Zare wani helix ne da aka yanke a cikin kayan aiki ko dai daga waje ko daga ciki kuma yana yin ayyuka masu mahimmanci da yawa. Na farko, zaren suna ƙirƙirar haɗin injina ta hanyar haɗa samfurin da aka zare na ciki tare da samfurin zaren waje. Wannan haɗin yana tabbatar da cewa sassa daban-daban na kayan aikin za a iya haɗa su da ƙarfi da juna.

Bugu da ƙari, zaren suna taka muhimmiyar rawa wajen watsa motsi. Suna iya juyar da motsin juyawa zuwa motsi na layi da akasin haka. Wannan ƙarfin yana da amfani musamman a aikace-aikace da yawa, kamar a cikin injina waɗanda ke buƙatar motsi na layi don yin takamaiman ayyuka.

Bugu da ƙari, zaren suna ba da fa'idodi na injiniya. Ta amfani da zaren zaren, ana iya samun mafi girman aikin injiniya ta kowane fanni. Wannan ya haɗa da ƙara ƙarfin ɗaukar nauyi, haɓaka juriya ga sassautawa ko girgizawa, da ingantaccen ƙarfin watsa wutar lantarki.

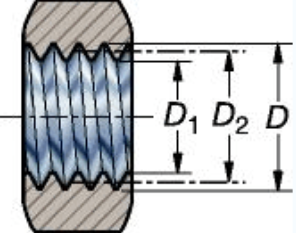

Akwai nau'ikan nau'ikan zaren daban-daban, kowannensu yana ƙayyade ma'auni na zaren. Wani muhimmin al'amari na zaren profile ne workpiece diamita. Wannan ya haɗa da babban diamita (mafi girman diamita na zaren) da diamita na farar (diamita a wurin hasashen inda faɗin zaren ya zama sifili). Waɗannan ma'aunai suna da mahimmanci don tabbatar da cewa zaren sun dace daidai da aiki yadda ya kamata.

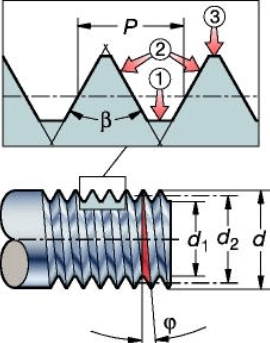

Fahimtar kalmomin zaren yana da mahimmanci don amfani da zaren yadda ya kamata. Wasu mahimman kalmomin sun haɗa da gubar (nisan axial da zaren ke tafiya a cikin cikakken juyin juya hali) da farar (nisa tsakanin maki daidai akan zaren da ke kusa). Daidaitaccen auna gubar da farar abu yana da mahimmanci don tabbatar da ingantaccen ƙirar zaren da dacewa.

A taƙaice, zaren suna aiki da ayyuka masu mahimmanci a cikin masana'antu daban-daban. Suna sauƙaƙe haɗin injiniya, watsa motsi da kuma samar da fa'idodin inji. Fahimtar bayanan bayanan zaren da kalmomin da ke da alaƙa yana da mahimmanci don amfani da zaren cikin nasara da tabbatar da ingantaccen aiki.

Magance Sirrin Pitch: Binciken Ma'anarsa da Hanyar Lissafi

Fitar zaren abu ne mai mahimmanci a fagen masana'antu da injina. Fahimtar abin da ake nufi da ƙididdige shi daidai yana da mahimmanci don ƙirƙirar sassa masu inganci masu inganci. A cikin wannan labarin, za mu nutse cikin ƙaƙƙarfan farawar zaren, da jumlolinsa, da yadda ake tantance shi daidai. Bugu da ƙari, za mu gabatar da Anebon, kamfani ƙware a cikin samfuri na sabis na mashin ɗin CNC da al'ada CNC milling, yana ba da sauri kuma abin dogaro akan layi don injinan CNC.

