Don injuna, abubuwan da suka shafi shaft kamar crankshafts, camshafts, da silinda liners suna amfani da chucks a kowane tsari na sarrafawa. A lokacin aiki, chucks cibiyar, matsa da kuma fitar da workpiece. Dangane da ikon chuck don riƙe kayan aiki da kuma kula da cibiyar, an raba shi cikin tsattsauran ra'ayi da ƙwanƙwasa mai iyo. Wannan labarin yafi tattauna waɗannan ƙa'idodin zaɓin chucks guda biyu da wuraren kulawa na yau da kullun.5aixs CNC machining sassa

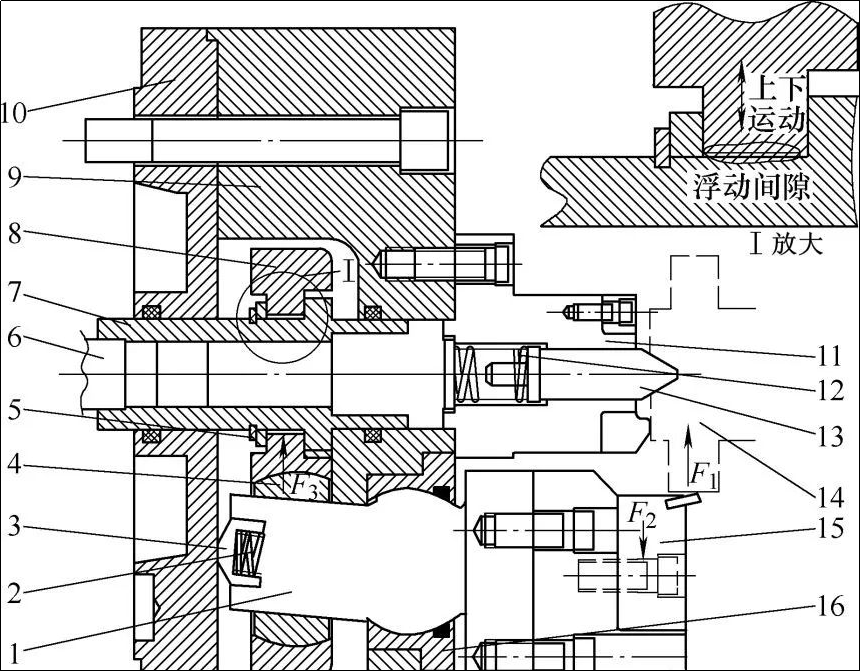

M chucks da iyo chucks sun bambanta sosai a cikin tsari da hanyoyin daidaitawa. Ɗaukar jerin chucks na alamar Jafananci a matsayin misali, Hoto 1 yana nuna tsarin aiki na ƙwanƙwasa mai iyo: aikin aiki yana ƙarƙashin aikin toshe tallafi na matsayi da saman. Axial da radial matsayi da clamping suna da za'ayi. Sa'an nan, chuck Silinda yana fitar da sandar ƙugiya ta tsakiya, farantin daidaitawar rata, farantin tallafi na hannun muƙamuƙi, haɗin gwiwa, da hannun muƙamuƙi ta sandar taye, a ƙarshe ya gane chuck jaw don matsa kayan aikin.

Lokacin da akwai wani gagarumin sabawa na coaxial tsakanin tsakiyar uku jaws na chuck da kuma tsakiyar workpiece, da muƙamuƙi na chuck cewa tuntubar da workpiece farko za a hõre wani karfi F2, wanda aka daukar kwayar cutar zuwa jaw. farantin tallafi na hannu ta hannun muƙamuƙi da haɗin gwiwa mai siffar zobe. F3 yana aiki akan farantin tallafi na hannu. Don chuck mai iyo, akwai tazara tsakanin sandar ja ta tsakiya na chuck da farantin goyan bayan hannu. A ƙarƙashin aikin ƙarfin F3, farantin tallafi na hannu yana amfani da rata mai iyo (farantin daidaitawa tata, sandar ja ta tsakiya na chuck, da farantin goyan bayan hannun muƙamuƙi tare suna samar da injin iyo na chuck), wanda zai motsa a cikin shugabanci na karfi har uku jaws manne da workpiece gaba ɗaya.

