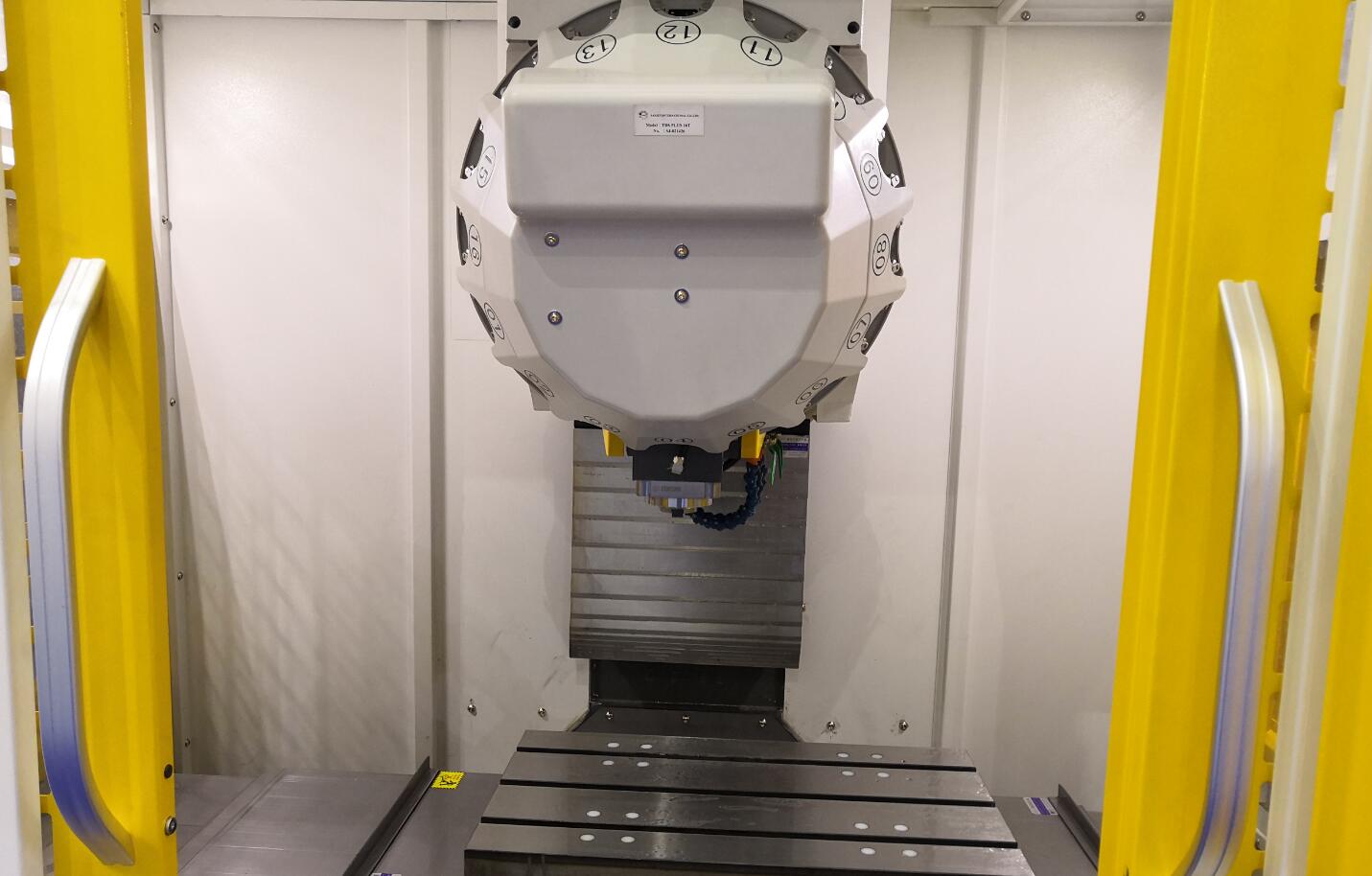

Lokacin rarraba matakai a cikin mashin ɗin ƙarfe na CNC, dole ne a sarrafa shi cikin sassauƙa dangane da tsari da ƙirar sassa, ayyuka na kayan aikin injin injin CNC, adadin sassa.Injin CNCabun ciki, adadin shigarwa, da kuma samar da ƙungiyar naúrar.

1. Tsara ta kayan aiki.

Don rage lokacin canza kayan aiki, damfara lokacin aiki, da rage kurakurai na matsayi mara amfani, ana iya sarrafa sassan bisa ga hanyar tattara kayan aiki, wato, a cikin matsawa ɗaya, yi amfani da kayan aiki guda ɗaya don aiwatar da duk abubuwan da za su yiwu gwargwadon yiwuwa. , sannan a canza wata wuka don sarrafa wasu sassa.aluminum part

2. Rarraba ta hanyar sarrafawa.

Tsarin tsari da siffar kowane bangare sun bambanta, kuma buƙatun fasaha na kowane farfajiya kuma sun bambanta. Don haka, hanyoyin sanyawa sun bambanta yayin sarrafawa ta yadda za a iya raba tsarin bisa ga hanyoyin sanyawa daban-daban.CNC karfe sashi

3. Rarraba ta roughing da gamawa

Lokacin rarraba hanyoyin bisa ga dalilai kamar daidaiton mashin ɗin, tsattsauran ra'ayi, da nakasar sassa, ana iya rarraba hanyoyin bisa ga ka'idar rarraba m da gamawa, wato, roughing sannan kuma gamawa. A wannan lokacin, ana iya amfani da kayan aikin inji daban-daban ko kayan aiki daban-daban don sarrafawa.

Anebon Metal Products Limited na iya samar da mashin ɗin CNC, simintin gyare-gyare, sabis na ƙirar ƙarfe, da fatan za a iya tuntuɓar mu.

Tel: +86-769-89802722 Email: info@anebon.com Website: www.anebon.com

Lokacin aikawa: Agusta-11-2020