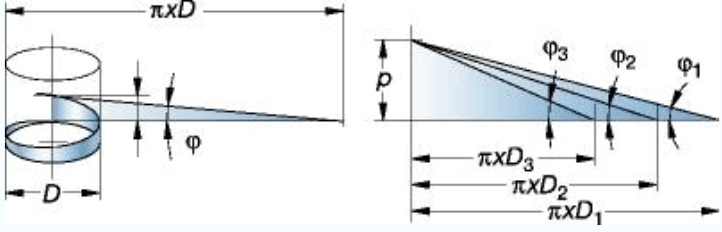

Geometry na zaren yana dogara ne akan diamita na farar zaren (d, D) da farar (P): nisan axial tare da zaren akan kayan aikin daga aya ɗaya akan bayanin martaba zuwa madaidaicin batu na gaba. Yi la'akari da shi azaman alwatika wanda ke kewaye da kayan aiki. Wannan tsarin triangular yana ƙayyade tasiri da aiki na abubuwan da aka zare. Madaidaicin lissafin farar zaren yana da mahimmanci don tabbatar da dacewa daidai, rarraba kayan aiki mafi kyau da ingantaccen aiki na sassan injina.

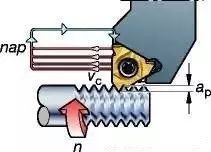

Domin tantance farar daidai, masana'anta suna amfani da fasahar injin CNC na ci gaba. Injin CNC, ko injin sarrafa lambobi na kwamfuta, tsari ne na masana'anta da ke amfani da kayan aikin injin da ke sarrafa kwamfuta don cire ainihin kayan daga albarkatun ƙasa don samar da sassan injin. CNC Machining Online Quoting sabis ne wanda kamfanoni masu ƙwararru da yawa ke bayarwa waɗanda ke ba abokan ciniki damar sauri da sauƙin samun ƙimancin farashi don al'adarsu.CNC machining sassa.

Anebon babban kamfani ne a cikin masana'antar kayan masarufi, yana ba da sabis na mashin ɗin CNC mai inganci da CNC milling na al'ada tun lokacin da aka fara shi a cikin 2010. Tare da ƙwararrun ƙwararrun ƙwararrun ƙwararru da kayan aikin zamani, Anebon yana samar da ingantaccen, samfuran inganci . Daidaitaccen injuna da aka shigo da su daga Japan. Su CNC niƙa da lathes kazalika da surface grinders taimaka musu su sadar da fice samfurin daidaici da inganci. Bugu da ƙari, Anebon yana da ISO 9001: 2015 bokan, yana nuna jajircewarsu na kiyaye mafi girman matakan samarwa da gamsuwar abokin ciniki.

Lokacin lissafin farar, yawanci ana bayyana shi cikin zaren kowane inch (TPI) ko millimeters. Don zaren awo, an ayyana farar a matsayin nisa a cikin milimita tsakanin igiyoyin zaren biyu maƙwabta. Sabanin haka, don tsarin zaren tushen inch, TPI yana tsaye ne don zaren kowane inci na layi. Daidaitaccen auna fitin zaren yana da mahimmanci don tabbatar da dacewa tsakanin sassan zaren da nisantar yuwuwar matsalolin kamar sako-sako, gatsewa ko rashin isassun kaya.

Injin CNCyana taka muhimmiyar rawa wajen cimma daidaiton ma'aunin filaye. Ta hanyar yin amfani da fasahar yankan-baki da kayan aiki daidai, sassan injin CNC na iya saduwa da mafi yawan buƙatu da ƙayyadaddun bayanai. Shirye-shiryen software na ci gaba suna ba injinan CNC damar yin ƙididdige ƙididdiga masu rikitarwa, tare da tabbatar da cewa an sami daidaitaccen filin zaren don kowane aikace-aikacen musamman.