Hoto 1 Tsarin ƙugiya mai iyo

1. Hannun hannu

2. Ruwan ruwa na rectangular

3. Siffar saman murfin

4. Spherical hadin gwiwa

5. Farantin gyaran gyare-gyare

6. Silinda jan sanda

7. Chuck tsakiya ja sanda

8. Farantin tallafi na hannu

9. Jikin Chuck 10. Chuck's end cover

10. Matsayin toshe tallafi

12. Workpiece da za a sarrafa

13. Chuck jaws 16. Tallafin ball

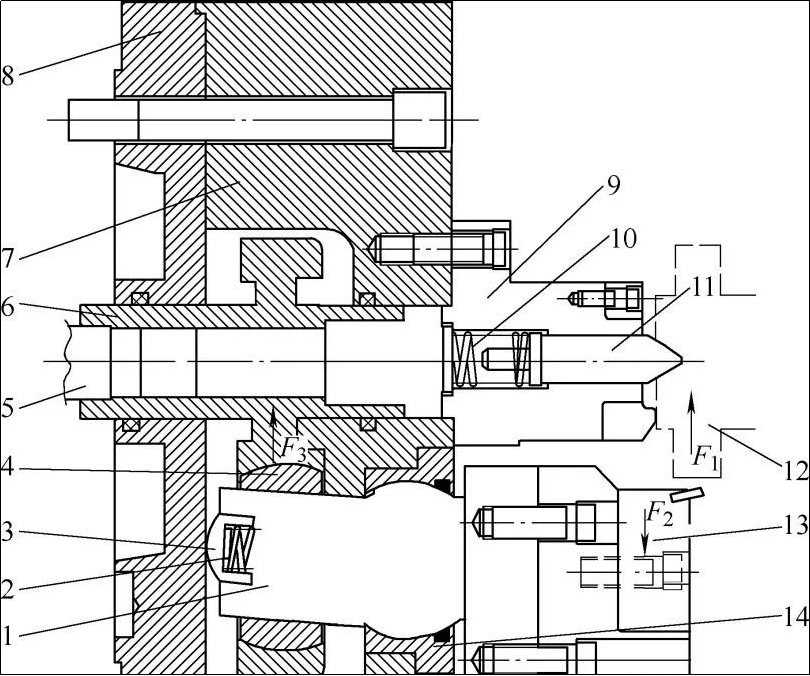

Hoto na 2 yana nuna tsarin aiki na tsattsauran ra'ayi

A karkashin aiki na sakawa goyon baya block da kuma saman, da workpiece ne matsayi da kuma clamped axially da radially, sa'an nan chuck man Silinda korar da tsakiyar jan sanda, mai siffar zobe hadin gwiwa da muƙamuƙi na chuck ta hanyar ja sanda. Hannun yana motsawa, kuma a ƙarshe, muƙamuƙi na chuck sun manne kayan aikin. Tunda sandar ja na tsakiya na chuck yana da alaƙa da ƙarfi tare da haɗin gwiwa mai siffar zobe da hannun muƙamuƙi, bayan an danne jaws (muƙamuƙi uku), za a kafa cibiyar matsawa. Cibiyar matsawa da aka kafa ta saman ba ta zoba, kuma aikin aikin zai sami nakasar matsewa a fili bayan an danne chuck. Kafin a yi amfani da chuck ɗin, ya zama dole a daidaita haɗin tsakanin tsakiyar chuck da tsakiyar cibiyar don tabbatar da cewa chuck ba zai bayyana kama ba bayan ƙulla. Yanayin manne.

Hoto 2 Tsari mai tsauri

1. Hannun hannu

2. 10. Ruwan ruwa na Rectangular

3. Siffar saman murfin

4. Spherical hadin gwiwa

5. Silinda taye sanda

6. Chuck tsakiya taye sanda

7. Chuck ta jiki

8. Rufin baya na Chuck

9. Matsayin toshe tallafi

10. Sama

11. Workpiece da za a sarrafa

12. Chuck's jaws

13. Taimakon Spherical

Daga nazarin tsarin chuck a cikin Hoto na 1 da Hoto na 2, ƙwanƙwasa mai iyo da tsauri suna da bambance-bambance masu zuwa.

