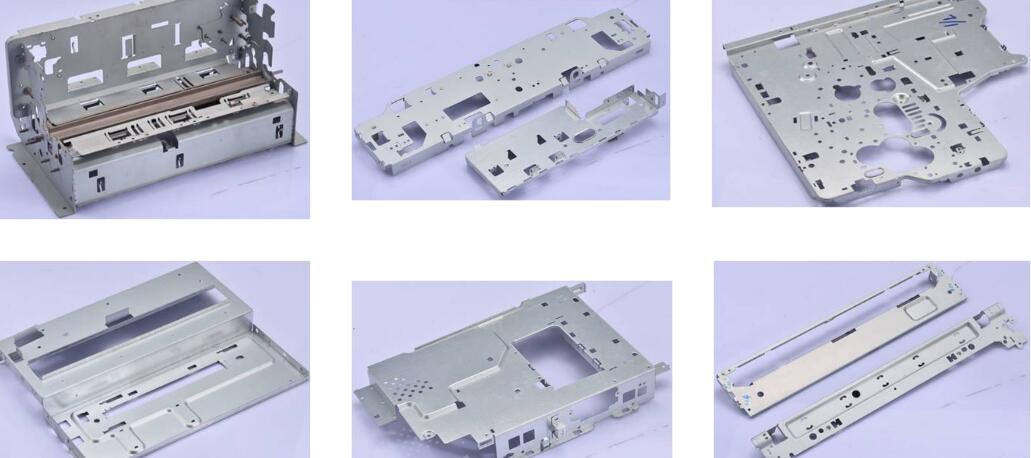

Sheet Metal Fabrication

A matsayin cikakken kayan aiki da kantin sayar da mutu, mun ƙware a duk fannoni na ƙirƙira ciki har da fiber Laser, CNC punching, CNC lankwasawa, CNC forming, walda, CNC machining, hardware shigar da taro.

Muna karɓar albarkatun ƙasa a cikin zanen gado, faranti, sanduna ko bututu kuma muna da gogewa a cikin aiki tare da abubuwa iri-iri kamar aluminum, jan karfe, bakin karfe da carbon karfe. Sauran ayyuka sun haɗa da saka kayan aiki, walda, niƙa, injina, juyawa da haɗawa. Yayin da kundin ku ya ƙaru muna kuma da zaɓi na yin amfani da kayan aiki da sassa na ku don aiki a sashen mu na stamping karfe. Zaɓuɓɓukan dubawa suna kewayo daga sauƙaƙe fasalin dubawa har zuwa FAIR & PPAP.