A taƙaice, fahimtar ƙaƙƙarfan farar sauti da ƙididdige shi daidai yana da mahimmanci don ƙirƙirar sassa na injuna masu inganci. Ta hanyar amfani da samfur na sabis na injina na CNC da kuma amfani da al'adaFarashin CNC, masana'antun na iya cimma daidaitattun daidaito da inganci a cikin samfuran su. Ƙaddamar da kyakkyawan aiki kuma tare da kayan aiki na zamani, kamfanoni kamar Anebon suna jagorantar hanyar samar da abin dogara, ingantaccen CNC machining online quote services. Tare da madaidaicin ilimin farar zaren, masana'anta na iya ƙirƙirar sassan zaren waɗanda suka dace da mafi girman matsayin aiki da aiki.

1. Lissafi da haƙuri na farar diamita na 60° haƙori mai siffa ta waje (ma'auni na ƙasa GB197/196)

a.Lissafi na farar diamita na asali girman

Matsakaicin girman diamita na zaren = babban diamita na zaren - ƙimar ƙimar ƙimar ƙimar.

Misalin tsari: d/DP×0.6495

Misali: Lissafin diamita na farar zaren M8 na waje

8-1.25×0.6495=8-0.8119≈7.188

b. Haƙurin jurewar diamita na zaren waje na 6h da aka saba amfani da shi (dangane da farar zaren)

Ƙimar mafi girma ita ce "0"

Ƙananan iyaka shine P0.8-0.095P1.00-0.112P1.25-0.118

P1.5-0.132P1.75-0.150P2.0-0.16

P2.5-0.17

Ƙididdigar ƙididdiga ta sama ita ce girman asali, kuma ƙaramar ƙididdige ƙididdiga na d2-hes-Td2 shine madaidaicin diamita na asali na girman-bangaɗi-bawul.

Ƙimar haƙuri na 6h sa diamita na M8: ƙimar iyaka ta sama 7.188 ƙananan ƙimar iyaka: 7.188-0.118=7.07.

C. Wanda aka saba amfani da shi 6g madaidaicin zaren farar diamita na asali na asali: (dangane da farar zaren)

P0.80-0.024P1.00-0.026P1.25-0.028P1.5-0.032

P1.75-0.034P2-0.038P2.5-0.042

Ƙididdigar ƙididdiga mafi girma d2-ges ita ce sabawar girman asali

Ƙididdigar ƙananan ƙididdiga na d2-ges-Td2 shine ainihin juriyar juzu'in girman girman

Misali, ƙimar juriyar juriyar farar diamita na 6g na M8: ƙimar iyaka ta sama 7.188-0.028=7.16 ƙimar ƙarancin iyaka: 7.188-0.028-0.118=7.042.

Lura:

① Haƙuri na zaren da ke sama suna dogara ne akan ƙananan zaren, kuma ana canza juriya na zaren lallausan zaren kuma ana canza su daidai da haka, amma ana haɓaka juriya kawai, don haka kulawar ba zai wuce ƙayyadaddun ƙayyadaddun bayanai ba, don haka ba a sanya su a cikin tebur ba. Sama ya fito.

② A cikin ainihin samarwa, bisa ga madaidaicin da ake buƙata ta ƙira da ƙarfin extrusion na kayan aiki na zaren, diamita na sanda mai gogewa yana ƙaruwa da 0.04-0.08 idan aka kwatanta da diamita na zaren da aka tsara, wanda shine diamita na zaren goge. sanda Misali, diamita na kamfanin mu M8 na waje thread 6g zaren goge sanda ne 7.08-7.13, wanda yake cikin wannan kewayon.

③Yi la'akari da bukatun tsarin samarwa, ƙananan ikon sarrafawa na diamita na firam na zaren waje ba tare da maganin zafi da jiyya a cikin ainihin samarwa ya kamata a kiyaye shi a matakin 6h kamar yadda zai yiwu.