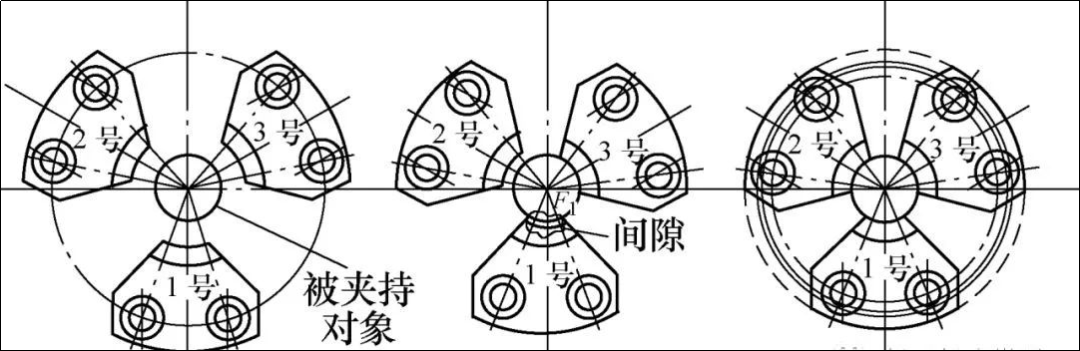

iyo Chuck: Kamar yadda aka nuna a cikin Figure 3, a kan aiwatar da clamping da workpiece, saboda daban-daban Heights na workpiece blank surface ko babban roundness haƙuri na blank, da No. 3 jaw zai zo cikin lamba tare da workpiece surface da kuma jaws na 1 da na 2 zasu bayyana. Idan workpiece ba a taba tukuna, a wannan lokaci, da iyo inji inji na iyo chuck aiki, ta yin amfani da surface na workpiece a matsayin goyon baya zuwa iyo da No. 3 muƙamuƙi. Muddin adadin da ke iyo ya isa, a ƙarshe za a matse muƙamuƙi na 1 da na 2. Kayan aikin yana da ɗan tasiri akan tsakiyar aikin.

Hoto na 3 Tsarin ƙugiya na muƙamuƙi masu iyo

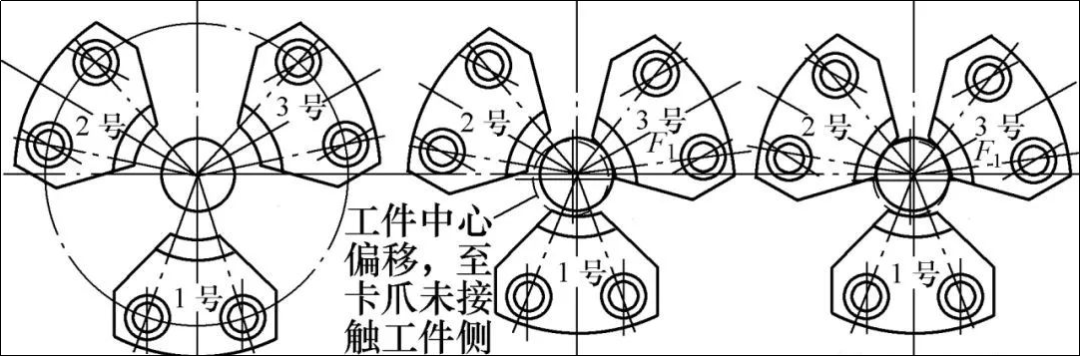

M Chuck: Kamar yadda aka nuna a cikin Figure 4, a lokacin da clamping tsari, idan concentricity tsakanin chuck da workpiece ba a daidaita yadda ya kamata, da No. 3 jaw zai tuntubi workpiece, da kuma No. 1 da No. zama a lamba tare da workpiece. , to chuck clamping force F1 zai yi aiki a kan workpiece. Idan ƙarfin yana da girma sosai, za a cire kayan aikin daga cibiyar da aka riga aka ƙaddara, tilasta aikin aikin motsa jiki zuwa tsakiyar chuck; lokacin da ƙarfi na chuck ya ƙanƙanta, wasu lokuta zasu faru. Lokacin da jaws ba zai iya cikakken tuntuɓar kayan aikin ba, rawar jiki yana faruwa yayin injin.cnc milling connector

Hoto na 4 Tsarin matsi na muƙamuƙi mai tsauri

Bukatun gyare-gyare kafin a yi amfani da chuck: Tsagewar chuck zai samar da cibiyar matsawa ta chuck da kanta bayan tadawa. Lokacin amfani da tsattsauran ra'ayi, dole ne a daidaita cibiyar clamping na chuck don daidaitawa tare da matsawa da sakawa na kayan aiki, kamar yadda aka nuna a cikin adadi 5 da aka nuna.cnc machining aluminum part

