1. Abubuwan al'amuran jiki na mashin ɗin titanium

Ƙarfin yankan kayan aiki na alloy na titanium ya ɗan fi girma fiye da na ƙarfe tare da taurin iri ɗaya. Duk da haka, abin da ke faruwa a zahiri na sarrafa gawa na titanium ya fi na sarrafa ƙarfe da sarƙaƙƙiya, wanda ke sa sarrafa gami da titanium ya fuskanci matsaloli masu yawa.

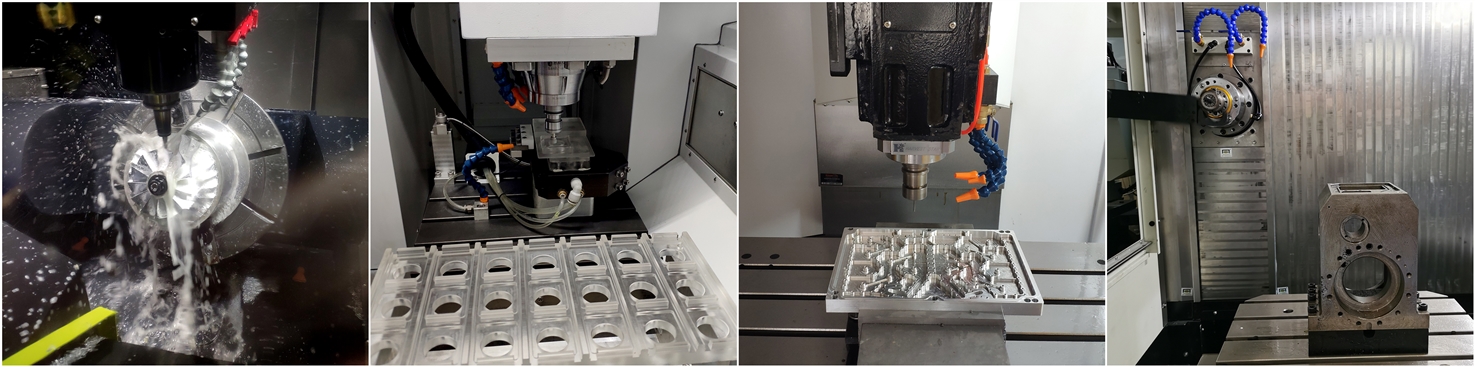

Thermal watsin mafi yawan titanium alloys ne sosai low, kawai 1/7 na karfe da 1/16 na aluminum. Saboda haka, zafi da aka haifar lokacin yankan alloys titanium ba za a yi saurin canja shi zuwa wurin aiki ba ko kwakwalwan kwamfuta sun tafi da su. Duk da haka, zai taru a wurin yankan, kuma zafin da ake samu zai iya kaiwa 1,000 ° C ko fiye, wanda zai sa kayan aikin yankan ya lalace, guntu, da fashewa da sauri. Samar da gefen da aka gina da kuma saurin bayyanar da aka sawa ya haifar da ƙarin zafi a cikin yanki na yanke, yana ƙara rage rayuwar kayan aiki.titanium machining

Babban yanayin zafi da aka haifar yayin aiwatar da yankewa kuma yana lalata amincin farfajiyar sassan alloy na titanium, wanda ke haifar da raguwar daidaiton juzu'i na sassan da kuma aiki mai ƙarfi wanda ke rage ƙarfin gajiyarsu sosai.

Ƙaƙƙarfan allo na titanium na iya zama da amfani ga aikin sashi, amma yayin yankan, nakasar nakasar kayan aiki shine muhimmin dalilin girgiza. Matsakaicin yanke yana haifar da aikin "lastic" don motsawa daga kayan aiki da billa, don haka juzu'i tsakanin kayan aiki da kayan aikin ya fi aikin yankewa. Har ila yau, tsarin jujjuyawar yana haifar da zafi, yana daɗaɗa matsalar rashin kyawun yanayin zafi na gami da titanium.