2. Ƙididdigewa da juriya na firam diamita na 60° zaren ciki (GB197/196)

A.6H matakin zaren farar diamita haƙuri (dangane da farawar zaren)

babba iyaka:

P0.8+0.125P1.00+0.150P1.25+0.16P1.5+0.180

P1.25+0.00P2.0+0.212P2.5+0.224

Ƙimar ƙarancin iyaka shine "0",

Ƙididdigar ƙididdiga mafi girma 2+TD2 shine ainihin girman + haƙuri.

Misali, diamita na zaren ciki na M8-6H shine: 7.188+0.160=7.348 babba iyaka: 7.188 shine ƙananan iyaka.

b. Dabarar ƙididdige diamita na zaren ciki daidai yake da na zaren waje

Wato, D2=DP×0.6495,wato, diamita na zaren ciki yana daidai da diamita na farar ×ƙimar ƙima.

c.6G aji zaren farar diamita na asali sabawa E1 (dangane da farawar zaren)

P0.8+0.024P1.00+0.026P1.25+0.028P1.5+0.032

P1.75+0.034P1.00+0.026P2.5+0.042

Misali: Ƙarfin babba na diamita na zaren ciki na M86G: 7.188+0.026+0.16=7.374

Ƙananan iyaka: 7.188+0.026=7.214

Matsakaicin iyaka na sama 2+GE1+TD2 shine ainihin girman diamita na farar+bangaɗi+haƙuri

Ƙimar ƙimar ƙaƙƙarfan ƙa'idar 2+GE1 ita ce girman diamita na farar + karkacewa

3. Lissafi da juriya na manyan diamita na zaren waje (GB197/196)

a.Upper iyaka na 6h manyan diamita na waje zaren

Wato, ƙimar ƙimar diamita na zaren misali M8 shine φ8.00, kuma haƙurin iyakar babba shine “0″.

b. Haƙuri na ƙananan iyaka na babban diamita na waje na aji 6h (dangane da farar zaren)

P0.8-0.15P1.00-0.18P1.25-0.212P1.5-0.236P1.75-0.265

P2.0-0.28P2.5-0.335

Ƙididdigar ƙididdiga don ƙananan iyaka na babban diamita: d-Td shine ainihin girman juriya na babban diamita na zaren.

Misali: M8 zaren waje 6h girman girman diamita: iyakar babba shine φ8, ƙananan iyaka shine φ8-0.212=φ7.788

c.Kididdigewa da Juriya na Babban Diamita 6g na Zaren Waje

6g na waje magana tunani sabawa (bisa zaren farar)

P0.8-0.024P1.00-0.026P1.25-0.028P1.5-0.032P1.25-0.024P1.75-0.034

P2.0-0.038P2.5-0.042

Ƙididdigar ƙididdiga mafi girma na d-ges shine ainihin girman zaren manyan diamita-labarin magana

Ƙididdigar ƙananan ƙididdiga na d-ges-Td shine ainihin girman zaren manyan diamita-madaidaicin juzu'i-haƙuri.

Misali: M8 zaren waje 6g babban diamita babba iyaka φ8-0.028=φ7.972.

Ƙananan iyaka φ8-0.028-0.212=φ7.76

Lura: ① Babban diamita na zaren ana ƙaddara ta diamita na zaren goge sandar da matakin lalacewa na zaren birgima farantin/nadiddigar haƙoran haƙora, kuma darajarsa ta yi daidai da na sama da tsakiyar diamita na zaren. Dangane da kayan aikin blank da zaren guda ɗaya, ƙaramin diamita na tsakiya, mafi girman babban diamita, kuma akasin haka, mafi girman diamita na tsakiya, ƙarami babban diamita.

② Don sassan da ke buƙatar magani mai zafi da jiyya na sama, la'akari da dangantakar dake tsakanin fasahar sarrafawa da kuma samar da ainihin, babban diamita na zaren ya kamata a sarrafa shi a ƙananan iyaka na 6h da 0.04mm ko fiye. Misali, don zaren waje na M8, babban diamita na zaren shafa (mirgina) ya kamata a ba da garantin zama sama da 7.83 kuma ƙasa da 7.95.