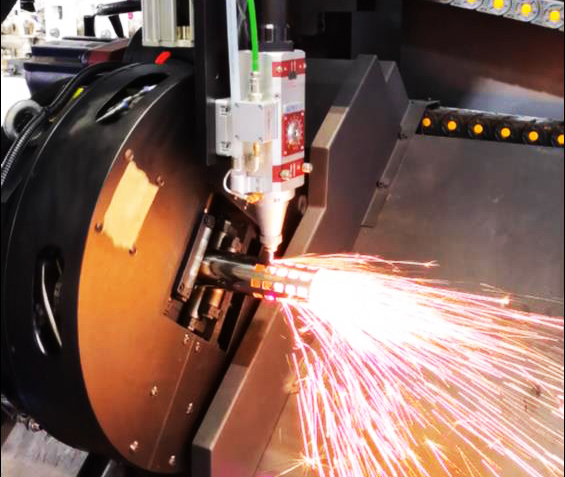

Laser Yankan

Karfe Lankwasawa

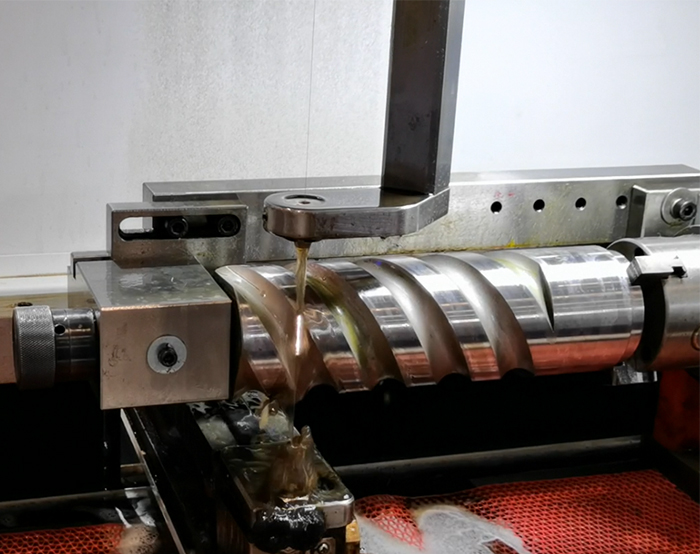

WEDM

Walda

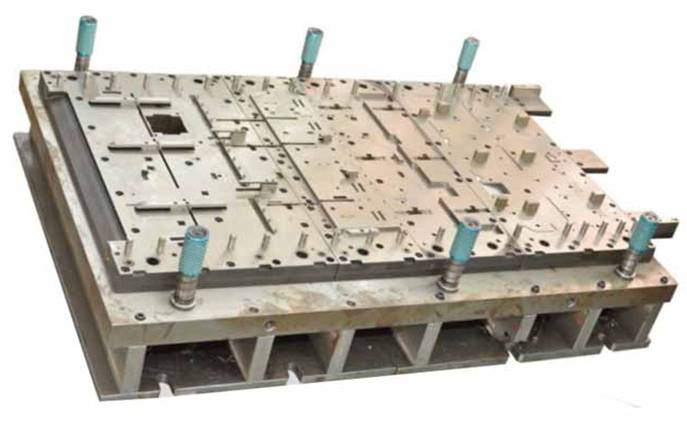

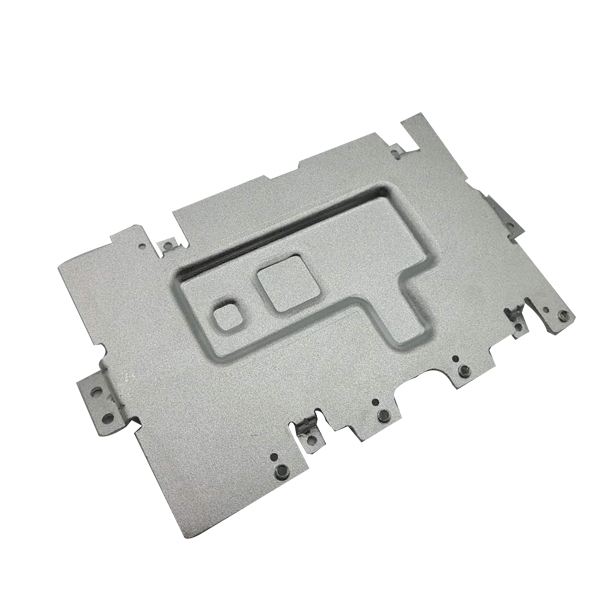

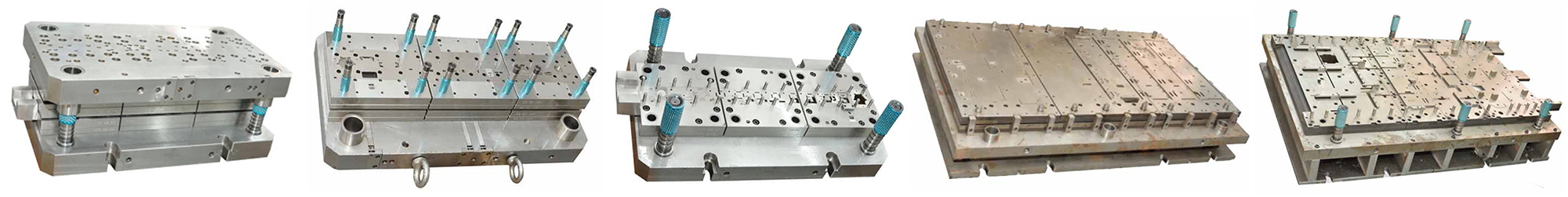

Sabis na Stamping

Za mu yi amfani da kayan aikin mu na ci gaba da ƙungiyar ƙwararrun ƙwararrun don keɓance samfuran da kuke tunanin, kuma mun yi imanin cewa za mu iya biyan bukatun ku duka dangane da farashi da inganci.

Menene Stamping?

A karfe takardar da aka kafa a cikin daban-daban takardar-kamar sassa da bawo, ganga-kamar workpieces a kan latsa ta mold, ko tube guda an sanya su cikin daban-daban tubular workpieces. Irin wannan tsari na kafa a cikin yanayin sanyi ana kiransa sanyi stamping, wanda ake kira stamping.

Yin amfani da hatimi shine fasahar samar da sassan samfur tare da takamaiman sifa, girman da aiki ta hanyar ƙarfin na'urar tati na yau da kullun ko na musamman, wanda ke lalata da lalata takarda a cikin ƙirar. Sheets, molds da kayan aiki sune abubuwa uku na tambari.

Babban nau'in tsari: naushi, lankwasa, sausaya, zane, kumbura, kadi, gyara.

Aikace-aikace: Jirgin sama, soja, injina, injinan noma, kayan lantarki, bayanai, layin dogo, gidan waya da sadarwa, sufuri, sinadarai, kayan aikin likita, kayan aikin gida da masana'antar haske.

Halaye

Muna amfani da madaidaicin gyare-gyare, madaidaicin kayan aikin na iya isa matakin micron, kuma madaidaicin maimaitawa yana da girma, ƙayyadaddun ƙayyadaddun abubuwa iri ɗaya ne, kuma ana iya fitar da ramuka da shugabanni.

(1) Tsarin mu na stamping yana da inganci sosai, mai sauƙin aiki, kuma mai sauƙin sarrafa injina da sarrafa kansa. Adadin bugun bugun da ake yi na gama-gari ya kai sau goma a cikin minti daya, kuma matsa lamba mai sauri na iya zama daruruwan ko ma dubbai a cikin minti daya, kuma ana iya samun naushi ga kowane bugun latsa.

(2) Tun da mutun ya tabbatar da girman da siffar daidaitaccen ɓangaren hatimi yayin yin tambari, kuma gabaɗaya baya lalata ingancin ɓangaren ɓangaren, kuma rayuwar mutuwar gabaɗaya tana da tsayi, ingancin tambarin ya tabbata. canjin canji yana da kyau, kuma yana da "daya". Halaye.

(3) Zamu iya dannawa da sarrafa sassa masu girman girma da hadaddun sifofi, kamar agogon tsayawa ƙanƙanta kamar agogo, har zuwa katako mai tsayi na mota, sassa masu rufewa, da sauransu, da nakasar sanyi ta taurare tasirin kayan tambari, ƙarfin naushi da taurin kai. sun fi girma.

(4) Yin tambari gabaɗaya ba shi da guntu guntu, ƙarancin amfani da kayan, kuma babu buƙatar sauran kayan dumama. Sabili da haka, hanya ce ta tanadin kayan aiki da sarrafa makamashi, kuma farashin kayan hatimi yana da ƙasa.

Kayayyaki