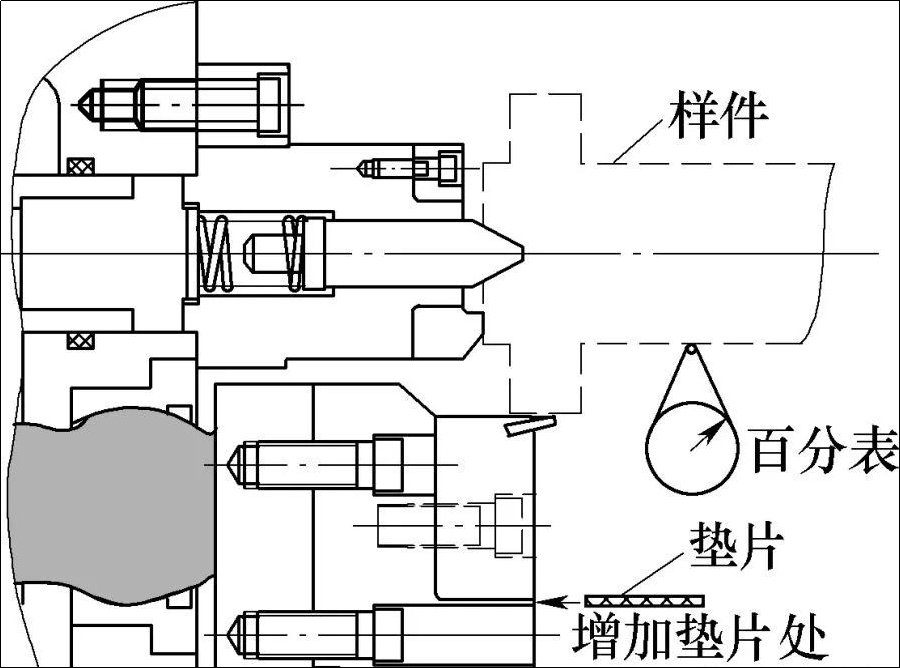

Hoto 5 Daidaita tsayayyen cibiyar chuck

Bisa ga binciken tsarin da ke sama, ana ba da shawarar bin ka'idodi masu zuwa a cikin daidaitawa da kuma kula da chuck: Ana maye gurbin lubrication da man shafawa na sassa masu motsi a cikin kullun. Motsi tsakanin sassa masu motsi a cikin chuck shine ainihin zamewar gogayya. Wajibi ne don ƙarawa akai-akai da maye gurbin ƙayyadadden matsayi na man mai / man shafawa bisa ga bukatun kiyayewa na chuck. Lokacin da ake ƙara mai, ya zama dole a matse duk wani mai da aka yi amfani da shi a lokacin da ya gabata, sannan a toshe tashar fitar da mai bayan an datse chuck ɗin don hana kogon ciki na chuck ɗin riƙewa.

Na yau da kullum dubawa da daidaitawa na clamping cibiyar na m Chuck da kuma tsakiyar workpiece: A m Chuck bukatar lokaci-lokaci auna ko cibiyar da chuck da cibiyar na workpiece sandar ne m. Auna guduwar diski. Idan ya zarce kewayon da ake buƙata, ƙara masu sarari yadda ya kamata a ɗaya ko biyu muƙamuƙi daidai da babban batu, kuma maimaita matakan da ke sama har sai an cika buƙatun.