4. Lissafi da haƙuri na ƙananan diamita na zaren ciki

a. Lissafi na ainihin girman ƙananan diamita na zaren ciki (D1)

Girman asali na ƙaramin zaren diamita = ainihin girman zaren ciki - ƙimar ƙira ×

Misali: Girman asali na ƙaramin diamita na zaren ciki M8 shine 8-1.25 × 1.0825=6.646875≈6.647

b. Ƙididdigar zaren ciki 6H ƙananan jurewar diamita (dangane da farawar zaren) da ƙananan ƙimar diamita

P0.8+0.2P1.0+0.236P1.25+0.265P1.5+0.3P1.75+0.335

P2.0+0.375P2.5+0.48

Ƙarƙashin ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙira na ciki 6H aji shine ainihin girman girman zaren ciki ƙananan diamita + karkacewa.

Lura: Ƙimar son zuciya shine "0" a matakin 6H

Ƙididdigar ƙididdiga don babban iyaka na matakin 6H na zaren ciki = D1+HE1+TD1, wato, girman asali na ƙananan diamita na zaren ciki + sabawa + haƙuri.

Misali: Babban iyaka na ƙaramin diamita na 6H sa M8 zaren ciki shine 6.647+0=6.647

Matsakaicin ƙaramin diamita na 6H sa M8 zaren ciki shine 6.647+0+0.265=6.912

c.Kididdigar asali na asali na ƙananan diamita na zaren ciki 6G (dangane da farar) da darajar ƙananan diamita

P0.8+0.024P1.0+0.026P1.25+0.028P1.5+0.032P1.75+0.034

P2.0+0.038P2.5+0.042

Ƙididdigar ƙididdiga don ƙananan iyaka na ƙananan diamita na zaren ciki 6G = D1 + GE1 shine ainihin girman zaren ciki + karkacewa.

Misali: Ƙananan iyaka na ƙaramin diamita na 6G sa M8 zaren ciki shine 6.647+0.028=6.675

Dabarar D1 + GE1 + TD1 don ƙimar ƙimar babba na ƙaramin diamita na 6G sa M8 na ciki shine ainihin girman zaren ciki + karkacewa + haƙuri.

Misali: Babban iyaka na ƙaramin diamita na 6G sa M8 zaren ciki shine 6.647+0.028+0.265=6.94

Lura:

① Tsawon hakori na zaren ciki yana da alaƙa kai tsaye da lokacin ɗaukar zaren na ciki, don haka blank ya kamata ya kasance a cikin iyakar babba na ajin 6H gwargwadon yiwuwa.

②Lokacin mashin ɗin zaren ciki, ƙarami ƙaramin diamita na zaren na ciki, ƙarancin ingantaccen kayan aikin sarrafawa - famfo. Daga ra'ayi na amfani, ƙananan ƙananan ƙananan diamita, mafi kyau, amma cikakkiyar la'akari, ana amfani da ƙananan diamita gabaɗaya tsakanin iyakar tsakiya da babba, idan an jefa baƙin ƙarfe ko aluminum, ya kamata a yi amfani da shi tsakanin ƙananan iyaka da matsakaicin matsakaicin ƙananan diamita .

③Lokacin da ƙaramin diamita na zaren ciki shine 6G, ana iya gane shi azaman 6H. Madaidaicin matakin ya fi la'akari da rufin diamita na zaren. Sabili da haka, kawai girman diamita na famfo ana la'akari da shi yayin aikin zaren, kuma ba a la'akari da ƙananan diamita. Diamita na ramin haske.

