | |||

| Mhangura: C37700, C28000, C11000, C36000 nezvimwe | |||

| Injiniya mapurasitiki: PBI,PI,PAI,PTFE,PEEK,PPS,PPSU,PEI,PSU,PC,PETP,POM,PA,UHMW-PE | |||

| Surface treatment: | Zvikamu zvesimbi | Stainless simbi zvikamu | Aluminium zvikamu |

| Galvanization | Kupukuta | Oxidized white | |

| Black oxidation | Passivation | Sandblast anodization | |

| Nickel plating | Laser engraving | Chemical film | |

| Chromeplate | Kuputika kwejecha | Brush coating | |

| Kurapa kwekupisa | Kupukuta | ||

| Upfu hwakaputirwa | Chromeplate | ||

BASA REDU:

1. 100% mugadziri

Fekitori yedu iri muguta reQingxi, Dongguancity, purovhinzi yeGuangdong, China ine vashandi zana vane zvikwereti zvakanyanya, kuvimbika pakuvimbisa kwako kwakakwana. Tine makore mazhinji ruzivo rwekugadzira uye ruzivo rwekutengesa kunze.

2. Kusarudzwa kwezvinhu zvakanakisisa.

Zvese zvinhu zvedu zvakagadzirwa nemhando yepamusoro kubva kune vakanyanya vatengesi.

3. Basa rakanaka

Isu tinogadzira zvinhu zvese tega. Ndiyo sevhisi yepamusoro kubva pawaya tsvimbo yekudyisa, kukoira, kudhirowa kwewaya, kuumba, kuruka, kupfuudza, kuongorora, kurongedza, kutumira, saka mhando inovimbiswa 100%.

4. Kudzora kwehutano

Chese chimedu chechigadzirwa, maitiro ese ekugadzira anoongororwa uye anodzorwa asati arongedza zvinhu mubhokisi rekutumira kunze.

Isu tinovimbisa kuti zvese zvechigadzirwa zvinotumirwa ndezvemhando yakanaka.

5. Mushure mekutengesa basa rakapiwa

Kunze kwezvo, mushure mekutengesa sevhisi inodiwa kuti uwedzere kunzwisisa kune zvaunoda. Isu tinochengeta kunetseka kwakanyanya

| Machining | Kugaya | Kutendeuka |

| Cnc Machining Terms

| Cnc Milling Titanium

| Cnc Kutendeuka Kumhanya uye Zvekudya

|

| Cnc Machining Terminology | Cnc Milling Tips

| Cnc Turning Software

|

| Cnc Machining Technology | Cnc Milling Tips Uye Tricks

| Cnc Turning Simulation

|

1. Mubvunzo: Ndeipi basa guru refekitari yako?

Mhinduro: Isu tinotarisa paOEM & ODM cnc kushandura zvikamu kweanopfuura makore gumi! Isu tiri nyanzvi muCNC machining zvikamu minda.

2. Mubvunzo: Ndingawana sei huwandu hwehuwandu hwekuraira uye ruzivo rwakabatana nemutengo?

Mhinduro: Yedu shoma yekuraira huwandu hunoenderana nekutsanangurwa kweodha yako. Iwe unogona kutitumira dhizaini yako yedhizaini uchiratidza zvinhu, chiyero, kushivirira kunodiwa, uye kurapwa kwepamusoro kwezvikamu.

3. Mubvunzo: Ndinogona kushanyira fekitori yako ndichishanyira maitiro ekugadzira?

Mhinduro: Unogamuchirwa kushanyira fekitari yedu chero nguva. Tichakutora kuairport kana chiteshi chechitima. Panguva imwecheteyo, isu tinogara tichipfura vhidhiyo yedu yekugadzira kune yako referensi yemaitiro edu ekugadzira