Wannan matsalar ta fi tsanani yayin yin injin sirara-bangon ko siffa mai siffar zobe, gurɓatattun sassa masu sauƙi. Ba abu ne mai sauƙi ba don na'ura sirara-ɓangare na gami da bangon titanium zuwa daidaiton girman girman da ake tsammani. Lokacin da kayan aiki ya ture kayan aikin, nakasar gida ta bangon bakin ciki ya wuce kewayon roba; nakasar filastik yana faruwa, kuma ƙarfin abu da taurin wurin yanke yana ƙaruwa sosai. Machining a farkon ƙaddarar saurin yanke ya zama mai girma, yana haifar da lalacewa mai kaifi.

"Zafi" shine "mai laifi" wanda ya sa ya zama ƙalubale don aiwatar da gami da titanium!

2. Ilimin fasaha na fasaha na titanium CNC machining

Dangane da fahimtar tsarin sarrafawa na alloys na titanium da ƙara ƙwarewa, ƙwarewar farko don sarrafa alloys titanium shine kamar haka:

(1) Ana amfani da abubuwan da aka saka tare da ingantattun lissafi don rage ƙarfin yanke aikin aikin, yanke zafi, da nakasa.

(2) Kula da abinci akai-akai don guje wa taurin kayan aikin. Kayan aiki ya kamata koyaushe ya kasance a cikin yanayin ciyarwa yayin aiwatar da yankan, kuma adadin yankan radial ya kamata ya zama 30% na radius yayin milling.

(3) Babban matsa lamba da manyan-zuba yankan ruwa da ake amfani da su tabbatar da thermal kwanciyar hankali na machining tsari da kuma hana workpiece degeneration da kayan aiki lalacewa saboda wuce kima zafin jiki.

(4) Rike gefen ruwa mai kaifi; kayan aiki mara kyau suna haifar da haɓaka zafi da lalacewa, da sauri yana haifar da gazawar kayan aiki.

(5) Machining a cikin mafi laushi yanayi na titanium alloy kamar yadda zai yiwu saboda kayan ya zama mafi ƙalubale ga na'ura bayan taurin, kuma maganin zafi yana ƙara ƙarfin kayan da lalacewa na shigarwa.

(6) Yi amfani da babban radius na hanci ko chamfer don yanke gwargwadon iyawa cikin yankan gefen. Wannan yana rage yanke ƙarfi da zafi a kowane wuri kuma yana hana karyewar gida. Lokacin milling titanium alloys, a cikin yankan sigogi, da yankan gudun yana da mafi muhimmanci tasiri a kan kayan aiki rayuwa vc, bi da radial alkawari (milling zurfin) ae.

3. Fara da ruwa don magance matsalar sarrafa titanium

Lalacewar tsagi na sakawa a lokacin mashin kayan haɗin gwal na titanium shine lalacewa na gida na baya da gaba a cikin zurfin yanke, wanda sau da yawa yakan haifar da taurin Layer da aka bari a baya. Halin sinadarai da yaduwar kayan aiki da kayan aikin aiki a yanayin aiki sama da 800 ° C suma dalilai ne na samuwar tsagi. Domin a lokacin da machining tsari, da titanium kwayoyin na workpiece tara a gaban ruwa da aka "welded" zuwa ruwa gefen karkashin high matsa lamba da kuma high zafin jiki, forming wani gina-up gefen. Lokacin da gefen da aka gina shi ya cire gefen yankan, yana cire murfin carbide na abin da aka saka, don haka aikin titanium yana buƙatar kayan sakawa na musamman da geometries.cCustomprecision machining

4. Tsarin kayan aiki wanda ya dace da mashin din titanium

Mahimmancin sarrafa kayan aikin titanium shine zafi, kuma dole ne a fesa babban adadin ruwan yankan matsa lamba akan yankan da sauri kuma daidai don cire zafi da sauri. Akwai na musamman jeri na milling cutters musamman don machining titanium.

Anebon Metal Products Limited na iya samar da CNC Machining, Die Casting, Sheet Metal Fabrication sabis, da fatan za a iya tuntuɓar mu.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Lokacin aikawa: Janairu-18-2022