5. Ƙididdigar ƙididdiga ta hanyar rarraba kai guda ɗaya

Ƙididdigar ƙididdiga guda ɗaya: n=40/Z

n: adadin da'irori wanda shugaban raba ya kamata ya juya

Z: daidai sashi na workpiece

40: kafaffen lambar shugaban fihirisa

Misali: Lissafi don niƙa hexagon

Sauya cikin dabara: n=40/6

Lissafi: ① Sauƙaƙe juzu'i: nemo mafi ƙanƙanta mai rarrabawa 2 kuma raba ta, wato, raba lambobi da ƙididdigewa da 2 a lokaci guda don samun 20/3. Yayin da ake rage makin, daidaiton rabonsa ya kasance iri ɗaya ne.

② Lissafin juzu'i: A wannan lokacin, ya dogara da ƙimar ƙima da ƙima; idan na'urar ƙididdigewa da ƙididdiga sun yi girma, to ana yin lissafin.

20÷3=6(2/3) shine darajar n, wato, kai mai raba ya kamata ya juya 6(2/3) da'ira. A wannan lokacin, juzu'in ya zama juzu'i; Matsakaicin adadin adadin adadi na 6 shine shugaban rabo ya juya 6 cikakkun da'ira. Juzu'i na 2/3 tare da juzu'i na iya zama 2/3 na da'irar kuma dole ne a sake ƙididdige shi a wannan lokacin.

③Zaɓi da ƙididdige farantin ƙididdiga: ƙididdige ƙasa da da'irar ɗaya dole ne a gane tare da taimakon farantin nuni na shugaban mai nuna alama. Mataki na farko a cikin lissafin shine a faɗaɗa juzu'in lokaci guda da 2/3. Misali: idan aka kara maki maki 14 a lokaci guda, 28/42 ne; idan aka kara girma sau 10 a lokaci guda, maki 20/30 ne; idan aka kara girma sau 13 a lokaci guda, makin shine 26/39…Ma'auni mai girma yakamata ya kasance daidai da bugun kira Zaɓi adadin ramuka akansa.

A wannan lokaci ya kamata a kula da:

①Dole ne a rarraba adadin ramukan da aka zaɓa ta hanyar ƙididdigewa 3. Misali, a cikin misalin da ke sama, ramukan 42 sune sau 14 na 3, ramukan 30 sau 10 na 3, ramukan 39 kuma sau 13 na 3. .

②Dole ne fadada juzu'i ya zama cewa ana faɗaɗa mai ƙididdigewa da ƙididdigewa a lokaci guda, kuma daidaitaccen rabo ya kasance baya canzawa, misali.

28/42=2/3×14=(2×14)/(3×14); 20/30=2/3×10=(2×10)/(3×10);

26/39=2/3×13=(2×13)/(3×13)

28/42 Ƙididdigar 42 ita ce a yi amfani da ramukan 42 na lambar maƙasudin don ƙididdigewa; mai lamba 28 yana motsawa gaba akan ramin sakawa na dabaran na sama, sannan ya juye ramin 28, wato, ramin 29 shine madaidaicin ramin dabaran na yanzu, 20/30 shine ramuka 10 gaba a wurin juyawa na motar. Farantin ramuka 30, kuma rami na 11 shine daidai ramin sakawa na wannan dabaran. 26/39 shine madaidaicin rami na wannan dabaran akan farantin ramuka 39, kuma ramukan 26 na ramukan 27th suna juyawa gaba.

Lokacin niƙa hexagon (kashi shida), ramuka irin su ramuka 42, ramuka 30, da ramuka 39 waɗanda za a iya rarraba su ta 3 ana amfani da su azaman ma'auni: aikin shine a jujjuya hannun sau 6, sa'an nan kuma matsa gaba akan ramin sakawa zuwa ramin. zama babba dabaran bi da bi. Juya 28+1/10+1/26+ sake! Ana amfani da ramin da ke cikin rami na sama na 29/11/27 azaman ramin sanyawa na dabaran.