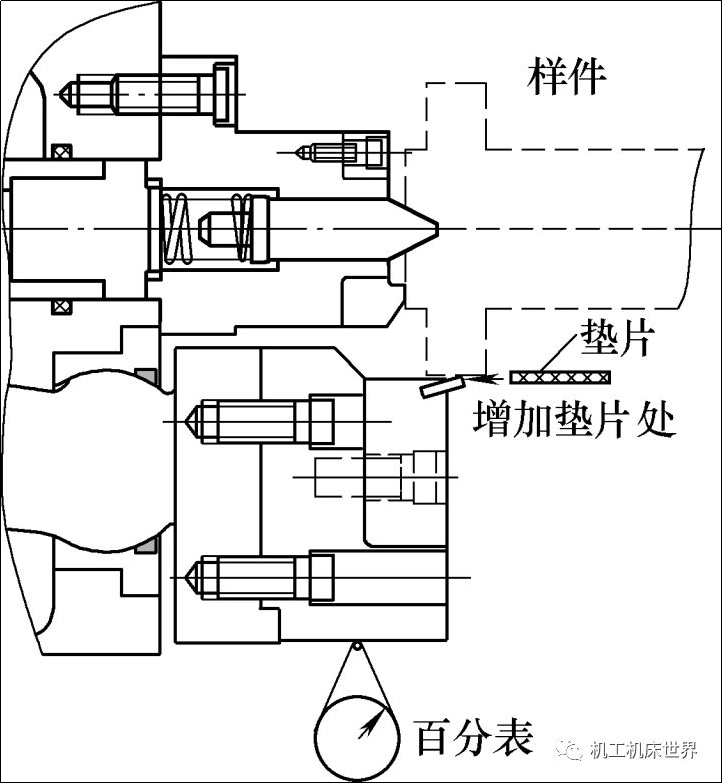

Dubawa lokaci-lokaci na adadin iyo na ƙugiya mai iyo (duba hoto 6). A cikin kulawar kullun yau da kullun, ya zama dole don auna yawan adadin da aka yi a kai a kai da madaidaicin madaidaicin ruwa, da kuma ba da jagora don kula da ciki na chuck a cikin mataki na gaba. Hanyar auna madaidaicin iyo: bayan chuck clamps samfurin, sanya chuck don aunawa. Juya katsin zuwa wurin ma'auni mai dacewa, auna ma'aunin bugun kira (buƙatar haɗa ginin mitar maganadisu zuwa ramin motsi), sa'annan sanya ma'aunin ma'auni azaman matsayin sifili. Sa'an nan sarrafa servo axis don motsa alamar bugun kira, buɗe chuck, sanya gasket mai kauri na Amm tsakanin jaws don aunawa da samfurin, matsa samfurin akan chuck, matsar da alamar bugun kira zuwa matsayi na sifili, kuma tabbatar da ko bayanan da mai nuna bugun kira ya danna game da Amm. Idan haka ne, yana nufin cewa daidaiton iyo yana da kyau. Idan bayanan sun bambanta sosai, yana nufin cewa akwai matsala tare da tsarin iyo na chuck. Auna sauran muƙamuƙi daidai yake da na sama.

Hoto 6 Duban adadin yawan iyo na chuck mai iyo

Sauyawa na yau da kullun na sassa kamar hatimi, gaskets, da maɓuɓɓugan ruwa a cikin chuck: maɓuɓɓugan rectangular, chuck body, chuck rear end cover, rectangular springs, and seals and springs in spherical supports dole ne a aiwatar da shi gwargwadon yawan amfani da abin da ke sama. sakamakon gwaji. Sauya akai-akai. In ba haka ba, gajiya zai lalata shi, yana haifar da adadi mai iyo da tsauri chuck runout.

Ta hanyar binciken da ke sama na abubuwan da ke da mahimmanci na daidaitawar tsarin chuck da kiyayewa, kula da ka'idodi masu zuwa a cikin zaɓin chucks: idan ɓangaren chuck clamping na ɓangaren da aka sarrafa shine sarari mara kyau, an fi son ciyawar iyo chuck, da tsayayyen chuck. ana amfani dashi a cikin kayan aiki. The chuck clamping surface na machined part ne saman bayan roughing, Semi-kammala/kammala. Bayan bin ƙa'idodin asali na sama, yin takamaiman zaɓi bisa ga yanayin aiki daban-daban ya zama dole.

Zaɓin tsattsauran ra'ayi:

① Yanayin injin yana buƙatar babban adadin yankan da babban ƙarfin yankewa. Bayan an clamped da workpiece da za a sarrafa da kuma goyan bayan tsakiyar firam, a muscular workpiece rigidity, da kuma babban workpiece juyi tuki ake bukata.

②Lokacin da babu tsarin tsakiya na lokaci ɗaya, kamar saman, ana buƙatar ƙirar chuck centering.

Zaɓin chuck mai iyo:

① Babban buƙatun ga tsakiya na workpiece sandal. Bayan an danne chuck ɗin, shawaginsa ba zai dame shi a matakin farko na sandar kayan aikin ba.

②A yankan adadin ba babba, kuma shi ne kawai ya zama dole don fitar da workpiece spindle don juya da kuma ƙara rigidity na workpiece.

Abin da ke sama yana bayanin bambance-bambancen tsari da kiyayewa da buƙatun zaɓi na iyo da tsattsauran ra'ayi, waɗanda ke taimakawa don amfani da kiyayewa. Kuna buƙatar zurfin fahimta da amfani mai sassauƙa; kuna buƙatar taƙaice koyaushe gwaninta a cikin amfani da kiyayewa akan rukunin yanar gizon.

Anebon Metal Products Limited na iya samar da CNC Machining, Die Casting, Sheet Metal Fabrication sabis, da fatan za a iya tuntuɓar mu.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Lokacin aikawa: Maris-31-2022