Misali 2: Lissafi don niƙa kayan haƙori 15.

Sauya cikin dabara: n=40/15

Yi lissafin n=2(2/3)

Shi ne a juya 2 cikakken da'ira, sa'an nan zaži fihirisa ramukan da za a iya raba ta 3, kamar 24, 30, 39, 42.51. Ƙara rami 1, wato 17, 21, 27, 29, 35, 37, 39, 45, a matsayin ramin sakawa na wannan dabaran.

Misali 3: Lissafin ƙididdigewa don niƙa haƙora 82.

Sauya cikin dabara: n=40/82

Yi lissafin n=20/41

Wato: muddin aka zaɓi farantin nuni mai ramuka 41, sai a juya 20+1 akan ramin matsayi na babbar dabaran, wato, ana amfani da ramuka 21 a matsayin ramin matsayi na dabaran na yanzu.

Misali 4: Lissafin ƙididdigewa don niƙa haƙora 51

Sauya dabarar n = 40/51, tunda ba za a iya ƙididdige maki a wannan lokacin ba, za ku iya zaɓar ramin kai tsaye, wato, zaɓi farantin nuni tare da ramuka 51, sannan kunna 51+1 babba a kan matsayi. rami, wato, ramuka 52, a matsayin dabaran na yanzu. Sanya ramuka wato.

Misali 5: Lissafin ƙididdigewa don niƙa haƙora 100.

Sauya cikin dabara n=40/100

Yi lissafin n=4/10=12/30

Zaɓi farantin index mai ramuka 30 a cikin lokaci, sannan sanya ramukan 12+1 ko 13 akan ramin madaidaicin dabaran a matsayin rami na saka dabaran na yanzu.

Idan duk fayafai masu ƙididdigewa ba su kai adadin ramukan da ake buƙata don ƙididdigewa ba, ya kamata a yi amfani da hanyar ƙididdige mahaɗin don ƙididdigewa, wanda ba a haɗa shi cikin wannan hanyar lissafi ba. A zahirin samarwa, ana amfani da hobbing gabaɗaya, saboda ainihin aiki bayan lissafin ƙididdiga na fili yana da matukar wahala.

6. Ƙididdigar ƙididdiga don hexagon da aka rubuta a cikin da'irar

① Nemo kishiyar gefen hexagon (S surface) na da'irar D

S=0.866D diamita ne × 0.866 (daidaitacce)

② Ƙirƙiri diamita (D) na da'irar daga kishiyar gefen hexagon (S saman)

D = 1.1547S kishiyar gefe × 1.1547 (daidaitacce)

7. Ƙididdigar ƙididdiga na gefen gaba da layin diagonal na hexagon a cikin tsarin sanyi

① Nemo kishiyar kwana e na kishiyar gefen (S) na hexagon na waje

e = 1.13s Gaban gaba × 1.13

② Nemo kishiyar kwana (e) daga kishiyar gefen (s) na hexagon ciki

e = 1.14s Gefen gefe × 1.14 (daidaitacce)

③ Sami diamita na kayan kan diagonal (D) daga ɓangarorin (s) na hexagon na waje

Ya kamata a lissafta diamita (D) na da'irar bisa ga kishiyar gefen (s jirgin sama) na hexagon (nau'i na biyu a cikin 6), kuma ya kamata a ƙara darajar cibiyar biya daidai, wato, D≥1.1547s. Za'a iya ƙididdige adadin kuɗin daga tsakiya kawai.

8. Ƙididdigar ƙididdiga na murabba'i da aka rubuta a cikin da'irar

① Zana da'irar (D) don nemo kishiyar gefen murabba'in (S saman)

S=0.7071D diamita ne × 0.7071

② Nemo da'irar (D) daga gefen kishiyar murabba'in (S saman)

D = 1.414S gefe guda × 1.414

9. Ƙididdigar ƙididdiga don ɓangarorin murabba'i masu gaba da juna da kusurwoyi dabam-dabam a cikin tsarin taken sanyi

① Nemo kishiyar kwana (e) daga kishiyar gefen (S) na filin waje

e=1.4s shine kishiyar gefen (s) × 1.4 siga

② Nemo kishiyar kwana (e) na kishiyar gefen (s) na murabba'in ciki

e = 1.45s shine kishiyar gefen (s) × 1.45 ƙididdiga

10. Ƙididdigar ƙididdiga mai girma hexagon

s20.866 × H/m/k yana nufin kishiyar gefe × gefe × 0.866 × tsawo ko kauri.

11. Ƙididdigar ƙididdiga don ƙarar yanke (mazugi).

0.262H (D2+d2+D ×d) shine 0.262× tsayi ×(babban diamita na kai × babban diamita na kai

12. Ƙididdigar ƙididdiga don ƙarar yanki (kamar kai mai madauwari)

3.1416h2(Rh/3) shine 3.1416× tsawo× tsawo×(radius -tsawo÷3).

13. Ƙididdigar ƙididdiga don machining girma na na ciki zaren famfo

1. Lissafin babban diamita na famfo D0

D0=D +(0.866025P/8)×(0.5 ~ 1.3) shine ainihin girman famfo babban zaren diamita + 0.866025 pitch÷8×0.5~1.3.

Lura: Zaɓin 0.5 ~ 1.3 yakamata a ƙayyade gwargwadon girman farar. Girman darajar farar, ƙarami ya kamata a yi amfani da ƙima. Akasin haka, ƙaramar ƙimar farar, mafi girman ƙimar daidaitattun ya kamata ya kasance.

2. Lissafin diamita na fam ɗin famfo (D2)

D2=(3×0.866025P)/8, wato matsa diamita=3×0.866025×pitch÷8

3. Lissafin diamita na famfo (D1)

D1=(5×0.866025P)/8 shine diamita na famfo = 5×0.866025×pitch÷8

Goma sha hudu,

Ƙididdigar ƙididdiga na tsawon kayan aiki don yanayin sanyi da aka samu na siffofi daban-daban

Da'irar ƙarar da'irar sananne shine diamita × diamita × 0.7854 × tsayi ko radius × radius × 3.1416 × tsayi. Wato d2×0.7854×L ko R2×3.1416×L

Lokacin ƙididdigewa, ƙarar X÷ diamita ÷ diamita ÷ 0.7854 ko X÷radius÷radius÷3.1416 na kayan da ake buƙata shine tsawon kayan.

Ƙimar ginshiƙi = X/(3.1416R2) ko X/0.7854d2

A cikin dabara, X yana wakiltar ƙimar ƙarar kayan da ake buƙata;

L yana wakiltar tsawon ƙimar ainihin ciyarwa;

R/d yana wakiltar ainihin radiyon ciyarwa ko diamita.

Manufar Anebon ita ce fahimtar kyakkyawan lalacewa daga masana'antu da samar da babban tallafi ga abokan ciniki na gida da na waje da zuciya ɗaya don 2022 Babban ingancin Bakin Karfe Aluminum High Precision Custom Made CNC Turning Milling Machining Spare Part don Aerospace, Domin fadada kasuwancinmu na duniya, Anebon yafi wadata abokan cinikinmu na ƙasashen waje Top ingancin kayan aikin inji, sassan niƙa da sabis na juyawa na cnc.

Sin wholesale China Machinery Parts da kuma CNC machining Service, Anebon goyon bayan da ruhun "bidi'a, jituwa, tawagar aiki da kuma rabawa, sawu, pragmatic ci gaba". Ka ba mu dama kuma za mu tabbatar da iyawarmu. Tare da irin taimakon ku, Anebon ya yi imanin cewa za mu iya ƙirƙirar makoma mai haske tare da ku tare.

Lokacin aikawa: Jul-10-2023